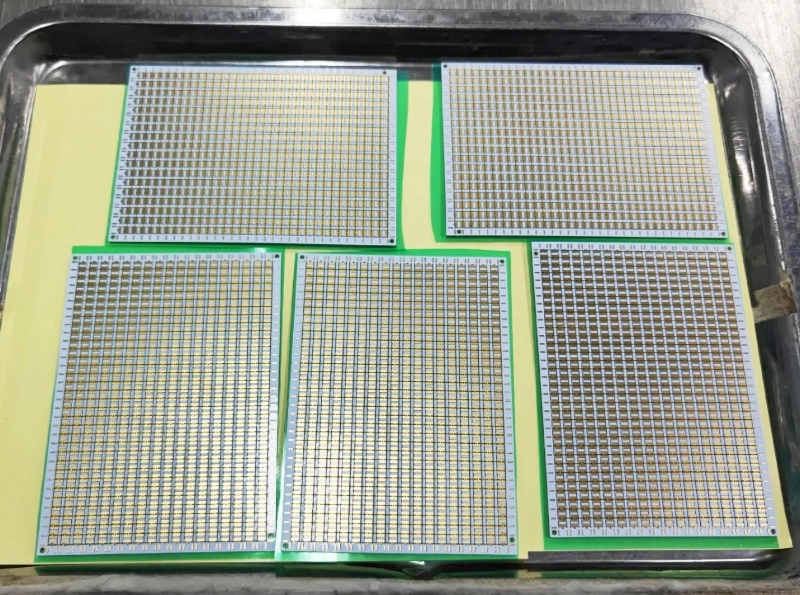

Preparation and Cutting

When cutting PCB substrates, precision and control are crucial — because even small errors can lead to electrical failures, delamination, or dimensional inaccuracies. Here are the key points to pay attention to during PCB substrate cutting:

1. Cutting Method Selection

Choose the right cutting process according to the material and board thickness:

● V-scoring / V-cut: Fast and clean for mass production; suitable for FR4 boards.

● Routing / CNC milling: Precise, good for irregular shapes; avoid excessive heat.

● Laser cutting: Ideal for high-density or flexible PCBs; provides smooth edges but needs proper heat control.

● Punching / die cutting: Efficient for thin, soft substrates like polyimide flex boards.

2. Control of Cutting Stress

● Avoid mechanical stress that can cause micro-cracks or delamination near copper traces or vias.

● Use sharp tools and proper feed rates to minimize vibration.

● For rigid boards, fix the board firmly to prevent bending during cutting.

3. Thermal Management

● Overheating can damage solder masks or deform laminates.

● Maintain proper cooling or use low-power cutting settings when using lasers or routers.

4. Dimensional Accuracy

● Compensate for tool wear, kerf width, and thermal expansion.

● Verify final dimensions using precision measurement tools — especially for boards that will be assembled in tight enclosures.

5. Dust and Burr Control

● Cutting generates fiberglass dust and burrs that can cause short circuits.

● Use vacuum extraction and deburring processes after cutting.

● Clean surfaces before further processing (like solder mask or component placement).

6. Edge Quality and Flatness

● Inspect for rough edges, burn marks, or delamination.

● Smooth edges help ensure better assembly fit and coating adhesion.

7. Safety and Clean Environment

● Fiberglass dust from FR4 is harmful — always use proper ventilation and PPE.

● Keep the cutting area free of contaminants to prevent static or debris interference.

8. Parameter Optimization

● Regularly optimize feed rate, spindle speed, and cutting depth for your specific substrate type.

● Test small samples before full production to fine-tune process parameters.

en

en