SMT Assembly Process Step

We offer system-level design, printed circuit board design, and layout services.

With a robust hardware design team, Wendefeng delivers comprehensive turnkey solutions at

competitive pricing with rapid delivery response times.

Our comprehensive turnkey services include:

Design Concept Development, Block Diagram, Power Estimation

Schematic Capture, BOM Cost Estimation

Enclosure/Chassis Design

PCB Layout Research

PCB Layout Design

Thermal/Power Simulation

Power Integrity and Signal Integrity Analysis

PCB Manufacturing and Assembly

Board Debugging and Testing

Hardware User Manual, Application Notes

PCB Board Design Services

System and Board-Level Architecture Specifications

Engineering Design Specifications

Component Selection

Component Obsolescence and Planning

Symbol Creation

Schematic/Capture

Timing Analysis

Netlist Generation

BOM Generation

Tools: (OrCAD, Concept HDL, Altium, PAD, Expedition)

From PCB schematic design and PCB board layout to testing, validation, and certification, we manage the entire lifecycle of the PCB design process. Please refer to the detailed breakdown of our printed circuit board design services below.

-

Technical Specification DevelopmentPreparing project specifications is a crucial component of our custom PCB design and layout services. This may include technical requirements, block diagrams, deliverables, assumptions, preliminary Bill of Materials (BOM) and BOM costs, as well as the tools and technologies specified for project development. This specification enables our designers to align with clients and meet their expectations by delivering high-quality PCB design services.

Technical Specification DevelopmentPreparing project specifications is a crucial component of our custom PCB design and layout services. This may include technical requirements, block diagrams, deliverables, assumptions, preliminary Bill of Materials (BOM) and BOM costs, as well as the tools and technologies specified for project development. This specification enables our designers to align with clients and meet their expectations by delivering high-quality PCB design services. -

Schematic DesignThe PCB design process always begins with the schematic. Schematics or circuit diagrams convey the electrical connections between different electronic components, such as integrated circuits (ICs) and discrete components. To deliver this PCB design service, we utilize professional CAD software like Altium Designer to define modules and design connections between various components.

Schematic DesignThe PCB design process always begins with the schematic. Schematics or circuit diagrams convey the electrical connections between different electronic components, such as integrated circuits (ICs) and discrete components. To deliver this PCB design service, we utilize professional CAD software like Altium Designer to define modules and design connections between various components. -

PCB LayoutAfter importing the schematic into the PCB layout, we manually place components on the board and route the traces. We consider the required number of layers and component dimensions potentially constrained by enclosure size. Within our PCB layout service, we analyze signal integrity and evaluate electrical constraints to ensure the safety of the board-level architecture. For complex layouts, we incorporate various simulations into our custom circuit board design service. Our experts arrange appropriate conductor routing, a primary factor influencing PCB manufacturing costs. We run DFM/DFA analysis to minimize PCB

PCB LayoutAfter importing the schematic into the PCB layout, we manually place components on the board and route the traces. We consider the required number of layers and component dimensions potentially constrained by enclosure size. Within our PCB layout service, we analyze signal integrity and evaluate electrical constraints to ensure the safety of the board-level architecture. For complex layouts, we incorporate various simulations into our custom circuit board design service. Our experts arrange appropriate conductor routing, a primary factor influencing PCB manufacturing costs. We run DFM/DFA analysis to minimize PCB -

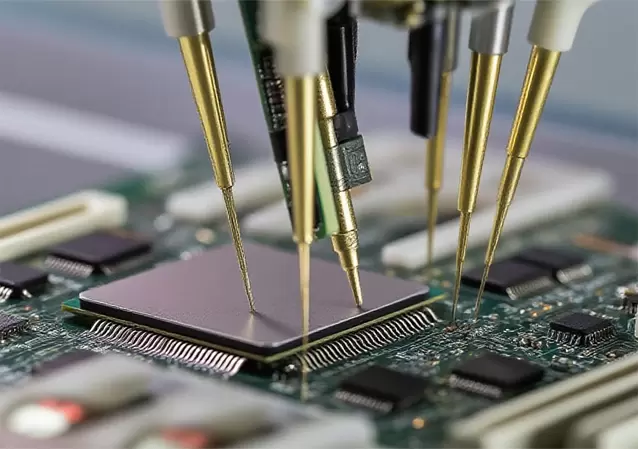

PCB Manufacturing and TestingOnce our PCB design layout is approved for production, we export it into formats supported by the manufacturer. We prepare the Bill of Materials (BOM) and Gerber files, which describe the design requirements for each image of the circuit board. The manufacturer uses this documentation as a reference for both PCB fabrication and assembly. For certain projects, we also create a 3D model of the PCB to ensure it fits within the enclosure. Testing is critical for both our PCB layout design services and the manufacturing phase. We provide manufacturers with the data and software required to perform resistance and impedance testing. After prototyping is complete, we conduct testing in-house.

PCB Manufacturing and TestingOnce our PCB design layout is approved for production, we export it into formats supported by the manufacturer. We prepare the Bill of Materials (BOM) and Gerber files, which describe the design requirements for each image of the circuit board. The manufacturer uses this documentation as a reference for both PCB fabrication and assembly. For certain projects, we also create a 3D model of the PCB to ensure it fits within the enclosure. Testing is critical for both our PCB layout design services and the manufacturing phase. We provide manufacturers with the data and software required to perform resistance and impedance testing. After prototyping is complete, we conduct testing in-house.

EN

EN