PCBA functional testing

is the final verification step for the PCBA, to ensure they perform correctly in a simulated environment. This involves set up and applying power, stimulate the board and measuring its outputs, to confirm they work as requirements and all components work together correctly.This step is crucial for functional verification, exposing errors, so the manufacturer could react accordingly, such as rework, repair and replace defective components.

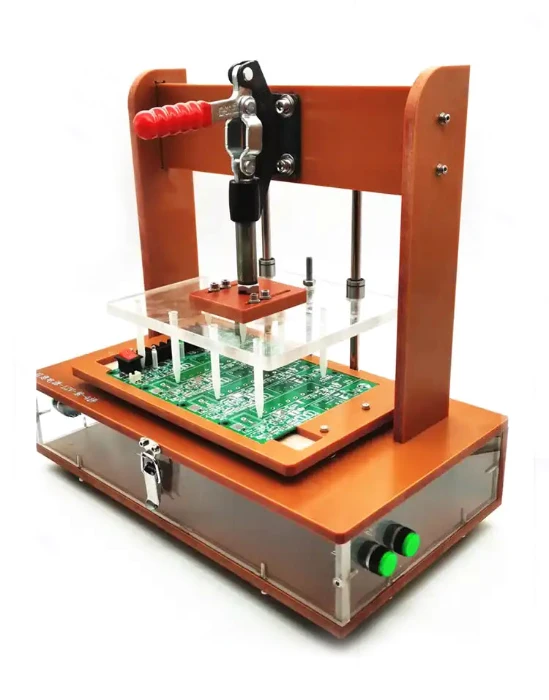

When go for mass production, we usually customize testing fixtures to assist this process, to accumulate the operation.

If you need this service, please consider to tech us how to operate, such as power on with certain current&voltage(such as 5V/1A), how to operate and measure the outputs.

en

en

WhatsApp

WhatsApp