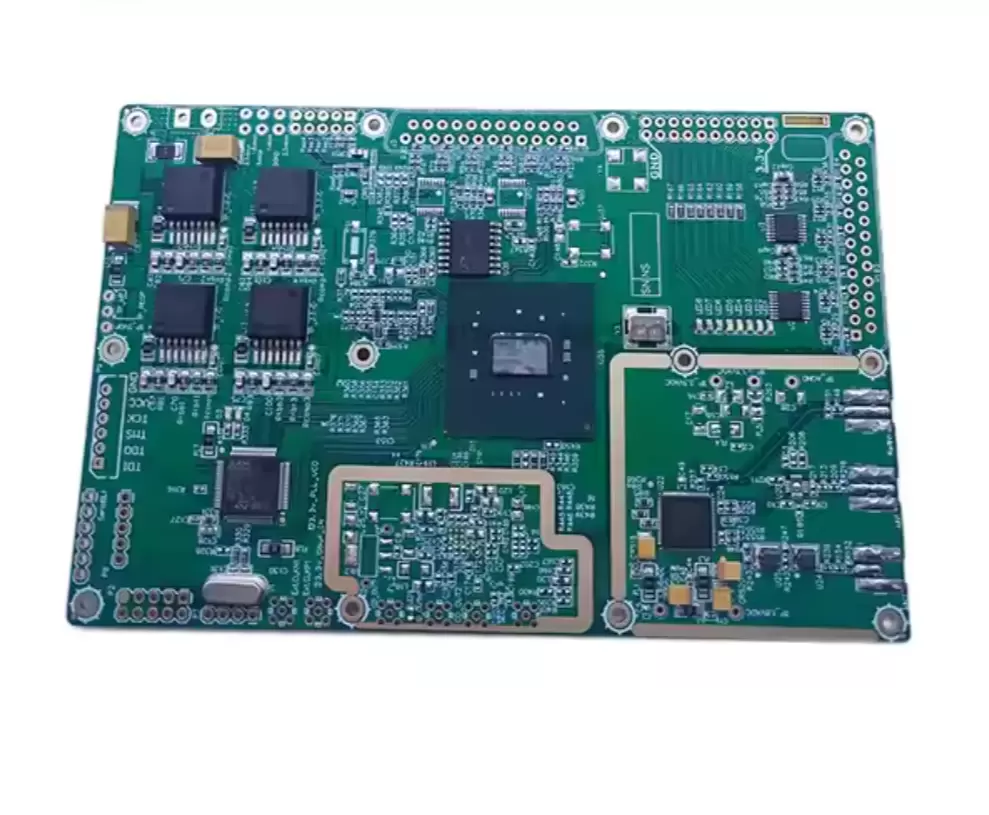

GPS Controller Module PCB Assembly

Case Study: High-Precision GPS Controller Module PCB Assembly Solution — Building a Reliable Core for Smart Mobility Devices

Project Background and Client Requirements

A technology enterprise specializing in intelligent transportation needed to develop a vehicle-mounted high-precision GPS controller module for commercial vehicle positioning, route planning, and remote monitoring systems. The module had to meet the following core requirements:

· Positioning Accuracy: Support dual-mode GPS/BDS positioning with an error margin ≤1 meter to ensure real-time location data precision.

· Environmental Adaptability: Operate stably in a wide temperature range (-40℃~85℃), withstand vehicle power fluctuations (9V~36V), and resist road vibration impacts.

· Miniaturized Design: Restricted to 50mm×30mm, requiring integration of high-density components such as RF chips, MCUs, and power management units.

· Anti-Interference Capability: Reduce signal disruption from on-vehicle electromagnetic environments (e.g., engines, wireless communication devices) to ensure stable data transmission.

· Mass Production Consistency: First batch trial production of 500 units, with subsequent monthly capacity of 10,000 units, requiring a low failure rate (PPM ≤50).

Challenges Faced by the Client

1. High-Density Assembly Issues: The module integrated 01005 passive components, 0.4mm-pitch BGA (RF chips), and LGA-packaged MCUs, making traditional SMT prone to solder bridging and cold joints.

2. Signal Integrity Risks: GPS RF signals (1.575GHz) are sensitive to PCB trace length and impedance matching. Microstrip line shifts or poor grounding during assembly could cause signal attenuation.

3. Wide-Temperature Reliability: Ordinary PCB materials risked solder joint cracking under extreme temperatures, requiring solutions to address mechanical stress during thermal cycling.

4. Mass Production Efficiency Bottlenecks: The client required a 4-week turnaround from sample validation to mass delivery, demanding a balance between precision and production speed.

Our Solution: Full-Process Precision Assembly and Technical Optimization

To meet the client’s needs, we developed a three-stage solution: “Design Optimization + Process Innovation + Full Inspection Control”:

1.

PCB Design and Material Adaptation

2.

· Adopted a 4-layer HDI (High-Density Interconnect) PCB with microvias and buried vias to shorten signal paths, controlling RF line impedance to 50Ω±10%.

· Selected high-Tg (170℃) FR-4 substrate with 1oz copper cladding to enhance thermal conductivity and mechanical strength, ensuring dimensional stability in wide-temperature environments.

· Designed full-coverage ground planes and RF shielding enclosures to reduce EMI (Electromagnetic Interference) impact on GPS signals.

3.

High-Precision SMT Assembly Processes

4.

· Solder Paste Printing Control: Used laser-cut stencils (0.12mm thickness) with 3D SPI (Solder Paste Inspection) to ensure BGA pad paste volume deviation ≤10%.

· Component Placement: Deployed Yamaha YSM40R high-speed placement machines with vision positioning systems (±2μm accuracy) for precise alignment of 01005 components and BGA.

· Reflow Soldering: Customized lead-free solder (Sn96.5Ag3.0Cu0.5) reflow profiles with peak temperatures of 255℃±2℃, ensuring solder joint wetting angles >150° for enhanced vibration resistance.

5.

Targeted Testing and Reliability Validation

6.

· First Article Inspection: Each first article underwent X-ray testing to check BGA solder void rates (required ≤5%) and AOI to detect component misalignment or pad bridging.

· Functional Testing: Built a simulated vehicle environment test platform to verify module performance under varying voltages and temperatures, including cold-start response time (≤30 seconds) and data output stability.

· Reliability Testing: Randomly selected 10% of samples for 1,000 thermal cycles (-40℃~85℃) and 100-hour vibration tests (10Hz~2000Hz), with 100% functional integrity post-testing.

Project Outcomes and Client Value

· Performance Compliance: The module achieved a positioning accuracy of ±0.8 meters and cold-start times ≤25 seconds in -40℃ environments, fully meeting the client’s intelligent transportation system requirements.

· Mass Production Assurance: Optimized processes increased single-shift 产能 to 2,000 units, with the first 500-unit batch achieving a 99.2% yield and PPM controlled below 30.

· Cost Optimization: Reduced client PCB assembly costs by 15% through material substitution (e.g., cost-effective domestic RF chips) and process efficiency improvements.

· Long-Term Partnership: Based on delivery quality, the client awarded us full assembly orders for their second-generation module (supporting 5G+GPS integrated positioning).

Why Choose Us?

From high-precision component assembly to rigorous environmental reliability validation, we deeply understand GPS controller modules’ core demands for “precision” and “stability.” With 14 years of experience in small-to-medium batch PCB assembly, we offer one-stop services for GPS/BDS positioning devices (vehicle-mounted, IoT, surveying instruments, etc.)—from design assistance (DFM) to mass production delivery—making every module a reliable core for your products.

en

en