How are solder balls generated during PCBA manufacturing

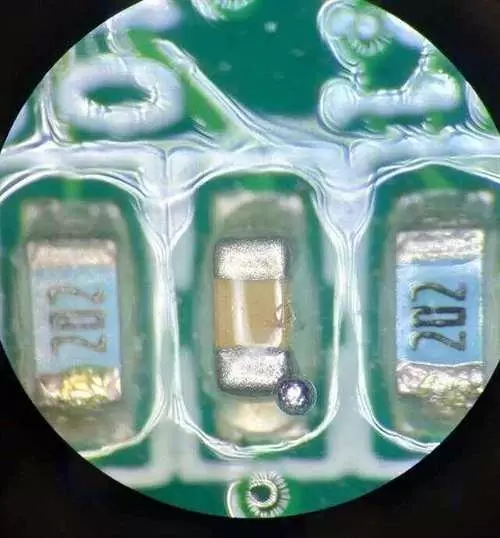

Solder balls are one of the most common defects in SMT and reflow soldering processes during PCBA Manufacturing. The root causes are commonly from the rapid evaporation of flux or moisture in the solder paste at high temperatures, splatter molten solder into tiny balls.

I. Detailed Explanation of Causes

1. Material and Environmental Factors

This is the most fundamental cause, primarily involving the characteristics of the solder paste itself and the storage environment.

1) Moisture Absorption of Solder Paste (Most Common Cause):

● Process: After being took out from the refrigerator, if the solder paste is not sufficiently warmed up (reaching room temperature and balancing moisture), or if the environmental humidity is too high, the solder paste will absorb moisture from the air.

● Result: During reflow soldering, the moisture vaporizes rapidly and expands, creating vapor pressure which "explodes" the solder before it melts, forming solder balls.

2) Flux Formulation Issues:

● Boiling point of flux too low/evaporation too fast: Rapid evaporation in the preheating process causes premature dispersion of solder particles.

● Improper timing of activator venting: Excessive gas generated during solder melting and cause splattering.

2. Process and Design Factors

Mainly reflected in printing, surface mount, and stencil design.

1) Excessive Solder Paste (Printing Process):

● Improper stencil design: Opening size too large or lack of anti-solder ball treatment (e.g., recessed openings, grid segmentation).

● Improper printing pressure/speed: Leading to excessive solder application or edge collapse, resulting in excessive solder.

2) Excessive Surface Mount Pressure:

Squeezing solder paste beyond the pads, adhering to the solder mask, generates solder balls during reflow.

3) Contamination on the Stencil Bottom or PCB Surface:

Contaminants (such as residual solder paste, dust) prevent complete separation of the stencil from the PCB surface, leading to distorted printed patterns and excess solder.

3. Thermal Process and Layout Factors

Reflected in profile settings of reflow soldering temperature and PCB design.

1) Inappropriate Reflow Temperature Profile (Most Critical Process Cause):

● Excessively rapid preheating: A typical "ramp-up rate" (e.g., >3°C/s) causes rapid solvent/moisture evaporation, resulting in a "popcorn" effect.

● Insufficient preheating time: Fail to activate flux sufficiently and evaporation leads to the violent release of residual volatiles in the reflow zone.

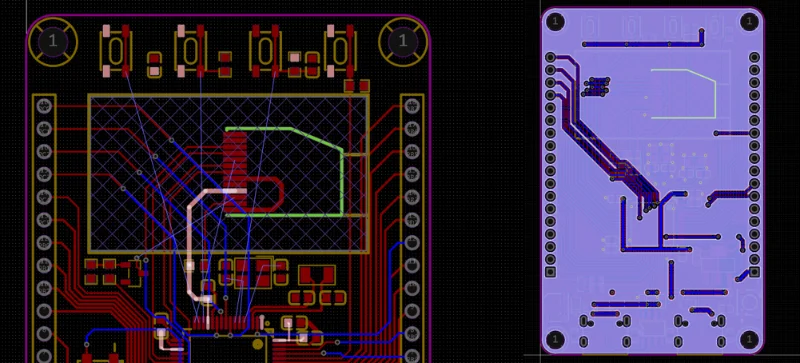

2) PCB Design and Layout Issues:

● Adjacent tall and short components, or insufficient pad spacing, cause molten solder to be pushed to the bottom of components or densely packed areas under surface tension, generate large solder balls.

● Poor design of pad or solder mask, resulting in an unreasonable solder wetting path.

II. Systemic Solutions and Preventive Measures

Based on the causes above, a systematic closed-loop control is necessary as below:

1. Material and Environmental Management

● Strict reheating: Refrigerated solder paste must be warmed up at room temperature (25±3°C) for 4-8 hours in a sealed state before use. Forced reheating by heating is prohibited.

● Standard Stirring: After warming up, stir according to the specified time and method, to ensure uniform composition.

● Environmental Control: Maintain workshop temperature and humidity at 22-28°C and 40-60%RH.

2. Optimization of Printing and Stencil Process

● For component pads which prone to generate solder balls, use "anti-solder ball" openings (e.g., concave or inverted trapezoidal).

● Reduce opening size appropriately (e.g., reduce area ratio by 5%-10%) to precisely control solder volume.

● Optimize stencil design.

● Ensure Printing Quality: Clean the bottom of the stencil regularly, calibrate the printing press, and ensure stable squeegee pressure and demolding parameters.

3. Precise Control of Heat Process during Reflow Soldering

● Optimize Temperature Profile: Set a mild and gradual preheating zone, controlling the heating rate at 1.0-2.0°C/s. An additional preheating platform (approximately 150°C, 60-120 seconds) can be added to allow solvents and moisture to evaporate fully and gradually.

● Ensure uniform hot air convection: Maintain the reflow oven regularly to ensure stable airflow in each temperature zone, uniform PCB heating.

4. PCB Design Collaboration

● Optimize component layout, avoid close proximity of components with significantly different heat capacities.

● Design pad sizes and spacing according to DFM (Design for Manufacturability) principles.

III. Investigation and Diagnostic Methods

When solder ball issues occur on the production line, it is recommended to follow these steps for analysis and troubleshooting:

1. Location: Are solder balls appearing around specific components or randomly distributed across the entire board?

2. Inspection: Observe or use 3D SPI to monitor the shape and thickness of the solder paste printing; check the cleanliness of the stencil.

3. Analysis: Compare and analyze the reflow temperature profiles of good and defective products, especially the preheating zone.

4. Verification: Adjust the most likely variable (e.g., extend the preheating time) and conduct small-batch verification.

Core Principle

The appearance of solder balls may indicate a systemic mismatch in the entire process chain. Only through rigorous material management, process parameter control, and design collaboration, then the solder ball issues could be systematically eliminated, ensure soldering quality.

Benlida has been manufacturing PCB for 14 years and also provide PCB assembly services. For over 1 decade, we continuously optimize SMT assembly processes for PCBA and focuse on quality control. Now we've established a mature management system and engineering quality team, to ensure every process step and provide high-quality PCB and PCB assembly services to global customers!

en

en

WhatsApp

WhatsApp