Selecting the Right PCB Laminate: FR4 vs. High-Frequency Alternatives for Your Design

You want your device to work well and last long. The PCB laminate you pick is very important. It affects how electricity moves and how clear signals are. It also helps your device stay strong over time. High-frequency signals can change the laminate’s features. This can change how your device works. Some laminates deal with these changes better. Choosing the right PCB laminate stops delays. It keeps signals clear and helps your product last longer.

Key Takeaways

Pick FR4 if you want to save money. It is good for basic electronics. FR4 works best at lower frequencies.

Use high-frequency laminates like PTFE or Rogers for special designs. These keep signals strong at high frequencies.

Learn about dielectric constant and dissipation factor. Lower numbers mean better results and less signal loss.

Do not make common mistakes when picking laminates. Always check if materials work together. Run signal tests to make sure everything works well.

Buy from certified suppliers. They give you good quality and reliable products. This helps your PCBs last longer and work better.

FR4 vs. High-Frequency Laminates

Key Differences

You have many options when picking a PCB laminate. FR4 and high-frequency laminates are not the same. The table below shows how they are different:

Property | FR4 | High-Frequency Laminates |

|---|---|---|

Electrical Performance | Adequate at lower frequencies | Superior at elevated frequencies |

Dielectric Constant Stability | Varies at high frequencies | Maintains stability |

Loss Tangent | Higher at high frequencies | Lower, reducing signal loss |

Cost | Cost-effective | Generally more expensive |

Suitability for Applications | General-purpose | High-speed and RF applications |

FR4 is good for most electronics that do not need high speed. You can use it for things that work at lower frequencies. High-frequency laminates, like PTFE or Rogers, are better for advanced designs. These materials keep their electrical properties steady, even when signals move fast.

Performance Overview

You want your signals to stay strong and clear. FR4’s dielectric constant changes when the frequency is high. This can make signals weaker and hurt performance. PTFE-based laminates keep the dielectric constant steady. They also have a lower loss tangent, so there is less signal loss.

FR4 works well for frequencies up to about 7 GHz. If your design uses higher signals, you should pick high-frequency laminates.

PTFE and similar materials are best for signals in the hundreds of MHz or GHz. They help keep signals clear and save energy.

Tip: If your project uses high-speed data or radio frequency signals, picking the right PCB laminate is very important. High-frequency laminates help stop problems like signal loss and unstable impedance.

You need to choose the material that fits your design. FR4 is a cheaper choice for many projects. High-frequency laminates give you better performance for advanced electronics. Picking the right PCB laminate helps your device work well and last longer.

Understanding FR4 Laminate

What Is FR4?

You can find FR4 in lots of electronics. FR4 is a glass epoxy laminate. It is made from glass fabric and epoxy resin. This makes it strong and dependable. FR4 does not catch fire easily. It also does not soak up much water. FR4 stays strong when it is wet or dry.

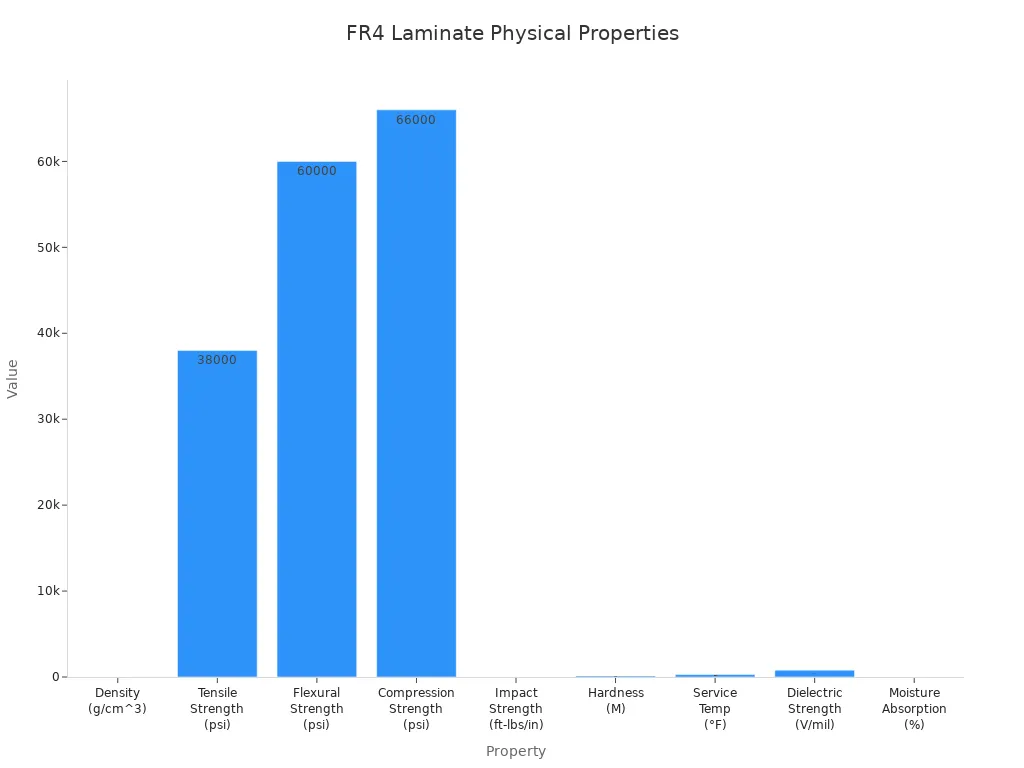

Here is a table that lists the main chemical and physical properties of FR4:

Property | Value |

|---|---|

Chemical Designation | Glass Epoxy |

Density (g/cm^3) | 1.85 |

Tensile Strength at Yield (psi) | 38000 |

Flexural Strength (psi) | 60000 |

Compression Strength (psi) | 66000 |

Impact Strength (Izod) (ft-lbs/in) | 14 |

Hardness (M) | 115 |

Service Temperature Continuous (°F) | 284 |

Dielectric Strength (V/mil) | 800 |

Moisture Absorption (%) | 0.1 |

Flammability | V-0 |

FR4 is tough and safe for many jobs. It has a good strength-to-weight ratio. FR4 also works well as an electrical insulator.

Note: FR4 is used a lot for PCB designs. It is cheap and easy to make.

When to Use FR4

Pick FR4 if you want something strong and not too expensive. FR4 is also good at stopping electricity from leaking. FR4 is used in many areas:

Cars use FR4 in ADAS and power units because it is reliable.

Factories use FR4 in robots and sensors.

Computers and home gadgets often have FR4 inside.

Phones and lights also use FR4 because of its good features.

FR4 gives you many benefits:

It costs less when you make a lot of boards.

It is simple to use in normal PCB making.

It keeps electricity safe with high dielectric strength.

But FR4 has some limits. It does not work well with high-frequency or very hot designs. FR4 can break if it gets too much stress. For most electronics, FR4 is a good choice. You can count on it to work well and save money.

High-Frequency Laminate Options

PTFE and Rogers Materials

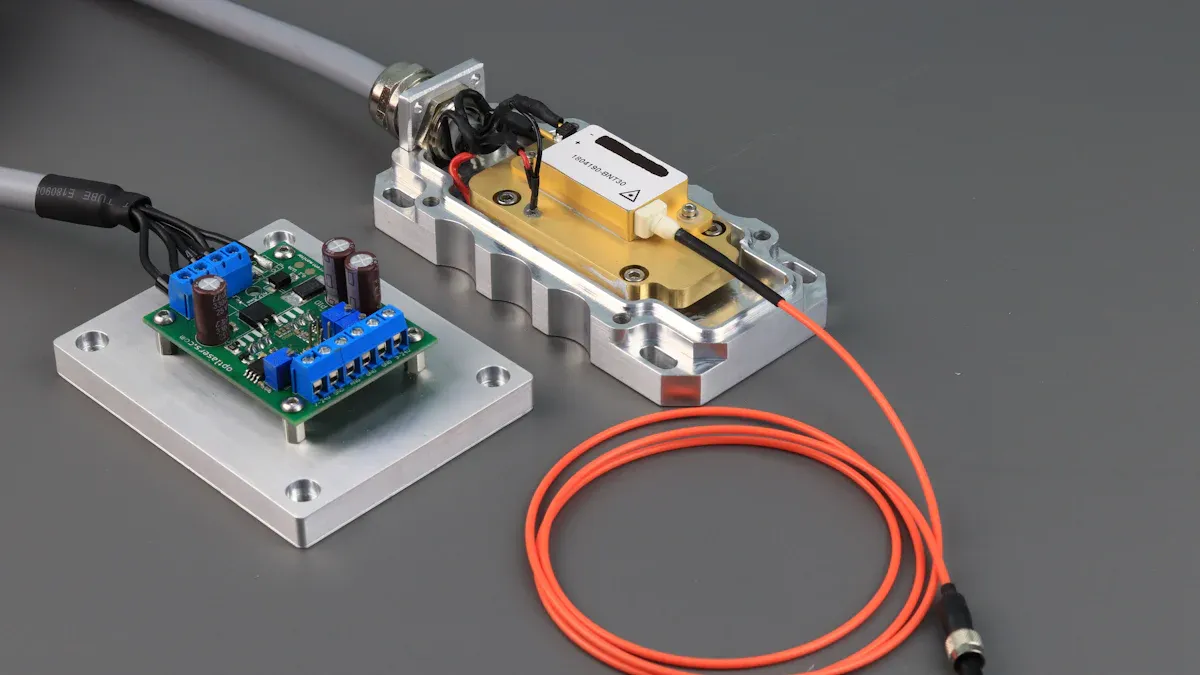

Sometimes, you need special materials for your PCB. PTFE and Rogers laminates are great for high-frequency jobs. PTFE is also called Teflon. It lets signals move with little loss. Rogers materials, like the 4350B series, work well up to 40 GHz. These laminates keep signals clear and strong, even when they move fast.

Here is a table that compares PTFE and Rogers laminates:

Property | Rogers 4350B | PTFE Teflon PCB |

|---|---|---|

Dielectric Constant (Dk) | 3.48 ± 0.05 at 10 GHz | Excellent dielectric properties |

Loss Tangent | 0.0037 at 10 GHz | Low signal loss |

Thermal Stability | High Tg > 280 °C | Good temperature resistance |

Moisture Absorption | 0.06% | Very low moisture absorption |

Thermal Conductivity | 0.69 W/mK | Strong heat dissipation |

These materials give you many good things:

Rogers 4350B keeps signals steady at high frequencies.

PTFE Teflon PCB does not break down in sunlight or air.

Both have low dielectric loss, so signals stay strong.

Tip: PTFE has a low dielectric constant, about 2.1. This is great for 5G and other fast signals. Rogers materials cost less and work well, with dielectric constants from 3.38 to 3.48.

When to Choose High-Frequency Laminates

Pick high-frequency laminates if you need fast, steady signals. These materials are best for RF and microwave circuits. They help stop signal loss and keep signals clear. PTFE and Rogers laminates help you get great signal quality.

Here is a table that shows where high-frequency laminates are best:

Type of PCB | Suitable Applications | Performance Characteristics |

|---|---|---|

FR4 | General electronics | Cost-effective, easy to manufacture |

High-frequency laminates | RF and microwave circuits | Lower loss factors, better performance at elevated frequencies |

These laminates can cost more and need special ways to make them. Rogers materials can cost $5 to $20 for each square foot. PTFE can cost more than $30 for each square foot. This is because it is rare and hard to make. You need special steps, but you get better results for tough jobs.

Pick high-frequency laminates for wireless, radar, satellite, or fast data PCBs. These materials help you choose the best PCB laminate when signal quality is very important.

Cost & Performance Factors

Dielectric Constant & Dissipation Factor

It is important to know how materials change your PCB’s performance. The dielectric constant (Dk) shows how much electrical energy a material can hold. This number affects how fast signals move and how much they slow down. The dissipation factor (Df) tells you how much energy becomes heat. Lower numbers mean less signal loss and better results.

Here is a table that compares some PCB materials:

Material | Dielectric Constant (Dk) | Dissipation Factor (Df) |

|---|---|---|

FR4 | 3.8 to 4.9 | 0.004 to 0.020 |

PTFE | 2.5 to 10.2 | 0.0014 to 0.0038 |

Polyimide | 2.8 to 4.1 | 0.003 to 0.01 |

The dielectric constant changes signal speed and impedance.

The dissipation factor shows how much signal turns into heat.

Low Dk and Df numbers are best for fast designs.

If you want strong signals and less heat, pick materials with low Dk and Df. High-frequency laminates like PTFE help keep signals clear, even when they move fast.

Application Scenarios

You need to match your material to your project’s needs. FR4 works well for many electronics, but it is not good for high frequencies. When signals go above 1 GHz, FR4 can cause signal loss and crosstalk. High-frequency laminates fix these problems.

Here are some common uses:

Communication equipment: Home routers, switches, and base station control boards.

Automotive electronics: Body control modules, infotainment systems, and window or door lock units.

Application Scenario | Characteristics |

|---|---|

5G Base Station AAU Modules | PTFE or ceramic-filled FR4 gives steady signals for advanced antennas |

Optical Fiber Switching Equipment | Ultra-low Df FR4 helps fast data move with fewer mistakes |

High-frequency laminates also work better in tough places. They keep their features steady when it is hot or wet. This makes them a smart pick for outdoor or factory use. You should always check your design needs to choose the right PCB laminate for your project.

Choosing the Right PCB Laminate

Design Requirements Checklist

You must pick a PCB laminate that fits your project. Every design needs different things. Look at how strong, safe, and heat-proof the material is. Also check how well it handles electricity. The table below shows what to check:

Category | Key Properties |

|---|---|

Mechanical | Peel Strength, Flexural Strength, Delamination Time |

Chemical | Flame Resistance, Moisture Absorption, Methyl Chlorine Resistance |

Electrical | Dielectric Properties, Insulating Properties, Electric Strength |

Thermal | Glass Transition Temperature (Tg), Thermal Expansion, Thermal Conductivity, Decomposition Temperature |

You want your PCB to last and work well. Strong boards do not break easily. Chemical resistance keeps water and chemicals out. Good electrical properties keep signals clear. Thermal properties help the board stay safe when it gets hot.

Think about what your board will do. High-frequency PCBs need special materials. These boards use PTFE or other advanced laminates to stop signal loss. Most regular PCBs use FR4 for normal jobs. The table below shows how needs change:

Aspect | High-Frequency PCBs | Standard PCBs |

|---|---|---|

Materials | PTFE, FR-4, RF-35 (lower dielectric loss) | FR-4 |

Signal Integrity | Stringent requirements, impedance matching | Basic connectivity |

Design Complexity | High complexity, requires controlled impedance | Relatively simple |

Applications | RF circuits, radars, satellites, 5G | General electronics |

Controlled impedance keeps signals from bouncing back.

Low-loss materials like Rogers RO4000 keep signals strong.

Shielding blocks unwanted signals.

Placing parts carefully helps control extra effects.

Tip: Write down what your design needs before you pick a laminate. This makes it easier to choose the right PCB laminate.

Common Mistakes

You want to avoid mistakes when picking a PCB laminate. Many people make errors that hurt how the board works or cost more money. You can learn from these common mistakes:

Error Type | Description | Solution |

|---|---|---|

Material Combination | Laminating PTFE with FR-4 without checking CTE difference | Request specific combinations during design |

Simulation Verification | Skipping signal transmission simulation | Always run simulations for verification |

Universal Lamination | Using pure FR-4 profiles causing resin bleed-out | Use correct profiles for RF layers |

Missing Transition Layer | Direct RF and FR-4 contact causing signal reflection | Add a transition layer to smooth Dk changes |

Incorrect Drilling | High drilling speed roughens PTFE hole walls | Adjust speed for PTFE layers |

Wrong Copper Foil Type | Standard copper increases high-frequency loss | Use rolled copper for RF layers |

Insufficient Precision | Slot position errors cause poor bonding | Ensure precision in hybrid lamination |

Lack of Reliability Test | Skipping thermal stress tests leads to cracking | Test reliability before batch production |

Always use low-loss laminates for high-frequency boards. Rogers RO3003 and Isola I-Speed work well above 5 GHz. Rogers RO3003 has a dielectric constant of 3.0 and a loss tangent of 0.0010 at 10 GHz. Isola I-Speed has a dielectric constant of 3.6 and a loss tangent of 0.006 at 10 GHz.

Never mix PTFE with FR-4 without checking heat expansion.

Always test your design to find signal problems.

Use the right settings for lamination and drilling.

Pick rolled copper for RF layers to lower signal loss.

Test your board for strength before making many boards.

⚠️ Note: Skipping these steps can cause signal loss, weak bonds, or board failure. Careful planning helps you avoid these problems.

You can pick the right PCB laminate by using a checklist and learning from mistakes. This helps your board work better and last longer.

Supplier & Sourcing Tips

Evaluating Suppliers

You want a supplier who can make both FR4 and high-frequency PCBs. The boards should always be good quality. First, check what skills the supplier has and what materials they use. Good suppliers use special materials and careful methods. This helps signals stay clear and strong. They also follow strict rules to make sure their boards are good enough for things like phones, cars, and planes.

Benlida is a great example. They have many types of PCBs. You can get FR4, high-frequency, HDI, and flexible boards from them. Benlida uses smart machines, like automated optical inspection and X-ray tools. These machines help make sure every board is made well. Their team talks with you to learn what you need. They work fast and give you service you can trust.

When you look at different suppliers, check these things:

Criteria | Description |

|---|---|

Dk (Dielectric Constant) | Affects impedance; lower values are better for high-frequency applications. |

Df (Dissipation Factor) | Measures dielectric loss; lower values reduce signal loss above 1 GHz. |

CTE | Low and steady CTE prevents layer misalignment in multilayer designs. |

Compatibility with FR4 | Important for hybrid stack-ups; prevents delamination during fabrication. |

Tip: Pick a supplier who can match materials for hybrid boards. They should keep quality high all the time.

Quality & Certification

You need a supplier who cares about safety and quality. Certified suppliers follow world rules and check their work carefully. This means your boards last longer and work better. Benlida has important certificates. They test their boards a lot, from the start to the end. They check designs and look for problems before you get the boards.

Here are the main certificates you should look for:

Certification | Importance |

|---|---|

ISO 9001 | Ensures a strong Quality Management System for consistent processes. |

ISO 13485 | Confirms compliance with medical device quality requirements. |

IATF 16949 | Focuses on defect prevention for automotive electronics. |

AS9100D | Verifies high-quality standards for aerospace applications. |

UL Certification | Ensures materials meet safety standards. |

REACH and RoHS | Confirms compliance with environmental regulations. |

A good supplier checks quality at every step. They test the materials, check the designs, and look at the finished boards. This stops problems and keeps your products working well. Benlida puts customers first. They use new technology and have service centers around the world. This makes them a good choice for your PCB needs.

You should think about some important things when picking a PCB laminate for your project. The table below lists what you should check:

Key Factor | Description |

|---|---|

Coefficient of Thermal Expansion (CTE) | Helps stop cracks and peeling apart |

Thermal Conductivity | Helps keep the board from getting too hot |

Moisture Resistance | Stops the board from coming apart in wet places |

Try to find a good mix of performance, price, and a supplier you can trust. It is smart to work with skilled companies like Benlida for special help. Look at what your design needs, test out samples, and pick materials that will last a long time. Ask experts for help so your PCB works the way you want.

FAQ

What is the main difference between FR4 and high-frequency laminates?

FR4 is used in most regular electronics. High-frequency laminates are better for fast signals. FR4 is cheaper. High-frequency laminates keep signals strong when they move fast.

How do I know which laminate fits my design?

Check how fast your signals are. If your signals are faster than 1 GHz, use high-frequency laminates. FR4 is fine for simple electronics.

Can I mix FR4 and high-frequency materials in one PCB?

You can use both types together, but their thermal expansion must match. If you do not check, the board can crack or lose signals. Ask your supplier for help with mixed designs.

What certifications should my PCB supplier have?

Certification | Why It Matters |

|---|---|

ISO 9001 | Makes sure quality is good |

UL | Shows the board is safe |

RoHS | Helps protect the environment |

Always ask for these certificates before you buy.

en

en

WhatsApp

WhatsApp