Understanding the Different Types of PCB Boards

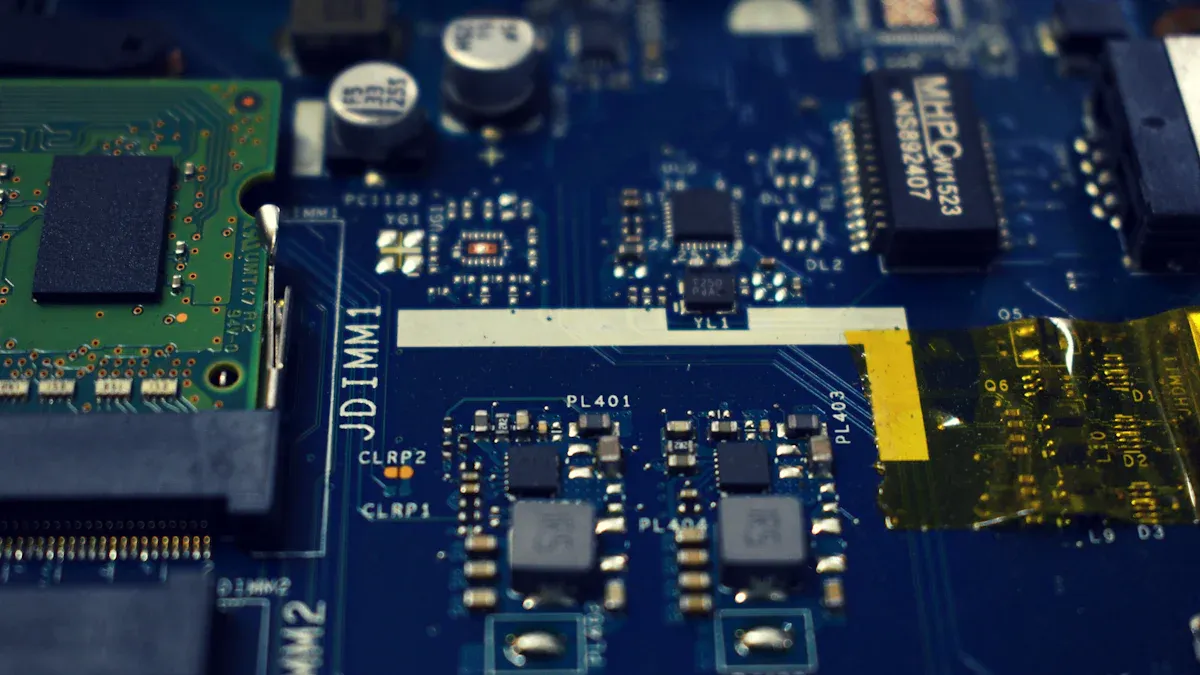

You can find a printed circuit board in almost every electronic device today. Different types of PCB boards have their own jobs. Here are some of the most common types you might find:

Rigid single or double-sided pcb boards are used in small devices and simple appliances.

Standard multilayer pcb boards are used in computers and big machines.

HDI pcb boards help smartphones and cars work better.

Flexible pcb boards are used in foldable gadgets and medical tools.

Rigid-flex pcb boards are used in electric vehicles and military equipment.

Benlida gives you expert help for every type of pcb. They make sure you get good quality and can trust each order.

Key Takeaways

Printed circuit boards (PCBs) have different types. Each type is made for a special job in electronics. Single-sided PCBs are easy to make and not expensive. They work well in simple things like calculators and remote controls. Double-sided PCBs use both sides for parts. This lets them handle harder jobs, like in smartphones and computers. Multilayer PCBs are strong and small. They fit in powerful things like medical machines and military tools. Flexible and rigid-flex PCBs are both strong and bendy. They are good for wearables and small electronics.

Main Types of Printed Circuit Boards

Printed circuit boards come in different shapes and sizes. Each kind has its own job in electronics. You can find these types in many things you use every day.

Single-Sided PCBs

Single-sided PCBs have all their parts and copper lines on one side. This makes them the easiest type of printed circuit board. You see them in simple electronics that do not need a hard design.

Characteristic | Description |

|---|---|

Structure | Conductive paths on one side, usually made of FR-4 or CEM-1/3. |

Manufacturing | Copper is cut to make circuit lines and pads. |

Component Placement | All parts go on the side without copper. |

You can find single-sided PCBs in:

Calculators, remote controls, and radios

LED lights and power boxes

Factory sensors and controls

Car dashboard switches and easy sensors

School kits and hobby projects

Tip: If you want a simple and cheap board, single-sided PCBs are a good pick.

Benlida makes single-sided PCBs with great care. They use visual checks and machines to make sure every board is right for you.

Double-Sided PCBs

Double-sided PCBs have copper on both sides. This lets you put parts on the top and bottom. You can make harder circuit board designs with this type. Double-sided PCBs are very common in today’s electronics.

Feature | Single-Sided PCB | Double-Sided PCB |

|---|---|---|

Structure | One layer of metal | Two layers of metal |

Application scope | Easy circuits (like LED lights) | Harder circuits (like computers) |

Advantages | Cheap, easy to make | Harder designs, smaller boards |

Material | Copper on one side | Copper on both sides |

Process | Solder on one side | Solder on both sides |

You will see double-sided PCBs in:

LED light systems

Power boxes

Hard drives

Car dashboards

Electronics like smartphones

Double-sided PCBs let you fit more parts in less space. This is good for small devices. Benlida uses smart checks, like AOI and in-circuit tests, to make sure every double-sided PCB works well.

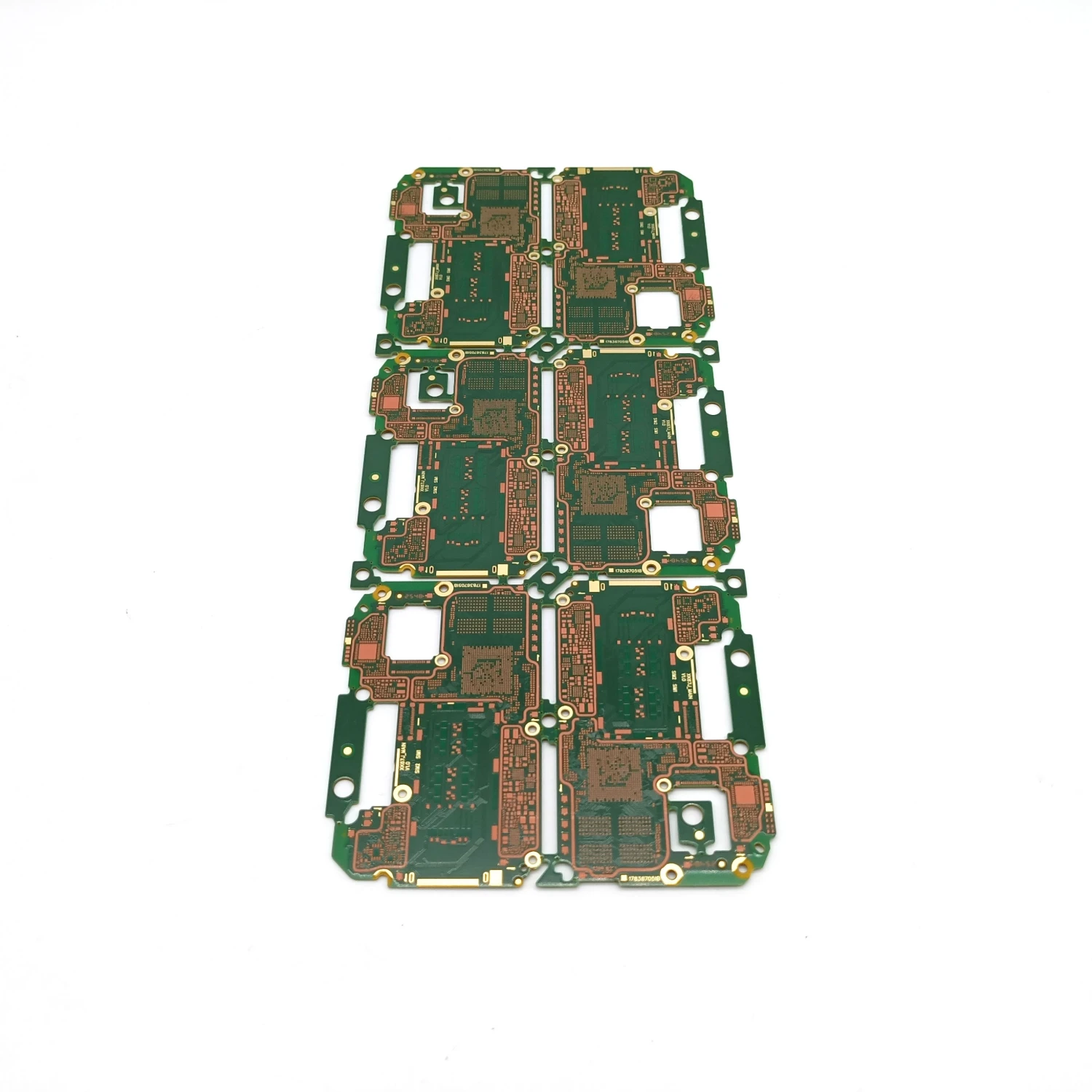

Multilayer PCBs

Multilayer PCBs have three or more copper layers with insulation between them. This kind of board lets you make very hard circuits. You find multilayer PCBs in things that need to work fast and last long.

Some good things about multilayer PCBs are:

More features: You can add extra parts and lines.

Better quality: Careful planning and tools give good results.

More power: These boards can handle more and go faster.

Stronger: The extra layers make them last longer.

Smaller and lighter: You get more in a small space.

One connection spot: This makes your device easier and lighter.

Multilayer PCBs are used in:

Phones and tablets

Computers and servers

Medical machines

Factory control systems

Airplanes and military tools

Note: More people want multilayer PCBs now. In May 2025, North America shipped over 21% more PCBs than last year.

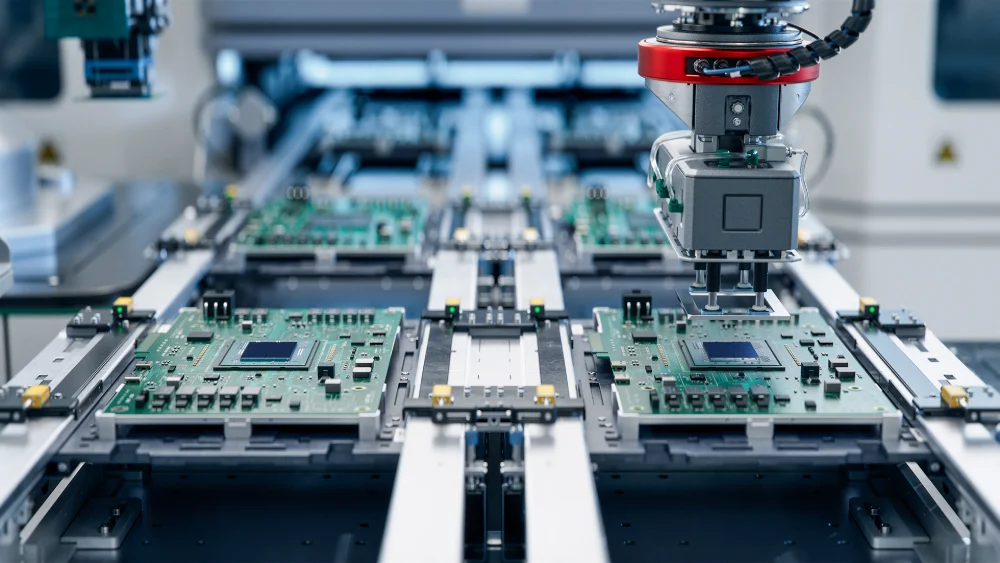

Benlida is good at making multilayer PCBs. They use X-rays and tests to check every layer and connection. You can count on Benlida to give you strong and high-quality multilayer printed circuit boards for your hardest jobs.

Benlida works hard to give you PCBs that meet tough rules. They use both people and machines, X-rays, and final tests to make sure every board is ready for you.

When you know the main types of printed circuit boards, you can pick the best one for your project. Benlida helps you from easy single-sided boards to hard multilayer designs.

Types of PCBs by Structure

Printed circuit boards come in many shapes. You can sort them by how they are made. There are three main types: rigid PCBs, flex PCBs, and rigid-flex PCBs. Each type is good for different jobs in electronics.

Rigid PCBs

Rigid PCBs are the most common kind. These boards do not bend or fold. You see them in almost every device at home or work. The rigid circuit board gives your device a strong base. It keeps all the parts in place. This helps the device last longer.

Feature | Rigid PCB | Flexible PCB | Rigid-Flex PCB |

|---|---|---|---|

Material | FR-4, glass epoxy | Polyimide, Kapton | FR-4 + Polyimide |

Flexibility | None | High (bend radius ~0.1 mm) | Partial (flexible sections) |

Layer Count | 1-20+ | 1-8 | 4-12+ |

Cost | Low | High | Highest |

Weight | Heavy (~1.5 g/cm² for FR-4) | Light (~0.2 g/cm² for polyimide) | Moderate |

Vibration Resistance | Moderate (5-10G) | High (10-20G) | High (15-20G) |

Applications | TVs, PCs, appliances | Wearables, smartphones | Aerospace, medical, automotive |

You will find rigid PCBs in many things. Some examples are computers, laptops, and tablets. They are also in mobile phones and TVs. Game consoles and home appliances use them too.

Rigid PCBs use strong materials like FR-4 and glass epoxy. These help the board keep its shape and protect the parts. The copper foil makes paths for electricity. Rigid PCBs are good for making lots of boards at once. They are easy to make and cost less. You can trust rigid PCBs for jobs that need a strong base.

Tip: If you want a board that stays flat and strong, pick a rigid PCB. Benlida makes rigid PCBs with high quality. They check every board for safety and performance.

Flexible PCBs

Flex PCBs are not like rigid PCBs. These boards can bend, twist, and fold. You use them when space is small or the board needs to move. Flexible PCBs use special materials like polyimide and Kapton. These make the board thin and light.

Some good things about flex PCBs are:

They bend a lot, so they fit in small spaces like smartphones and medical wearables.

They are light and thin, good for drones and portable electronics.

They handle shaking well, which helps in mobile devices and cars.

They can bend many times and still work.

Flexible printed circuit boards help you make small and light devices. You can use flex PCBs in foldable phones and tablets. They are also in medical devices and wearables. Drones and robotic arms use them too. Printer heads and cameras need them as well.

Material Type | Role in Performance |

|---|---|

Polyimide Film | Gives thermal resistance, flexibility, and chemical stability. |

Copper Foil | Forms the paths for signals and power. |

Coverlay | Protects the board from moisture and damage. |

Adhesives | Holds the layers together and adds strength. |

Stiffeners | Adds support where needed. |

Benlida is very good at making flexible PCBs. They use advanced tools to check every flex PCB. You get boards that work well in tough places and last a long time.

Note: Flex PCBs are great for new technology. If you want your device to bend or fit in a small space, flex PCBs are the best choice.

Rigid-Flex PCBs

Rigid-flex PCBs mix the best parts of rigid and flexible PCBs. You get a board with stiff and bendy parts. This helps you build devices that are strong but can fit in small or odd spaces.

Rigid-flex PCBs use both FR-4 and polyimide materials. The stiff parts hold heavy parts and give strength. The bendy parts let the board fold or twist. You see rigid-flex PCBs in aerospace and military equipment. They are also in medical devices that need to bend. Cars and driver systems use them too. Wearable tech and smart gadgets need them. Industrial robots and control units use them as well.

Rigid-flex PCBs help you save space and weight. You can connect parts without extra wires or connectors. This makes your device work better and easier to build.

Challenge | Explanation |

|---|---|

Complex Design Rules | You must plan for both mechanical and electrical needs. |

Bend Radius Considerations | You need to pick the right bend radius to avoid damage. |

Material Selection | Choosing the right materials keeps the board strong and reliable. |

Signal Integrity and EMI | You must keep signals clear, even when the board bends. |

Connector Placement | Good placement stops stress and keeps the board working. |

Layer Transition | You need to move signals between layers without losing quality. |

Thermal Management | You must control heat, especially in flexible parts. |

Assembly and Manufacturing | Building rigid-flex PCBs takes special care and skill. |

Testing and Inspection | You need special tools to check every part of the board. |

Mechanical Reliability | The board must survive many bends and movements. |

Cost | Making rigid-flex PCBs costs more because of the complex design. |

Design for Manufacturability | You must work closely with the maker to get the best results. |

Environmental Factors | The board must resist moisture and heat in tough places. |

Design Verification | You need strong tests to make sure the board works as planned. |

Pro Tip: Rigid-flex PCBs need careful planning. Work with a trusted maker like Benlida to get the best results. Benlida uses advanced methods and checks every board for quality and safety.

Benlida is great at making both flexible and rigid-flex PCBs. You get boards that can change, are strong, and have good signal quality. Benlida’s boards work well in hard places and help you make better products.

When you pick the right type of PCB—rigid, flex, or rigid-flex—you make your device stronger, lighter, and more reliable. Benlida helps you with expert advice and high-quality boards for every need.

Advanced and Special PCB Types

Technology keeps getting better. This means new types of pcb boards are made. Some advanced pcbs have special features. These features help with high speed, high power, or when you need things to work really well. Here are four important types you might use for your next project.

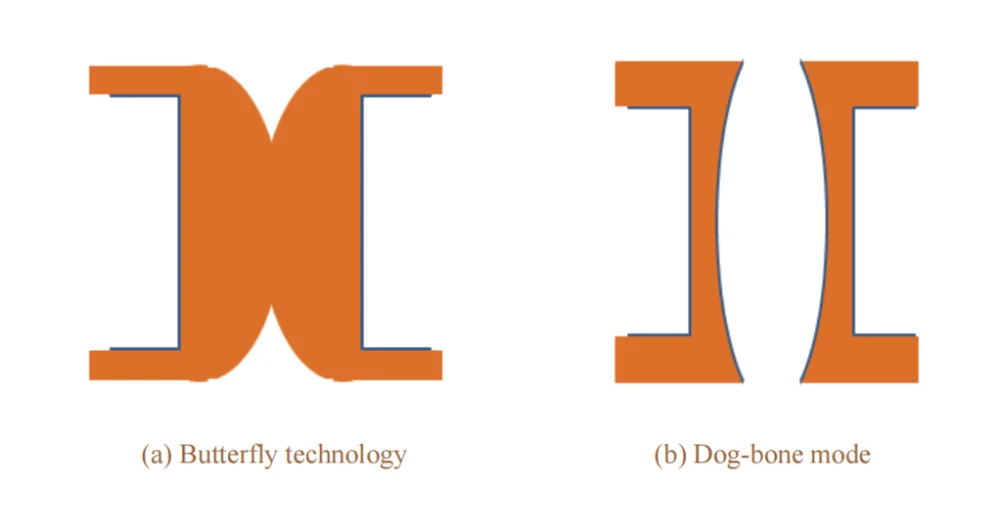

HDI PCBs

HDI pcbs can fit more connections in a small space. They do this better than regular multi-layer pcbs. You find these boards in smartphones, tablets, and cars. HDI pcbs use thin lines, tiny holes, and special layers. This lets them fit more circuits in less room.

Unique Feature | HDI PCB | Standard Multilayer PCB |

|---|---|---|

Improved Thermal Performance | Uses copper foil for better heat dissipation | Typically uses aluminum, less efficient |

Better Signal Integrity | Maintains signal quality over longer distances | Signal quality can degrade over distance |

Greater Reliability | Improved insulation reduces crosstalk | More prone to short circuits |

Higher Density | Supports more connections per unit area | Limited connections per area |

Smaller Size | Smaller footprints ideal for portable devices | Larger footprints |

Mechanical Strength | Can withstand more stress due to design | Less mechanical strength |

Lower Cost | Faster and cheaper to produce | Can be more expensive |

HDI pcbs help you make smaller and faster devices. They also make your devices more reliable. People want these boards as electronics get smaller and smarter. Benlida uses smart tools to make HDI and multi-layer pcbs. These boards meet the needs of today’s technology.

Metal-Core & Aluminum PCBs

Metal-core and aluminum pcbs are good at handling heat. You use these boards in things like LED lights, power converters, and motor controllers. The metal core spreads heat out. This keeps your parts cool and helps them last longer.

The metal core moves heat away from hot spots.

Aluminum pcbs work well with high voltage and strong currents.

These boards are tough and can handle shaking and big temperature changes.

Advantage | Description |

|---|---|

Thermal Conductivity | Aluminum pcbs have much higher thermal conductivity than regular boards. |

Heat Dissipation | The metal core acts as a heat sink, spreading heat across the board. |

Power Handling | These pcbs let you run parts at higher power without overheating. |

Shielding | The metal core blocks unwanted signals and keeps your device stable. |

Benlida’s metal-core and aluminum pcbs are strong and reliable. You can use them for jobs that need high power and lots of heat.

Ceramic PCBs

Ceramic pcbs are different from other pcb boards. They use special materials that move heat away fast. This keeps your circuits safe. You find ceramic pcbs in satellites, military gear, and high-power LEDs.

Feature | Ceramic PCB | Traditional PCB |

|---|---|---|

Thermal Conductivity | Very High | Low |

Mechanical Strength | Excellent | Good |

Dimensional Stability | Excellent | Good |

Electrical Insulation | Excellent | Good |

Applications | Aerospace, Military, High-Power Electronics | Consumer Electronics |

Ceramic pcbs work well where heat and reliability are important. They keep their shape and work even when it gets hot or cold fast. Benlida makes ceramic and multi-layer pcbs for tough jobs.

LED PCBs

LED pcbs are special boards for lighting and displays. These boards help LEDs last longer and shine brighter. You see LED pcbs in streetlights, TVs, and car headlights.

LED pcbs save energy and use up to 75% less power.

They last much longer than regular bulbs—up to 25,000 hours.

These boards are small, light, and fit into many shapes.

LED pcbs are safe for the environment and easy to recycle.

They move heat away from the LEDs, so your lights stay bright and cool.

Benlida’s LED and multi-layer pcbs help you make better lighting and display products. You get boards that are safe, strong, and ready for the future.

When you learn about different pcb boards, you see how each one solves a special problem. Benlida gives you the right pcbs for every job, like HDI, ceramic, LED, and multi-layer pcbs.

You now know that each type of PCB board has its own job. Rigid, flexible, and rigid-flex PCBs are made for different uses. When you pick a PCB, think about these main things:

Factor | Description |

|---|---|

Application-Specific Requirements | Choose materials that fit what your project needs. |

Electrical Performance | Make sure signals are clear and heat is managed. |

Mechanical Properties | Decide if your board should bend or stay stiff. |

Environmental Resistance | Check if your board can handle heat, cold, or wet places. |

Flexible and rigid-flex PCBs will be used more as smart and wearable devices become popular. Benlida is ready to help you with any PCB or PCBA work.

FAQ

What is the main difference between single-sided and double-sided PCBs?

Single-sided PCBs have copper lines on one side. Double-sided PCBs have copper on both sides. You can use double-sided PCBs for more complex circuits.

How do I choose the right PCB type for my project?

You should think about your device’s size, how much it bends, and how much power it uses. Benlida can help you pick the best option.

Can Benlida make flexible and rigid-flex PCBs?

Yes, Benlida makes both flexible and rigid-flex PCBs. You get boards that fit small spaces and handle movement well.

Why do LED products need special PCBs?

LEDs make heat. Special PCBs, like aluminum or metal-core, move heat away. This helps your lights last longer and shine brighter.

en

en

WhatsApp

WhatsApp