How Ceramic PCB Improves Heat Dissipation in LED Lighting Systems

Introduction: The Thermal Challenge in LED Lighting

As the world shifts toward energy-efficient lighting, LED (Light Emitting Diode) systems have become the dominant technology in residential, industrial, and automotive applications. However, while LEDs consume less energy, they produce significant heat during operation. Poor heat dissipation can lead to reduced brightness, color shift, and a shortened lifespan.

Traditional FR-4 or metal-core PCBs (MCPCBs) used in LED modules can only handle limited thermal loads. When LED power density increases, these substrates struggle to maintain temperature uniformity. That’s where Ceramic PCBs—built from advanced materials like Alumina (Al₂O₃), Aluminum Nitride (AlN), and Silicon Carbide (SiC)—offer a true breakthrough.

With thermal conductivity up to 220 W/m·K (compared to FR-4’s 0.25 W/m·K) and operational resilience from -55°C to over 800°C, ceramic PCBs redefine what’s possible in LED heat management and reliability.

The Science Behind Ceramic PCB’s Thermal Superiority

1. Direct Heat Pathway

Ceramic PCBs eliminate the need for intermediate dielectric layers found in FR-4 and MCPCB structures. The ceramic substrate itself acts as both an electrical insulator and a thermal conductor, allowing heat generated by LED chips to flow directly into the heatsink or surrounding air.

2. High Thermal Conductivity

Among ceramic substrates, AlN stands out for its superior heat conduction—typically between 140 and 220 W/m·K. Al₂O₃, while slightly lower at 18–30 W/m·K, still far exceeds traditional laminates. This direct thermal transfer prevents localized hotspots, ensuring longer LED life and consistent color output.

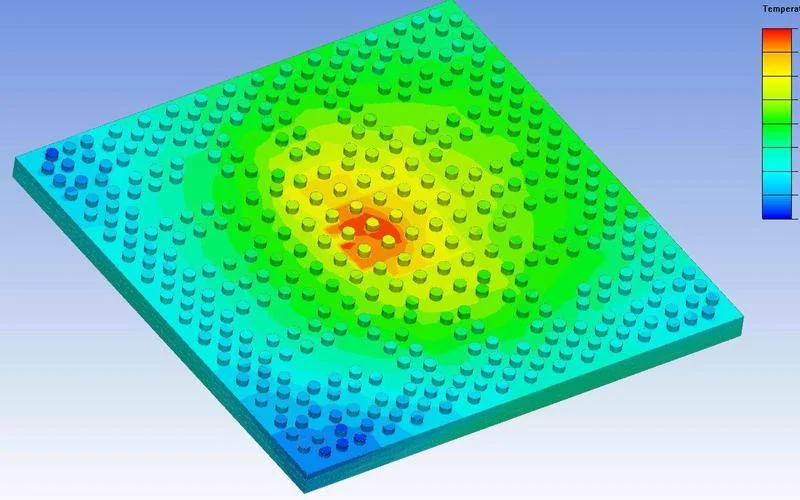

3. Uniform Temperature Distribution

The crystalline structure of ceramic materials enables homogeneous heat spreading across the substrate. In high-power LED arrays or COB (Chip-on-Board) modules, this uniformity minimizes stress on solder joints and semiconductor materials.

4. Stability Under Extreme Temperatures

Unlike organic laminates that expand and contract, ceramic PCBs maintain structural and dimensional stability under wide temperature swings. This stability reduces cracking, delamination, and component stress in LED assemblies operating continuously or in outdoor environments.

Why Ceramic PCBs Dominate LED Lighting Applications

A. Enhanced Efficiency

The higher the junction temperature of an LED, the lower its light output. Ceramic PCBs keep junction temperatures low, improving luminous efficacy by up to 20–30%. Cooler operation translates to higher brightness and energy savings.

B. Extended Lifespan

Ceramic’s excellent thermal resistance prevents heat buildup that degrades phosphor coatings or encapsulants. LED modules built on ceramic PCB substrates can operate continuously for tens of thousands of hours without performance decay.

C. Compact and Lightweight Design

Because ceramic substrates can handle high power densities, designers can integrate more LED chips into smaller spaces without overheating. This enables slimmer lighting modules, reducing the need for bulky external cooling systems.

D. Resistance to Harsh Environments

Ceramic materials are chemically inert and corrosion-resistant. This makes them ideal for outdoor, automotive, and industrial lighting systems that must withstand moisture, dust, and vibration.

E. Superior Electrical Insulation

Ceramics combine high dielectric strength with low dielectric loss, ensuring safety and efficiency in high-voltage LED drivers and arrays. The substrate provides both thermal and electrical separation in a single structure.

Comparing Ceramic PCB Materials for LED Design

Property | Al₂O₃ (Alumina) | AlN (Aluminum Nitride) | SiC (Silicon Carbide) |

Thermal Conductivity | 18–30 W/m·K | 140–220 W/m·K | 120–180 W/m·K |

Dielectric Constant | 9.8 | 8.8 | 10 |

Thermal Expansion (ppm/°C) | 6–8 | 4.5 | 4.0 |

Cost Efficiency | High | Moderate | Low |

Typical LED Application | General lighting, sensors | High-power LEDs, automotive, industrial | Aerospace and extreme temperature lighting |

Alumina (Al₂O₃):

Common in consumer and general-purpose lighting, Al₂O₃ offers a balance between cost and performance. It’s suitable for applications where moderate heat dissipation is required.

Aluminum Nitride (AlN):

Preferred for high-intensity LED arrays, automotive headlights, and UV curing systems, AlN provides unmatched thermal performance, maintaining junction temperatures far below standard MCPCBs.

Silicon Carbide (SiC):

Used in specialized or extreme environments, SiC delivers high mechanical strength and temperature resistance, suitable for aerospace and defense lighting.

Ceramic PCB Design Techniques for Better LED Thermal Management

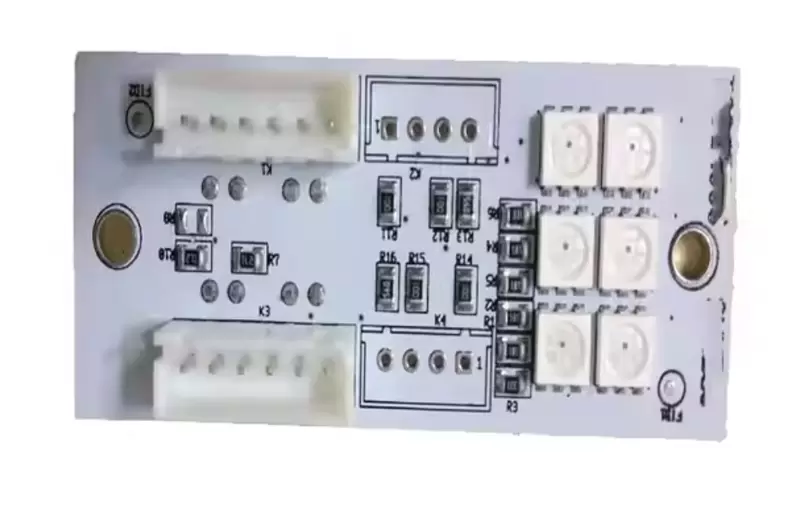

Chip-on-Board (COB) Assembly:

Ceramic substrates enable direct die bonding without the need for additional isolation layers, improving heat conduction.

Metalized Through-Holes:

Via metallization enhances vertical thermal pathways, spreading heat from surface LEDs to the underlying structure.

Thick Copper Metallization:

Techniques like Direct Bond Copper (DBC) or Direct Plated Copper (DPC) add thick copper layers that increase both thermal and current capacity.

Reflective Ceramic Coatings:

White ceramic surfaces improve light reflection efficiency while maintaining thermal balance, ideal for high-lumen LED modules.

Real-World Applications of Ceramic PCBs in LED Lighting

Automotive Headlights and Daytime Running Lights (DRLs): With high power and heat concentration, ceramic substrates ensure stability and long-term brightness.

Industrial and Street Lighting: Outdoor fixtures benefit from ceramic’s corrosion and weather resistance.

Stage and Studio Lights: Ceramic PCBs support compact, high-power LEDs in environments with continuous thermal cycling.

UV and Infrared LEDs: The ability to withstand high energy radiation makes ceramics ideal for curing, disinfection, and sensing systems.

Aerospace and Defense Lighting: Exceptional mechanical and thermal endurance enable performance in extreme conditions.

The Benlida Advantage

Benlida Circuit has established itself as a leading ceramic PCB manufacturer, specializing in advanced substrates such as Al₂O₃, AlN, and SiC. With precision manufacturing technologies like DBC, DPC, and thick-film metallization, Benlida ensures outstanding heat performance, dimensional accuracy, and reliability.

To explore high-performance ceramic PCB solutions for LED and other power applications, visit Benlida's Ceramic PCB product page.

Conclusion

As LED systems continue to evolve toward higher brightness and efficiency, managing heat effectively remains critical. Ceramic PCBs have proven to be the superior substrate technology—delivering exceptional thermal conductivity, mechanical stability, and reliability.

By leveraging advanced materials such as Al₂O₃, AlN, and SiC, ceramic PCBs have transformed LED performance, ensuring brighter illumination, longer operational life, and reduced maintenance.

For engineers and OEMs aiming to optimize LED efficiency and reliability, ceramic PCB technology represents a clear path forward.

en

en

WhatsApp

WhatsApp