Ceramic PCB vs FR4: A Complete Comparison for Modern Applications

Introduction: Why Substrate Choice Defines PCB Performance

The performance, reliability, and lifespan of modern electronics depend heavily on one foundational choice—the PCB substrate material. While FR4 remains the most widely used material for general-purpose circuit boards, it faces limitations in high-power, high-temperature, and high-frequency environments.

In contrast, Ceramic PCBs leverage advanced substrates such as Alumina (Al₂O₃), Aluminum Nitride (AlN), and Silicon Carbide (SiC) to provide exceptional thermal conductivity and stability. With conductivity reaching up to 220 W/m·K (versus FR4’s 0.25 W/m·K) and operational resilience between –55 °C and 800 °C, ceramic circuit boards are redefining standards in aerospace, automotive, LED lighting, and 5G communication systems.

This article explores the complete comparison between Ceramic PCB vs FR4, examining their structure, performance, and applications to help you choose the right material for your next project.

What Is FR4 PCB?

FR4 is a glass-fiber reinforced epoxy laminate. It’s lightweight, cost-efficient, and easy to fabricate, which has made it the industry standard for decades. FR4 boards offer adequate electrical insulation and mechanical stability for low- to mid-power applications, including consumer electronics, computers, and IoT devices.

However, when electronic systems demand higher power density or operate in harsh conditions, FR4 substrates begin to reach their physical limits. Heat buildup, delamination, and dielectric breakdown become significant risks, especially in high-frequency circuits.

What Is Ceramic PCB?

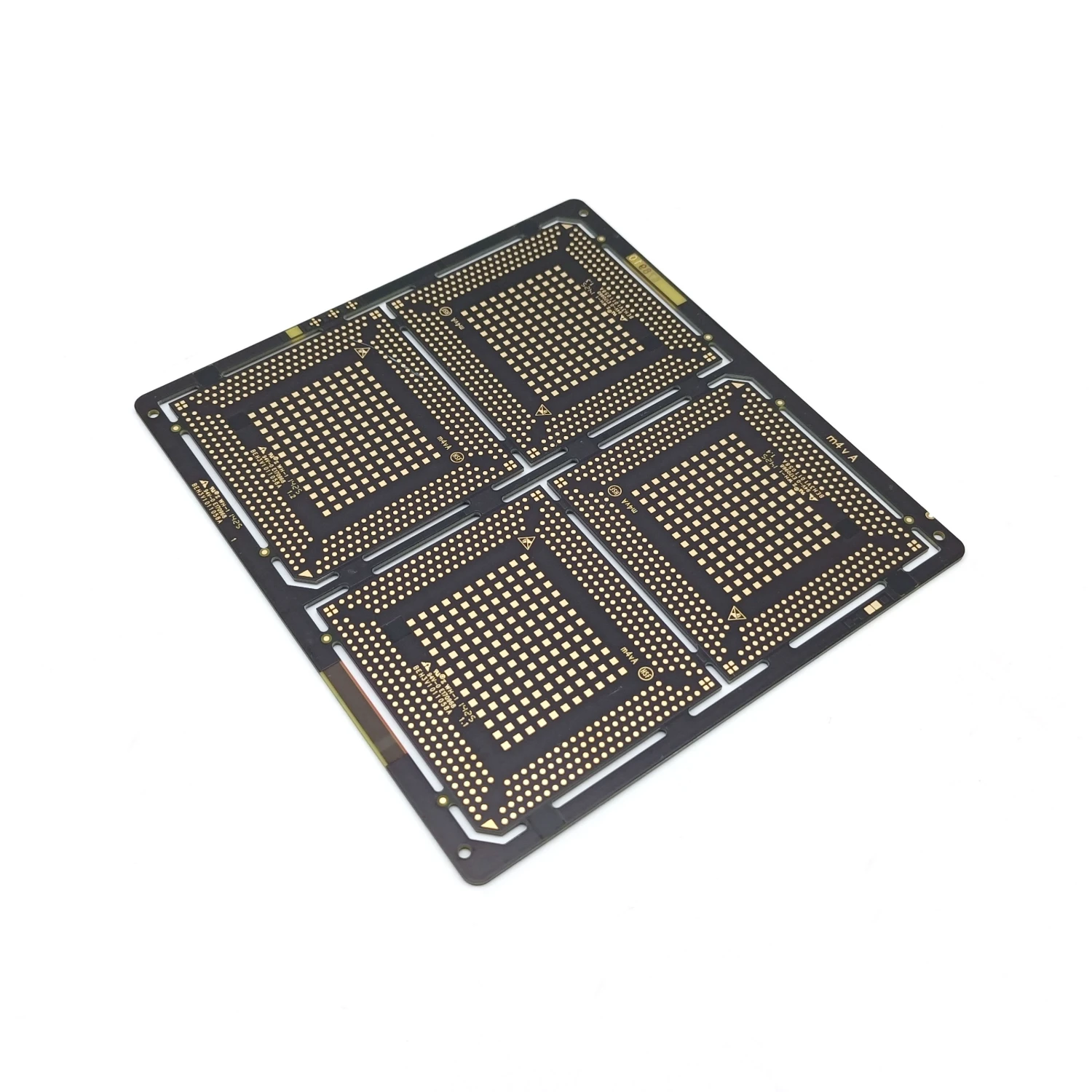

Unlike FR4, Ceramic PCBs are built on inorganic materials such as Al₂O₃, AlN, or SiC. These ceramics combine high thermal conductivity, excellent electrical insulation, and mechanical rigidity, making them ideal for extreme operating environments.

A ceramic PCB can directly dissipate heat from electronic components without thermal vias or extra metal cores, which is why it’s preferred in LED drivers, EV inverters, power modules, and RF systems.

Structural Differences

Property | FR4 PCB | Ceramic PCB |

Base Material | Fiberglass + Epoxy Resin | Al₂O₃, AlN, SiC (inorganic) |

Thermal Conductivity | ~0.25 W/m·K | 18–220 W/m·K |

Operating Temperature | –40 °C to +140 °C | –55 °C to +800 °C |

Dielectric Strength | Moderate | Excellent |

Coefficient of Thermal Expansion (CTE) | 16–18 ppm/°C | 4–8 ppm/°C |

Moisture Absorption | High | Near Zero |

Mechanical Strength | Moderate | High |

Cost Efficiency | Very High | Moderate to High |

Typical Applications | Consumer electronics, IT hardware | Power electronics, LEDs, aerospace, RF systems |

The difference is clear: ceramic substrates offer drastically superior thermal and mechanical properties, enabling devices to perform under conditions that would destroy FR4 boards.

Key Performance Comparison

1. Thermal Conductivity

The standout distinction between ceramic and FR4 PCBs lies in heat transfer. FR4’s thermal conductivity (0.25 W/m·K) severely limits its ability to handle high-power components. In contrast, AlN ceramics can reach 220 W/m·K, allowing heat to dissipate directly through the substrate.

In LED, power amplifier, and automotive applications, ceramic PCBs eliminate the need for additional cooling infrastructure, leading to more compact designs.

2. Electrical Insulation

Ceramic substrates combine high electrical insulation with strong heat conduction—an advantage that FR4 cannot match. This unique balance allows high-voltage and high-current operations without compromising safety or dielectric reliability.

3. Temperature Stability

FR4 begins to soften at around 130–140 °C (its glass transition temperature). Beyond this point, it loses structural integrity and may delaminate. Ceramic materials like AlN and SiC remain stable beyond 600 °C, ideal for aerospace, defense, and automotive control modules.

4. Frequency Performance

At high frequencies, FR4’s dielectric constant and loss tangent vary significantly, leading to signal distortion. Ceramic substrates, particularly AlN, maintain a consistent dielectric constant (~8.8) and extremely low loss tangent (~0.0003), ensuring clear, fast signal transmission in RF and microwave circuits.

5. Environmental Resistance

FR4 is vulnerable to humidity, UV radiation, and chemical exposure. Ceramic substrates are nonporous, corrosion-resistant, and chemically stable, ensuring performance even in humid or corrosive environments.

Application Scenarios

FR4 PCBs:

Consumer electronics (computers, smart devices, routers)

Low-power LED drivers

General-purpose controllers

Entry-level automotive modules

Ceramic PCBs:

Power converters, IGBT modules, and EV inverters

High-brightness LED arrays and COB lighting

RF amplifiers, radar systems, and satellite communications

Aerospace navigation and defense electronics

Medical and industrial sensors operating at high temperatures

In power-intensive or high-frequency scenarios, ceramic substrates provide unparalleled efficiency and durability, while FR4 remains cost-effective for low-power designs.

Manufacturing Technologies

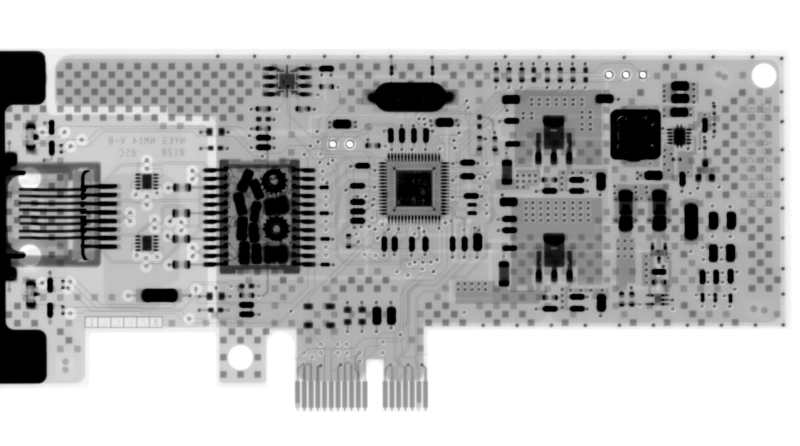

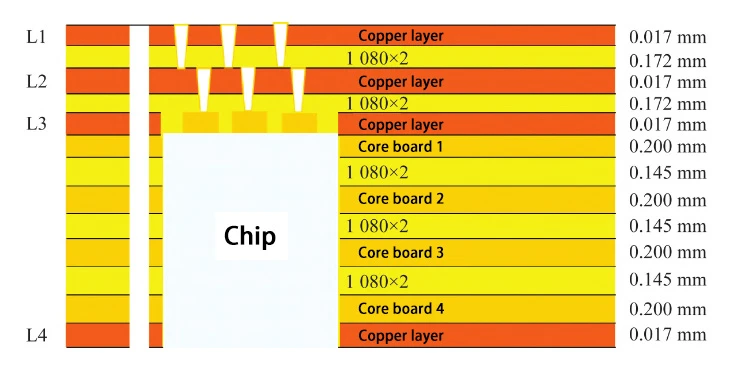

FR4 PCBs are fabricated through multilayer lamination, drilling, and copper plating—an efficient process for mass production. However, the epoxy-based bonding limits thermal cycling resistance.

Ceramic PCBs, in contrast, utilize high-precision processes such as:

Direct Bonded Copper (DBC): Fuses copper foil directly onto the ceramic surface for high current handling.

Direct Plated Copper (DPC): Enables fine-line circuit designs and thinner metallization.

Thick-Film Printing: Applies conductive pastes and sinters them at high temperature for multilayer structures.

These methods enhance mechanical stability and thermal conduction, though they require specialized equipment and expertise.

Case Example: LED Thermal Management

In high-power LED lighting, FR4 boards struggle with thermal bottlenecks. As heat accumulates, LED efficiency drops, causing color shift and degradation. By using Al₂O₃ or AlN ceramic PCBs, heat is directly dissipated from the LED junction, maintaining consistent brightness and extending lifespan.

Benlida's ceramic PCB solutions have been successfully integrated into industrial, automotive, and architectural LED systems, achieving stable operation even under extreme thermal loads.

Advantages Summary

Feature | Ceramic PCB | FR4 PCB |

Thermal Efficiency | Excellent | Limited |

Signal Integrity (RF) | Excellent | Average |

High-Temperature Endurance | Excellent | Poor |

Moisture Resistance | Excellent | Weak |

Durability & Longevity | Outstanding | Moderate |

Conclusion: Choosing the Right PCB for Your Application

Both FR4 and ceramic PCBs play essential roles in modern electronics. FR4 remains suitable for low-cost, general-purpose designs, but when performance, reliability, and heat management matter, ceramic PCB technology is the clear choice.

Industries such as aerospace, automotive, and telecommunications depend on ceramic substrates to ensure consistent, high-efficiency operation in extreme environments.

With expertise in Al₂O₃, AlN, and SiC materials, Benlida Circuit provides advanced manufacturing solutions tailored to power electronics, LEDs, and RF applications. To learn more or request technical consultation, visit the official Ceramic PCB page.

en

en

WhatsApp

WhatsApp