From Al₂O₃ to AlN: Choosing the Right Ceramic PCB Substrate

Introduction: The Evolution of Ceramic PCB Materials

As electronic systems become smaller, faster, and more powerful, the limitations of traditional PCB substrates like FR-4 are becoming more apparent. High-power and high-frequency devices demand superior heat dissipation, electrical insulation, and dimensional stability—characteristics that only advanced ceramics can deliver.

Ceramic Printed Circuit Boards (PCBs) have emerged as the backbone of next-generation electronics, particularly in aerospace, electric vehicles, 5G infrastructure, and industrial control systems. Leveraging materials like Alumina (Al₂O₃), Aluminum Nitride (AlN), and Silicon Carbide (SiC), ceramic PCBs achieve thermal conductivity up to 220 W/m·K, compared to just 0.25 W/m·K for FR-4.

By combining these remarkable properties with exceptional temperature resilience—from -55 °C to over 800 °C—ceramic PCBs enable the reliable operation of mission-critical technologies under extreme environmental conditions.

For detailed technical specifications and product examples, you can visit Benlida's Ceramic PCB page.

Why Ceramic PCBs Dominate Extreme Environments: Six Core Advantages

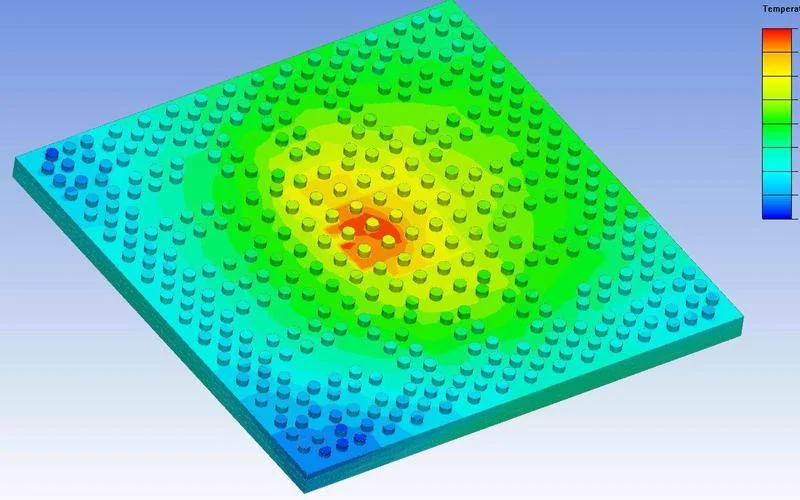

1. Unrivaled Thermal Management

Ceramic substrates like AlN and Al₂O₃ have exceptional thermal conductivity, enabling direct and efficient heat transfer from active components. This eliminates the need for thermal vias or bulky heat sinks. In high-power modules such as IGBTs or LED drivers, this capability ensures consistent temperature balance and prevents overheating.

2. Extreme-Temperature Stability

Unlike organic laminates, ceramics maintain structural and electrical integrity at temperatures above 500 °C. This property is vital in aerospace avionics, automotive inverters, and military systems that experience wide temperature fluctuations. Both Al₂O₃ and AlN remain dimensionally stable even after hundreds of thermal cycles, reducing fatigue and microcracking.

3. Superior High-Frequency Performance

For 5G, radar, and RF applications, ceramic PCBs offer low dielectric loss and stable permittivity across frequency bands. The low-loss tangent of AlN (~0.0003) ensures that high-frequency signals travel with minimal attenuation, enabling clearer communication and improved antenna performance.

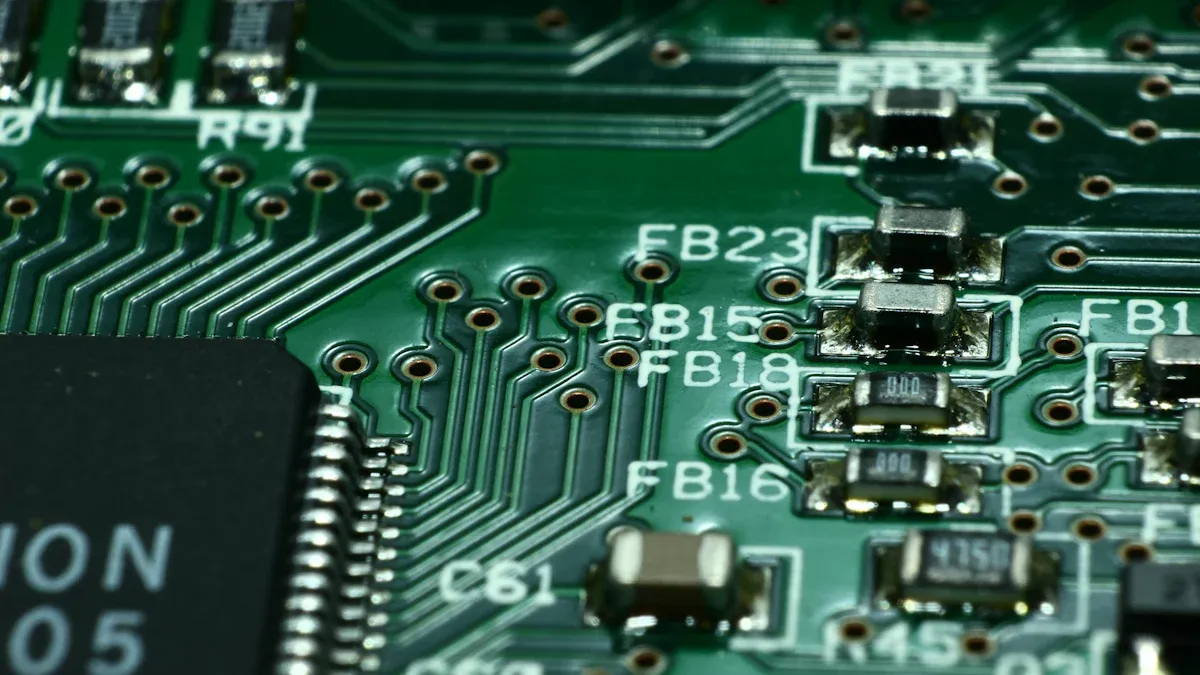

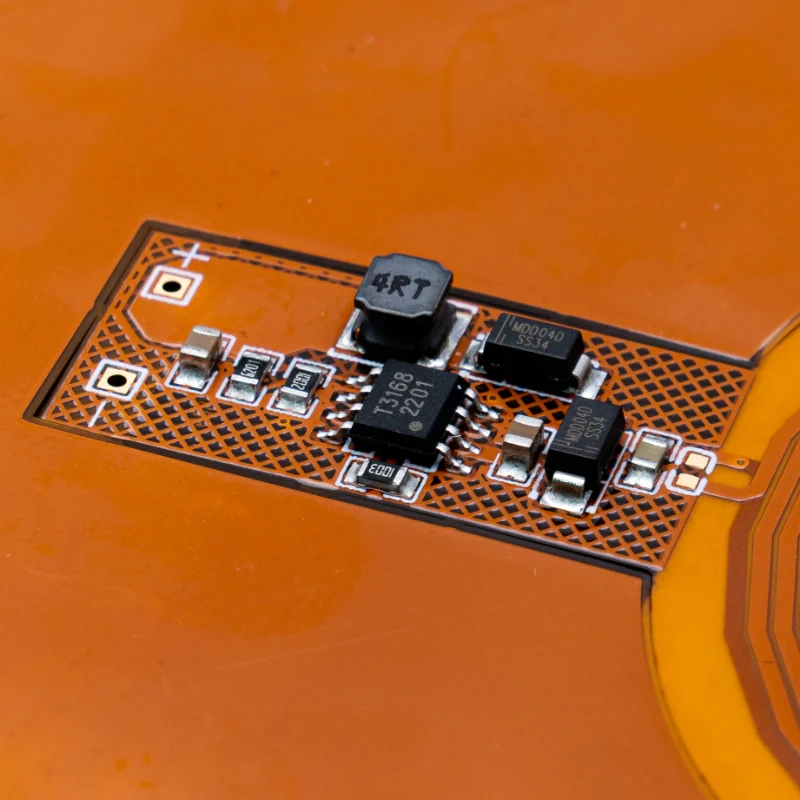

4. Ultra-High Density and Miniaturization

Because ceramic substrates can handle high temperatures and support fine-line metallization, they allow ultra-high-density interconnects (HDI) and miniaturized circuits. This capability is critical in sensors, wearable electronics, and compact control modules where every millimeter counts.

5. Zero Degradation in Harsh Conditions

Ceramic PCBs are immune to humidity, UV exposure, and chemical corrosion. Their inorganic nature prevents delamination, oxidation, and material aging, even in outdoor or marine environments. This makes them ideal for industrial automation, defense equipment, and offshore communication systems.

6. High Voltage and Current Reliability

With dielectric strengths exceeding 15 kV/mm, ceramic PCBs handle high-voltage operations safely. Their strong insulation properties enable designers to pack more power into smaller footprints without risking dielectric breakdown—a key advantage in electric vehicles and power converters.

Comparing Popular Ceramic Substrates

Different ceramic materials offer distinct benefits depending on performance requirements. The two most widely used are Alumina (Al₂O₃) and Aluminum Nitride (AlN), each excelling in specific categories.

Property | Alumina (Al₂O₃) | Aluminum Nitride (AlN) |

Thermal Conductivity | 18–30 W/m·K | 140–220 W/m·K |

Dielectric Strength | Excellent | Excellent |

Dielectric Constant (1 MHz) | 9.8 | 8.8 |

Thermal Expansion (ppm/°C) | 6–8 | 4.5 |

Cost Efficiency | High | Moderate |

Applications | LEDs, sensors, general power PCBs | RF modules, laser drivers, power amplifiers, EV inverters |

Al₂O₃ (Alumina):

The most commonly used ceramic material, Alumina is cost-effective and provides solid electrical insulation and decent thermal conductivity. It’s widely used in LED lighting, automotive sensors, and consumer electronics.

AlN (Aluminum Nitride):

Chosen for premium, performance-critical designs, AlN combines superior thermal conductivity and high-frequency stability. It’s the substrate of choice for advanced power modules, laser systems, and high-frequency telecommunications.

SiC (Silicon Carbide):

Though less common, SiC offers unmatched thermal and mechanical resilience, suitable for aerospace propulsion systems and extreme industrial electronics.

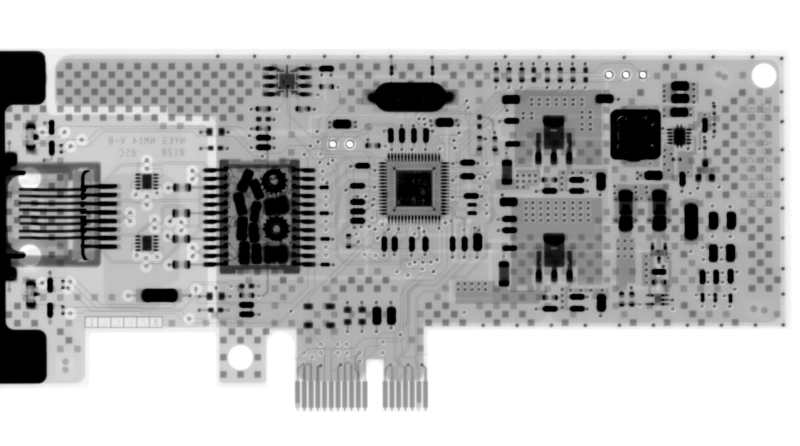

The Role of Manufacturing Technology

The performance of a ceramic PCB depends not only on material selection but also on precise manufacturing processes.

Direct Bonded Copper (DBC):

Copper foil is bonded directly onto the ceramic substrate at high temperature, creating excellent adhesion and high current capacity.

Direct Plated Copper (DPC):

Enables thinner metallization layers and fine-line circuitry, ideal for miniaturized high-frequency designs.

Thick-Film Printing:

Conductive, resistive, and dielectric pastes are printed onto ceramic substrates and fired, creating compact, multilayer structures.

Each method requires advanced process control to avoid microcracks, maintain adhesion strength, and ensure dimensional accuracy.

Applications of Al₂O₃ and AlN Ceramic PCBs

Power Electronics: Inverters, rectifiers, and converters rely on AlN PCBs for efficient heat dissipation and electrical isolation.

LED Lighting: Al₂O₃ substrates provide cost-effective thermal management for high-brightness LEDs.

Automotive Electronics: Ceramic PCBs withstand high vibration and temperature in EV charging and control systems.

5G Communication: AlN’s low dielectric loss supports antenna arrays and power amplifiers.

Medical Devices: Ceramic PCBs ensure stability in diagnostic equipment and imaging sensors.

Aerospace Systems: Lightweight and thermally stable, ceramics support mission-critical avionics and radar electronics.

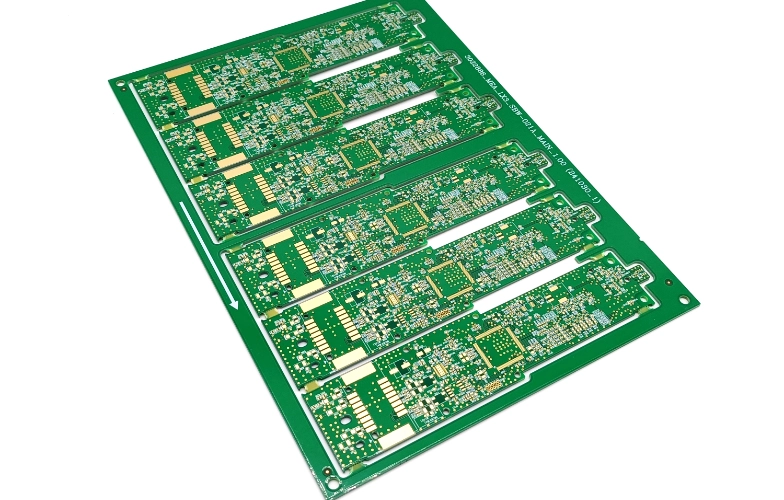

Choosing the Right Partner

Selecting the ideal substrate is only half the challenge—manufacturing precision defines the final performance. Benlida Circuit brings decades of experience producing high-quality ceramic PCBs for global clients. From Al₂O₃ to AlN, Benlida’s production lines ensure consistency, tight tolerance, and reliability through advanced processes like DBC and DPC.

To explore substrate options and custom fabrication capabilities, visit Benlida's Ceramic PCB page for detailed insights.

Conclusion

From the robust durability of Al₂O₃ to the superior thermal and electrical performance of AlN, ceramic PCBs redefine what’s possible in high-power electronics. As industries push toward higher density, speed, and efficiency, these materials will remain at the forefront of innovation.

Whether you are designing a power module, RF transceiver, or industrial sensor, selecting the right substrate—and the right manufacturing partner—will determine long-term success. With expertise in both material science and fabrication, Benlida provides reliable, high-performance solutions that empower the future of electronic design.

en

en

WhatsApp

WhatsApp