Balancing the Thickness of Conformal Coating on PCB&PCBA

In the electronics manufacturing industry(EMS), conformal coating is a crucial armor which protects PCBA from environmental damages, such as humidity corrosion, dust, salt mist, and other chemical corrosions. However, its protective effect is not simply a matter of "the thicker the better." Coating thickness, an ordinary process parameter, actually is a core indicator for the long-term reliability of a product and directly affects it's lifespan.

I. Protection and Risk: The Two Sides of Coating Thickness

1. Coating Too Thin: Insufficient Protection, Ineffective

When the conformal coating is too thin, its protective effectiveness will be greatly reduced, leading to:

● Reduced Protective Capacity: It cannot effectively cover the PCB surface, leave blind areas and un-covered spots. Humidity and contaminants can easily penetrate, leading to dendrite growth and electrochemical migration.

● Insufficient Insulation Strength: When going through high voltage or in high humidity environments, the thin coating could be easily broken down, causing leakage or short circuits.

● Weaken Mechanical Protection: Insufficient protection to physical damages, such scratches and vibration stress.

2.Coating Too Thick: Introducing Other Reliability Risks

Blindly increasing coating thickness will not simply improve reliability but also might introduce a series of issues:

● Internal Stress Accumulation: Excessive thick coating will lead to a significant increase for shrinkage from internal stress, potentially damage component's leads, especially for fragile ones, and even crack the coating itself, thus leave a pathway for environmental corrosion.

● Degradation of Heat Dissipation: Conformal coating is poor conductors of heat, excessively thick coating definitely hinders heat dissipation from components, leading to localized overheating and accelerate aging.

● Increase the Manufacturing Cost and Weight: Too many coating will increase production costs and increase the weight on the PCB&PCBA.

II. Process Control: How to Control Coating Thickness Precisely

Control the coating thickness requires a systematic approach from three aspects: materials, equipment, and processes:

1. Material is Fundamental

Different conformal coating materials, such as acrylic, polyurethane, silicone, they are different for viscosity, solid content, and thixotropic properties, resulting in various coating thickness ranges. Selecting the material must be based on a comprehensive evaluation, considering the product's protection level and process capabilities.

2. Coating Process is the Key

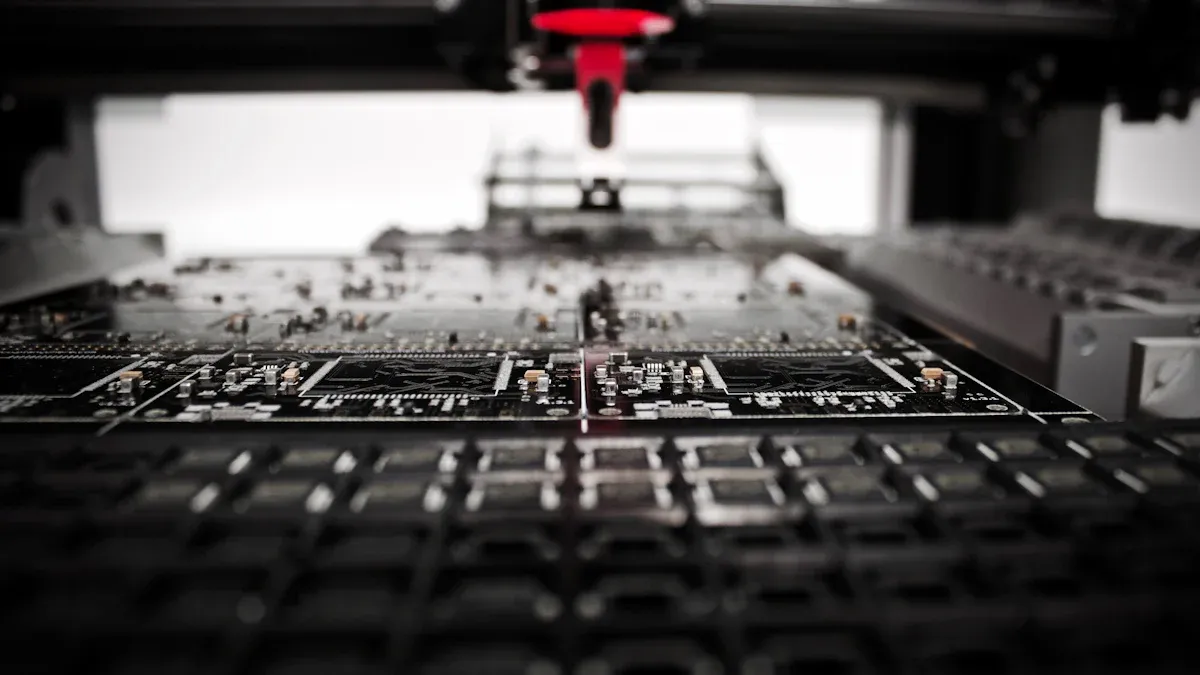

● Spraying: The most common method, using mechanical equipment to control parameters such as spray pressure, flow rate, coverage, moving speed, and distance between the PCB and sprayer, to adjust thickness. Must calibrate the equipments regularly.

● Brushing: Manual operation, simple and flexible, but thickness uniformity highly depends on operator skill and method, sometimes it might resulting in brush marks and uneven thickness.

● Dip Coating: Mostly used for outdoor equipment, providing full conformal paint coverage. Thickness is controlled through viscosity and placement method.

3. Process Monitoring and Measurement are Guaranteed

● "Wet Film": Measure the coating thickness immediately after coating, it could get the coating results right away and provide reference for process adjustments; this is part of process control.

● "Dry Film": Measure the coating thickness after curing, this is the final thickness for quality judgment.

Other methods include:

● Ultrasonic Thickness Measurement.

● Micrometer/Microscope Thickness Measurement.

III. Authority Standards and Practical Approaches

Industry standards provide clear guidance and references for thickness control. The most authoritative IPC-A-610 standard (Electronic Assembly Acceptability) recommends that conformal coating thickness should be controlled between 30μm and 130μm. For most applications, a thickness of 50μm-80μm is considered the optimal balance between reliability, processability, and cost-effectiveness.

Practical Approaches

1. Define Requirements: Clearly define the operating environment of the final product (e.g., automotive, marine, industrial) and determine the protection level.

2. Select Materials: Choose the appropriate conformal coating type based on the environment and process.

3. Process Development and Validation: Establish a stable coating process window through Design of Experiments (DOE).

4. Set Control Limits: Set strict upper and lower limits based on IPC standards or customer requirements.

5. Continuous Monitoring: Incorporate thickness monitoring into critical process control points, using statistical methods for control and providing data support for process optimization.

Conclusion

The thickness of conformal coatings needs to strike an optimal balance between insufficient and excessive protection. This requires process engineers to understand the material properties, precise control of process parameters, and strict implementation of process control. Only by precise thickness control, then a solid, long-lasting, economical, and reliable defense armor can be built, as conformal coating protection for electronic products.

Regarding conformal coatings, Benlida also conducts the following inner process as support work:

1. Coating thickness measurement: Using a high-precision ultrasonic thickness gauge, the coating quality is authoritatively tested according to IPC standards.

2. Coating process assessment: Optimizing process parameters such as spraying and dip coating to improve thickness uniformity and consistency.

3. Reliability testing: Conducting tests such as damp heat cycling, salt spray corrosion, and insulation resistance to verify the effectiveness of coating protection.

4. Failure analysis: Performing root cause analysis on PCBA failures caused by coating issues.

Benlida is a professional EMS manufacturer for PCB and PCB assembly, with years of experience and feedback from market, Benlida also provides related services, such as conformal coating, firmware flashing, and functional testing, as one-stop turnkey service. If you need more information about conformal coating, such as material selection, coating process and cost, please contact Benlida to know more!

en

en

WhatsApp

WhatsApp