Material Selection Guide for Ceramic PCB: Al₂O₃, AlN, SiC—What’s Best?

Introduction: Why Substrate Material Matters in Ceramic PCBs

As electronic systems continue to push the limits of power density, miniaturization, and thermal performance, the choice of substrate material has become one of the most crucial factors in PCB design. For applications that must operate in extreme environments—whether in aerospace, EV power modules, or medical electronics—Ceramic PCBs offer a superior alternative to traditional FR-4 or metal-core boards.

With thermal conductivities up to 220 W/m·K (compared to FR-4’s 0.25 W/m·K) and operational reliability from –55 °C to 800 °C, ceramic substrates provide unmatched performance for high-power, high-frequency, and high-reliability electronics.

However, not all ceramics are the same. The three main materials used—Alumina (Al₂O₃), Aluminum Nitride (AlN), and Silicon Carbide (SiC)—each have unique physical, thermal, and electrical properties that influence cost, manufacturability, and performance.

In this guide, we’ll explore how to choose the right material for your ceramic PCB application and what trade-offs to consider.

Understanding the Role of Ceramic Substrates

Ceramic substrates serve three essential purposes in high-performance PCB design:

Thermal Conduction – Efficiently transferring heat from power devices to maintain safe operating temperatures.

Electrical Insulation – Preventing arcing or leakage in high-voltage and high-frequency circuits.

Mechanical Stability – Providing rigidity, dimensional accuracy, and resistance to environmental stress.

These properties make ceramic PCBs indispensable for industries like automotive power electronics, renewable energy systems, RF communication, and medical instrumentation.

The Three Main Ceramic PCB Materials

1. Alumina (Al₂O₃): The Cost-Effective All-Rounder

Alumina, or Aluminum Oxide, is the most widely used ceramic substrate in PCB manufacturing. It provides a strong balance between cost, mechanical strength, and thermal performance.

Key Properties:

Thermal Conductivity: 18–30 W/m·K

Dielectric Constant: 9.8

Thermal Expansion (CTE): 6–8 ppm/°C

Maximum Operating Temperature: ~350 °C

Advantages:

Excellent mechanical strength and hardness.

Stable electrical insulation.

High chemical resistance and corrosion protection.

Cost-effective and readily available.

Applications:

LED lighting modules.

Sensor and control circuits.

Medical instruments requiring sterilization resistance.

General industrial electronics.

Limitations:

While durable and versatile, Al₂O₃ has relatively low thermal conductivity compared to AlN or SiC, making it less suitable for extreme heat or power applications.

2. Aluminum Nitride (AlN): The Thermal Performance Champion

Aluminum Nitride (AlN) has rapidly become the go-to substrate for high-power and high-frequency applications. It combines excellent electrical insulation with thermal conductivity up to 220 W/m·K, approaching that of metals while maintaining the benefits of ceramics.

Key Properties:

Thermal Conductivity: 140–220 W/m·K

Dielectric Constant: 8.8

Thermal Expansion (CTE): 4.5 ppm/°C

Maximum Operating Temperature: ~600 °C

Advantages:

Superior heat dissipation for high-current or high-density devices.

Low dielectric loss and high electrical resistivity.

Close CTE match to silicon chips—minimizing thermal stress.

Excellent dimensional stability and reliability.

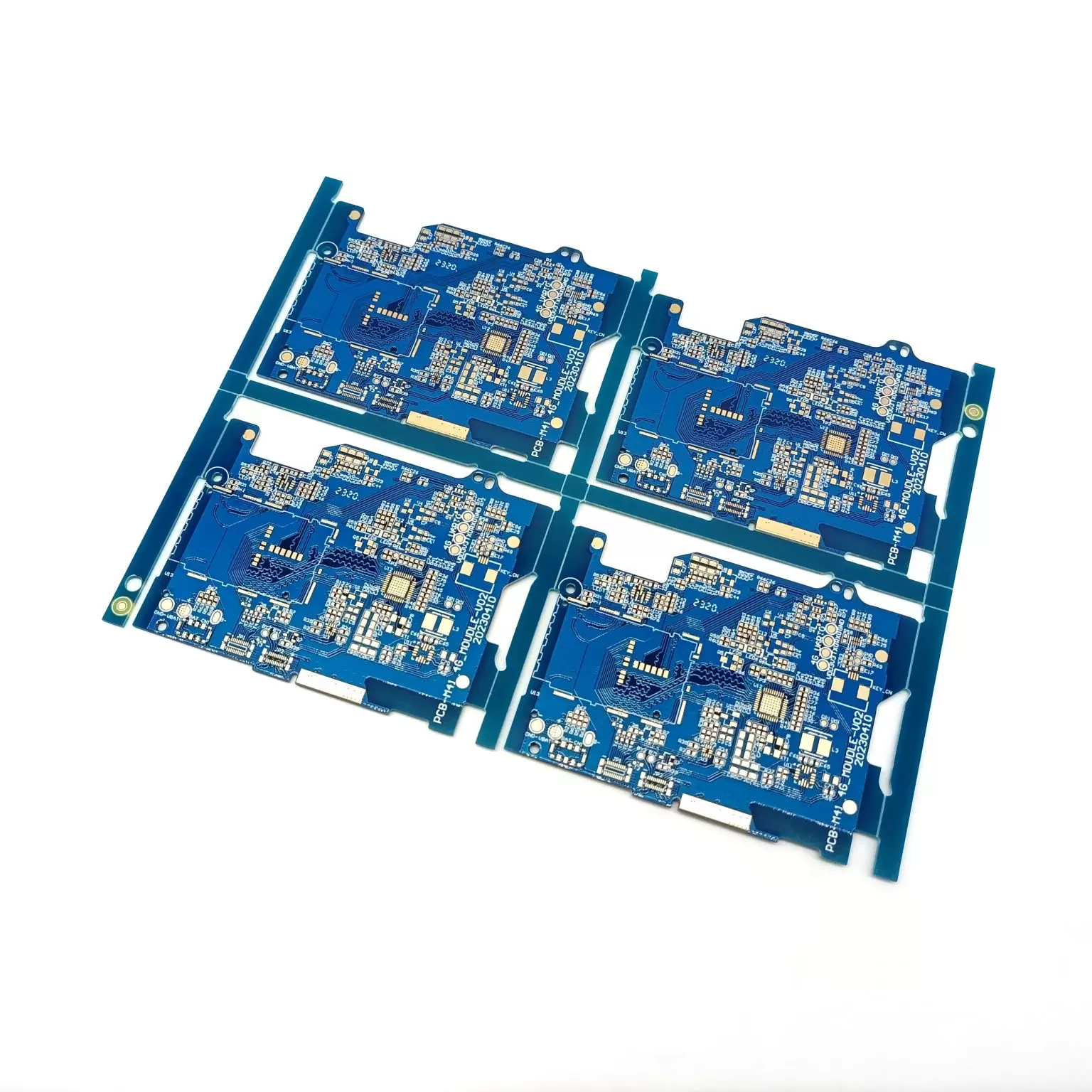

Applications:

Power modules and converters in EVs and industrial drives.

RF and microwave circuits for 5G and satellite systems.

LED modules and laser diodes.

High-precision instrumentation.

Limitations:

Higher manufacturing complexity.

More brittle than Al₂O₃.

For applications where thermal management and electrical performance are mission-critical, AlN provides the best combination of reliability and conductivity.

3. Silicon Carbide (SiC): The High-Temperature Specialist

Silicon Carbide (SiC) stands out for its mechanical robustness, chemical inertness, and high thermal tolerance. It’s used in the most demanding environments, including aerospace, military, and power semiconductor packaging.

Key Properties:

Thermal Conductivity: 120–180 W/m·K

Dielectric Constant: ~10

Thermal Expansion (CTE): ~4 ppm/°C

Maximum Operating Temperature: 800 °C+

Advantages:

Exceptional high-temperature endurance.

High mechanical and chemical strength.

Ideal for extreme conditions—vibration, radiation, and corrosive exposure.

Compatible with wide bandgap semiconductors (SiC, GaN).

Applications:

Aerospace and defense electronics.

Power converters for renewable energy systems.

Engine and turbine monitoring sensors.

Harsh-environment industrial automation systems.

Limitations:

Difficult to process due to hardness.

Higher cost and limited commercial availability compared to Al₂O₃ or AlN.

Comparing the Three Ceramic PCB Materials

Property | Al₂O₃ (Alumina) | AlN (Aluminum Nitride) | SiC (Silicon Carbide) |

Thermal Conductivity (W/m·K) | 18–30 | 140–220 | 120–180 |

Dielectric Constant | 9.8 | 8.8 | 10 |

CTE (ppm/°C) | 6–8 | 4.5 | 4.0 |

Max Operating Temp (°C) | ~350 | ~600 | 800+ |

Mechanical Strength | Excellent | Moderate | Outstanding |

Cost Efficiency | High | Medium | Low |

Typical Applications | LEDs, sensors | Power modules, 5G | Aerospace, energy systems |

Matching Material to Application

Application | Recommended Material | Reason |

LED Lighting | Al₂O₃ | Reliable, cost-effective heat dissipation. |

EV Power Modules | AlN | High thermal conductivity and electrical insulation. |

5G RF Systems | AlN | Low loss tangent and stable high-frequency response. |

Aerospace Electronics | SiC | Exceptional temperature and vibration resistance. |

Medical Devices | Al₂O₃ or AlN | Biocompatibility and sterilization resistance. |

Renewable Energy Inverters | AlN or SiC | Handles high current and fluctuating loads. |

When choosing the right substrate, consider factors like thermal load, voltage level, ambient environment, and mechanical stress. In most cases, Al₂O₃ provides an affordable entry point, AlN offers top-tier thermal performance, and SiC is reserved for the harshest operating environments.

The Role of Manufacturing Technology

The choice of substrate is only half the equation—the fabrication method determines the final board’s performance.

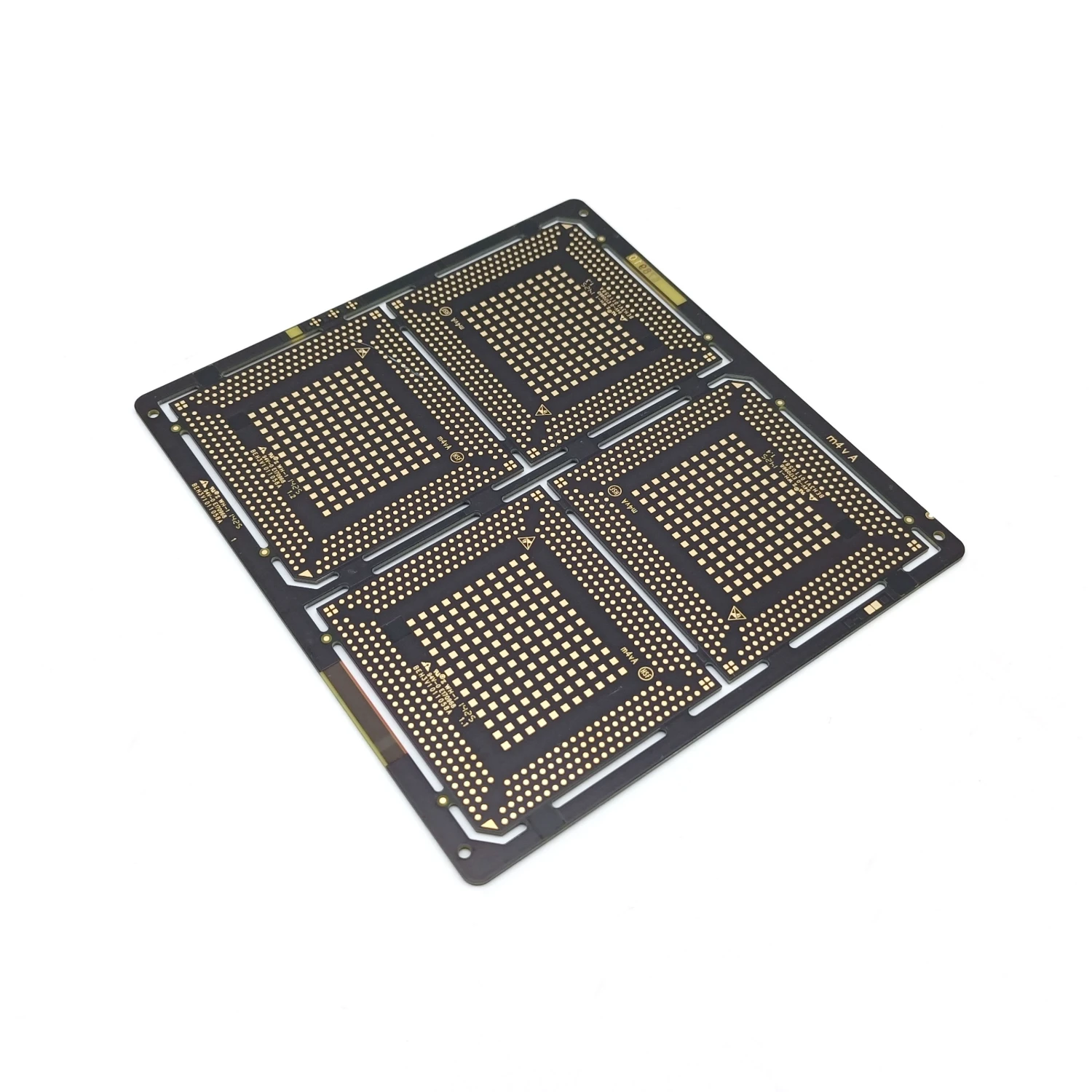

Direct Bonded Copper (DBC): Ideal for high-current AlN and SiC PCBs.

Direct Plated Copper (DPC): Enables thin, high-precision circuits on ceramic.

Thick-Film Printing: Suited for hybrid circuits on Al₂O₃.

Benlida Circuit, with its advanced DBC and DPC manufacturing capabilities, provides tailored ceramic PCB solutions for various industries—balancing performance, cost, and scalability.

Learn more at Benlida's Ceramic PCB page.

Conclusion: Selecting the Best Ceramic for Your Design

The ideal ceramic substrate depends on your project’s power density, environmental conditions, and performance expectations.

Choose Al₂O₃ for cost-effective, general-purpose solutions.

Opt for AlN when superior heat dissipation and stability are required.

Select SiC for extreme environments or aerospace-grade applications.

No matter your choice, ceramic PCBs represent the next generation of reliability and performance in electronics—enabling safer, more efficient, and more compact designs.

Benlida Circuit continues to lead in ceramic PCB manufacturing, providing customized solutions that integrate material expertise with advanced process technology.

en

en

WhatsApp

WhatsApp