Why Ceramic PCB is Ideal for Harsh Environment Electronics (vibration, moisture, heat)

Introduction: When Conditions Push Electronics to the Limit

In critical industries such as aerospace, automotive, defense, and industrial automation, electronics often face punishing conditions—intense vibration, temperature swings, moisture exposure, and high voltages. In these environments, even the smallest failure can lead to serious consequences.

Traditional FR-4 or metal-core PCBs struggle to maintain stability under such stress. They suffer from delamination, thermal fatigue, and corrosion, all of which compromise long-term reliability.

That’s why engineers worldwide are turning to Ceramic PCBs—advanced circuit boards that combine exceptional thermal performance, mechanical strength, and chemical resistance.

Made from Alumina (Al₂O₃), Aluminum Nitride (AlN), or Silicon Carbide (SiC), ceramic substrates provide thermal conductivity up to 220 W/m·K, remain stable between –55°C and 800°C, and maintain their structural integrity even under extreme vibration and humidity.

Why Ceramic PCB Outperforms in Harsh Conditions

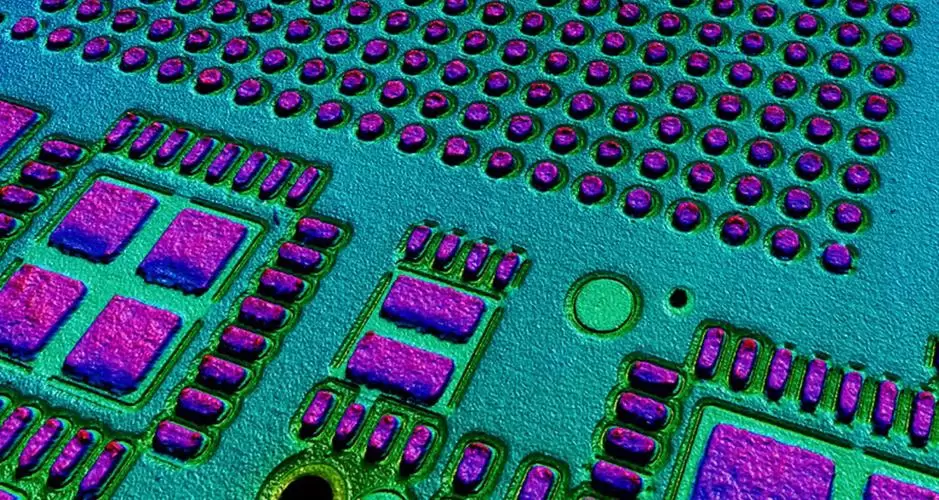

Ceramic PCBs are engineered for resilience. Their inorganic crystalline structure and direct metal bonding technology make them far more robust than organic or composite alternatives. Let’s break down how these boards maintain superior performance in vibration, moisture, and heat exposure.

1. Resistance to Vibration and Mechanical Stress

In environments with high mechanical shock—such as automotive engines, aerospace control systems, and defense electronics—vibration-induced failures are a major concern.

Why Ceramic PCBs excel:

Rigid Structure: The crystalline lattice of Al₂O₃, AlN, and SiC gives the substrate high compressive strength and stiffness. This prevents cracking or warping under prolonged vibration.

Low Coefficient of Thermal Expansion (CTE): Ceramic substrates have a CTE of 4–8 ppm/°C, closely matching that of semiconductor materials. This minimizes mechanical stress between the substrate and components.

Superior Adhesion with Copper Layers: Direct Bonded Copper (DBC) and Direct Plated Copper (DPC) methods form chemical bonds rather than adhesive interfaces, ensuring copper traces stay intact even under high vibration or bending loads.

Result: Electronics using ceramic PCBs show minimal fatigue, no delamination, and stable performance over millions of vibration cycles.

2. Moisture and Corrosion Resistance

Humidity and condensation can cause oxidation, corrosion, and short circuits in conventional PCBs. FR-4 and metal-core boards absorb moisture due to their epoxy content, leading to dielectric breakdown and swelling.

Ceramic PCBs eliminate these issues entirely.

Zero Moisture Absorption: Ceramic materials are inorganic and nonporous, meaning they do not absorb water or moisture vapor.

Corrosion-Resistant Surface: Ceramic substrates and their metalized layers (especially with ENIG or silver finishes) resist oxidation and chemical degradation.

Stable Dielectric Properties: Electrical insulation remains constant even in high-humidity or underwater environments.

Applications benefiting from this:

Marine and offshore electronics.

Environmental monitoring sensors.

Medical sterilization equipment.

Outdoor lighting and surveillance systems.

Example: A ceramic PCB-based radar sensor in coastal applications can operate continuously without the corrosion issues typical of FR-4-based systems.

3. Exceptional Heat Dissipation and Thermal Stability

Heat is the enemy of reliability. Overheating leads to circuit drift, material expansion, and component failure. Ceramic PCBs address this at the material level.

High Thermal Conductivity: AlN can reach 140–220 W/m·K, efficiently spreading heat away from power semiconductors. Even Al₂O₃, with 18–30 W/m·K, significantly outperforms FR-4.

Extreme-Temperature Resistance: Unlike organic boards that degrade around 130°C, ceramic PCBs remain stable up to 800°C, making them ideal for heavy-duty applications.

Uniform Heat Distribution: The dense ceramic lattice structure ensures even thermal spreading, reducing localized hotspots.

In practical terms:

Ceramic PCBs allow high-power LED arrays, IGBT modules, and laser drivers to run cooler, last longer, and perform more consistently.

4. High Voltage and Electrical Reliability

High-voltage systems—like EV inverters, X-ray machines, or radar transmitters—require substrates with excellent insulation. Moisture, contamination, and dielectric fatigue can lead to dangerous arcing or short circuits.

Ceramic PCBs solve this problem with:

Dielectric Strength >15 kV/mm.

Low Dielectric Constant (~8.8) ensuring consistent signal transmission.

Minimal Leakage Current, even at elevated temperatures.

Because ceramics combine thermal conductivity with electrical insulation, they eliminate the need for additional dielectric layers or insulation coatings, simplifying design and improving reliability.

5. Chemical and Environmental Durability

Ceramic PCBs maintain performance where chemical exposure or radiation would destroy conventional boards.

Resistant to acids, solvents, and industrial gases.

Nonflammable and UV-resistant.

Unaffected by long-term exposure to vacuum or radiation (ideal for space and nuclear applications).

This makes SiC-based ceramic PCBs the go-to choice for aerospace propulsion, high-radiation zones, and industrial sensors in chemical plants.

6. Long-Term Reliability and Lifecycle Benefits

Every factor above—vibration resistance, corrosion immunity, and thermal endurance—adds up to one key advantage: longevity.

Ceramic PCBs typically exhibit:

>10x lifespan compared to FR-4 boards in extreme environments.

Stable electrical parameters over decades of operation.

Reduced maintenance and downtime, critical for mission-dependent systems.

In applications like EV chargers, industrial robotics, or satellites, this reliability translates to lower lifecycle costs and higher safety.

Material Selection for Harsh Conditions

Condition | Recommended Material | Key Benefit |

High Vibration (Automotive, Aerospace) | Al₂O₃ or AlN | Strong rigidity, low CTE |

High Heat (Power Modules, LEDs) | AlN | Thermal conductivity up to 220 W/m·K |

Corrosive/Moisture Environments | SiC | Chemical inertness and zero water absorption |

Radiation Exposure | SiC | Stability under radiation and vacuum |

General Industrial Use | Al₂O₃ | Cost-effective durability |

The right choice depends on balancing cost, thermal demand, and environmental exposure.

The Benlida Advantage in Harsh-Environment PCB Manufacturing

Benlida Circuit specializes in manufacturing high-performance ceramic PCBs using advanced Al₂O₃, AlN, and SiC substrates. Their processes—including Direct Bonded Copper (DBC), Direct Plated Copper (DPC), and Thick-Film Printing—ensure strong metallization, precise circuitry, and long-term reliability even under the harshest conditions.

Applications include:

Automotive and EV power systems.

Aerospace guidance electronics.

LED lighting for outdoor and industrial use.

Defense and radar modules.

Renewable energy converters and power amplifiers.

Explore the full range of solutions on Benlida’s Ceramic PCB product page.

Conclusion

When electronics must perform in vibration, moisture, and heat, material strength and thermal stability are non-negotiable. Ceramic PCBs, built from Al₂O₃, AlN, or SiC, combine the mechanical resilience, corrosion resistance, and high-temperature tolerance that harsh environments demand.

From electric vehicles to aerospace control systems, these boards ensure continuous, safe, and efficient operation—where other materials would fail.

Benlida Circuit continues to lead the industry with precision-engineered ceramic PCBs designed to withstand the world’s toughest operating conditions.

en

en

WhatsApp

WhatsApp