A Brief Overview for Power Supply Efficiency Testing for Electronic Products/PCBA

Power supply efficiency testing is far more than simply "measuring power consumption", it's a systematic engineering with multiple strategic values. It's impact going throughout every stage of the lifecycle of electronic product, from design to market competition and long-term operation, it's core value far exceeding the testing itself.

I. Commercial and Market Advantages: The Key to Market Access

1. Meeting Mandatory Regulations and Market Access

● Passport to Global Market: Countries worldwide (such as China, the US, the EU, and Australia) have implemented mandatory regulations on energy efficiency for various electronic products (such as the EU ErP Directive, the US DOE standard, and China's energy efficiency label). Passing the test and obtaining certification is a prerequisite for the legal sale of a product.

● Avoiding Risks: Non-compliant products might be banned for selling, even fines and lawsuits. Energy efficiency testing is an "insurance policy" to ensure compliance and mitigate legal and commercial risks.

2. Obtain Voluntary Certifications to Achieve Product Premium

● A Symbol of Quality and Performance: Stringent voluntary certifications such as 80 PLUS (desktop/server power supplies), Energy Star, and CoC have become added value for high-performance, high-quality power supplies. These labels significantly enhance product value and brand image, enabling premium sales.

3. Create a Tag as Environmental Friendly

● Responding to ESG and Carbon Neutrality: Enterprise-level procurement (such as data centers and cloud service providers) and consumers are increasingly concerned about the environmental impact of products. Excellent energy efficiency performance is the most direct proof of a environmental friendly, effectively responding to the ESG needs of customers and investors.

● Proof of Energy Consumption: For commercial and industrial customers (such as factories and base stations), electricity costs are a major long-term operating cost. An accurate energy efficiency test report can clearly calculate the energy savings over the product's entire lifecycle, a decisive weapon to defeat high-energy-consuming competitors.

II. Technological and Engineering Advantages: The Driving Engine of Product Excellence

1. Precise Design Optimization: From "Usable" to "Excellent"

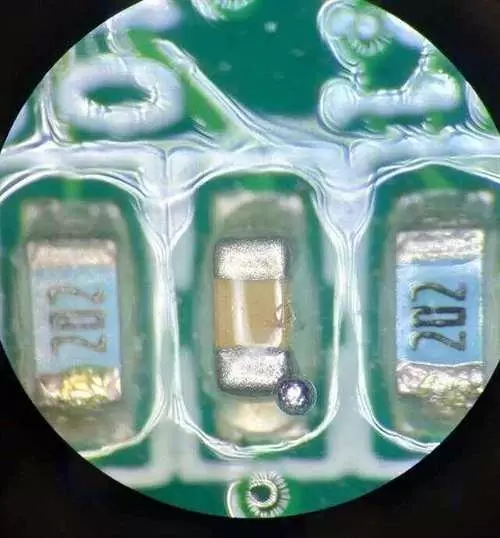

● Locating the Root Cause of Losses: Energy efficiency testing is not just about measuring percentages, but also an analysis of loss. By measuring efficiency at different loads, combined with technologies such as thermal imaging, engineers can precisely pinpoint whether losses originate from switching losses, conduction losses, core losses, or drive losses.

● Guidance for Component Selection: Based on test data, MOSFETs with lower Rds(on), inductors with lower DCR, and capacitors with lower ESR can be scientifically selected, achieving the optimal balance between performance and cost.

● Verifying Thermal Design: High efficiency means less heat loss. Energy efficiency test data is a direct basis for verifying the rationality of the heat dissipation scheme, ensuring that the product can still operate stably in high-temperature environments.

2. Improving System Reliability and Reducing Long-Term Failure Rate

● Heat is the number one factor which affect the lifespan of electronic products: Higher efficiency directly means lower temperature rise. For every 10°C reduction in the operating temperature of components (such as electrolytic capacitors and power semiconductors), their expected lifespan can be doubled. Therefore, high efficiency directly translates to higher system reliability, lower return rates, and longer warranty confidence.

● Optimized EMI Design: High-efficiency power supply topologies and optimized switching waveforms typically also mean lower noise and easier EMI testing, reducing subsequent remediation costs.

III. Cost and Operational Advantages: Benefits Throughout the Lifespan

Reduce Lifecycle Costs

● For Users: Significantly reduce electricity expenses, the most direct long-term economic benefit.

● For Manufacturers: Through optimized design, sometimes it's possible to reduce heatsink size, use smaller magnetic components, and simplify thermal management without sacrificing or even improving performance, thereby reducing overall material costs.

● For Carriers: For example, in data centers, high-efficiency power supplies can significantly reduce electricity expenses and air conditioning cooling load, directly improving PUE (Power Usage Effectiveness). The operating cost savings far exceed the initial power supply costa.

The advantage of power supply efficiency testing is a complete value loop from compliance to advance, from cost to benefit, from design to market. It's not a passive cost expenditure, but a proactive strategic investment that drives comprehensive upgrades in product performance, reliability, market acceptance, and environmental responsibility.

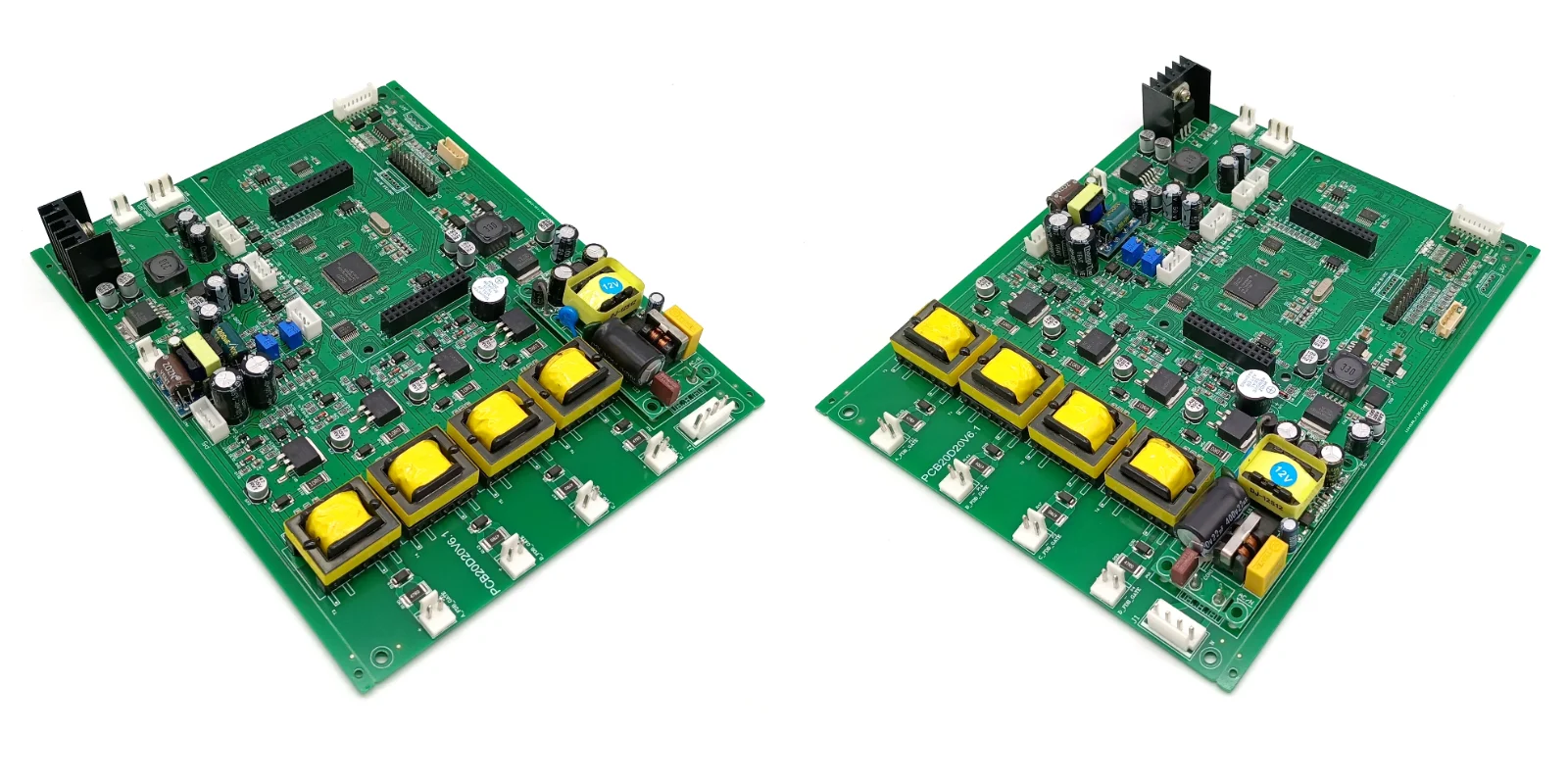

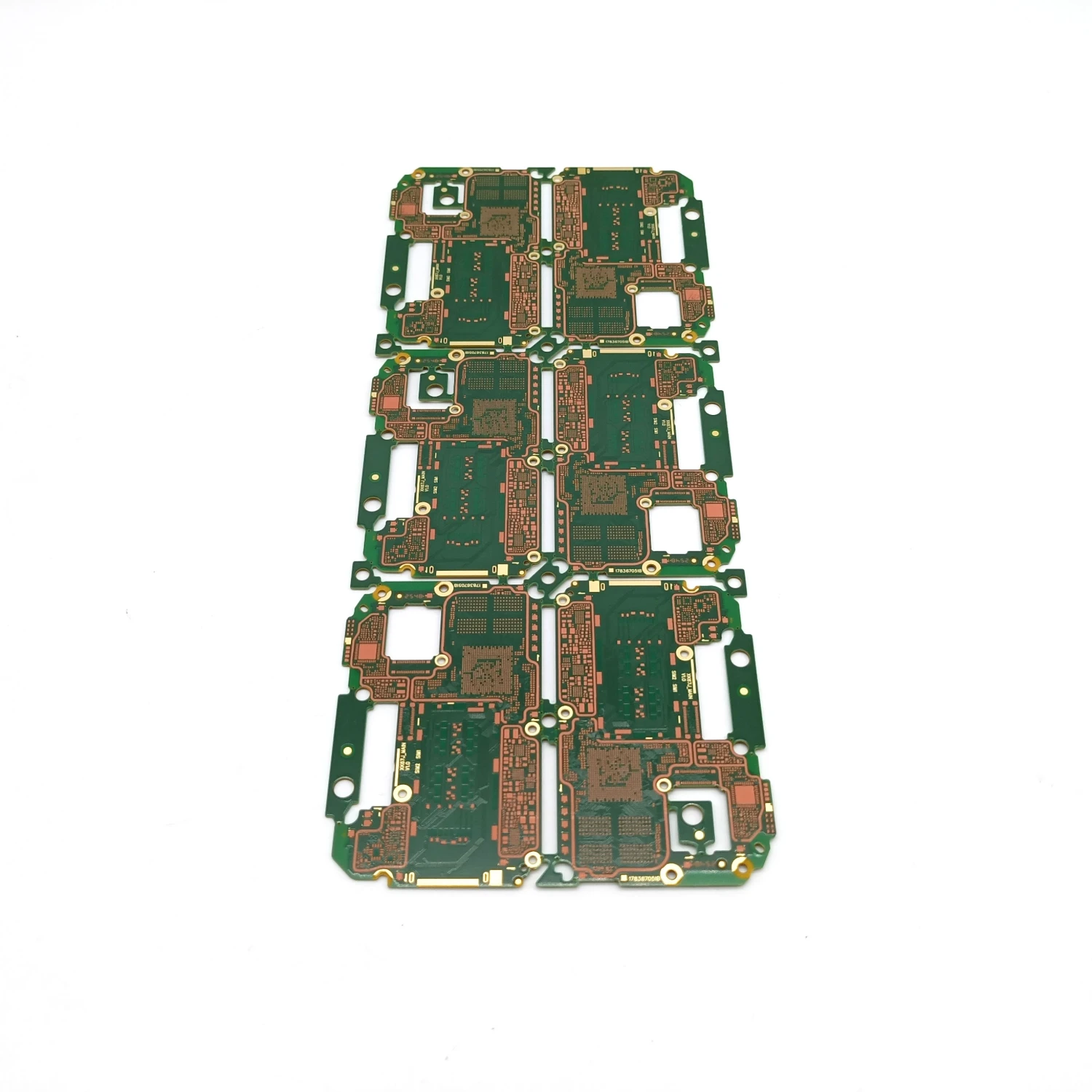

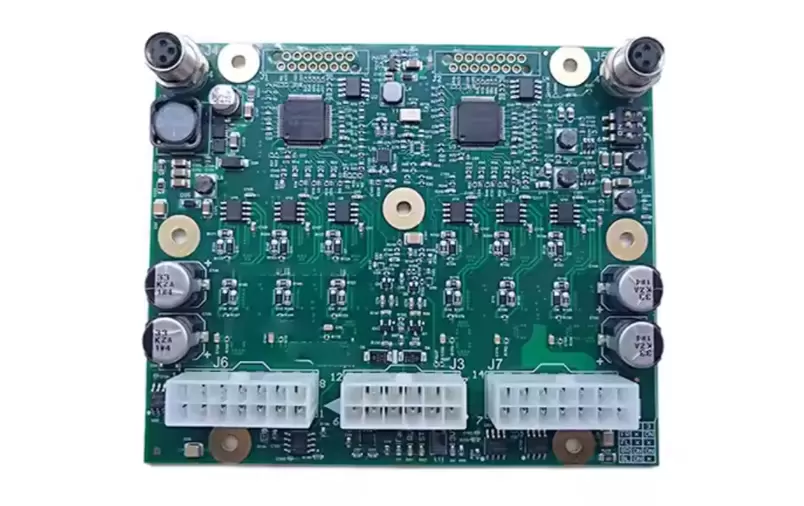

Benlida has been manufacturing PCBs and PCBAs for 14 years, committed to provide top-class PCB&PCB assembly services to global markets. We also actively develop our engineering capabilities to provide support&consult to our clients in the electronics industry. If you need PCBs and PCBAs, please feel free to contact Benlida!

About the auther:

Sonic Yang

As a major of Electronics and Mechanical Automation, Sonic has been engaged in PCB design, R&D, manufacturing of eletronics for around 22 years, as engineering director and coordinates with supply chain(components&CNC parts), providing professional supports and consults for global customers.

en

en

WhatsApp

WhatsApp