The Mindset of Quality Management in PCBA Factory: Zero Defect

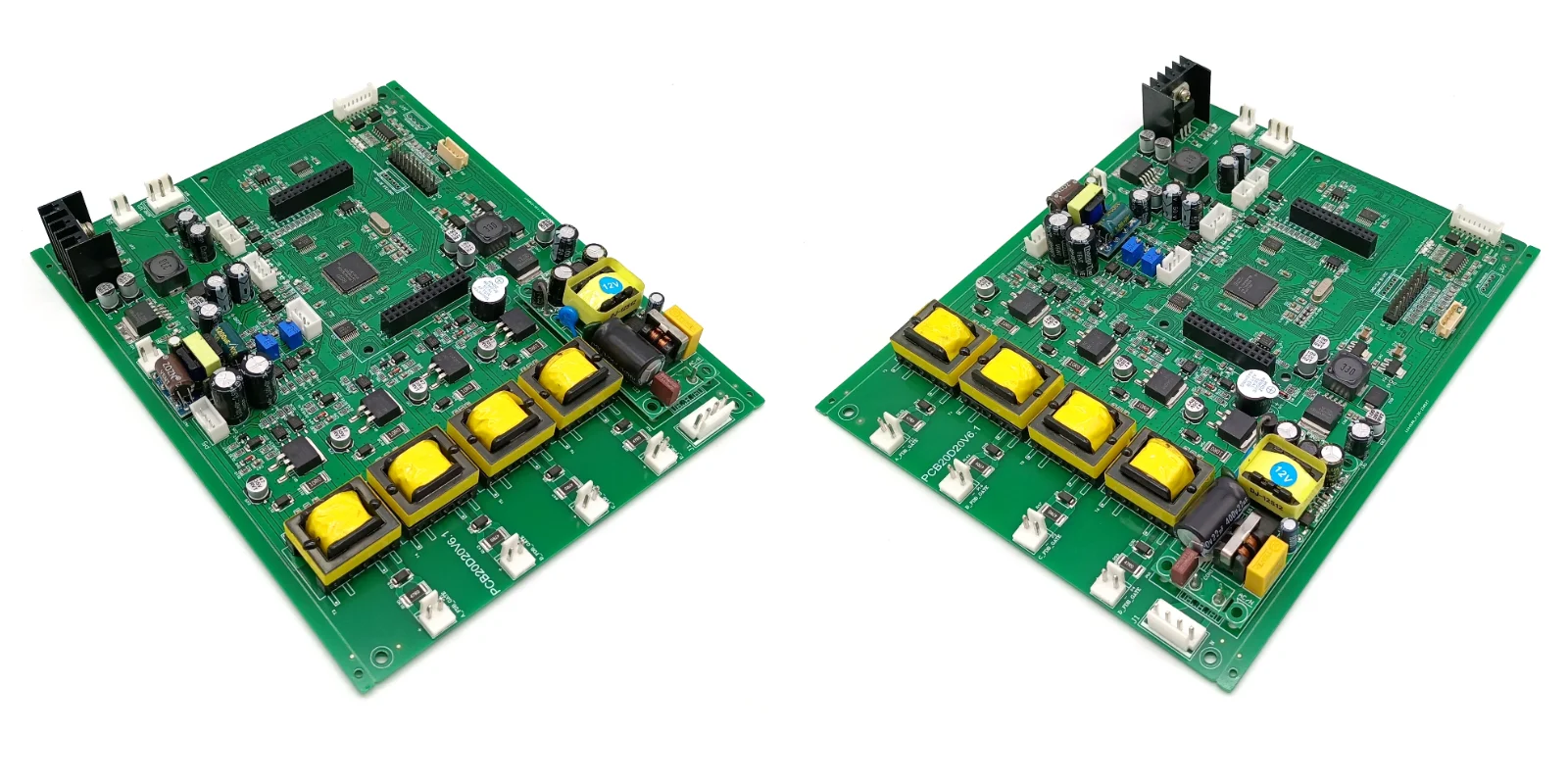

Quality management in PCBA factory is a systematic quality assurance that going through the entire manufacturing process. The fundamental purpose is to ensure that every PCBA is assembled correctly, works correctly, and reliably in the long term, through multi-level and multi-dimensional inspection and verification, ultimately deliver "zero-defect" PCBA to the customers.

The core concept of quality management in PCBA factory can be summarized in the following four directions:

Direction 1: Defects Interception and Screening(Immedicate Feedback)

This is the most direct and core objective of quality management.

1. Intercepting Defects: Through quality inspection methods such as 3D SPI, AOI, online testing, and flying probe testing, identify the quality defects during the manufacturing process in real time, such as open circuits, short circuits, cold solder joints, false solder joints, incorrect components, missing components, and reversed polarity errors.

2. Preventing Defective PCBA to Customers: Before final packaging and shipment, functional testing could simulate the actual working state of the PCBA and ensure that every PCBA could work well before leaving the factory, avoid to deliver the defective PCBA to customers.

Direction 2: Performance Verification and Validation(Customer Oriented)

Ensuring the functions of PCBA are normal and reliable.

1. Verifying Design Purposes: Through functional testing and more in-depth system testing, verify that the PCBA's hardware, software, and overall performance meet the design requirements (e.g., power consumption, signal integrity, communication speed).

2. Ensuring Consistency and Compatibility: In mass production, ensure that the performance fluctuations of each PCBA are within acceptable ranges and that it can collaborate with other parts in the overall system, stably and compatiblely.

Direction 3: Reliability Assessment and Risk Prevention (Long-Term)

This is crucial for ensuring viability of electronics and reputation, covering the electronic product's lifecycle for several years or even more than a decade.

1. Reveal Potential Defects: Through environmental stress screening, aging tests, and other methods, apply stresses such as temperature and humidity cycling, vibration, and high-temperature power-on to accelerate the exposure of defects that might be hidden in normal-temperature, testing and cause early failures (e.g., cold solder joints, component parameter drift, material defects).

2. Product Lifespan and Durability Assessment: Accelerated age testing is conducted for critical applications, such as automotive, medical, military, and even aerospace, to assess durability in harsh environments, summarize regulation from data for lifespan prediction.

Direction 4: Process Feedback and Ongoing Improvement (System)

Test data is the most important reference for improvement in the production process.

1. Monitor the Real-time Process: Test data from AOI and ICT can be fed back to the SMT line in real time. For example, if the solder joint defect rate of a component suddenly spikes, an immediate alert have to be issued, to check the solder paste printer and SMT machines, review the cause of the defects and solve issues immediately.

2. Close Loop of Process&Quality: By analyzing defects which found in testing, the root causes can be traced back to design, materials, and manufacturing processes, urge design optimization, supplier management, and process adjustments, ongoing improvement and quality feedback loop, improve quality of PCBA and effeciency, then reducing overall costs ultimately.

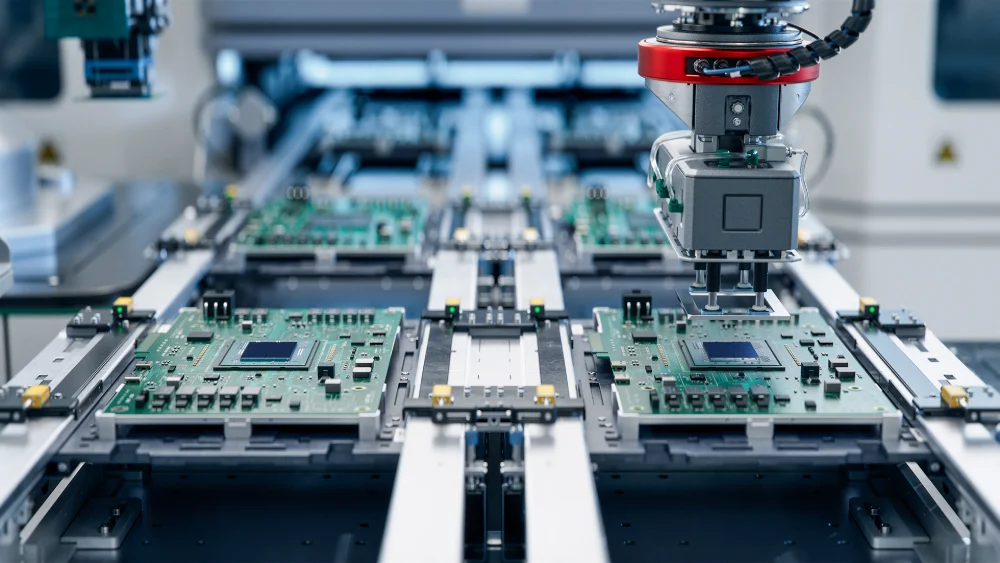

The quality management system in PCBA factory is a multi-leveled safety inspection:

1. Optical inspection methods such as 3D SPI and AOI, could screen out physically , visible defects quickly.

2. ICT and FCT testing confirm physical performance.

3. Aging and environmental testing simulates safe and reliable operation under harsh environmental pressures.

4. Data analysis throughout the entire process summarizes patterns, continuously improves, and can be extended to quality management in other projects.

The core purpose of quality management is to identify and resolve defects during the manufacturing process, optimize and improve quality, confirm performance and stability, prevent deliver defective PCBA to customers, and avoid longer-term potential risks such as after-sales losses, reputation damage and safety risks.

Benlida has been manufacturing PCB and PCBA for 14 years, we deeply understand the value of quality management system in factory and for our customers&team: responsible for each PCBA, customers and ourselves. We strictly follow quality management principles, processes and keep training team members, also we collaborate with customers to develop and optimize testing solutions, improve process capabilities. "Benlida is dedicated to a zero-defect, top-class, professional PCB & PCBA manufacturer!"

en

en

WhatsApp

WhatsApp