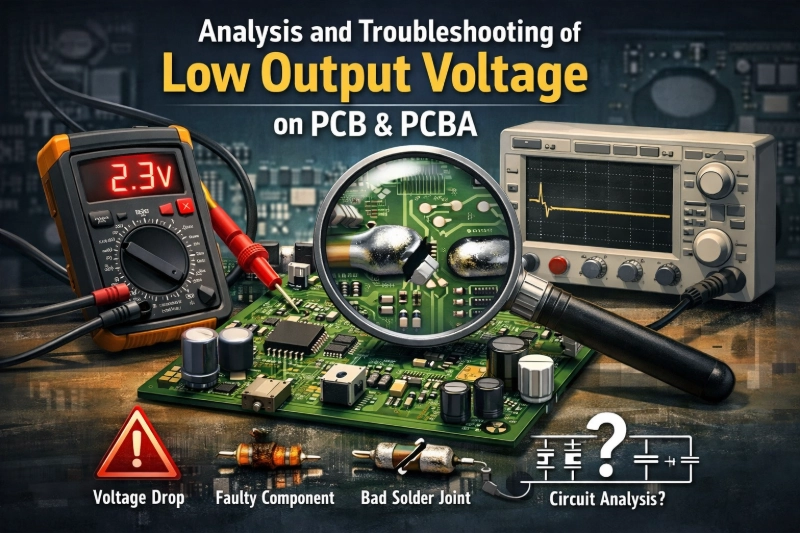

Fault Analysis on Three-Proofing Lacquer Failure of Printed Circuit Board

Abstract

In response to a ground power-off fault in the AC power supply system of a certain type of aircraft, the macroscopic morphology of the printed circuit boards inside the AC generator controller was examined. SEM and EDS analyses, as well as ion chromatography tests, were carried out to determine the fault location and cause. Through principle review and fault simulation, a latent failure caused by three-proofing lacquer degradation was resolved. This fault analysis provides reference and guidance for the maintenance personnel of airborne products.

Keywords:AC power supply system;printed circuit board;three-proofing lacquer

1 Fault Description

During a ground engine run-up inspection of a certain type of aircraft, cockpit personnel reported “main AC generator power-off, one-up-three-down display loss.” The commander then instructed the engine shutdown and organized troubleshooting. After inquiry, it was learned that the aircraft had just completed a flight mission and no abnormalities were detected during the flight. When the fault occurred, the “main AC” warning light in the cockpit flashed. Video playback showed the loss of the “one-up-three-down” display. Flight data analysis revealed the presence of a “main AC power supply subsystem fault” signal. The initial judgment was that the fault was caused by a power-off event in the main AC power supply system.

The main AC power supply system provides 115 V / 400 Hz three-phase AC power to the aircraft and supplies 28 V DC through transformer rectifiers. It is the most important power source of the aircraft. In the subsequent troubleshooting process, after multiple ground power-on checks and engine run-up inspections, the main AC power-off fault did not reappear. No problems or suspicious points were found after inspecting the relevant wiring. To thoroughly determine the cause, maintenance personnel performed off-aircraft deep inspection of components related to this power-off event, including the main AC generator, current transformer, AC generator controller, and contactors. The inspection mainly included: visual (disassembly) inspection, room-temperature performance tests, insulation tests, high-low temperature cycling tests, vibration tests, etc.

2 Fault Localization

Inspection revealed that the AC generator controller reported abnormal fault codes during high-low temperature cycling tests, while no abnormalities were found in other components. Therefore, it was initially determined that the fault was located in the AC generator controller. This controller uses a microprocessor as its core. Except for the voltage regulator and internal power supply, the remaining circuits are all digital. The product contains eight printed circuit boards internally. Among them, AP6 is the bus board, and AP1, AP2, AP3, AP4, AP5, and AP7 perform functions such as voltage regulation, signal conversion and BIT (Built-in Test), internal power supply, signal input and conversion, input and control, CPU control, and signal transmission. The BIT technology used can isolate faults down to the SRU (Shop Replaceable Unit) level, significantly improving maintainability and reliability.

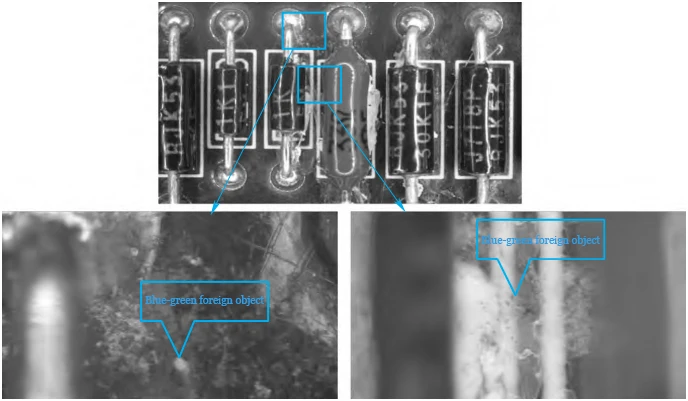

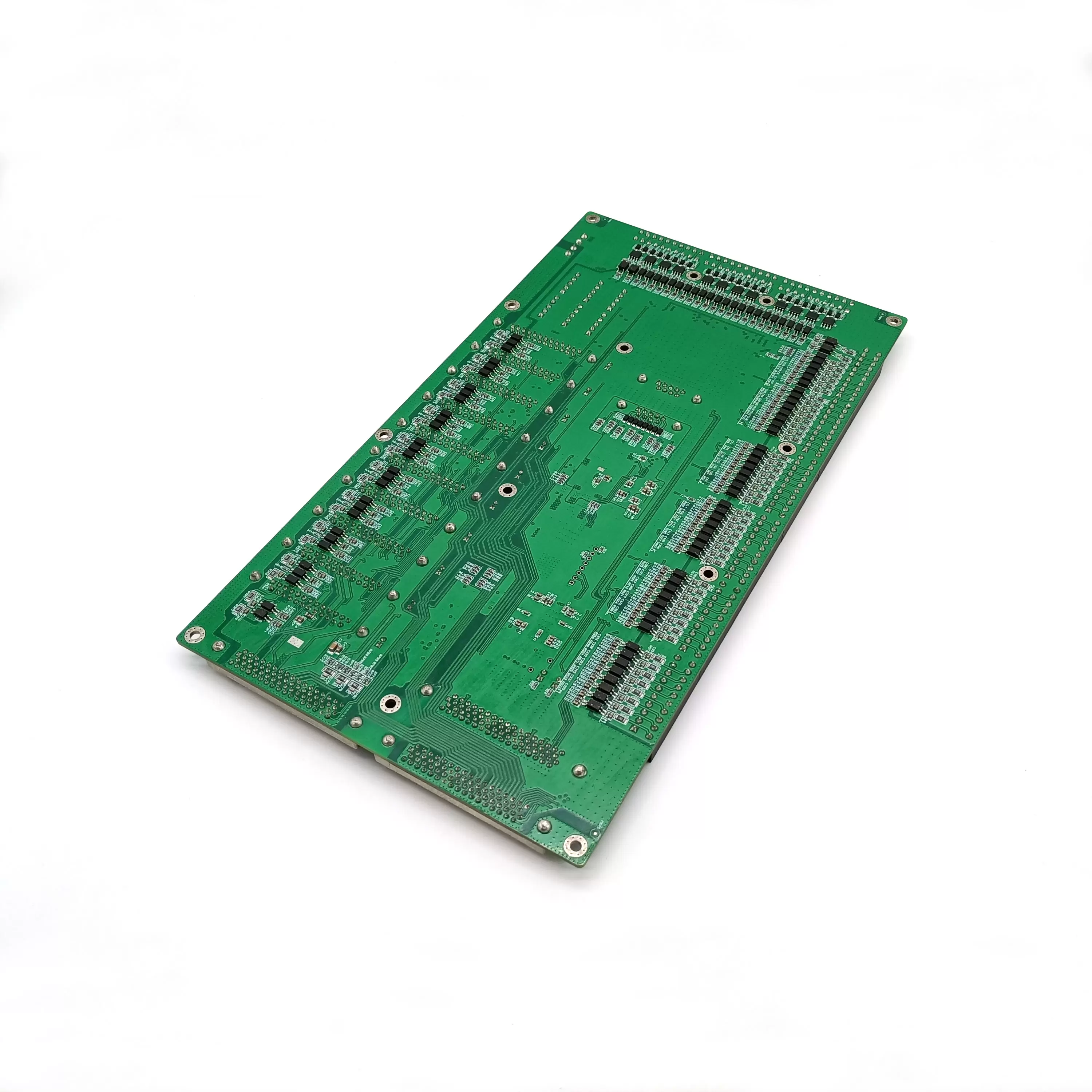

After preliminarily determining the fault location, AP1–AP7 circuit boards were replaced one by one, and maintenance BIT and power-generation tests were performed under –55 °C to 70 °C temperature-cycling conditions. After multiple rounds of testing, the AP2 printed circuit board (see Figure 1) was found abnormal. Failure analysis was then carried out on the AP2 board assembly.

Figure 1 Front and Back Appearance Photos of AP2 Printed Circuit Board (Blue indicates the R228–R241 area)

3 Visual Inspection

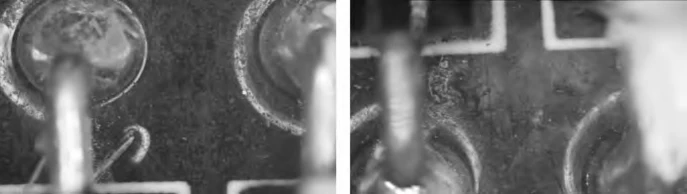

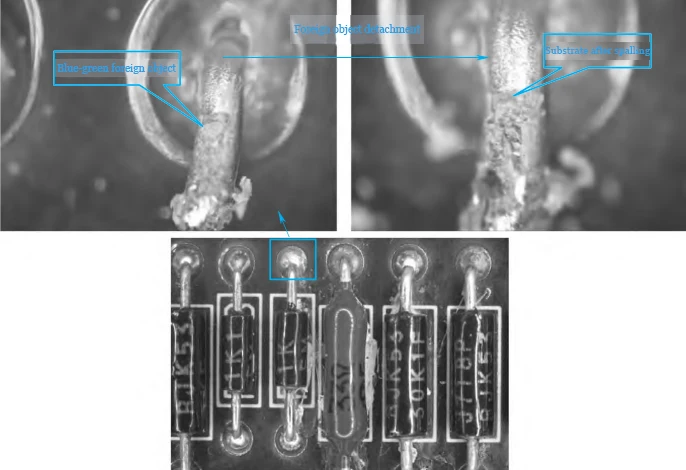

Visual examination of the AP2 printed circuit board and electronic components revealed that the board’s appearance was generally intact, with no burnt, broken, or darkened traces. The electronic components appeared normal, with no discoloration, burn marks, looseness, or solder detachment. Using a 10× magnifying glass, small blue granular foreign matter was found on the leads of resistors R228 and R241. Further inspection with a stereo microscope revealed several obvious blue-green foreign particles around the two leads and nearby board surface, with diameters of approximately 0.1–0.8 mm. No similar foreign matter was found elsewhere on the board (as shown in Figures 2 and 3). After removing the blue-green foreign matter from one of the leads, the exposed metal substrate of the lead was visible, as shown in Figure 4.

Figure 2 Visual Inspection (R228–R241 Area)

Figure 3 Visual Inspection (Other Areas)

Figure 4 Visual Inspection (After Removal of Blue-Green Foreign Matter)

4 SEM & EDS Analysis

SEM and EDS analyses were performed on the blue-green foreign matter in the R228–R241 area. The results showed that the foreign matter mainly contained copper (Cu), chlorine (Cl), tin (Sn), and lead (Pb), as well as small amounts of carbon (C) and oxygen (O). Among these, copper (Cu) and chlorine (Cl) accounted for a relatively high proportion. The SEM & EDS results of the blue-green matter are shown in Figure 5.

Figure 5 Blue-Green Foreign Object SEM & EDS Results

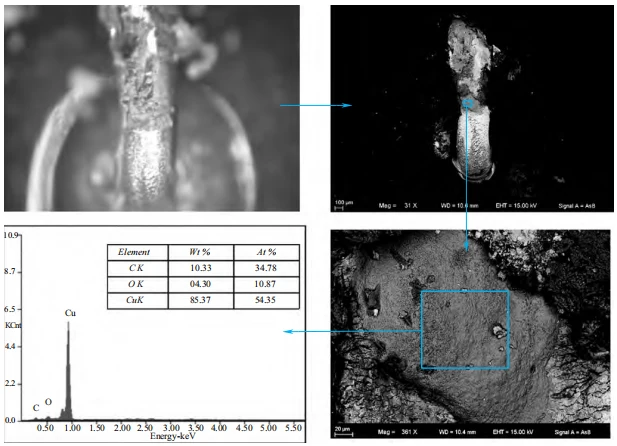

SEM & EDS analysis of the lead surface after removal of the blue-green foreign matter revealed that the metal substrate mainly contained copper (Cu), with small amounts of carbon (C) and oxygen (O). The SEM & EDS results of the exposed lead surface are shown in Figure 6.

Figure 6 SEM & EDS Results of Pin Surface After Removal of Blue-Green Foreign Particle

5 Ion Chromatography Analysis

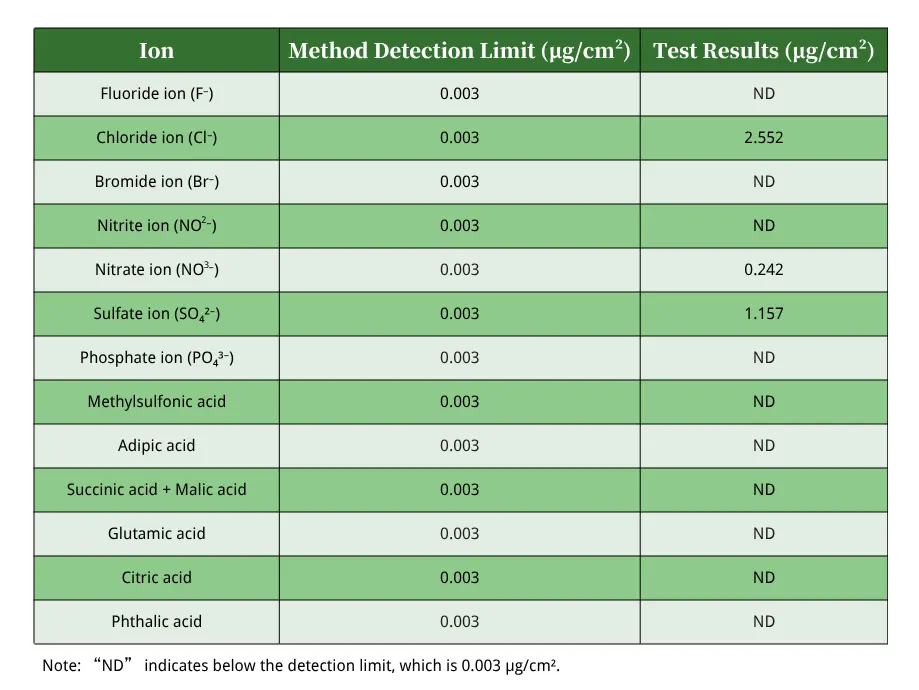

Ion chromatography tests were conducted on the surface of the R228–R241 area. Abnormally high concentrations of chloride ions (Cl⁻), nitrate ions (NO₃⁻), and sulfate ions (SO₄²⁻) were detected. Detailed results are shown in Table 1, and the ion chromatogram is shown in Figure 7.

Table 1 Ion Chromatography Test Results

Figure 7 Ion Chromatogram

6 Result Analysis

Visual inspection of the AP2 printed circuit board revealed visible blue-green foreign matter in the R228–R241 area, while no similar material was found elsewhere. SEM & EDS analysis detected copper (Cu), chlorine (Cl), tin (Sn), and lead (Pb) in the blue-green material. After the material was removed, the exposed metal substrate mainly contained copper (Cu), indicating that the blue-green matter was primarily corrosion products containing copper. Ion chromatography of the R228–R241 area showed high concentrations of chloride (Cl⁻), nitrate (NO₃⁻), and sulfate (SO₄²⁻) ions, while no significant ion residue was detected elsewhere. This indicates that substantial corrosion products were generated in this region. Combined with the material characteristics of the components in the R228–R241 area and the detected elements and ions, it can be inferred that the blue-green foreign matter was mainly corrosion products formed from resistor leads and solder under specific conditions.

7 Fault Reproduction

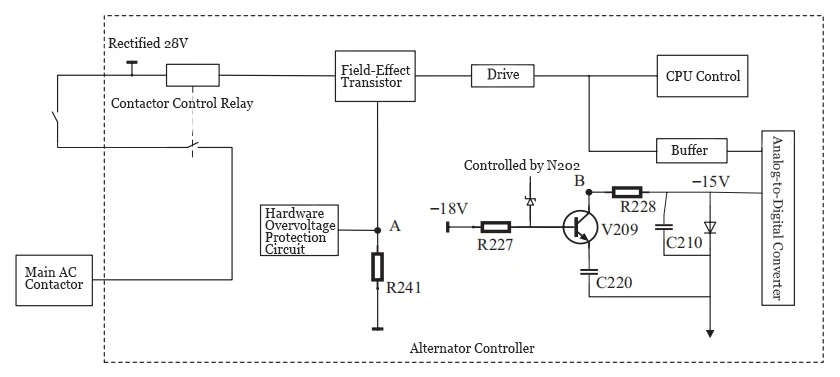

The AC generator controller, together with the main AC generator, current transformer, and contactor, forms the aircraft's main AC power supply system. The controller regulates generator voltage and monitors the operating status of the power-generation system in real time. When abnormalities occur, the controller performs necessary control and protection actions, isolates the fault, and transmits fault information to the aircraft’s electromechanical control system. Pilots and maintenance personnel can view the status of the main AC system through this control system. Its working principle is illustrated in Figure 8.

Figure 8 Schematic Diagram of Alternator Controller Operation

Analysis of the schematic shows that points A and B correspond to two adjacent leads of resistors R228 and R241. Under normal conditions, point A is approximately +5 V and point B is approximately –15 V. If corrosion causes insulation degradation between A and B, and moisture creates a conductive path, the voltage at point A will drop and the voltage at point B will rise. A drop in point A voltage triggers the hardware overvoltage protection circuit, which outputs a control signal to disconnect the main contactor, causing the main AC generator to power off—consistent with the observed ground test failure. When condensation conditions change and the conductive path disappears, the voltage returns to normal and the fault disappears.

To verify this analysis, water droplets (simulating moisture condensation) were applied to the R228–R241 region during a BIT test of the AC generator controller. The BIT then reported the same fault code as during the high-low temperature cycling test. Further, when the faulty unit was installed on the main AC system test bench and water was applied to the same area, the bench indicated “disconnect main contactor control signal,” interrupting the power-generation test—consistent with the actual ground test failure.

8 Conclusion and Recommendations

The AC generator controller is installed in the right forward equipment bay of the aircraft. The side covers of the product housing contain many ventilation openings. Combined with its non-sealed structural design, these conditions promote corrosion. When aircraft temperature changes abruptly, moisture condenses on internal circuit boards and component surfaces. If defects exist in the protective coating (three-proofing lacquer) on the printed circuit board, component leads gradually corrode. Corrosion products and moisture form conductive paths, triggering the overvoltage protection circuit and causing unintended shutdown of the main AC generator.

Failure of the three-proofing lacquer applied to the printed circuit board is the main cause of this fault. Three-proofing lacquer is a special coating designed to protect circuit boards and related equipment from environmental damage. It has good resistance to high and low temperatures and forms a protective film after curing, providing excellent insulation, moisture resistance, leakage protection, dust resistance, corrosion resistance, and aging resistance. Because this type of fault is highly concealed, maintenance personnel should strengthen inspection of the three-proofing coating during maintenance of airborne products. A magnifying glass can be used to check for edge lifting, local blistering, peeling, cracking, pinholes, or uncoated areas. If defects are found, repair or re-coating should be performed to ensure complete coverage of defective areas.

en

en

WhatsApp

WhatsApp