Why do capacitors buldge and is it enough to replace them on circuit board/PCBA?

When a capacitor bulges and the equipment stops to work, usually, replacing it by a new capacitor with the same specifications, that could solve the issue and get the equipment back to work. However, it might just solve the issue temporarily but not permanently: a bulging capacitor is not just a cause, but more like a symptom, indicating there are other issues on the circuit board.

If only replace the bulging capacitor while ignoring the root cause, the new capacitor might bulge again soon, or even cause more serious malfunctions and explosion.

Why can't simply replace and be done with it? — Let's dive deeper to the Root Cause

A bulging capacitor is usually a symptom of other issues. Here are detailed explanations for various causes:

1. Systemic Issues (Most Common, and Most Dangerous)

● Poor Heat Dissipation, Overheating

Causes: Ventilation blocks, cooling fans failed, buldging capacitors are near high-power&heat-generating components (such as CPUs, LGBT, etc). The lifespan of capacitor follows the "10-degree rule": when the temperature increase every 10°C, the lifespan will be decrease in half.

Observation: measure the temperature around the bulging capacitor, to see is it abnormally hot. Also if the inner space of the equipment is dusty, it indicates the internal heat dissipation is poor.

Conclusion: If the airflow is not cleaned and the fan is not replaced, which means the ventilation isn't doing well, the new capacitor will fail again soon in such environment.

● Unstable or Excessive Voltage

Causes: Power management circuit (such as a PWM chip) fails, voltage regulator circuit fails, or surge voltage from the grid, those causes could cause the voltage exceed than the rated standards which should be applied on the capacitor.

Observation: measure the voltage and ripple voltage across the capacitor, are they normal or not.

Conclusion: The new capacitor will be quickly damaged due to overvoltage, and may even explode.

● Excessive Ripple Current

Causes: Power load changes dramatically (such as motor starts and stops frequently) which requires the power supply to provide large instantaneous current, resulting in a large ripple current. This current flows through the capacitor, force it to heat up internally (heating power P = Iripple² × ESR).

Observation: Requires professional equipment (such as an oscilloscope with a current probe) to measure the ripple current.

Conclusion: The capacitor will bulge due to internal overheating, even if the ambient temperature is not high.

2. Capacitor quality and local issues

● Poor capacitor quality or at the end of its lifespan: the capacitor is inferior, refurbished, or even short lifespan. Or a high-quality capacitor has been working for many years and aged.

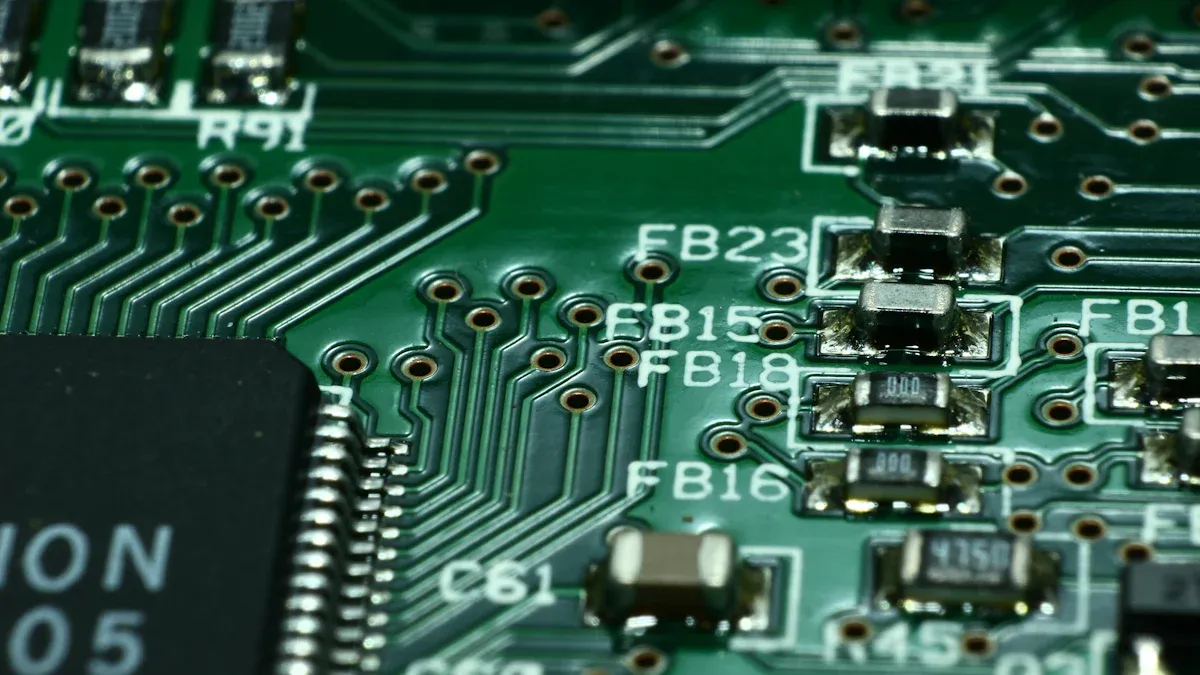

● Poor heat dissipation: The capacitor is near to overheating components, or location is not good for heat dissipation.

Replacing Procedure:

1. Safety first: Power off the equipment immediately and discharge the capacitor, (by shorting the leads with a resistor) to prevent electric shock.

2. Observation and recording: Record the specifications of the bulging capacitor (capacitance e.g., 1000μF, voltage rating e.g., 25V). Observe the PCB and see are there other components burnt, poor soldering, or burn marks on the PCB.

3. Figuring the root causes: Based on the number and location of the bulging capacitors, assess are the problems from other parts or just capacitors themselves.

4. Replace the capacitor:

● Choose the replacement: A capacitor with the same or higher value. A higher voltage rating is preferable to a lower one (e.g., use 35V instead of 25V), and the capacitance should be same. It is best to choose capacitors with low ESR (Equivalent Series Resistance), high temperature resistance (e.g., 105℃), and long lifespan.

● Mind the polarity: Electrolytic capacitors have positive/anode and negative/cathode, be careful about them and solder it correctly.

5. Find the root cause: If the issue was caused by heat dissipation or high voltage, these issues must be resolved at first (clean dust, inspect the fan, check the power supply circuit) before replacing the capacitor.

6. Power-on testing and monitoring: After replacement, monitor the equipment's working status. If it is possible, use a professional device to monitor the temperature of the new capacitor.

When encountering such situations where capacitors burn out repeatedly or the root cause cannot be figured out, may you can consider the following solutions:

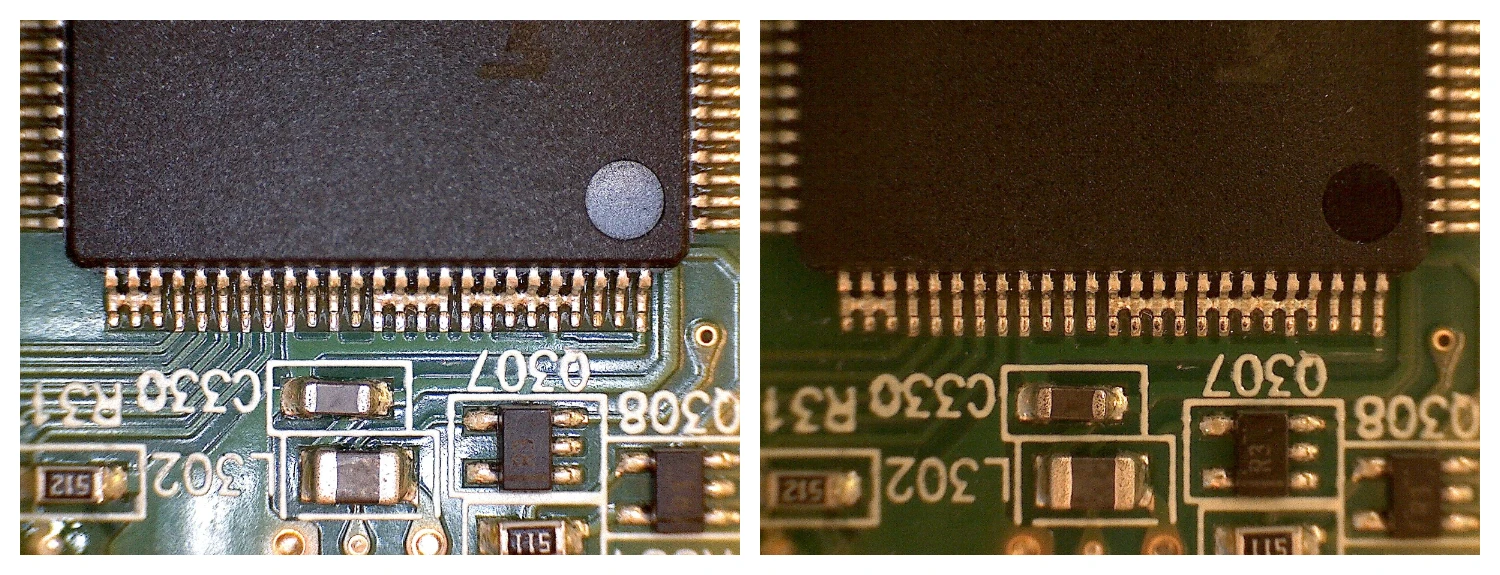

1. Capacitor Failure Analysis (FA): Perform professional dissection and analysis of the bulging capacitor, observing its internal condition by microscope for further assessment: it is overheating, overvoltage, or a quality issue, figuring the root cause of the failure accurately.

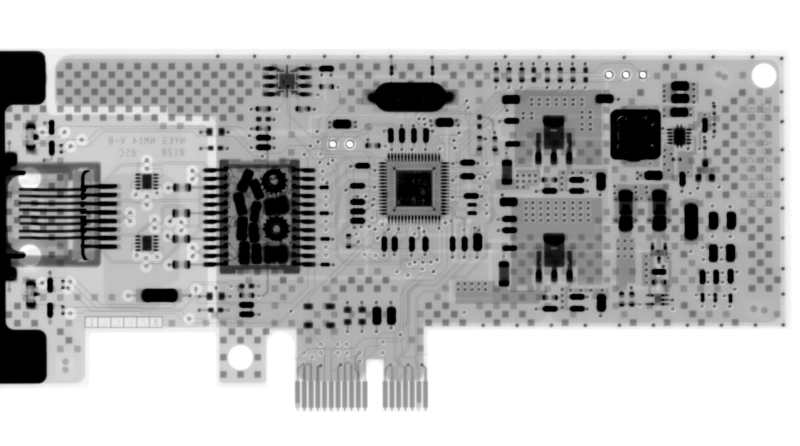

2. Circuit System Diagnosis: Use devices such as oscilloscopes and thermal imagers to measure the voltage and ripple current, at the capacitor's working peak and scan the temperature distribution of the circuit board, to diagnose accurately: is it the heat dissipation, power supply, or load.

3. Component Reliability Test: Seek support from professional team, to inspect the capacitors and verify the capacitance, withstand voltage, ESR, and other parameters, identify is it genuine and eliminate potential risks at the source.

4. Providing Rectification Solutions: Based on the statistic data, seek professional rectification suggestions, such as capacitor selection, circuit improvement, and enhanced heat dissipation solutions.

Benlida has been manufacturing PCB and PCBA for 14 years, with experience in production and professional engineer team, nowadays Benlida has built robust relationships with customers and also provides engineering services for electronics.

If you meet issues relating to electronics, maybe Benlida could help!

en

en

WhatsApp

WhatsApp