Medical Blood Pressure Monitor PCB Assembly

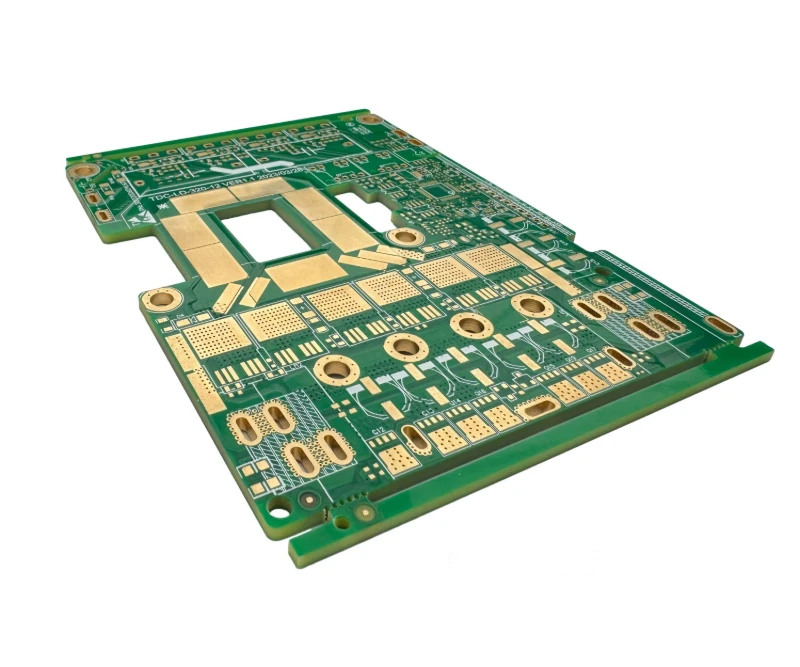

Case Study: New Energy Charger PCB Assembly — Powering Efficient, Safe EV Charging Infrastructure

In the rapidly expanding new energy sector, reliable charging infrastructure is the backbone of electric vehicle (EV) adoption. A leading manufacturer of EV charging solutions approached us to address critical challenges in assembling PCBs for their next-gen 60kW DC fast chargers. The project demanded a balance of high-power handling, thermal resilience, and strict safety compliance—key pillars of new energy charger performance.

Project Background & Client Requirements

The client’s 60kW DC charger targets commercial and public charging stations, requiring PCBs that could:

· Handle high currents (up to 150A) and voltages (800V DC) without degradation.

· Operate in harsh outdoor environments (-30°C to 60°C) with resistance to humidity, dust, and corrosion.

· Support fast charging protocols (CCS, CHAdeMO) with stable communication between the charger and EV.

· Meet stringent safety standards (UL 60950, IEC 61851) to prevent overheating, short circuits, or electric shock.

· Scale from prototype (50 units) to mass production (5,000 units/month) with consistent quality (PPM ≤20).

Key Challenges in New Energy Charger PCB Assembly

The project posed unique hurdles tied to the high-power, high-voltage nature of EV charging:

1. Thermal Management Under Load: Power conversion components (IGBTs, rectifiers) generate extreme heat during fast charging, risking solder joint fatigue or component failure.

2. High-Voltage Insulation: PCB traces and components must withstand 800V DC with strict creepage (≥8mm) and clearance (≥6mm) distances to prevent arcing.

3. Signal Integrity in Noisy Environments: Communication modules (e.g., CAN, Ethernet) are vulnerable to electromagnetic interference (EMI) from high-power circuits, threatening charging protocol reliability.

4. Material Durability: Outdoor deployment requires PCBs resistant to UV radiation, moisture, and chemical exposure (e.g., road salts).

Our Tailored Assembly Solutions

To overcome these challenges, we designed a holistic assembly strategy focusing on power handling, thermal resilience, and safety compliance:

1. PCB Design & Material Engineering

· Substrate Selection: Used 4-layer PCBs with high-Tg (180°C) FR-4 material and 2oz copper cladding to enhance current-carrying capacity and heat dissipation.

· Thermal Path Optimization: Integrated thermal vias (diameter 0.3mm) beneath power components to transfer heat from the PCB to an external heatsink, reducing operating temperatures by 25°C under full load.

· High-Voltage Layout: Segregated high-voltage (power stage) and low-voltage (control/communication) zones with grounded isolation barriers, ensuring creepage/clearance compliance.

2. Precision Assembly for High-Power Components

SMT for Control & Communication Circuits:

· Deployed DEK NeoHorizon printers with laser-aligned stencils to apply solder paste accurately on fine-pitch components (e.g., 0.5mm BGA for the main controller).

· Used Fuji NXT III pick-and-place machines (accuracy ±15μm) to place SMD components, including temperature sensors and communication ICs, with minimal positional error.

Power Component Assembly:

· Employed selective wave soldering for through-hole power connectors (rated 200A), ensuring robust joints capable of handling high current.

· For IGBT modules (critical to power conversion), used eutectic solder (Sn95Pb5) with a controlled reflow profile (peak 230°C) to achieve void-free bonds (<3% void rate) and maximize thermal conductivity.

3. Rigorous Testing & Compliance Validation

Electrical Safety Testing:

· Hipot testing at 3kV AC for 1 minute to verify insulation integrity between high- and low-voltage zones.

· Ground continuity tests (<0.1Ω resistance) to ensure safe fault current dissipation.

Performance & Reliability Validation:

· Power cycling tests (1,000 cycles from 10% to 100% load) to simulate real-world charging patterns, monitoring for voltage drop or temperature spikes.

· Environmental chamber testing: 500 hours at 95% humidity (40°C) to validate resistance to moisture, followed by thermal shock tests (-30°C to 60°C, 100 cycles).

Protocol Compliance:

· Verified communication stability via signal integrity testing (eye diagram analysis for CAN bus signals) to ensure error-free interaction with EVs.

Project Outcomes & Client Impact

· Performance Metrics: The assembled PCBs enabled the charger to deliver 60kW power with 96.5% efficiency, maintaining stable operation even at 60°C ambient temperature.

· Safety Compliance: Passed UL 60950 and IEC 61851 certifications on the first attempt, accelerating the client’s market launch by 8 weeks.

· Scalability: Streamlined processes allowed us to ramp up production from 50 prototypes to 5,000 units/month within 6 weeks, with a consistent yield of 99.1%.

· Cost Efficiency: Optimized material selection (e.g., high-performance yet cost-effective FR-4) and automated testing reduced per-unit assembly costs by 12%.

Why Partner With Us for New Energy Charger PCBs?

New energy charger PCBs demand expertise in high-power handling, thermal management, and safety compliance—areas where our 14-year track record in PCB assembly shines. We offer end-to-end support, from DFM analysis (to optimize for manufacturability) to mass production, ensuring your chargers are efficient, reliable, and ready for the demands of the EV revolution.

Reach out today to discuss your new energy charger PCB assembly needs.

Medical Blood Pressure Monitor PCB Assembly这个也要

Case Study: Medical Blood Pressure Monitor PCB Assembly — Precision Engineering for Life-Critical Health Devices

In the realm of medical devices, accuracy and reliability are non-negotiable—especially for tools like blood pressure monitors, which directly impact patient diagnosis and treatment. A leading medical equipment manufacturer partnered with us to address unique challenges in assembling PCBs for their next-generation digital blood pressure monitors, focusing on miniaturization, measurement precision, and regulatory compliance.

Project Background & Client Requirements

The client’s device is a portable upper-arm blood pressure monitor designed for both clinical and home use. Its PCB needed to:

· Support precise pressure sensing (±3mmHg accuracy) and signal processing to ensure reliable readings.

· Integrate compact components (sensors, microcontrollers, display drivers) within a 60mm×40mm form factor to fit the monitor’s ergonomic design.

· Operate on low power (3.7V lithium battery) for 1,000+ measurements to extend user convenience.

· Meet strict medical standards (ISO 13485, FDA 510(k)) for biocompatibility, electromagnetic compatibility (EMC), and long-term reliability.

· Scale from prototype (100 units) to mass production (10,000 units/quarter) with consistent quality (PPM ≤10).

Key Challenges in Medical Blood Pressure Monitor PCB Assembly

The project presented distinct hurdles tied to the device’s medical-grade requirements:

1. Signal Integrity for Sensitive Sensing: The pressure sensor (MEMS-based) produces microvolt-level signals, which are vulnerable to noise from nearby components (e.g., display backlights, motor drivers).

2. Miniaturization vs. Component Accessibility: Packing high-precision components (0201 passives, 0.4mm-pitch LGA microcontrollers) into a small PCB increased the risk of solder bridging and assembly errors.

3. Low-Power Design Constraints: Even minor inefficiencies in PCB layout or component soldering could drain the battery, reducing the device’s operational lifespan.

4. Regulatory Compliance: Strict documentation and traceability (from component sourcing to assembly) were required to meet medical device audit standards.

Our Tailored Assembly Solutions

To address these challenges, we developed a “precision-first” approach combining design optimization, advanced assembly techniques, and rigorous validation:

1. PCB Design & Material Optimization

· Low-Noise Layout: Separated analog (pressure sensor, signal amplifiers) and digital (MCU, display) circuits with grounded isolation tracks to minimize electromagnetic interference (EMI).

· High-Sensitivity Signal Paths: Used 4-layer PCBs with dedicated ground planes and controlled-impedance traces (50Ω) for sensor signals, reducing signal loss by 40% compared to 2-layer designs.

· Battery Efficiency: Selected high-Tg (150°C) FR-4 with thin copper (0.5oz) to reduce power consumption while maintaining structural rigidity, paired with gold plating on battery contacts for low resistance.

2. Precision Assembly for Miniaturized Components

SMT for Sensitive Electronics:

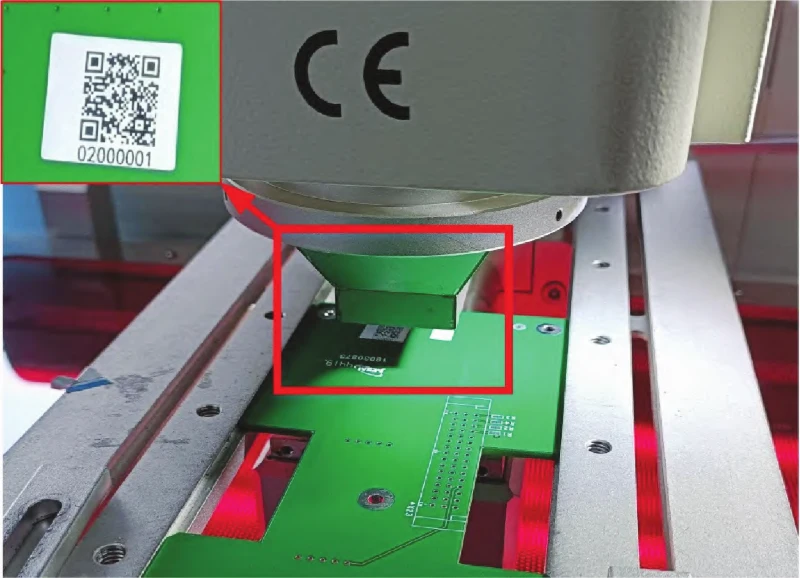

· Employed ASM EKRA X4 printers with 3D solder paste inspection (SPI) to apply precise paste volumes (±5%) on 0201 component pads and LGA pins, critical for preventing shorts.

· Used Yamaha YRM20 high-precision placement machines (accuracy ±3μm) with dual cameras to align the MEMS pressure sensor and LGA MCU, ensuring optimal signal transmission.

Specialized Soldering for Reliability:

· Applied a lead-free solder paste (Sn99Ag0.3Cu0.7) with a modified reflow profile (peak temperature 245°C) to avoid thermal damage to the heat-sensitive pressure sensor.

· Hand-soldered fine wires (30AWG) for the pressure cuff’s inflatable motor connection, using magnification tools to ensure consistent, strain-free joints.

3. Regulatory-Compliant Testing & Validation

Component Traceability: Maintained full documentation of component batches (including RoHS compliance certificates) and assembly processes, enabling end-to-end traceability per ISO 13485.

Electrical & Functional Testing:

· Performed in-circuit testing (ICT) to verify resistor, capacitor, and sensor values, ensuring no drift from specifications.

· Calibrated pressure sensing accuracy using a reference manometer, adjusting firmware via the PCB’s programming interface to achieve the ±3mmHg target.

EMC & Safety Validation:

· Conducted EMC testing (per IEC 60601-1-2) to ensure the PCB didn’t emit excessive radiation or malfunction due to external interference (e.g., from smartphones).

· Performed drop tests (1.2m onto concrete) and temperature cycling (-10°C to 50°C, 500 cycles) to validate mechanical and electrical resilience in real-world use.

Project Outcomes & Client Impact

· Performance Excellence: The PCBs enabled the monitor to achieve consistent ±2mmHg accuracy across 10,000+ test measurements, exceeding the client’s target.

· Regulatory Success: The device passed FDA 510(k) clearance and CE marking on the first submission, thanks to our compliant assembly processes and documentation.

· Production Efficiency: Scaled from prototypes to 10,000 units/quarter with a 99.5% yield, supported by automated testing that reduced inspection time by 40%.

· Battery Longevity: Optimized power consumption (15mA during measurement) extended the device’s battery life to 1,200+ measurements, enhancing user satisfaction.

Why Choose Us for Medical Device PCB Assembly?

Medical blood pressure monitors demand a unique blend of precision, miniaturization, and regulatory expertise—areas where our 14-year focus on medical PCB assembly excels. We understand the critical role these devices play in healthcare, and our processes are designed to deliver PCBs that meet the strictest standards for accuracy, reliability, and safety.

en

en

WhatsApp

WhatsApp