Advantages, Disadvantages and Applications of Ceramic Circuit Boards/Ceramic PCB

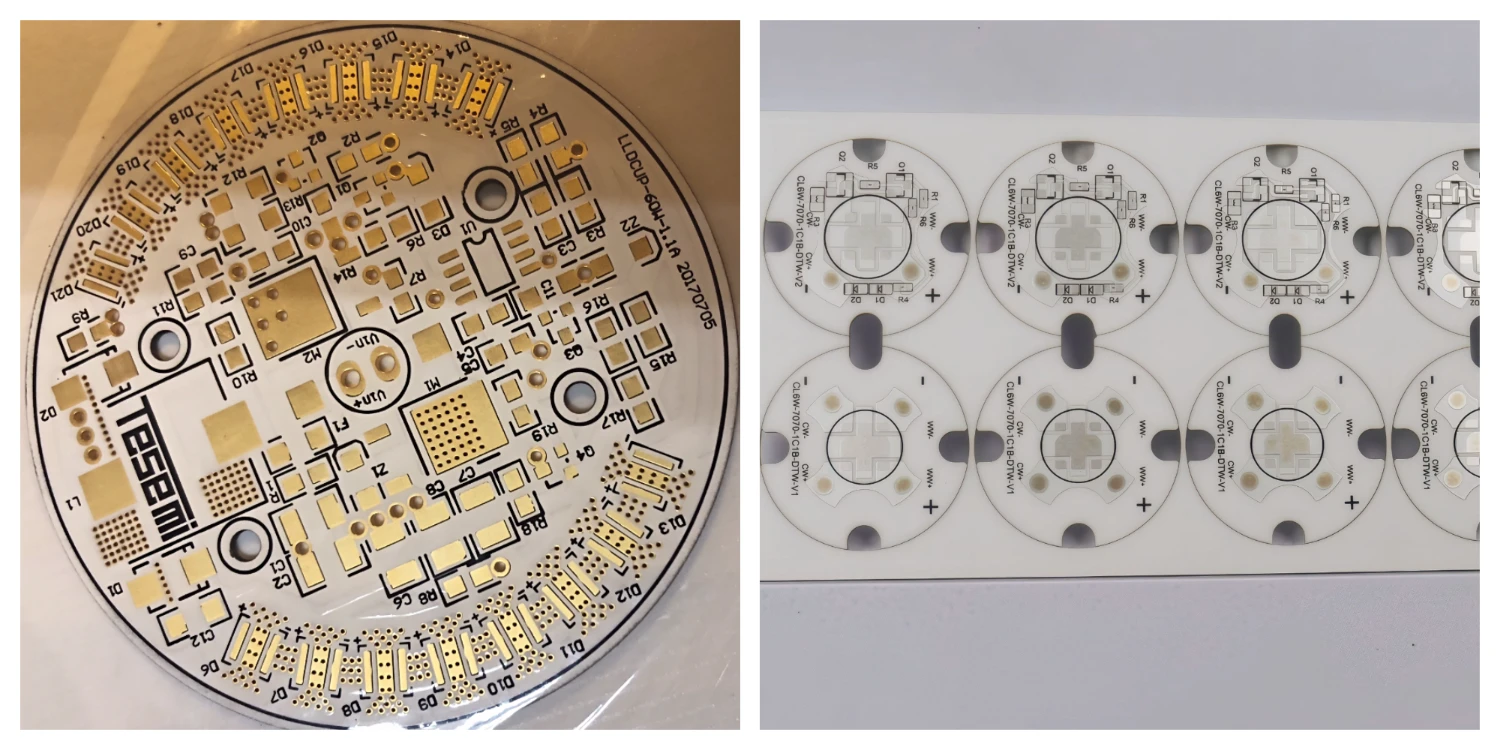

Ceramic PCB, also known as ceramic substrates, are PCBs that made by ceramic materials, such as alumina, aluminum nitride, beryllium oxide, and silicon nitride, as the carrying substrate. Ceramic PCB are fundamentally different from common FR-4 substrates, and more prone to apply on high-tech electronics and industries. This article provides a comprehensive overview of ceramic PCB.

1. Core Advantages

1) Excellent at Heat Dissipation: This is the most important advantage of ceramic PCB. The thermal conductivity of ceramic materials (especially aluminum nitride, AlN) is much more higher than other traditional substrates, it provides rapid heat dissipation, decrease the working temperature of some components, and improving reliability and performance significantly.

2) Matching of Thermal Expansion Coefficient with Chips: Many high-power semiconductor chips (such as GaN, SiC) use silicon or silicon carbide as the substrate. The thermal expansion coefficient of ceramics (especially AlN) is very close to these materials. During drastic temperature changes, it can reduce stress between the chip and the substrate, prevent solder joint cracking, improve product lifespan and thermal cycling resistance.

3) Excellent Properties:

● High resistance for insulation and high voltage breakdown, suitable for high-voltage applications.

● Low dielectric constant and dielectric loss, resulting in low signal transmission loss and low delay at high frequencies (RF/microwave), stable performance.

4) High Mechanical Strength and Stability: Ceramic materials are hard, dense, wear-resistant, corrosion-resistant, and non-deformable, provide reliable stability in harsh mechanical and chemical environments.

5) High Hermeticity: Ceramic itself is airtight and humidity-proof, providing excellent protection for internal circuits and chips, suitable for hermetically sealed packages with reliability.

6) Suitable for High-Density Assembly: Through thin-film or thick-film processes, very tiny circuits could be printed on ceramic substrates, achieving high-density interconnection.

2. Disadvantages

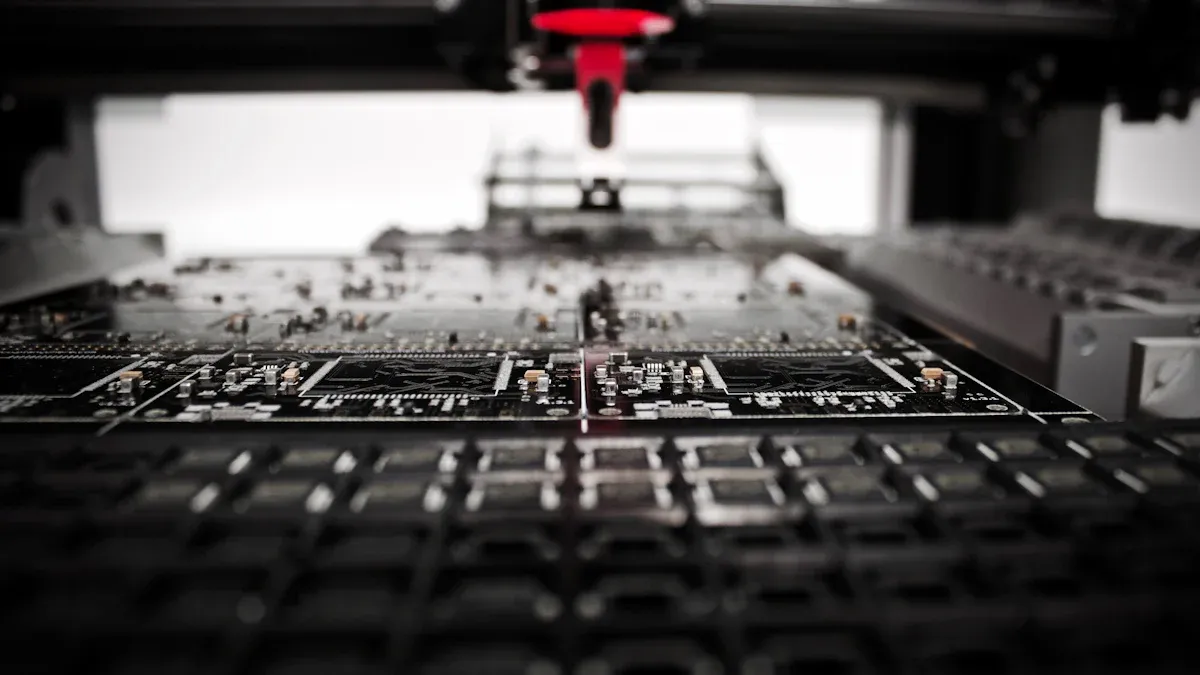

1) High cost: The cost of ceramic materials, processing equipment (such as laser drilling and high-temperature sintering), and the complexity of the process technology, are far higher than ordinary PCBs, resulting in a very high unit price.

2) High brittleness and fragility: This is an inherent characteristic of ceramic materials. They are prone to break under mechanical force, bending, or uneven stress, have to be very careful during transportation and assembly.

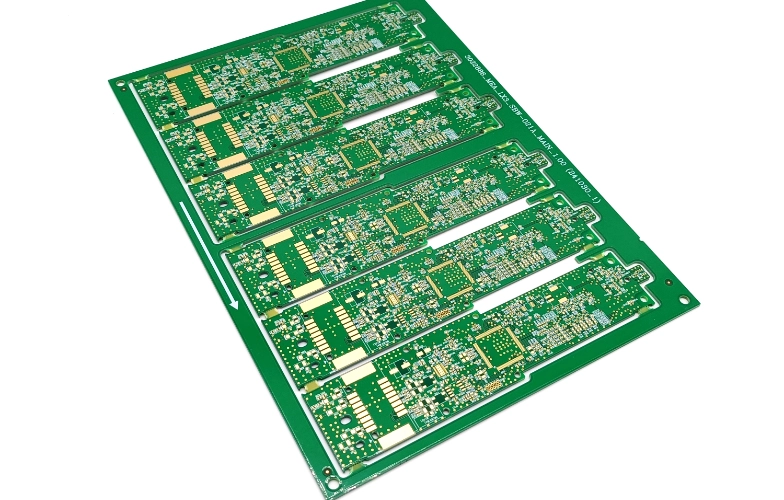

3) Limited size: Due to the sintering process, large ceramic substrates are more prone to deforming and cracking during manufacturing process, thus the size is smaller and difficult to manufacture in larger size like ordinary PCBs.

4) Difficult to manufacture:

● Drilling: Due to the high hardness of ceramics, through-holes usually have to be drilled by laser, which is costly, slow, and has a higher rate of defects.

● Impossible for post-processing modifications: Once it is sintered, the circuits cannot be modified like ordinary PCBs.

3. Applications (application of advantageous characteristics)

Ceramic PCB are mainly applied in fields with high requirements for performance, reliability, and heat dissipation:

1) High-power electronics and automotive electronics:

● IGBT modules, SiC/GaN power devices: electric drive inverters for new energy vehicles, power chargers.

● Industrial frequency converters, UPS uninterruptible power supplies, and power modules in high-voltage power transmission (HVDC).

2) High-brightness LEDs and Semiconductor Lighting: LED packaging substrates, especially high-power COB packages. Excellent heat dissipation is crucial for LED luminous efficacy, lifespan, and light decay.

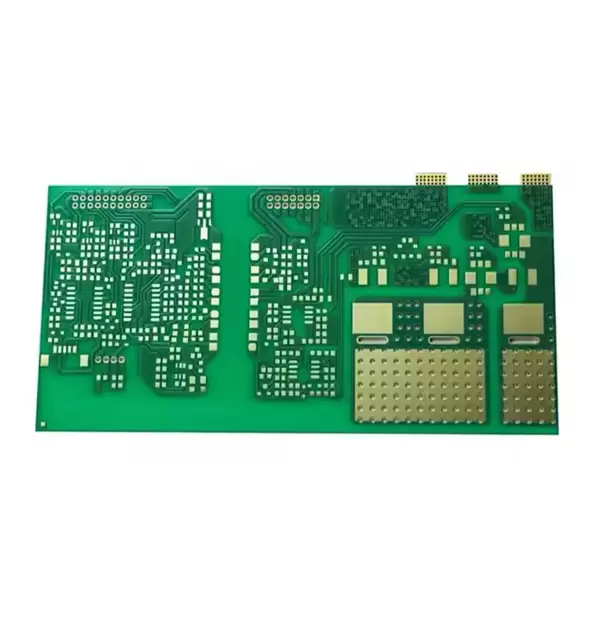

3) RF/Microwave and Semiconductor Packaging:

● RF power amplifiers in 5G/6G communication base stations, microwave and millimeter-wave devices, and phased array antennas.

● Microwave integrated circuits and satellite communication equipment.

● Chip packaging and substrates for multi-chip modules.

4) Aerospace and Military: Radar systems, electronic countermeasures equipment, and missile guidance systems. These require resistance to extreme temperature changes, high vibration, and strong shock environments.

5) Lasers and Optoelectronic Devices: Heat sinks and circuit carriers for high-power semiconductor lasers, ensuring stable laser output.

6) Sensors and High-Temperature Electronics: High-temperature pressure sensors, accelerometers, and other MEMS devices, as ceramics themselves can withstand high-temperature environments.

4. Comparison of Different Types of Ceramic Substrates

| Material | Advantages | Disadvantages | Typical Applications |

| Alumina | Relatively low cost, well-developed technology, balanced overall performance | Moderate thermal conductivity (~20-30 W/mK), slightly poor at matching of thermal expansion coefficient | Widely applied in various low-to-medium power LEDs, thick-film circuits, and electronic packaging substrates |

| Aluminum Nitride | Excellent thermal conductivity (~170-200 W/mK), excellent matching of thermal expansion | High cost, difficult to manufacture | High-power IGBTs, high-power LEDs, high-frequency microwave devices, lasers |

| Silicon Nitride | Highest bending strength, good fracture toughness, excellent thermal shock resistance | Moderate thermal conductivity (~60-90 W/mK), highest cost | Applications with extremely high mechanical reliability requirements, such as electric vehicle power modules (requiring vibration resistance) |

| Beryllium Oxide | Excellent thermal conductivity (~280 W/mK), good at high-frequency performance | Highly toxic, powder is harmful to the human body, processing is limited | Primarily applied in certain high-frequency, high-power military and aerospace fields (gradually being replaced by AlN) |

In summary

Ceramic PCBs are manufactured and dedicated to meet specialized requirements. Their material properties determine they are excellent for heat dissipation, stability, and reliability, but the complex manufacturing process also results in high costs. As stable and trustworthy PCBs for electronic devices in extreme working conditions&environments, which are way more better than traditional PCBs, engaged for modern high-performance electronic systems, higher power, higher frequency, smaller size, and great reliability.

Benlida specializes in PCB manufacturing for 14 years, it has been focusing on quality, continuously upgrade the processes, and provide customer-oriented service, prioritizing quality above all. If you need ceramic PCB, please contact Benlida to know more!

en

en

WhatsApp

WhatsApp