PCB Manufacturing Process Step-by-Step

1. What Is PCB Manufacturing?

PCB manufacturing (also called PCB fabrication) is the process of turning electronic circuit design files&documents into physical printed circuit board (PCB)—a layered structure made of insulating material and patterned copper that routes signals and power between components.

PCB fabrication vs. PCB assembly (FAB vs. PCBA)

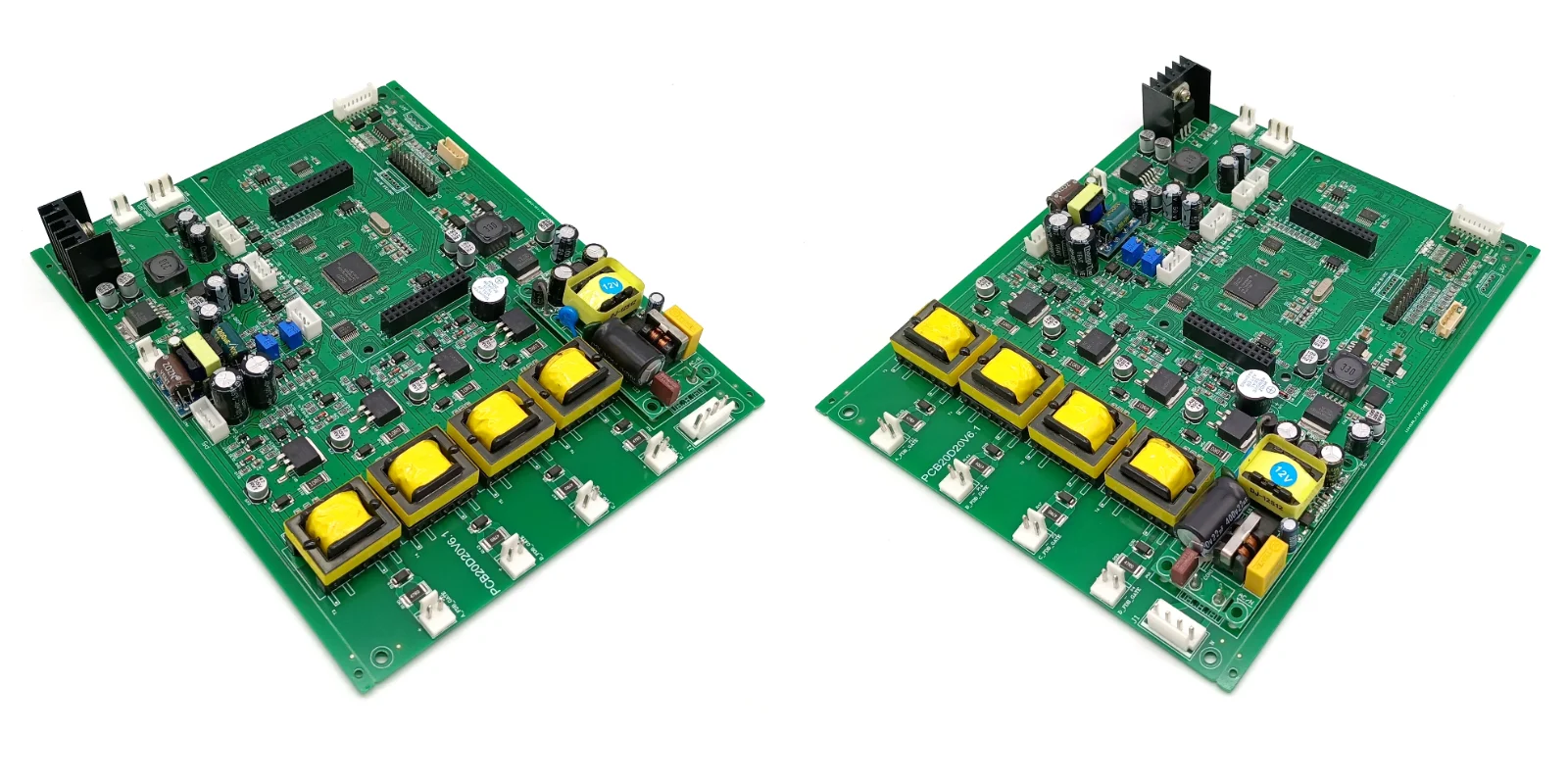

PCB fabrication (FAB) creates the bare board: copper layers, vias, solder mask, silkscreen, and surface finish.

PCB assembly (PCBA) installs components onto the surface of bare board through SMT and through-hole processes, as assembled product.

Why PCB manufacturing quality affects product reliability

Most “mysterious” failures aren’t mysterious at all. They could always be traced back to fabrication progress: marginal plating in vias, unstable impedance, resin voids from lamination, poor solder mask registration, or contamination that shows up later as leakage. A clean, controlled PCB manufacturing process is the basement for everything that follows—signal integrity, thermal performance, assembly yield, and long-term reliability.

2. How a PCB Goes from Concept to Finished Board

Think of PCB manufacturing as a chain and each step “locks” quality for the next one.

Whole-View workflow (design → fabrication → testing)

Design & output files (Gerber, drill, stack-up, notes)

Material prep (laminates, copper, prepreg selection)

Inner layer imaging & etching (for multilayers boards)

Lamination (bonding layers into one panel)

Drilling (through holes, vias, microvias as required)

Hole metallization & copper plating

Outer layer imaging & etching

Solder mask and silkscreen

Surface finish (HASL/ENIG/Immersion Silver/Hard Gold, etc.)

Electrical test and inspection

Profiling / routing / depanelization

Final inspection, packaging, and delivery

Single-layer vs. multilayer workflows

Single-layer: copper patterning happens once, then mask/finish/test.

Multilayer: inner layer always being manufactured first, then laminate with the outer layers. That adds complexity—registration, lamination control, via reliability—also the risk of profile changes.

Where most defects originate

Defects rarely come from one dramatic mistake. They come from small deviations that compound:

Imaging/etching: under/over etch affecting trace width

Lamination: trapped voids, resin starvation, layer shift

Drilling: rough hole walls, misregistration, drill wander

Plating: thin copper in vias, voids, poor adhesion

Solder mask: poor registration causing exposed copper or coverage issues

If you understand where defects originate, it becomes easier to design for manufacturability and choose a supplier who controls the right variables.

3. PCB Design Files That Manufacturers Actually Need

Good fabrication starts with clear and comprehensive files. If your files is not comprehensively integrated, the board might be manufactured “technically correct” but practically unusable.

3.1 Essential files for PCB fabrication

Gerber files

These files define the copper layers, traces&spaces, solder mask, silkscreen, paste layers (if provided), and mechanical outlines. Modern Gerber files include embedded aperture data, reducing ambiguity.

Drill files

Drill files define the locations and diameters of plated and non-plated holes. For complex boards, separate drill files or clear drill tables could avoid misunderstanding.

Stack-up drawings

A stack-up indicates the factory how the board stack up, it should specify:

Layer order

Dielectric thickness

Copper weights (inner/outer)

Material system (FR-4 grade, high-Tg, Rogers, etc.)

Controlled impedance structures (single-ended/differential, target ohms)

Read-me / fabrication notes

This is where critical requirements belong:

Controlled impedance targets and test coupon needs

Finished thickness tolerance

Surface finish preference

Solder mask type

Via structures: blind/buried, via-in-pad, micro-via stacking

Any special requirements (e.g., CAF resistance, cleanliness standards)

3.2 Common design mistakes that delay PCB production

Incomplete stack-ups

“Standard stack-up” sounds convenient, but it’s not universal. Without a defined stack-up, impedance targets and thickness could drift.

Unclear impedance requirements

If you have DDR, PCIe, USB, HDMI, RF traces, or tight timing margins, impedance must be explicit:

target impedance (e.g., 50Ω single-ended, 90/100Ω differential)

tolerance (e.g., ±10%)

reference plane assumptions

coupon requirements for verification

Missing solder mask definitions

Mask openings, expansions, and dam widths, these matter for assembly yield—especially for fine pitch parts. If mask data is incomplete, you may see slivers, bridging risks, or pad exposure issues.

If you want a manufacturer who can help to spot out these potential issues at early stage, Benlida provides PCB engineering support alongside fabrication services through its workflow on Benlida

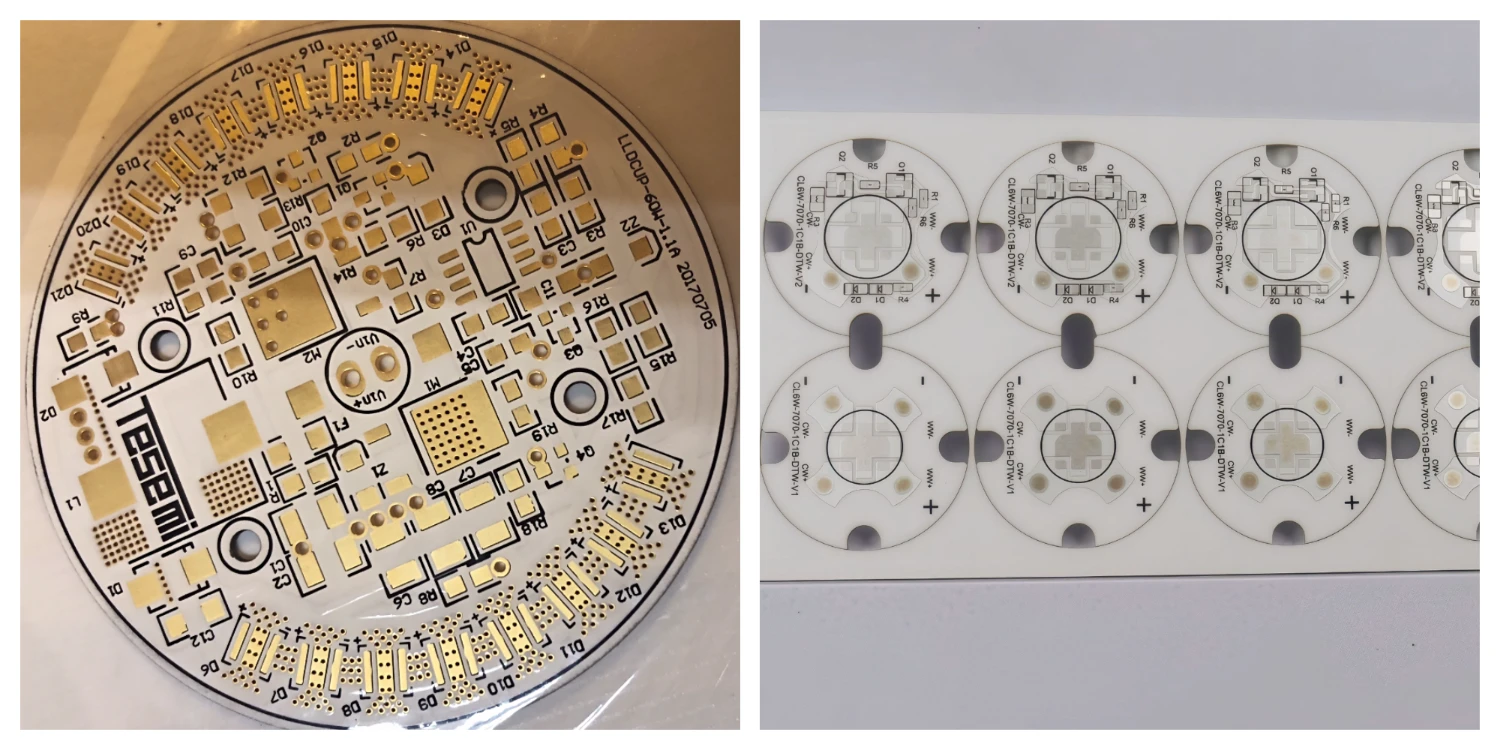

4. Materials Used in PCB Manufacturing

Materials are where performance starts. Gerber files and use different materials to manufacture, and the boards might behave very differently in real hardware.

4.1 PCB substrate materials

FR-4

FR-4 is a glass-reinforced epoxy which widely applied for electronic products.

High-Tg materials

High-Tg (glass transition temperature) materials help when boards encounter higher thermal stress—multiple reflow cycles, higher operating temperatures, or demanding reliability requirements. They can improve dimensional stability and reduce risk of delamination.

High-frequency (Rogers, PTFE, hybrids)

For RF and high-speed designs, dielectric stability and loss are very important. Materials like Rogers and PTFE-based could systematically reduce loss and improve signal performance, particularly at higher frequencies.

4.2 Copper thickness and it’s impact

Copper Thickness 1OZ vs 2OZ (and beyond)

Copper thickness affects:

current carrying capacity (thicker copper handles more current for the same trace width)

thermal performance (more copper could dissipate heat faster)

manufacturability (thicker copper will make fine traces&space much harder to etch)

A common trade-off: thicker copper boosts power capability but may limit the smallest trace/space that manufacturer can reliably achieve. That’s why it is important to align design intention and manufacturing capability at first beginning.

5. Inner Layer Fabrication: Where Accuracy Begins

For multilayer PCB, inner layers are the “foundation.” Errors here if get laminated and buried inside of the board, then it will beyond to fix.

Copper-clad laminate preparation

The laminate is cleaned and prepared to ensure good adhesion of imaging materials and avoid contamination that could affect etching.

Photo-resist application (simple explanation)

Photo-resist is a light-sensitive coating which applied on copper surface, take it like a temporary “protective paint” that determines which copper remains and which copper will be etched away.

UV exposure and circuit pattern transfer

A photo-tool (film) or direct imaging system exposes the photo-resist. Exposed areas are developed, revealing a pattern that matches your design.

Inner-layer copper etching

Etching removes unwanted copper. This is where trace widths and spacing can shift if the process isn’t controlled. In tight designs, small variations can affect impedance or create opens/shorts.

6. Multi-layer PCB Lamination

Lamination bonds multiple layers into one rigid structure.

What is prepreg and why it matters

Prepreg is thin fiberglass film pre-impregnated with resin. Under heat and pressure, it melts and cures, becoming the “glue” that bonds layers together while providing insulation between copper layers.

Heat, pressure and epoxy flow

During lamination:

Heat softens the resin

Pressure forces intimate contact between layers

Resin fills gaps and bonds everything

Cooling cures the resin into a stable structure

Common lamination defects and prevention

Voids: trapped air or insufficient resin flow

Delamination: poor bonding due to contamination or incorrect lamination profile

Layer shift: registration problems that cause misalignment

Well-controlled lamination is one of the biggest separators between average and excellent PCB manufacturers.

7. PCB Drilling Technologies: Mechanical vs. Advanced Methods

Drilling is a step that turns a flat laminated panel into a board with interconnections. In the PCB drilling process, every hole is a electrical path—whether it becomes a plated via, a component lead hole, or a mechanical mounting feature. That’s why drilling quality direct impact on reliability, plating performance, and long-term stability.

CNC Mechanical Drilling (for Through Holes)

For most standard designs, CNC mechanical drilling is the most common and cost-effective PCB drilling process. It’s used for:

Through holes for connectors and through-hole components

Standard vias connecting multiple layers

Non-plated holes for tooling and mounting (when specified)

Why tool control matters:

Drill bit, spindle speed, feed rate, and “hit count” (how many holes a bit drills before replacement) all affect the quality of hole wall. Worn tools would create rough hole walls, smear resin, or leave micro-cracks—all of which weaken plating adhesion and reduce via reliability.

Micro-via Drilling Basics (Laser for HDI Density)

When designs require smaller interconnects—especially in HDI—mechanical drilling reaches its limits. Micro-vias are usually made by laser drilling, which allows:

Smaller diameters than standard drills

High-density fan-out for BGAs and compact modules

Shorter interconnect paths for better electrical performance

In practice, laser-drilled micro-vias support tight routing and layer-to-layer connections without consuming as much board as traditional vias.

Why Hole Accuracy Determines Via Reliability

At the end, PCB via holes are only reliable if the drilled geometry is clean, consistent, and correctly placed. A via is only as good as the hole, it starts with:

Smooth hole walls support strong copper adhesion during metallization and plating

Accurate hole diameter helps achieve consistent plating thickness and stable resistance

Correct registration ensures PCB via holes land cleanly on pads, maintaining annular ring integrity and reducing breakout risk

Clean drilling reduces resin smear, improving inner-layer connectivity and long-term durability

If your design includes dense via fields, tight tolerances, or HDI structures, drilling quality is most important and requires process management rigorously.

8. Through-Hole Metallization and Copper Plating

After drilling, holes are just empty cylinders through insulating material. To connect layers electrically, those holes must be plated.

Why drilled holes must be plated

Plated holes create conductive pathways between copper layers—essential for multi-layer connections and through-hole components.

Chemical copper deposition

A thin initial copper layer is deposited chemically so that the hole walls become conductive.

Electrical interconnection between layers

Once conductive, the board goes through electrolytic plating to build copper thickness in holes and on surfaces.

Plating thickness control

Thickness control matters for:

via reliability (too thin will increase crack risk)

current carrying capacity

long-term durability under thermal cycling

9. Outer Layer Imaging and Final Circuit Formation

Outer layers are built after lamination, drilling, and initial plating.

Outer-layer photo-resist process

Like inner layers, outer layers use photo-resist, exposure, and development to define copper patterns.

Differences vs. inner layers

Outer layers must consider:

existing plated copper thickness

via pads and annular ring requirements

final trace width after plating and etching

Final copper etching principles

After pattern plating (depending on process), unwanted copper is etched away to reveal final outer circuits.

10. Protective and Functional PCB Coatings

10.1 Solder mask: purpose and types

Solder mask protects copper from oxidation and prevents solder bridging during assembly. It also improves insulation and reduces accidental shorts.

Common solder mask colors exist for practical reasons (contrast, inspection preference, branding), but color alone is not a performance guarantee. What matters is mask quality, registration, adhesion, and thickness control.

10.2 Silkscreen: more than labels

Silkscreen adds:

Designators reference

polarity marks

assembly and inspection guidance

traceability information (lot codes, identifiers)

In real production, clean silkscreen could reduces mistakes during assembly and speeds up inspection.

11. PCB Surface Finishes

Surface finish protects copper pads and ensures good solderability. The “best” finish depends on component types, shelf life, and performance requirements.

Finish | Cost | Shelf Life | Lead-Free | Best Use Case |

HASL | Low | Long | Optional | Cost-sensitive designs |

ENIG | Medium | Long | Yes | Fine-pitch components |

Immersion Silver | Medium | Short | Yes | High-frequency boards |

Hard Gold | High | Very Long | Yes | Edge connectors |

A practical way to choose: start from your assembly requirement (fine pitch, BGA, connector wear, RF loss) and work backward to the finish that supports it with minimal risk.

12. Electrical Testing and Quality Assurance in PCB Manufacturing

Testing verifies that what you designed is what you received.

Continuity and isolation testing

Continuity checks that nets connect where they should

Isolation checks that nets don’t short where they shouldn’t

Flying probe vs fixture testing

Flying probe: flexible, good for prototypes and lower volumes

Fixture testing: fast for volume production but requires a test fixture

Why testing is non-negotiable

Skip the testing process could save time today but it leaves risks in future: if any short or open shows up after assembly, the costs of components and assembly labor, debug time, and schedule, all will be wasted away. Electrical testing is one of the most important process for reliability.

13. PCB Profiling, Routing, and Board Separation

After fabrication and finishing, the board must be shaped by following design requirements.

CNC routing

Routing by CNC, to cut the final outline.

V-scoring

V-scoring creates a controlled “V-cut” so boards could be separated cleanly from there, after assembly — commonly in panelized production.

Choosing the right depanelization method

Use routing for complex shapes or when edge quality matters

Use V-scoring for straight-line separation and high throughput

Consider assembly stresses: poor depanelization choices can crack solder joints or damage components

14. Final Inspection, Packaging, and Delivery

Visual inspection

Inspection for visible defects: solder mask issues, scratches, missing markings, surface finish anomalies.

Dimensional accuracy

Verifies board outline, hole-to-hole distances, and critical features—especially important for connector alignment and enclosures.

Vacuum packaging and moisture control

Proper packaging could reduce oxidation and moisture absorption. For sensitive materials, moisture control could avoid issues during reflow.

15. How to Choose the Right PCB Manufacturer

This is the knowledge of process becomes a real purchasing advantage. The “right” partner isn’t just the one with the lowest price—it’s the PCB manufacturer who can consistently achieve your technical targets, your schedule, support you with engineering capacity and from prototype to mass production.

Capability checklist

When evaluating a PCB supplier, don’t just ask “Can you make it?”, ask “Can you make it repeatably?” Confirm they can reliably support:

Layers and stack-up requirements: Can they build your exact stack-up and achieve thickness targets?

Trace/space and drill tolerances: Especially important for dense routing and fine-pitch components.

Controlled impedance verification: Ask how impedance is built, measured, and reported (coupons, test methods, tolerances).

Special materials: High-Tg FR-4, Rogers/PTFE, and hybrid constructions for RF/high-speed designs.

HDI features: Micro-vias, blind/buried vias, via-in-pad (and whether VIPPO is supported when needed).

Surface finish options: ENIG/ENEPIG/Immersion Silver/HASL/Hard Gold—matched to your assembly and reliability goals.

If your product has tight electrical margins, choose a partner whom has proved custom PCB fabrication capability—because process control matters more than marketing claims.

Quality certifications and process proof

Certifications can be a useful baseline, but what really separates a dependable PCB manufacturer is how they control quality day-to-day. Check for:

IQC/Incoming material inspection (laminates, prepreg, copper, chemicals)

Process control points throughout imaging, etching, drilling, lamination, and plating

Cross-sectioning and plating verification (via wall copper, annular ring, resin fill where applicable)

Electrical testing coverage (flying probe vs testing fixture, continuity/isolation strategy)

Traceability and lot control (issues can be isolated and prevented from repeating)

A strong PCB supplier will be able to explain these controls clearly and show typical inspection/testing outputs, not just promise them.

Turnaround time vs cost trade-offs

Fast quotes don’t always mean fast boards, and low unit pricing doesn’t always mean low total cost. The best partners help you to balance:

Yield (first-pass success rate)

Rework risk (hidden cost of marginal builds)

Schedule stability (realistic lead times and predictable delivery)

Technical support (DFM feedback, engineering communication)

Long-term consistency (repeatability across batches)

In practice, the best value often comes from a PCB manufacturer who prevents problems at early stage—especially for advanced designs where custom PCB fabrication quality directly affects assembly yield and field reliability.

If you’re looking for a PCB manufacturer, comparing PCB supplier capabilities, or planning custom PCB fabrication for a new project, Benlida provides PCB fabrication and engineering support through all the process, you can know Benlida more from website here.

16. Frequently Asked Questions About PCB Manufacturing

How long does PCB fabrication take?

Lead time depends on layer count, materials, special processes (HDI, controlled impedance), surface finish, and testing requirements. Prototypes can be faster, while complex multilayer boards may require more process steps.

What affects PCB manufacturing cost?

The biggest cost drivers typically include:

layer count and board size

material selection (standard FR-4 vs high-frequency laminates)

fine features (tight trace/space, small drills)

special via structures (blind/buried, microvia stacking)

surface finish choice

testing and inspection requirements

What tolerances are realistic?

Realistic tolerances depend on design complexity and materials. The best approach is to align tolerances with functional needs—then confirm manufacturability with your chosen supplier before production starts.

Can prototypes and mass production use the same process?

The core steps are similar, but tooling, panelization, test strategy, and process optimization may differ. A strong manufacturer can build prototypes that scale cleanly to mass production without redesign surprises.

17. Conclusion: Why Process Knowledge Leads to Better PCBs

PCB manufacturing isn’t magic—it’s a chain of controlled steps where each stage affects the next. When designers understand the process, they make better decisions about stack-ups, materials, vias, and tolerances. When manufacturers run disciplined processes, boards deliver consistent electrical performance, assembly yield, and long-term reliability.

If you’re planning a new board or troubleshooting manufacturing yield, collaborating early with a capable fabrication partner, that would make the difference. To explore fabrication capabilities, engineering support, and manufacturing services, visit Benlida.

en

en

WhatsApp

WhatsApp