Medical equipment pcb assembly

The Crucial Role of PCB Assembly in Medical Equipment

Medical equipment spans a vast spectrum, from diagnostic imaging devices like Magnetic Resonance Imaging (MRI) machines and X - rays to life - saving implantable devices such as pacemakers and cochlear implants. In each of these, PCB assemblies are the nerve centers, enabling the functionality, precision, and reliability that are non - negotiable in healthcare.

For diagnostic imaging equipment, high - performance PCBs are essential for processing and transmitting the vast amounts of data generated. In an MRI machine, for example, the PCB assembly manages the complex signals that create detailed images of the human body. The accuracy of these images can be the difference between early disease detection and a missed diagnosis, highlighting the criticality of well - designed and assembled PCBs.

Implantable medical devices present a unique set of challenges and requirements for PCB assembly. These devices must be miniaturized, highly reliable, and biocompatible. Pacemakers, which regulate the heart's rhythm, rely on PCB assemblies that can function flawlessly for years inside the human body. The PCB materials used need to be carefully selected to ensure they do not cause any adverse reactions in the body. Additionally, the assembly process must meet the most stringent quality control standards to guarantee the device's long - term performance.

Technological Innovations in Medical Equipment PCB Assembly

Advanced Materials

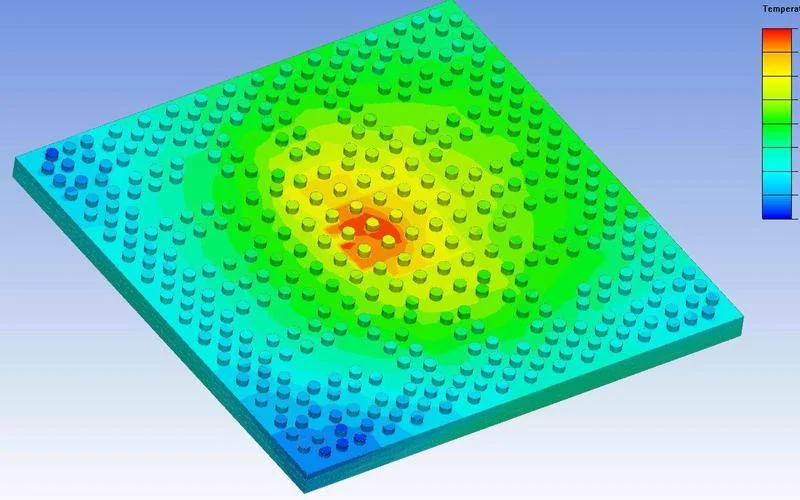

The choice of materials in medical PCB assembly is constantly evolving. Traditional materials like FR - 4 are being complemented or replaced by more specialized options. For instance, in some applications, aluminum PCBs are gaining popularity due to their excellent heat dissipation properties. This is crucial in high - power medical devices where overheating can lead to malfunctions. The use of materials with high - temperature resistance and better electrical insulation properties is also on the rise, enabling PCBs to operate in more extreme conditions.

In implantable devices, biocompatible materials are of utmost importance. Materials that can withstand the body's physiological environment without degrading or causing an immune response are being developed and refined. These materials ensure the long - term safety and functionality of implantable PCBs.

Miniaturization and High - Density Interconnects (HDI)

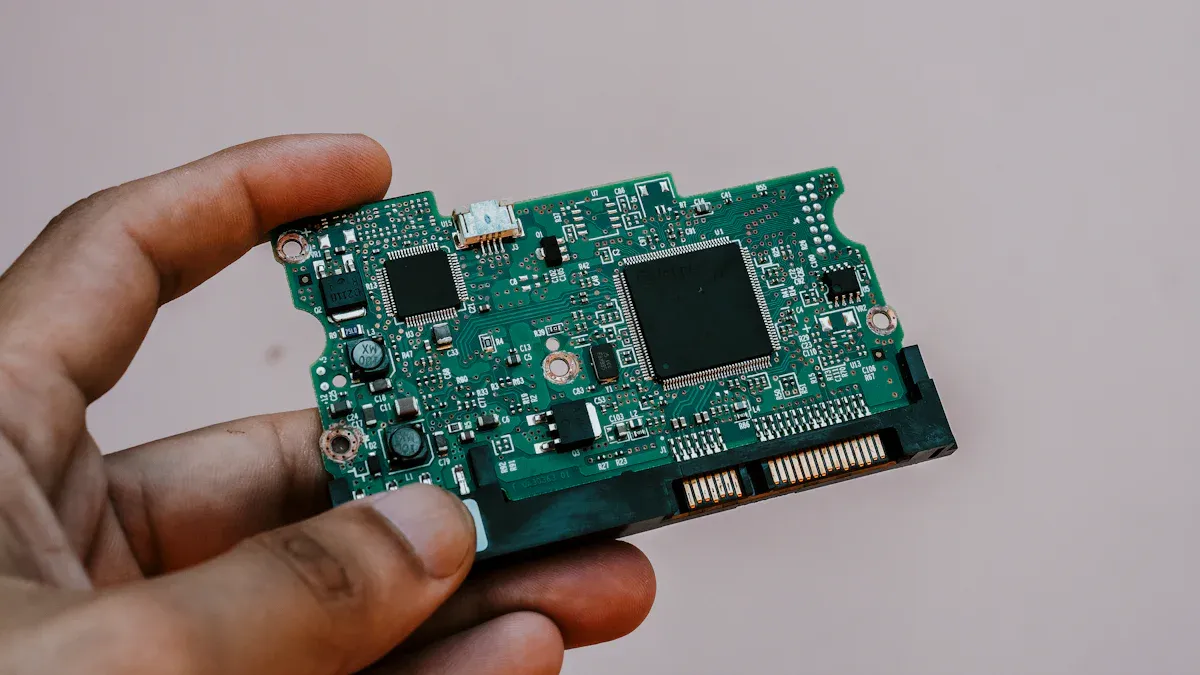

As medical equipment trends towards miniaturization, PCB assembly technology is keeping pace. High - Density Interconnect (HDI) PCB designs are becoming increasingly prevalent. HDI allows for smaller, more compact PCB layouts while maintaining high levels of functionality. In portable medical devices such as handheld diagnostic tools or wearable health monitors, HDI PCBs enable the integration of multiple components in a limited space.

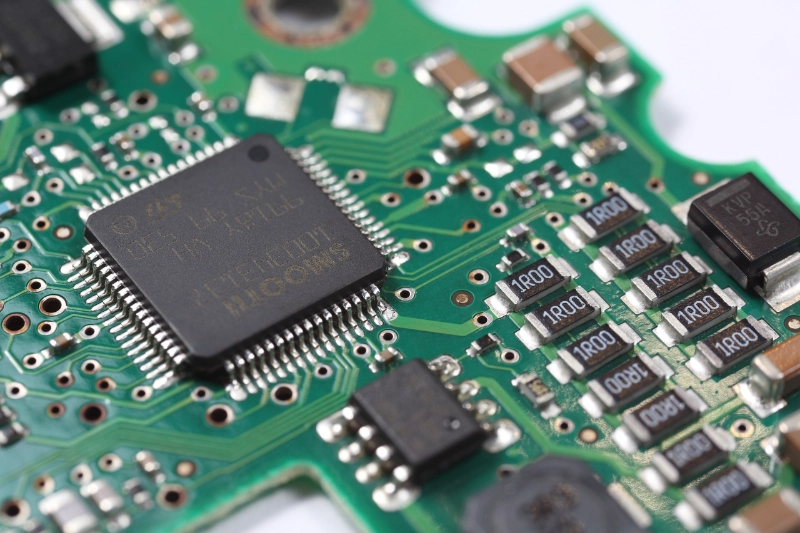

The miniaturization of components themselves is also a significant factor. Passive components like resistors and capacitors are getting smaller, and advanced packaging technologies such as Ball Grid Arrays (BGAs) and Chip - Scale Packages (CSPs) are being used more frequently. This not only reduces the overall size of the PCB but also improves its performance by minimizing signal transmission distances.

Precision Manufacturing and Assembly Techniques

Medical PCB assembly demands the highest level of precision. Automated assembly processes, such as Surface Mount Technology (SMT), have become the norm. SMT machines can place components with micron - level accuracy, ensuring reliable electrical connections. In addition, new soldering techniques, like laser soldering, are being adopted. Laser soldering offers precise heat application, reducing the risk of damage to sensitive components and improving the quality of solder joints.

Advanced inspection methods are also an integral part of the precision manufacturing process. Automatic Optical Inspection (AOI) systems can quickly and accurately detect defects in solder joints, component placement, and PCB traces. X - ray inspection is used for more complex PCBs, especially those with hidden solder joints or multiple layers, to ensure the integrity of the assembly.

Challenges in Medical Equipment PCB Assembly

Stringent Regulatory Requirements

The medical device industry is one of the most highly regulated sectors globally. PCB assemblies for medical equipment must comply with a plethora of regulations, such as ISO 13485 (which sets the standard for quality management systems in the medical device industry) and the requirements of the US Food and Drug Administration (FDA). These regulations cover every aspect of the PCB assembly process, from the selection of materials to the final product testing.

Meeting these regulatory requirements adds complexity and cost to the manufacturing process. Manufacturers need to invest in quality control systems, documentation, and regular audits to ensure compliance. Any deviation from the regulations can result in product recalls, financial penalties, and damage to the company's reputation.

Design Complexity

Medical equipment PCBs often have complex designs, especially in devices that integrate multiple functions. The need to combine analog and digital circuits, high - speed signal processing, and power management on a single PCB presents significant design challenges. Designers must carefully consider factors such as signal integrity, power distribution, and electromagnetic interference (EMI) to ensure the proper functioning of the device.

Moreover, as medical technology advances, new features and capabilities are added to equipment. This continuous evolution requires PCB designers and assemblers to stay ahead of the curve, constantly updating their skills and knowledge to handle the latest design requirements.

Ensuring Long - Term Reliability

Medical equipment is expected to have a long lifespan, often several years or even decades. PCB assemblies must be able to withstand continuous use, varying environmental conditions (such as temperature and humidity changes), and mechanical stress. Ensuring long - term reliability is a major challenge, as components can degrade over time due to factors like electrical overstress, thermal cycling, and corrosion.

Manufacturers need to conduct extensive reliability testing, including accelerated life tests, to predict the lifespan of PCB assemblies. They also need to select components with high reliability ratings and design robust PCB layouts that can tolerate component failures without causing a complete system breakdown.

Future Outlook

The future of medical equipment PCB assembly looks promising, with several trends likely to shape the industry. The increasing prevalence of chronic diseases, especially in an aging global population, will drive the demand for advanced medical devices. This, in turn, will fuel the need for more sophisticated PCB assemblies.

The growth of telemedicine and remote patient monitoring is another significant trend. With the development of 5G technology, medical devices will be able to transmit data more quickly and efficiently over long distances. PCBs in these devices will need to support high - speed communication interfaces and advanced data processing capabilities.

The integration of artificial intelligence (AI) and machine learning (ML) into medical equipment is also on the horizon. PCBs will play a crucial role in enabling the computational power required for AI and ML algorithms to operate in real - time, for example, in diagnostic devices that can analyze patient data and provide accurate diagnoses.

In conclusion, medical equipment PCB assembly is a dynamic and critical field at the intersection of electronics and healthcare. Technological innovations are enabling the development of more advanced and reliable medical devices, but challenges such as regulatory compliance and design complexity remain. As the industry continues to grow and evolve, PCB assembly will be at the forefront of driving medical technology forward, ultimately improving patient care and outcomes.

en

en

WhatsApp

WhatsApp