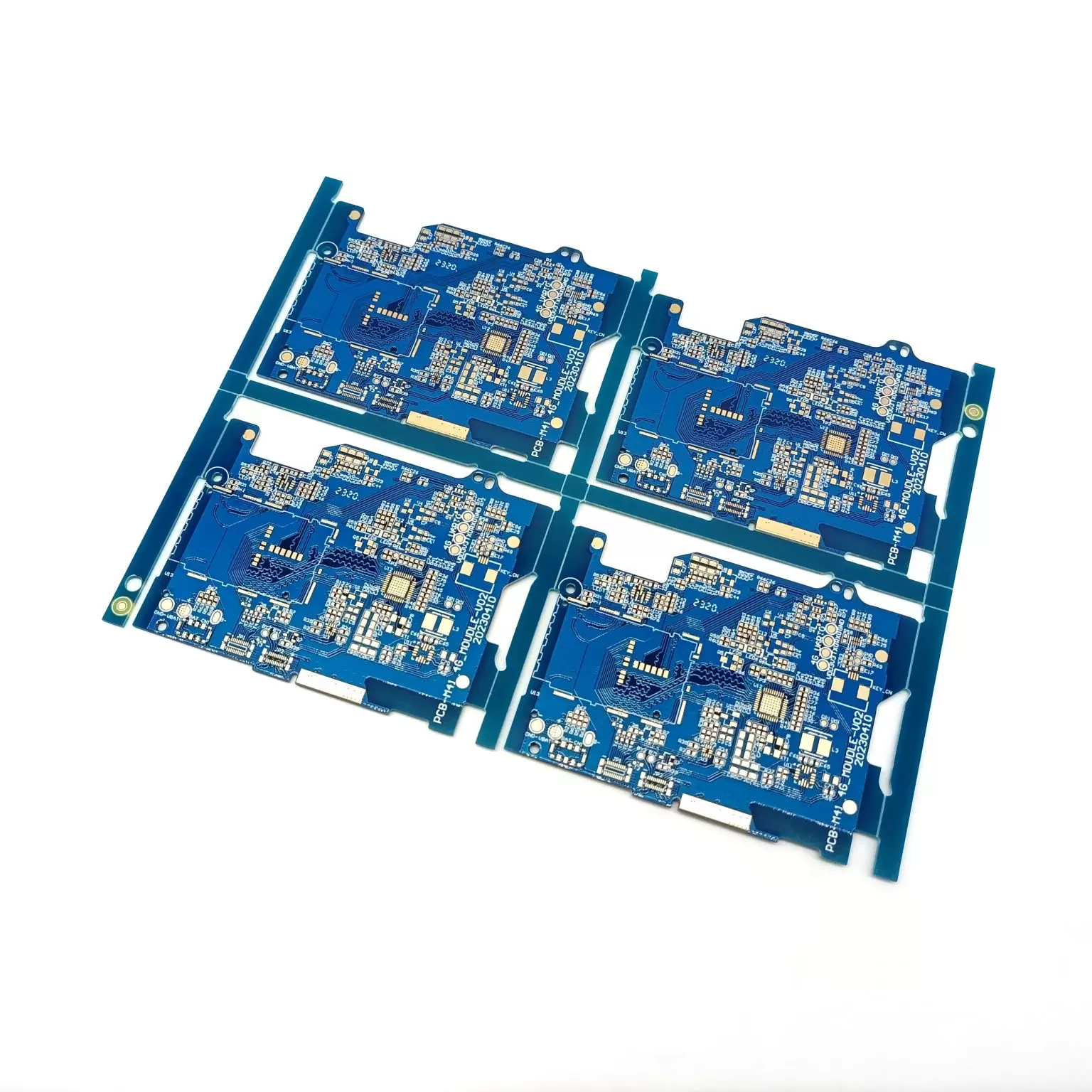

Best Practices for High-Quality PCB SMT Assembly and Production

You should use Best Practices to get good PCB SMT assembly and production. Bad assembly can make electronic products stop working. For example:

Most SMT quality problems happen because of solder paste issues.

Wrong component direction causes about 20% of assembly mistakes.

If you work with skilled manufacturers like Benlida, you can avoid these problems. You get good materials, smart manufacturing steps, and strong testing. Careful quality checks help your products work well and have fewer mistakes.

Key Takeaways

Use good methods in PCB SMT assembly to stop expensive problems and slowdowns.

Pick strong materials and good tools to make sure parts stay together and work well.

Do careful checks, like using machines to look for mistakes early.

Pick trusted companies like Benlida for help and fast shipping.

Work with your company to make things better and get good results.

Best Practices for PCB SMT Assembly

Why Best Practices Matter

You should follow best practices in PCB SMT assembly. If you skip steps, you might make mistakes. These mistakes can cost you money and time. Here are some things that can happen if you do not use best practices:

You might spend more money fixing last-minute changes.

The assembly process can take longer than planned.

Mistakes in manufacturing can make products not work.

You may get fewer good products and more bad ones.

You could pay more for warranties and hurt your brand.

If people do not understand the project, it can slow things down.

These problems can hurt your budget and your reputation. Using best practices helps you stop these problems before they start. You can save money by not having to fix or throw away bad products. Good quality control, like using automated optical inspection and statistical process control, helps you find mistakes early. It is cheaper to fix problems early than to fix them later.

Tip: Work with your manufacturer early. This helps you find and fix problems before you start making your product. It can save you time and money.

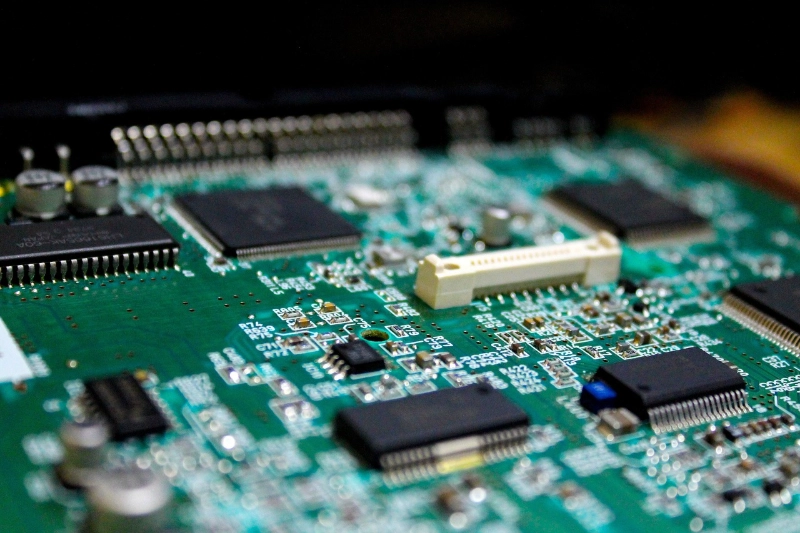

Key Principles for Quality

You should try to get high quality at every step of PCB SMT assembly. Industry standards like IPC-A-610 tell you how to check soldering, component alignment, and how your boards should look. If you follow these rules, you make fewer mistakes and do not have to fix as much. This makes your customers happier.

Here are some important rules that match international quality standards:

IPC-A-610 gives rules for soldering, alignment, and how assemblies should look.

The standard says what PCBs must do to work well and last long.

If you follow IPC-A-610, you make fewer mistakes and customers are happier.

You can also use these best practices to make your assembly better:

Best Practice | Description |

|---|---|

Protection against electrostatic discharges | Use earthed mats and resin floors to stop ESD from hurting parts. |

Protection of MSD components | Keep moisture-sensitive devices in a drying cabinet and check their dates. |

Double quality control | Use X-ray checks with AOI to find mistakes that other checks miss. |

You should watch for common SMT assembly problems. Here are some examples and how to stop them:

Tombstoning: Happens from uneven heating; fix your reflow profile.

Solder Bridges: Stop this by making sure solder mask is clear.

Incomplete Solder Joints: Check your stencil and reflow heat.

Component Misalignment: Use vision systems to place parts right.

Voiding: Use a window pane pad design to help stop this.

When you use these best practices, you get fewer mistakes and your products work better. If you use the same component footprints and design for manufacturability, you can lower your costs by up to 40%. Following these rules makes your work easier and faster.

Design Considerations

Component Selection

You must pick the right parts for your PCB SMT assembly. Good parts help your board work well and last longer. When you choose parts, remember these things:

Electrical ratings: Each part should fit your circuit’s needs.

Heat and durability: Pick parts that can take heat and stress.

Compliance and lifecycle: Make sure parts follow rules and will not be outdated soon.

Supplier selection: Use trusted suppliers for steady parts and support.

If you focus on these things, your assembly will be more reliable and less likely to fail.

PCB Layout and DFM

A smart PCB layout makes assembly easier and helps you get more good boards. Design for manufacturability (DFM) helps you avoid common problems. Here is how DFM can help you:

DFM lowers mistakes like misaligned parts and soldering problems.

You get fewer bad boards and faster production.

Product quality gets better because there are fewer errors.

Simple designs help you make more working boards.

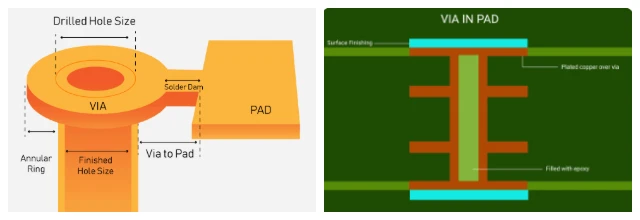

Keeping layer and via offsets right helps with drilling.

Using minimum annular rings and teardrops can help you get more good boards.

Modern PCB layout software gives you tools to check your design before building. Here is a table showing how these tools help:

Feature | How It Helps You |

|---|---|

Design Rule Checks (DRC) | Finds layout mistakes early |

Signal Integrity | Stops noise and crosstalk |

3D Visualization | Finds problems before making the board |

Auto-Routing | Makes trace paths better for assembly |

Simulation and Testing | Tests circuits before you build them |

Testability and Standardization

You should plan for easy testing from the start. Add test points to your PCB design so you can check and fix boards after assembly. Test points let you measure signals at different spots. This makes it easier to find problems. Good placement and clear labels make testing faster and more accurate.

Here are some standards that help you check and fix boards:

Standard | Focus Area | When to Use |

|---|---|---|

IPC-A-600 | Checks bare board quality | Before adding components |

IPC-A-610 | Checks solder joints and part placement | After assembly |

Following these Best Practices in design helps you build better boards and makes every step easier.

SMT Assembly Process

Materials and Solder Paste

You need to choose the right materials for your SMT assembly. Solder paste is one of the most important materials. It holds components in place and forms strong electrical connections. If you use high-quality solder paste, you get better joints and fewer problems. Look at the table below to see what makes good solder paste:

Property | Description |

|---|---|

Melting Point | Different types melt at different temperatures. SAC305 melts at 217–220°C. |

Joint Strength | Strong joints and good wetting help your board last longer. |

Application Suitability | SAC305 works well for high-reliability jobs. Low-temp paste is good for heat-sensitive parts. |

Storage Conditions | Keep paste sealed and cold (0-10°C). Let it warm up before use. |

Environmental Factors | Use paste in rooms with 20-25°C and 45-65% humidity. |

Printing Process | Clean stencils and use the right pressure for even printing. |

Tip: Store solder paste in a cool place and only open it when you are ready to use it. This keeps it fresh and stops problems like oxidation.

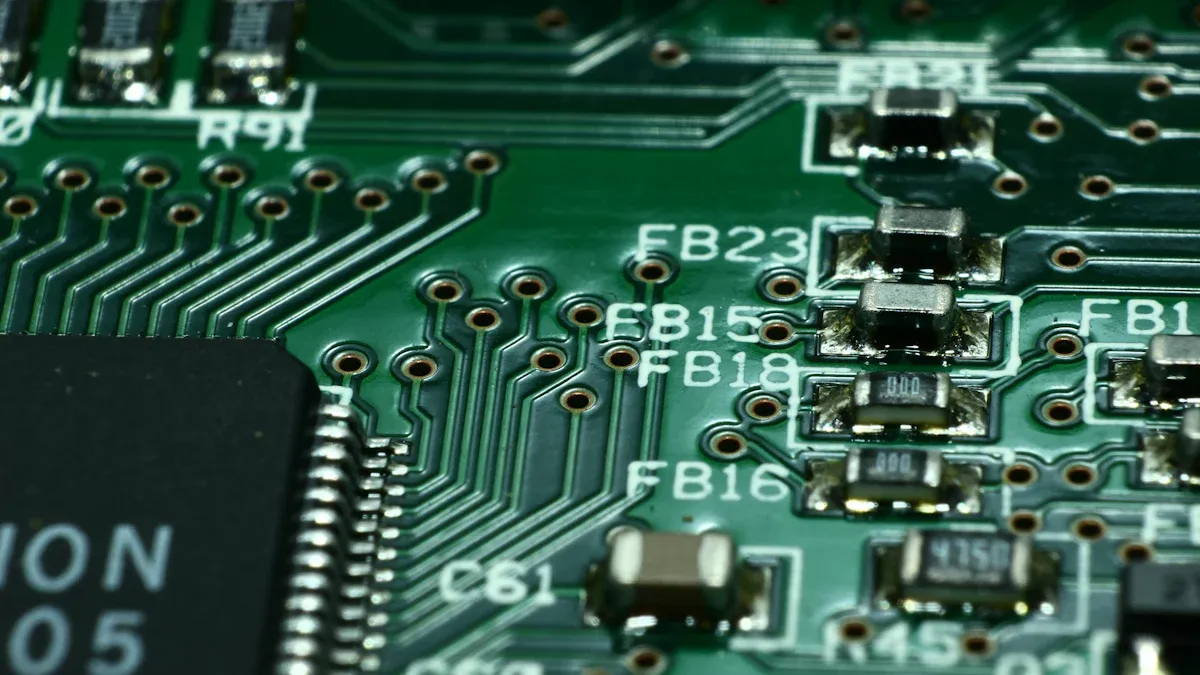

Equipment and Programming

You get better results when you use advanced automated machines. Benlida uses high-end equipment that places parts with great accuracy. These machines can put parts in the right spot within ±0.01mm. They also work fast and can place up to 200,000 parts every hour. The table below shows why this matters:

Feature | Description |

|---|---|

Placement Accuracy | Machines place parts within ±0.01mm, so you get fewer mistakes. |

Speed | Fast machines help you finish big jobs quickly. |

Calibration | Machines check themselves and fix small errors as they work. |

Tolerance | They meet or beat the standard tolerance of ±0.05mm for SMT assembly. |

You must program these machines carefully. Good programming tells the machine where to put each part and how much solder to use. If you set the machines right, you get boards that work well and last longer.

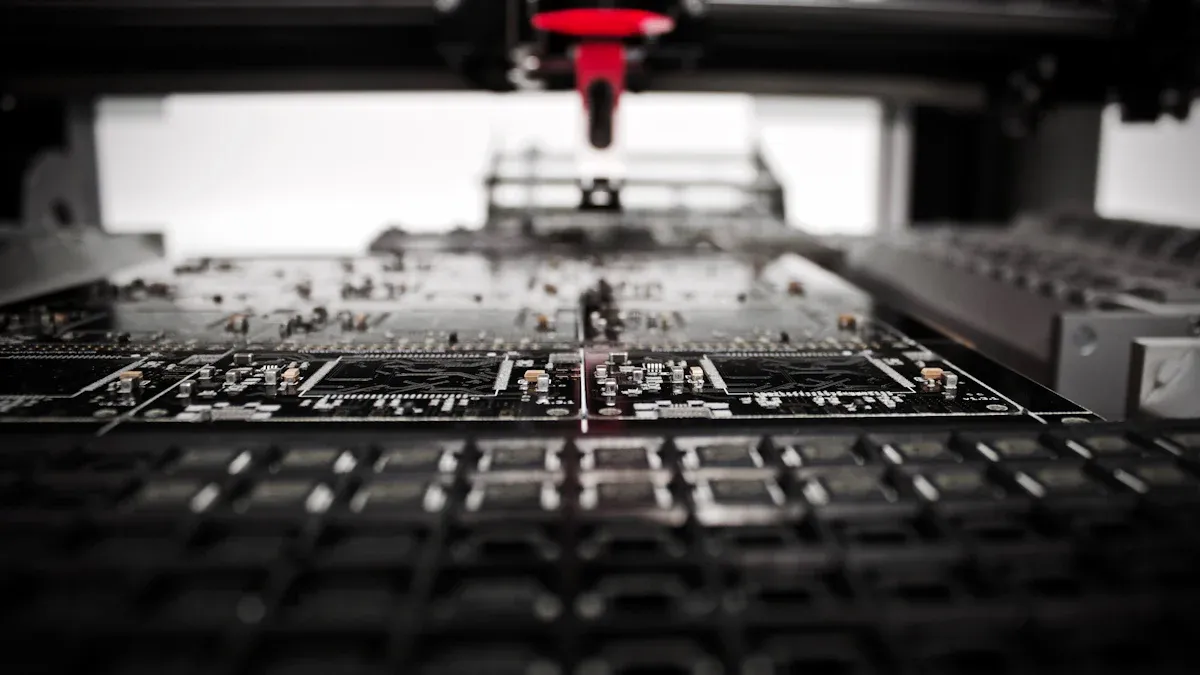

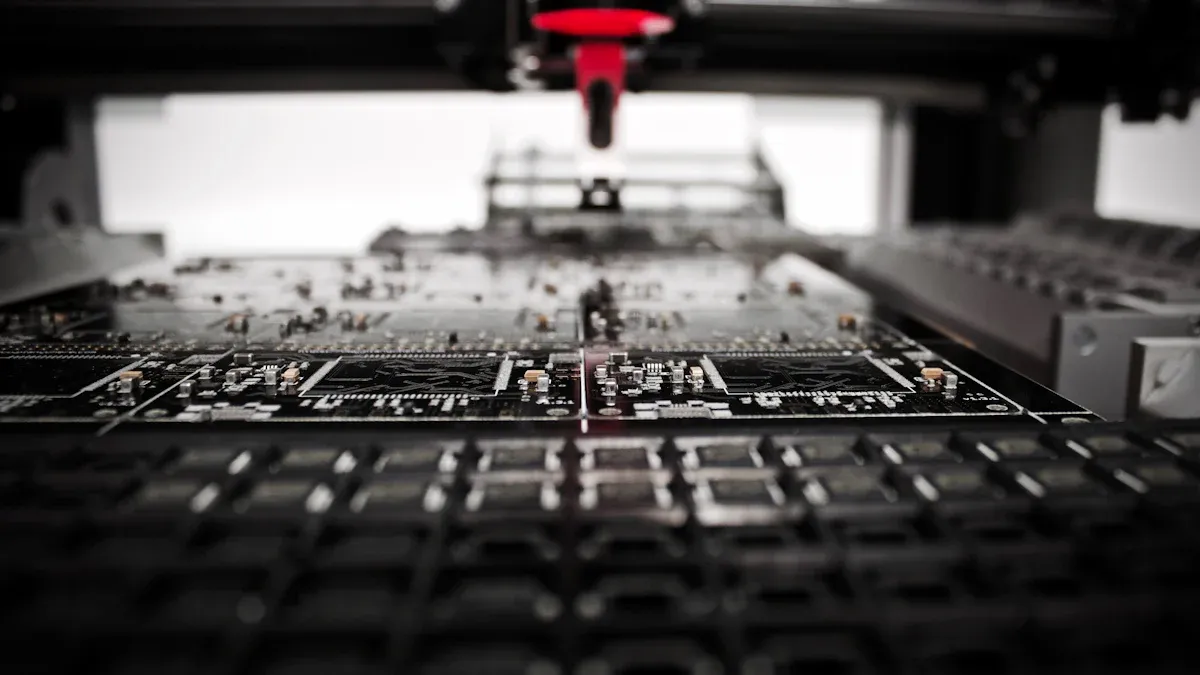

Assembly Steps Overview

You follow a clear set of steps in SMT assembly. First, you print solder paste onto the board. Next, you use machines to place the parts. After that, you heat the board in a reflow oven to melt the solder and make strong joints. Finally, you inspect the board to check for mistakes.

Print solder paste on the pads.

Place components using automated machines.

Reflow the board in an oven.

Inspect the board for errors.

Benlida’s advanced equipment and careful process help you get high-quality boards every time. When you follow Best Practices, you reduce errors and make sure your products work as planned.

Process Controls and Inspection

Solder Paste Application

You have to put solder paste on carefully. The right amount on each pad makes strong joints. Use a clean stencil so the paste spreads evenly. If you use too much or too little, you can get problems. Solder bridges or weak joints can happen. Always check the stencil for any damage before you start. Clean the stencil often so paste does not dry or block holes. Good solder paste use helps you stop many SMT problems.

Tip: Keep solder paste in a cool place. Let it warm up to room temperature before you use it. This keeps the paste fresh and easy to use.

Reflow Profile Optimization

You need to control the reflow oven’s heat and cool steps. This is important for strong solder joints. The right heat profile keeps the IMC layer between 1 and 3 micrometers. This helps stop joints from getting brittle. Slow heating and cooling help the solder form a good structure. This makes joints stronger and less likely to crack. If you rush, you might see cracks or parts lifting off.

Good heat profiles keep IMC thickness just right.

Controlled cooling makes solder strong and tough.

Slow heating and cooling lower the chance of cracks.

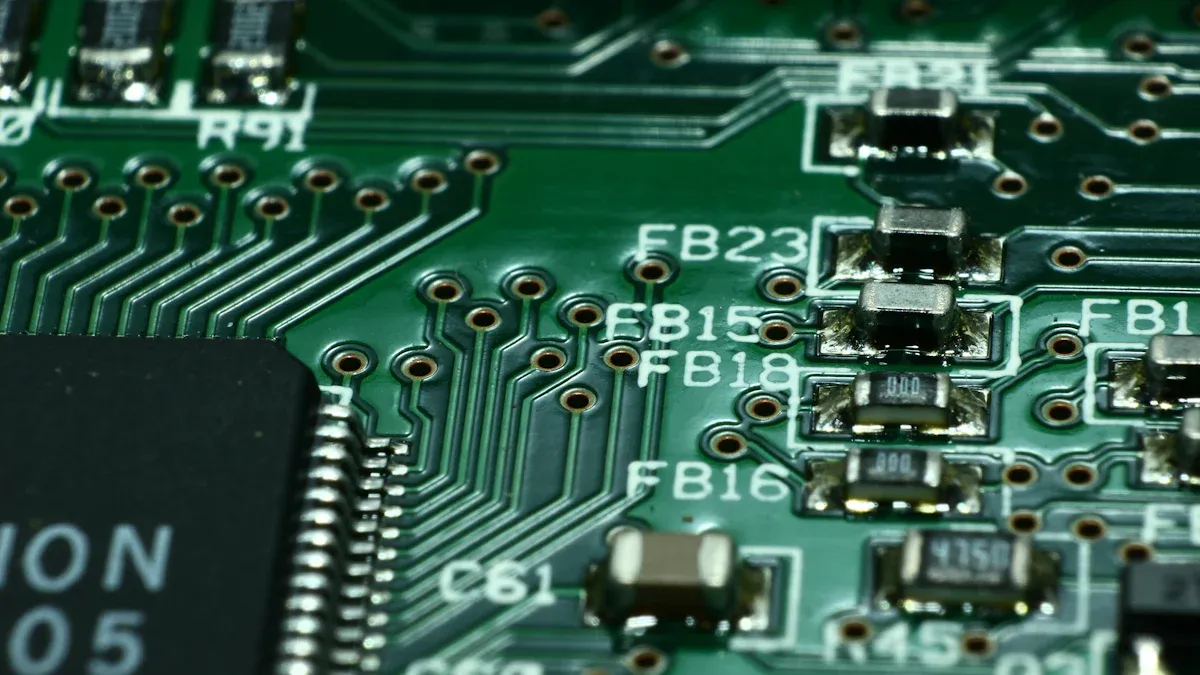

Cleanliness and Inspection Methods

You must keep your boards clean after you finish assembly. Dust, flux, or other stuff can make boards fail later. Use the right cleaning steps to get rid of these things. Inspection is also very important. You can use different tools to check for problems.

Inspection Method | Effectiveness Description |

|---|---|

Automated Optical Inspection (AOI) | Finds up to 95% of visible problems. |

X-ray Inspection | Finds hidden solder problems, especially under BGA parts. |

Thermal Imaging | Finds hot spots or uneven heat, helps fix profiles, and cuts defects by up to 30%. |

You should look for problems like tombstoning, solder bridges, parts in the wrong place, not enough solder, and cold solder joints. AOI and X-ray tools help you find these problems fast. Clean boards and good inspection give you the best chance for strong products.

Quality Assurance Measures

AOI and Functional Testing

You need good inspection tools to find mistakes early. Automated Optical Inspection, or AOI, uses cameras and smart programs to check each board. AOI can spot tiny problems that people might not see. It gives quick and correct results. Benlida uses AOI with AI to make sure boards are high quality. The table below shows how AOI with AI is better than old tools:

Metric | AI-Powered AOI Performance | Conventional Tools |

|---|---|---|

Defect Classification Accuracy | 97–99% | Lower |

False Positive Rate | 4–6% | ~50% |

True Defect Detection Rate | >97% | Lower |

First-Pass Yield | ~98.5% | ~98.2% |

Benlida also uses flying probe and functional tests. These tests check if boards work the right way. You can trust that each board will work well in real life.

Note: Testing early and well helps you avoid expensive repairs. It also keeps your products working well.

ESD and MSD Protection

You must keep your boards safe from static and moisture. Electrostatic discharge, or ESD, can hurt many electronics. This damage costs a lot of money every year. You can lower failures and make better boards by doing these things:

Control static in work areas.

Stop static fields from forming.

Watch all sources of static.

Lower the number of static charges.

Check and care for anti-static gear.

Benlida uses strong ESD and MSD rules. You get better boards and fewer problems.

Qualification and Final Testing

You want every board to pass tough final checks. Benlida puts quality and customers first. The team uses tests to check strength, how long boards last, and if they work. Final tests include AOI, flying probe, and real-life checks. You get boards that fit your needs and last longer. This careful work helps your products do well and gives you peace of mind.

Troubleshooting and Defect Prevention

Common SMT Defects

You can find many types of problems during SMT assembly. Each problem can change how your board works. If you know about these problems, you can fix them early. Here are some common SMT defects:

Insufficient or excess solder: Not enough solder makes weak joints. Too much solder can make shorts.

Nonwetting or dewetting: Solder does not stick to the terminals well.

Disturbed joint: The joint looks rough because parts moved while cooling.

Fracture or cracked joint: Cracks show up in the solder and make it weak.

Pinhead or blowhole: Small holes appear in the solder from trapped gas.

Bridging: Solder connects two pads by mistake and causes a short.

Mounting adhesive on land: Glue ends up in the wrong place and blocks connections.

Solder splashing: Solder spreads out because there is not enough heat.

Open connection: Parts do not line up, so the joint does not form.

Tip: If you see these problems, stop and check your materials and machine settings.

Prevention Strategies

You can stop most SMT problems by using smart steps. Good habits and careful checks make your boards stronger. The table below shows some of the best ways to stop mistakes before they happen:

Strategy | Key Actions |

|---|---|

Optimize Solder Paste Management | Watch paste quality, use the right stencil, and check the printing process closely. |

Enhance Component Placement Precision | Calibrate machines, set the right pressure, and use tacky paste to hold parts steady. |

Fine-Tune Reflow Profiles | Change heat profiles for each part, keep heating even, and watch the oven in real time. |

Improve PCB and Pad Design | Follow design rules, make pads the right size, and keep them even for each part. |

You should check your process at every step. Regular checks help you find small problems before they get big. If you use these steps, you will have fewer problems and better boards in your SMT assembly.

Partnering with Reliable Manufacturers

Choosing the Right Partner

You need a partner you can trust for PCB SMT assembly. A good manufacturer helps you avoid mistakes and delays. Benlida is special because they have lots of experience and care about customers. Their team knows how to handle hard designs and always delivers boards on time.

When picking a manufacturer, check these important things:

Criteria | Description |

|---|---|

Manufacturing Capabilities | They can build tricky multi-layer boards and work with tiny parts. |

Quality Control Processes | They have many checks and keep defects under 1%. |

Certifications | They have important certificates like ISO 9001 and RoHS. |

Range of PCB Assembly Services | They offer many services like finding parts, making samples, and testing. |

Lead Times and Scalability | They finish orders fast and can handle big or small jobs. |

Technical Support and Communication | They give updates and answer questions quickly. |

Benlida does all these things well. You get strong quality checks, quick orders, and clear updates. Many people trust Benlida for both small and big jobs.

Tip: Always ask about a manufacturer's certificates and how they check quality before starting your project.

Collaboration and Continuous Improvement

Working together with your manufacturer gives better results. You can give feedback, fix problems fast, and make your products better. Benlida likes to talk openly and work as a team. This helps you get the best results for every order.

Here are ways working together helps the process:

Strategy | Contribution to Process Improvement |

|---|---|

Continuous Training | Workers learn new skills and make fewer mistakes. |

Lean Production | They waste less and make work steps better. |

Process Monitoring | They spot and fix mistakes early, so products are good. |

Supplier Management | They work with good suppliers to get the best parts on time. |

Benlida helps you at every step. The team listens and changes when you need it. Because they always try to get better, your boards are always high quality.

When you pick Benlida for PCB & PCBA Manufacturing Services, you get a partner who wants you to do well.

You can get good and reliable PCB SMT assembly if you follow best practices at every step. These steps help you put parts in the right place, keep machines working well, and stop problems before they start. The table below shows how best practices help your products last longer:

Benefit | Description |

|---|---|

Precision | Putting parts in the right spot lowers mistakes. |

Equipment Maintenance | Taking care of machines helps them work better. |

Defect Prevention | Doing things early helps products work longer. |

Cost Efficiency | Fewer problems save money and keep your good name. |

If you work with skilled partners like Benlida, you get good help and strong results. Use these tips to make better products. If you need more help, contact Benlida to see how they can help with your next project.

FAQ

What is SMT assembly?

SMT assembly is when you put electronic parts right on top of a printed circuit board. Machines do this job quickly and very accurately. This way, you can make smaller and stronger devices.

How do you prevent common SMT defects?

You need to check if the solder paste is good. Use stencils that are clean and set up machines the right way. You look at boards with AOI and X-ray tools. Keep your work area clean and control static. These steps help you stop most problems.

Why should you choose Benlida for PCB & PCBA Manufacturing Services?

You get new machines, strong quality checks, and fast shipping. Benlida helps with technical questions and lets you order any amount. The team cares about quality and what customers need.

How long does PCB assembly usually take?

You can get your order done quickly. Benlida can finish most jobs in just five days. The time depends on your design and how big your order is.

What types of PCBs can Benlida produce?

You can buy multi-layer, HDI, ceramic, LED/aluminum, flexible, and rigid-flex PCBs. Benlida has options for many uses and different industries.

en

en

WhatsApp

WhatsApp