The Role of Flexible PCBs in Automotive Electronics and Smart Dashboards

Automotive electronics have evolved dramatically over the past decade, moving from simple control circuits to complex networks that manage safety, entertainment, energy efficiency, and connectivity. As vehicles become smarter and more integrated, the electronic architecture behind them must adapt to meet new challenges.

One of the key innovations driving this transformation is the Flexible Printed Circuit Board (Flexible PCB or FPC). Combining lightweight construction with exceptional durability and design freedom, flexible PCBs enable the seamless integration of electronic systems into modern automotive interiors, particularly curved dashboards, infotainment modules, lighting controls, and advanced driver-assistance systems (ADAS).

Benlida Circuit, a specialist in high-reliability FPC manufacturing, has developed flexible PCB solutions that meet the automotive industry's stringent requirements for performance, safety, and thermal stability. Their circuits are engineered to withstand over 100,000 flex cycles, function in temperature extremes from -40°C to 150°C, and fit into compact, irregular spaces where traditional rigid boards cannot.

1. The Automotive Electronics Revolution

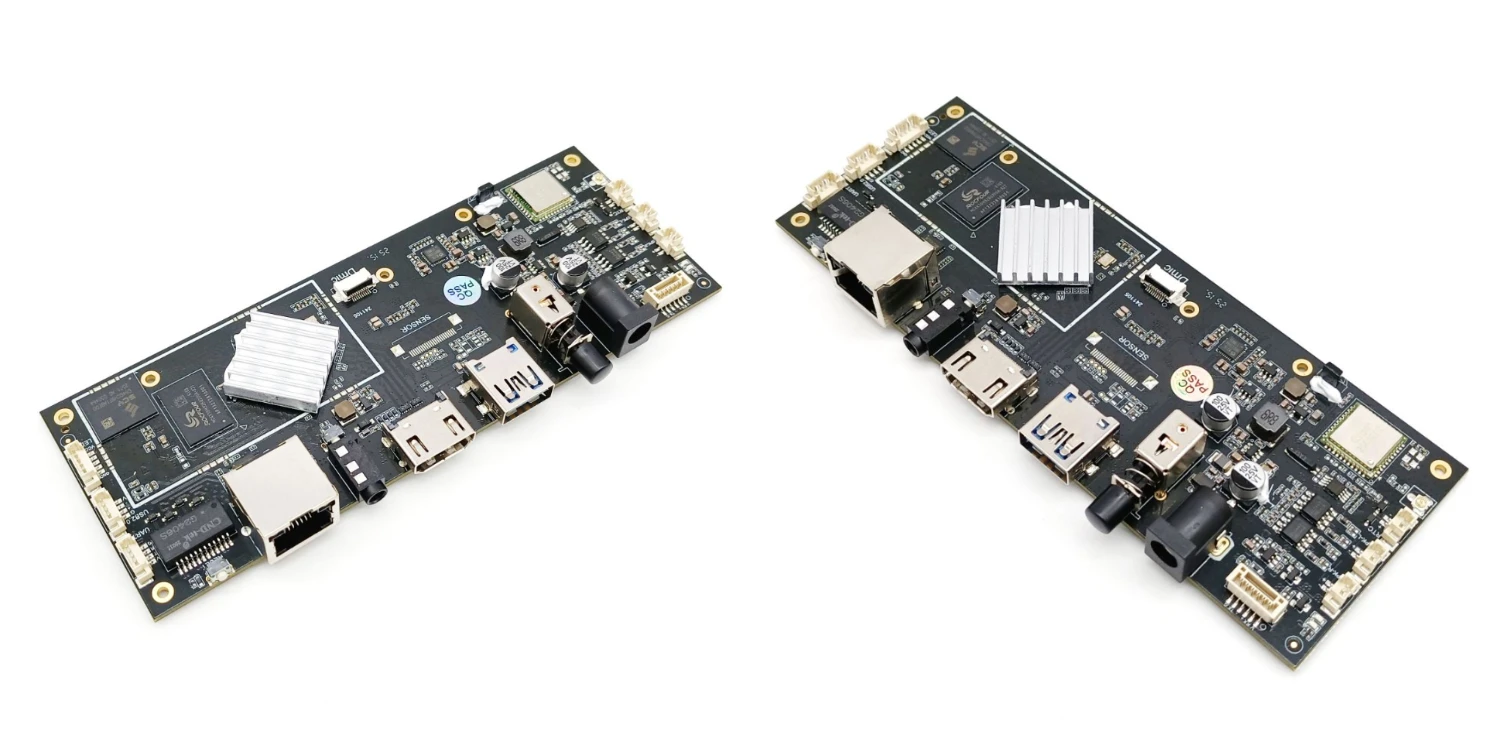

Today’s vehicles are essentially computers on wheels. They incorporate dozens of electronic control units (ECUs), digital instrument clusters, LED lighting systems, and smart dashboards—all interconnected through high-speed data networks.

With the rise of electric and autonomous vehicles, these systems are growing even more complex. Engineers need circuit solutions that are thin, light, and adaptable while maintaining exceptional reliability under vibration, heat, and motion.

This is where Flexible PCBs offer a decisive advantage. By eliminating bulky wire harnesses and allowing circuit traces to bend and conform to the vehicle’s shape, they simplify assembly, reduce weight, and increase design possibilities.

2. Why Flexible PCBs Excel in Automotive Applications

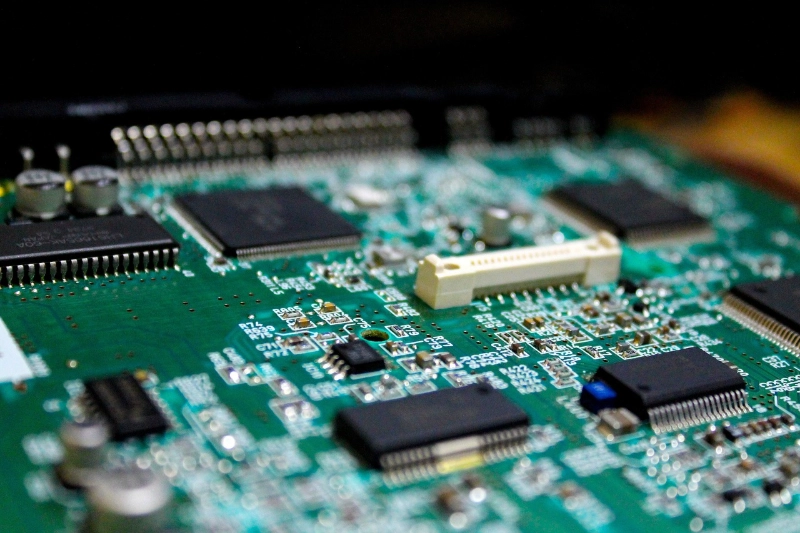

Flexible PCBs are constructed from polyimide (PI), PET, or PTFE materials that allow continuous bending and folding without fracture. Benlida’s advanced designs provide the mechanical endurance and electrical precision required for automotive electronics.

Key performance advantages include:

Flexibility and shape adaptability: Ideal for curved dashboard surfaces and compact control panels.

High temperature resistance: Stable operation in engine bays and infotainment zones.

Lightweight structure: Contributes to fuel efficiency and better EV range.

Reliability under vibration: With fewer connectors and solder joints, there are fewer potential failure points.

Superior signal integrity: High-density interconnect (HDI) patterns minimize interference for high-speed data lines.

By enabling three-dimensional electronic designs, flexible circuits make modern automotive interiors not only more functional but also sleeker and safer.

3. Smart Dashboards: The Perfect Fit for Flexible PCBs

One of the most visible transformations in automotive electronics is the smart dashboard—a central hub that combines display systems, sensors, lighting, and touch interfaces.

Rigid PCBs limit the dashboard’s curvature and layout. In contrast, Benlida’s flexible PCBs allow engineers to route circuitry around complex contours, integrate lighting modules directly into the panel, and connect touch sensors and displays without excessive connectors.

Advantages in dashboard applications include:

Integration of multiple functions (display, lighting, sensors) into one assembly.

Support for thin, continuous, and curved display designs.

Reduction in wire harness complexity, improving assembly efficiency.

Consistent performance under temperature fluctuations and mechanical stress.

Flexible PCBs thus enable the elegant, minimalist dashboard designs that define modern vehicles while maintaining electrical reliability.

4. Enhancing Vehicle Performance and Safety

Beyond aesthetics, flexible circuits also play an important role in functional and safety-critical automotive systems.

Applications include:

Lighting Systems: Adaptive headlights, taillights, and ambient interior lighting rely on flexible PCBs for compact and reliable LED control.

Sensor Integration: Radar, LIDAR, and camera modules in ADAS systems require flexible interconnects with precise signal integrity.

Battery Management Systems (BMS): In electric vehicles, flexible PCBs provide lightweight, heat-resistant interconnections between cells.

Infotainment and Connectivity: High-speed data transfer for multimedia systems benefits from low EMI flexible circuits.

Benlida's high-density flexible PCBs use 50μm line widths to ensure minimal signal loss—critical for applications involving real-time communication, sensor data, and control signals.

5. Reliability in Harsh Environments

Automotive electronics must operate reliably across years of use, exposed to heat, cold, moisture, and vibration. Benlida’s flexible PCBs are tested and validated for extreme environmental durability, ensuring consistent performance across challenging conditions.

Environmental resilience includes:

Temperature resistance from -40°C to 150°C

Moisture and dust protection through advanced lamination and surface finishes

Vibration absorption due to material flexibility

Long life expectancy even under repetitive motion

By reducing connectors and mechanical joints, flexible circuits simplify design and minimize weak points—enhancing safety and service life.

6. Manufacturing Precision at Benlida Circuit

Benlida’s automotive-grade FPCs are produced using advanced facilities and precision fabrication processes.

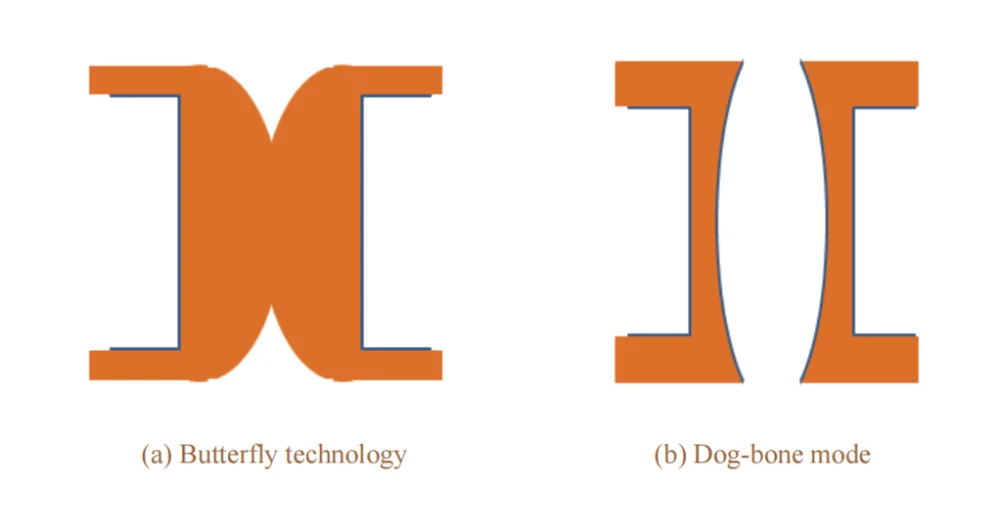

Key specifications:

Layers: 1–12

Copper Thickness: 0.5oz–1oz

Min. Hole Size: 0.05mm–0.1mm

Surface Finishes: ENIG, Immersion Silver, OSP

Finished Thickness: 0.1mm–0.3mm

Min. Trace/Space: 0.10mm / 0.10mm

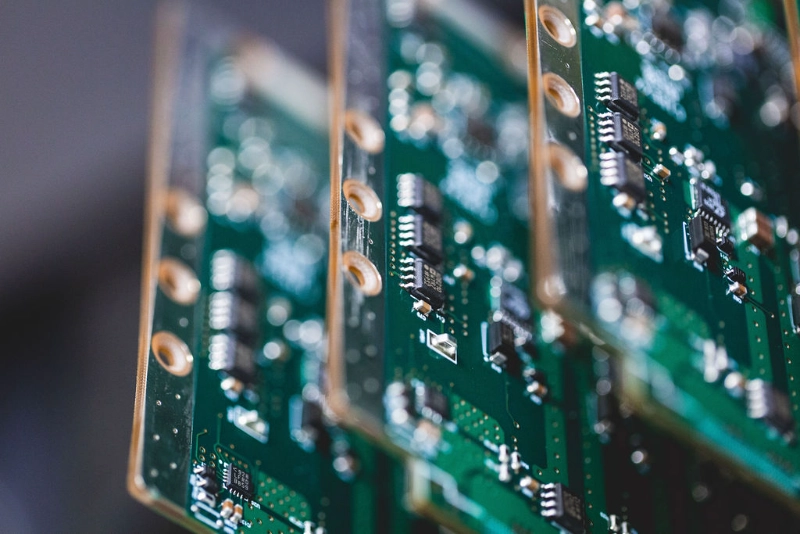

Each board is manufactured with tight dimensional control and undergoes testing for mechanical endurance, electrical continuity, and environmental performance. This ensures compliance with automotive reliability standards while enabling customized solutions for OEM and Tier 1 suppliers.

7. Lightweight and Sustainable Design

The shift toward electric vehicles (EVs) and sustainability has made weight reduction and energy efficiency central design priorities.

Flexible PCBs contribute by replacing heavy wire harnesses with lightweight printed conductors, helping automakers reduce vehicle mass and improve power efficiency. In EV battery management and in-cabin electronics, every gram saved translates into extended driving range and improved efficiency.

Furthermore, flexible circuits simplify disassembly and recycling processes by minimizing part count and connector usage—supporting eco-friendly design strategies.

8. The Future: Flexible PCBs in Next-Gen Mobility

As automotive innovation accelerates, flexible PCBs will continue to expand into new domains:

Autonomous vehicle sensor networks requiring high-speed data transmission.

Integrated lighting surfaces that merge aesthetics with functionality.

Transparent and flexible displays for next-generation dashboards.

Smart seating and interiors with embedded electronics for comfort and safety.

Benlida's ongoing development of multi-layer flexible PCBs and hybrid rigid-flex designs ensures readiness for these emerging trends, enabling automakers to integrate more electronics into smaller, more adaptable spaces.

Conclusion

From the curvature of a dashboard to the precision of a sensor module, flexible PCBs are redefining automotive electronics. Their combination of thinness, durability, and design flexibility supports both the aesthetic and functional evolution of modern vehicles.

With proven performance across temperature extremes, vibration, and continuous motion, Benlida’s flexible PCB technology provides automakers with the foundation for smarter, safer, and more efficient designs.

As the automotive industry continues its transition to electrification and intelligent mobility, flexible circuits will remain the hidden enablers behind every curved display, adaptive light, and intelligent control system.

en

en

.webp)

WhatsApp

WhatsApp