PCB Circuit Board Material Properties: Thermal, Electrical, and Mechanical Considerations

You must pick the right pcb material so your pcb circuit board works well and lasts long. Heat can make electrical strength go down, which can hurt how well it works. If materials grow at different speeds, heat and cold can make layers pull apart. The mechanical strength of a pcb helps it take stress and keeps it working for a long time. Benlida uses new ways to make boards that fit these needs, so you can trust every material you pick.

Key Takeaways

Pick PCB materials that move heat away well. This stops the board from getting too hot. It also helps your circuit board last longer.

Use materials with a high glass transition temperature (Tg) for tough places. High Tg materials keep their shape and work well when temperatures change.

Think about the dielectric constant when picking PCB materials. A lower dielectric constant lets signals travel faster. This is very important for fast and high-frequency uses.

Make sure your PCB has high insulation resistance. This stops electricity from leaking out. Test your PCB often to find problems early.

Choose materials that are strong and can bend a little. This helps your PCB handle bumps and tough weather.

Thermal Properties of PCB Circuit Boards

Thermal Conductivity in PCB Material

It is important to know about thermal conductivity in your pcb. This property shows how well a pcb material moves heat away from hot spots. If you use your pcb in things like LED lights or power electronics, you need a material that spreads heat fast. This keeps your parts cool and working right.

Here is a table that lists the thermal conductivity for common pcb materials:

Material | Thermal Conductivity (W/m·K) |

|---|---|

FR4 | 0.2 - 0.5 |

Polyimide | 0.3 - 0.5 |

Alumina | ~20x FR4 |

Aluminum Nitride | ~100x FR4 |

Beryllium Oxide | >100x FR4 |

If you pick a material with higher thermal conductivity, your pcb will handle heat better. This means your board is less likely to get too hot and will last longer. In fast and high-frequency devices, you need to watch this property closely. Too much heat can hurt the traces and make your board stop working. Benlida uses special ways to pick the right material for each job, so your pcb works well in all situations.

Heat Resistance and Board Longevity

Heat resistance is another important thing to look for in a pcb material. The glass transition temperature, or Tg, tells you how much heat a material can take before it changes shape or gets weak. If you use your pcb in hard places, like airplanes or defense, you need a high Tg material.

PCBs with high Tg materials do not get damaged easily by temperature changes. This is important for boards that need to be very reliable.

High Tg values give your pcb better thermal stability. Your board will not break down quickly when it gets hot.

High-Tg pcbs keep their shape even when it is hot. This helps your electronics last longer.

You need high Tg materials for electronics that must work well for a long time.

You can measure heat resistance with tests like the guarded hot plate or the 3-omega method. These tests check how well your pcb material handles heat. Benlida uses strict rules for testing, so you get a pcb that is safe and works well.

Managing Thermal Stress in Printed Circuit Boards

Thermal stress can cause many problems in your pcb. When your board heats up and cools down, different materials grow and shrink at different speeds. This can make cracks, broken connections, or even layers peel apart. You want to stop these problems to keep your pcb working well.

Here are some common problems caused by thermal stress:

Failure Mode | Description |

|---|---|

Solder Joint Fatigue | Heating and cooling many times makes small cracks in solder joints. |

Via and PTH Cracking | Different growth rates can break vias or plated through holes, especially during fast temperature changes. |

Delamination | Too much heat can make layers come apart, which makes the board weak. |

Component Failure | Heat stress can hurt parts, making your pcb stop working sooner. |

You can control thermal stress by picking the right pcb material and using smart design. Benlida uses materials with high thermal conductivity, thermal vias, and heat sinks to spread heat. The team also uses thermal simulation tools to find hot spots before making your board. These steps help you get a pcb that stays strong and works well, even in hard places.

Tip: If you want your pcb to last longer, always pick materials with good thermal properties and work with a company like Benlida that uses advanced ways to manage heat.

Electrical Properties of PCB Material

Dielectric Constant and Signal Integrity

It is important to know about the dielectric constant in your pcb. The dielectric constant, or Dk, shows how much electrical energy a pcb material can hold. If the dielectric constant is lower, signals move faster on your pcb. This is very important for fast digital and RF designs. If you use a material with a high dielectric constant, signals can slow down and get weaker. This can make signal integrity worse, especially in high-frequency circuits.

Here is a table that lists the dielectric constant range for common pcb materials:

Material | Dielectric Constant Range |

|---|---|

FR-4 | 4.2 to 4.8 |

Ceramic | 3 to 10 |

PTFE | Approximately 2.1 |

When you pick a pcb material with a lower dielectric constant, signals move faster and lose less strength. For example, if you lower the Dk from 4.0 to 2.5, signal speed can go from about 50% to 63% of the speed of light. This is a big change for high-speed and high-frequency uses. You need to choose the right material to keep your signal integrity strong and your pcb working well.

Tip: Always pick a dielectric constant that fits your design. This helps keep your signals strong and your board working right.

Insulation Resistance in PCB Circuit Boards

Insulation resistance tells you how well your pcb stops electricity from leaking between traces. High insulation resistance means your board blocks unwanted current and keeps circuits safe. In important fields like aerospace or medical devices, you need at least 1 megaohm (MΩ) of resistance for every 1,000 volts.

Many things can make insulation resistance go down over time. High humidity can cause reactions that eat away metal traces. This lowers resistance and can make short circuits. Dendritic growth, which happens in wet places, forms tiny metal branches that connect traces and cause problems. If the air around your pcb has more than 60% humidity, the risk of failure goes up. At 80% humidity or more, the danger is much higher.

You can use the Temperature Humidity Bias Test (THB) to see how your pcb handles heat, moisture, and voltage stress. If insulation resistance drops below one million ohms in this test, moisture has started to hurt your board. Voltage and moisture together can move metal ions and make paths for current, which raises leakage. Over time, these breakdowns can burn spots on your pcb and make permanent paths for current.

High insulation resistance keeps circuits safe.

Humidity and voltage stress can lower resistance and cause problems.

Regular testing helps you find issues before they get worse.

Electrical Stability in Different Environments

Your pcb needs to stay stable in many places. Changes in temperature, moisture, corrosion, vibration, and electromagnetic interference can all affect electrical stability. Each thing can cause different problems for your pcb.

Environmental Factor | Impact on PCB Stability |

|---|---|

Temperature Fluctuations | Can make solder joints crack and fail from heating and cooling. |

Moisture | Can break down dielectric properties and cause Electromigration. |

Corrosion | Can damage copper traces and solder joints, making them thin or open. |

Vibration | Can cause stress and even physical damage. |

Electromagnetic Interference (EMI) | Can create unwanted currents and mess up signals in fast circuits. |

You might see short circuits, broken traces, or power failures if your pcb material cannot handle these stresses. Bad soldering, poor etching, or not enough copper can also cause electrical problems. You need to pick materials that keep their properties in tough places. This helps your pcb work well and last a long time.

Benlida uses strong testing and careful checks to make sure every pcb meets high standards for electrical performance. You get boards you can trust, even in hard places.

Note: Always think about where your pcb will be used. Pick materials that protect against moisture, heat, and vibration to keep your signals and electrical properties strong.

Mechanical Properties of Printed Circuit Boards

Strength and Durability of PCB

You want your pcb to stay strong when it bends or gets pulled. The strength and durability depend on the mechanical properties of the pcb material you pick. If you choose a strong laminate, your board will not crack or break easily. Here is a table that shows how much pulling force common materials can take:

Material | Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|

FR-4 | 70 - 415 | N/A |

Polyimide | 231 (room temp), 139 (200°C) | N/A |

Ceramic | N/A | N/A |

Tensile strength means how much force a pcb can take before it snaps. Polyimide stays strong even when it gets hot. FR-4 works for many uses because it has a wide range of strength. If your pcb has high strength, it can handle drops, shocks, and shaking.

Flexibility and Environmental Resistance

Flexibility lets your pcb bend without breaking. This is important for things that move or twist. Polyimide is a good choice for flexible boards. Environmental resistance means your board can handle heat, cold, and wet places. Here is a table that shows how different properties help your pcb last in tough spots:

Mechanical Property | Influence on Durability in Vibration |

|---|---|

Flexural Strength | Shows how well the board bends without damage. |

Tensile Strength | Tells how much pulling force the board can take. |

Peel Strength | Shows how well layers stick together. |

Moisture Absorption | Low absorption keeps the board stable and reliable. |

When the temperature goes up and down, your pcb gets bigger and smaller. This can hurt solder joints and make parts not last as long.

If your pcb gets wet for a long time, the epoxy glass and resin can get weak and crack.

High humidity makes your pcb soak up water, which can cause short circuits and more leaks.

Hot places make your pcb take in water faster, which can change how it works and make leaks.

Handling and Assembly Considerations

You need to think about how you will handle and put together your pcb. Picking the right material can stop warping, bending, and other problems when you build your board. Here is a table that shows common problems and ways to fix them:

Mechanical Challenge | Mitigation Strategy |

|---|---|

Warped or Bent Components | Place parts to lower stress. Use flat leads. Make footprints for heat changes. Add fasteners for heavy parts. Use a balanced layout. Add thermal relief for big connections. |

PCB Warpage | Use balanced layers. Pick materials that stay the same size and do not change much with heat. Choose materials that work well in hot places. |

When you pick the right material, it is easier to build your pcb and it works better. This helps your board work in many places and keeps your devices working well.

Tip: Always pick a pcb material that fits your needs. This makes your board strong, flexible, and reliable for real-life use.

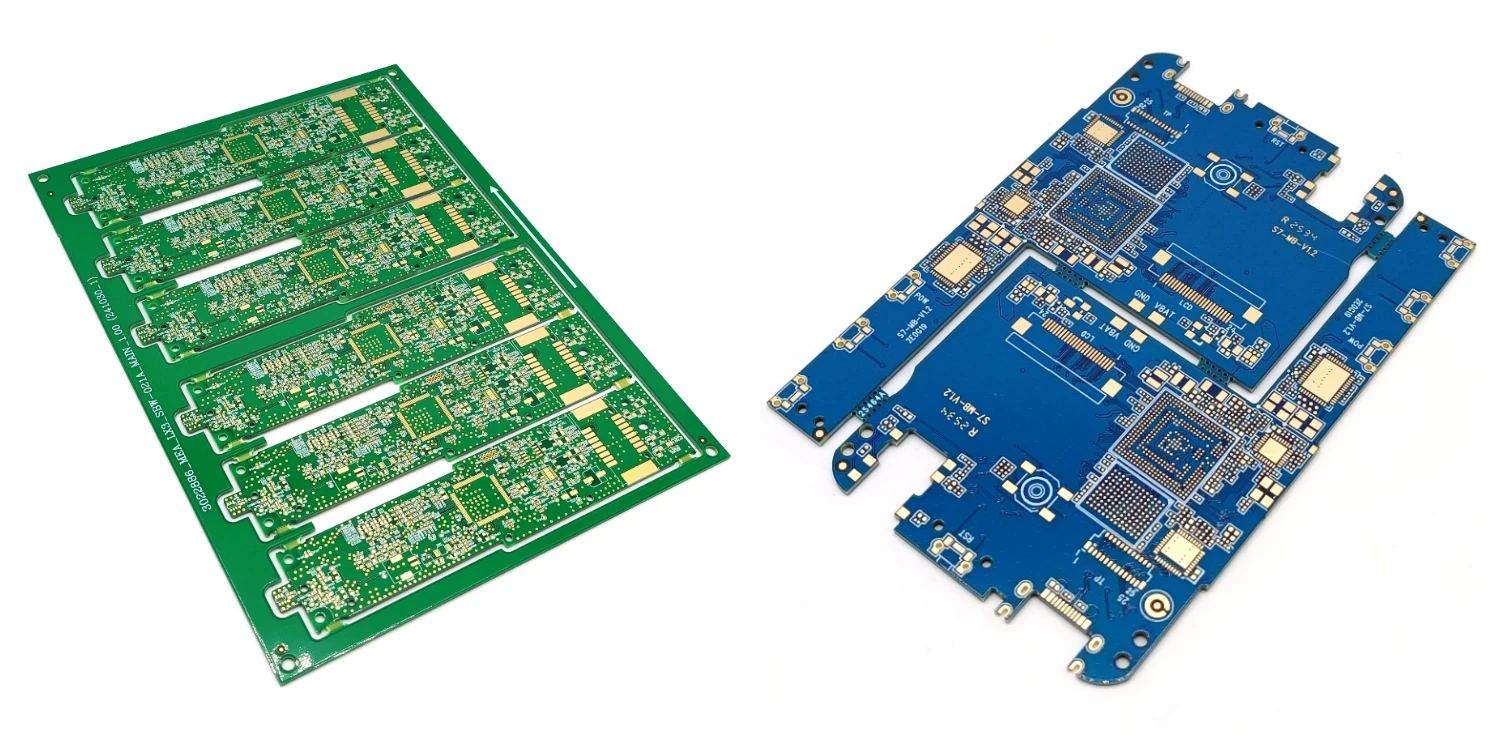

PCB Material Comparison

FR-4: Standard PCB Substrate

FR-4 is a very common pcb material. You find it in things like phones, laptops, and home gadgets. FR-4 prepreg and laminates give strong insulation and good strength. They also do not catch fire easily. These features make FR-4 a good choice for cars, control systems, and even planes. The mix of fiberglass and epoxy helps balance cost, safety, and how well it works. FR-4 can handle tough places and keeps your pcb working right.

FR-4 is strong and safe, so it is great for most electronics.

Polyimide: High-Temperature PCB Material

Polyimide is used when you need a pcb for very hot places. Polyimide prepreg and laminates keep their shape and work well above 250°C. They have great thermal stability and strong mechanical strength. Polyimide also resists chemicals and keeps its electrical properties in many temperatures. This material is best for harsh and hot places where other materials might fail. You see polyimide in cars, planes, and factories that need boards to last a long time.

Polyimide has high dielectric strength and low signal loss.

It fights off chemicals and works in hard places.

Ceramic: Advanced PCB Circuit Board Solutions

Ceramic is a top-level pcb material. You use ceramic when your board needs to handle 350°C to over 800°C. Ceramic moves heat away very well, sometimes up to 180 W/m·K. This helps your board stay cool better than other materials. Ceramic does not expand much, so it fits well with silicon chips and lowers stress. It gives great electrical insulation, even with high heat and voltage. You find ceramic pcbs in RF systems, power electronics, and places with lots of shaking or bumps.

Performance Metric | Ceramic PCB | FR-4 PCB | Polyimide PCB |

|---|---|---|---|

Thermal Conductivity | Very high | Low | Moderate |

Max Temperature (°C) | 800+ | 130-140 | 250+ |

Electrical Insulation | Excellent | Good | Excellent |

Mechanical Strength | High | Good | High |

Benlida has many pcb material choices. They offer fr-4 prepreg and laminates, polyimide prepreg and laminates, and advanced ceramic boards. You can trust Benlida to help you pick the best material for your needs.

Application-Specific PCB Solutions

High-Frequency PCB Circuit Boards

High-frequency boards need special materials. These materials help signals move fast and stay strong. You should look for a low and steady dielectric constant. A low dissipation factor means less energy is lost. High thermal conductivity helps heat move away quickly. These things keep your signals clear and your board cool. The table below shows what is important for high-frequency boards:

Property | Description |

|---|---|

Dielectric Constant (Dk) | Low and steady Dk keeps signals fast and strong. |

Dissipation Factor (Df) | Low Df means less energy is lost and better performance. |

Coefficient of Thermal Expansion | Low CTE stops layers from coming apart when it gets hot or cold. |

Thermal Conductivity | High thermal conductivity helps heat move away fast. |

Moisture Absorption | Low moisture absorption keeps electrical properties steady. |

Glass Transition Temperature (Tg) | High Tg gives better thermal stability. |

Benlida uses advanced materials for high-frequency pcb circuit boards. You get boards you can trust for fast data and RF uses.

High-Temperature PCB Material Selection

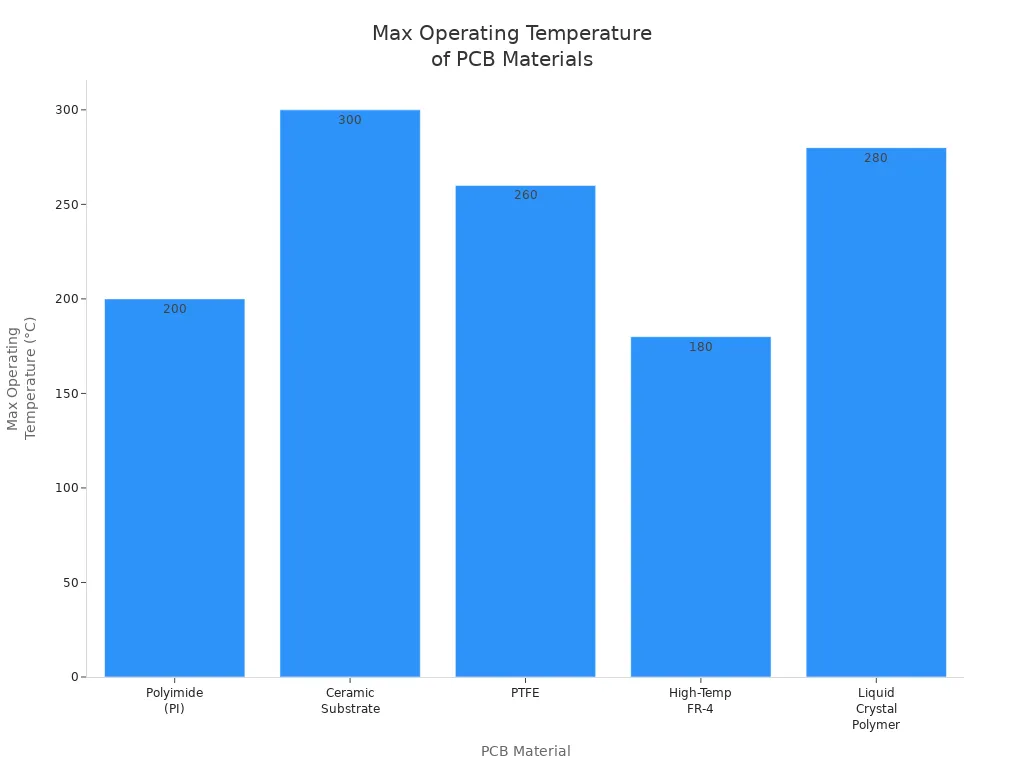

Boards that get very hot need strong materials. Polyimide, ceramic, PTFE, and high-temperature FR-4 work well in heat. These materials keep their shape and work even when it is hot. The chart below shows how much heat each material can take:

Material | Max Operating Temperature | Features |

|---|---|---|

Polyimide (PI) | 200°C or higher | Great heat resistance, strong, bends easily, and resists chemicals. |

Ceramic Substrate Materials | >300°C | Very high thermal conductivity and heat resistance. |

PTFE | 260°C (short-term) | Low dielectric constant, good for high-frequency uses. |

High-Temperature FR-4 | 170-180°C | Good insulation and saves money. |

Liquid Crystal Polymer (LCP) | >280°C | Low moisture absorption, steady size, and great for high-frequency. |

Benlida helps you pick the best material for hot places. You get boards that last and stay safe.

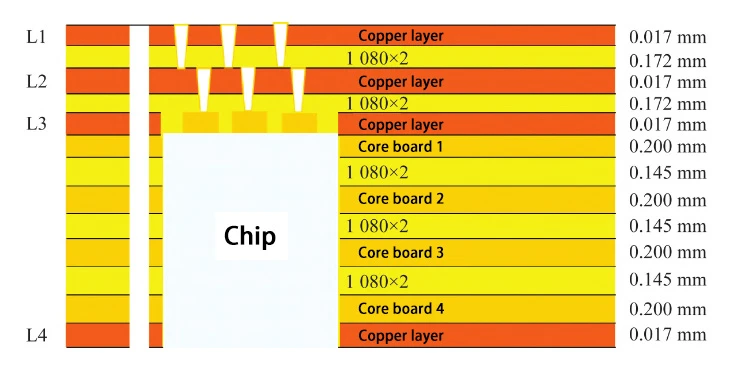

Flexible and Rigid-Flex PCB Applications

Some devices need boards that bend or fit in small spaces. Medical and car companies use these boards for many things. Flexible boards use polyimide film so they can bend and stay strong with chemicals. Rigid boards use FR4 and polyimide laminates for strength. Copper foil makes the paths for electricity. Coverlay protects the flexible parts. Adhesives hold the layers together.

Medical: Wearable monitors, hearing aids, and surgery tools.

Automotive: Sensor arrays, dashboard lights, and driver systems.

Benlida makes flexible and rigid-flex boards for your needs. You get boards that work well in tough places.

Tip: Pick the right material for your project. Benlida gives you special solutions for every industry.

When you pick a pcb circuit board, you should think about a few key things. The table below lists what is most important:

Factor | Description |

|---|---|

Electrical Performance | Dielectric properties, signal integrity, thermal conductivity, and thermal expansion. |

Mechanical Properties | Flexibility, rigidity, tensile strength, layer count, and board thickness. |

Environmental Resistance | Moisture resistance, chemical resistance, flammability ratings, and operating temperatures. |

Cost | Manufacturing ease, fabrication techniques, and material availability. |

Compliance with Standards | IPC, RoHS, and industry-specific requirements. |

If you match these things to what you need, your board will last longer. It will also work better. You can ask Benlida for help and get good solutions.

FAQ

What is the most common PCB material?

FR-4 is used in most PCBs. It is strong and does not catch fire easily. FR-4 also gives good insulation. You see it in phones, computers, and control systems.

How do you choose the right PCB material for high temperatures?

Pick polyimide or ceramic for hot places. These materials do not change shape when heated. They work well in cars, planes, and factories.

Why does thermal conductivity matter in PCB design?

Thermal conductivity helps heat move away from hot spots. If your material has high thermal conductivity, your board stays cool. This helps your board last longer. It is important for power electronics and LED devices.

Can flexible PCBs handle tough environments?

Yes, flexible PCBs use polyimide film. These boards bend and stay strong. They also resist chemicals. You can use them in medical devices and cars.

en

en

WhatsApp

WhatsApp