Automotive Applications: How Ceramic PCB Handles Extreme Conditions

Introduction: The New Demands of Automotive Electronics

The modern automotive industry has evolved from mechanical engineering to advanced electronics integration. Electric vehicles (EVs), autonomous driving systems, and intelligent sensors rely on high-performance circuit boards that can handle heat, vibration, voltage stress, and environmental exposure.

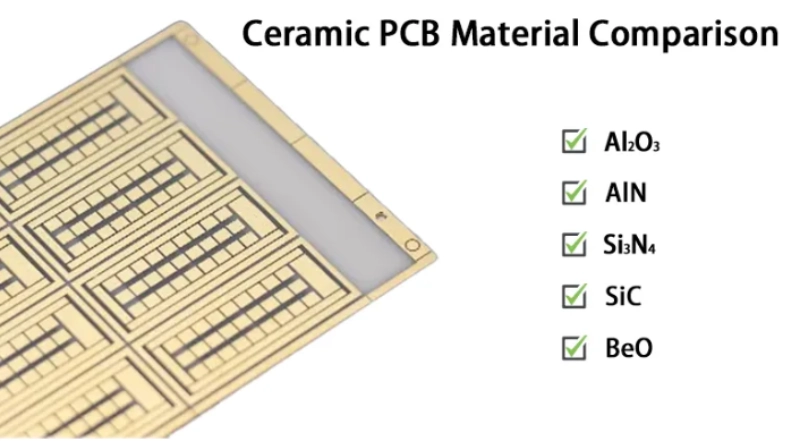

Traditional FR4 PCBs are insufficient in such demanding conditions. This has led to the rise of Ceramic Printed Circuit Boards (PCBs) — engineered with Alumina (Al₂O₃), Aluminum Nitride (AlN), or Silicon Carbide (SiC) substrates — which combine thermal conductivity up to 220 W/m·K and operating stability from –55°C to over 800°C.

These characteristics make ceramic PCBs the material of choice for automotive power modules, battery management systems, radar sensors, and LED headlights operating under extreme environments.

Why Automotive Electronics Need Ceramic PCBs

The shift toward electric and intelligent vehicles has introduced new challenges: higher current flow, faster data transmission, and compact thermal packaging. In these systems, thermal management and electrical reliability determine safety and performance.

Ceramic PCBs address these challenges through:

Superior heat dissipation for power conversion circuits.

Stable electrical insulation under high voltage and frequency.

Resistance to vibration and corrosion.

Dimensional stability across wide temperature ranges.

With these properties, ceramic substrates enable the creation of smaller, more powerful, and more durable electronic systems for automotive use.

1. Unrivaled Thermal Management in Power Modules

The heart of any electric vehicle lies in its inverter, converter, and motor drive — all of which operate under intense heat conditions. FR4 and metal-core boards quickly reach their thermal limits, leading to performance degradation or failure.

In contrast, AlN-based ceramic PCBs offer thermal conductivity between 140–220 W/m·K, allowing direct and efficient heat transfer from power semiconductors such as IGBTs or MOSFETs to the heatsink.

Key Benefits for Power Modules:

Lower junction temperatures.

Higher energy efficiency and stability.

Compact designs without additional cooling hardware.

This efficiency is one reason why automotive OEMs and Tier 1 suppliers increasingly specify AlN ceramic boards in EV traction systems and high-power DC/DC converters.

2. Extreme-Temperature Stability for Reliability

Automotive electronics are exposed to drastic temperature swings — from freezing cold starts to under-hood conditions exceeding 150°C. Ceramic PCBs excel in maintaining electrical insulation and mechanical integrity under such stress.

Al₂O₃ substrates provide good stability for control modules and sensors.

AlN and SiC substrates perform flawlessly in extreme environments like EV charging systems or engine control units (ECUs).

Ceramic materials also have a low coefficient of thermal expansion (CTE), closely matching that of silicon chips. This minimizes stress on solder joints and prevents delamination or cracking during thermal cycling — a major advantage over FR4 boards.

3. High-Frequency Performance for ADAS and Radar

Modern vehicles rely heavily on radar, LiDAR, and communication systems operating in the 24–77 GHz frequency range. These high-frequency circuits require materials with minimal dielectric loss and stable signal transmission.

Ceramic PCBs, especially AlN and SiC, maintain a low dielectric constant (~8.8) and low loss tangent (~0.0003), ensuring minimal signal attenuation. This allows radar sensors and communication modules to perform with exceptional accuracy, reliability, and range.

Applications include:

Adaptive cruise control radar.

Blind-spot detection systems.

Vehicle-to-vehicle (V2V) communication.

4. Ultra-High Density and Miniaturization

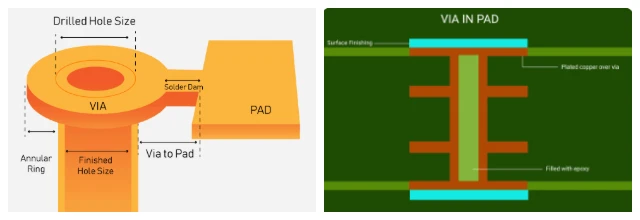

Automotive design trends demand more functionality in smaller spaces — from compact sensor arrays to integrated control units. Ceramic PCBs support fine-line metallization and multilayer stacking using DPC (Direct Plated Copper) and thick-film techniques.

This enables:

High-density interconnects (HDI) for compact modules.

Precise circuitry for mixed-signal and RF designs.

Enhanced component integration without thermal compromise.

As a result, ceramic substrates allow automotive engineers to build smaller, lighter, and more efficient electronic assemblies.

5. Zero Degradation in Harsh Environments

Automotive electronics face constant exposure to vibration, moisture, and chemical agents. Ceramic PCBs, being inorganic and chemically inert, exhibit zero degradation under such conditions.

Their robust construction ensures long-term reliability even in:

Engine compartments with oil and fuel exposure.

Brake and transmission systems with mechanical vibration.

Exterior sensors exposed to humidity, salt, or UV radiation.

This resilience ensures the stable performance of critical systems like ABS modules, transmission controllers, and safety sensors.

6. High Voltage and Current Reliability

Ceramic substrates exhibit dielectric strength exceeding 15 kV/mm, making them ideal for high-voltage automotive systems, including battery management units (BMUs) and on-board chargers (OBCs).

They also handle large current flows efficiently, supporting high-voltage architectures in EVs without the risk of breakdown or dielectric failure. This combination of electrical insulation and thermal conductivity allows for compact, efficient, and safe designs.

Manufacturing Techniques for Automotive-Grade Ceramic PCBs

The reliability of automotive ceramic PCBs depends heavily on the manufacturing process. The most common techniques include:

Direct Bonded Copper (DBC): Creates a strong, thermally efficient bond between copper and ceramic for high-power circuits.

Direct Plated Copper (DPC): Allows fine-line circuit creation, ideal for compact radar and control modules.

Thick-Film Printing: Integrates resistors, conductors, and capacitors directly on the ceramic layer.

Each process requires tight quality control to ensure adhesion, conductivity, and stability. Benlida Circuit, a specialist in advanced ceramic PCB manufacturing, employs all three methods to deliver customized automotive-grade solutions.

Learn more about their capabilities at Benlida's Ceramic PCB product page.

Real-World Applications in Automotive Systems

Electric Vehicle Inverters: Efficiently manage heat generated by high-power IGBT modules.

Battery Management Systems (BMS): Provide electrical isolation and stable operation under varying charge cycles.

Radar and Communication Modules: Ensure high-frequency reliability with low dielectric loss.

LED Headlights: Maintain brightness and lifespan through superior heat dissipation.

Charging Stations and OBCs: Enable safe high-voltage operation and power conversion.

Conclusion

Ceramic PCBs have become a cornerstone of automotive innovation, ensuring performance, reliability, and safety in extreme conditions. Their ability to withstand high temperatures, manage heat efficiently, and deliver precise electrical performance sets them apart from traditional substrates.

As vehicles continue to evolve toward electrification and autonomy, ceramic PCB technology will play an even greater role — empowering the future of intelligent mobility.

Benlida Circuit stands at the forefront of this transformation, providing Al₂O₃, AlN, and SiC-based PCBs tailored to automotive, industrial, and aerospace applications.

To explore how ceramic technology can enhance your automotive electronics, visit Benlida's Ceramic PCB solutions.

en

en

WhatsApp

WhatsApp