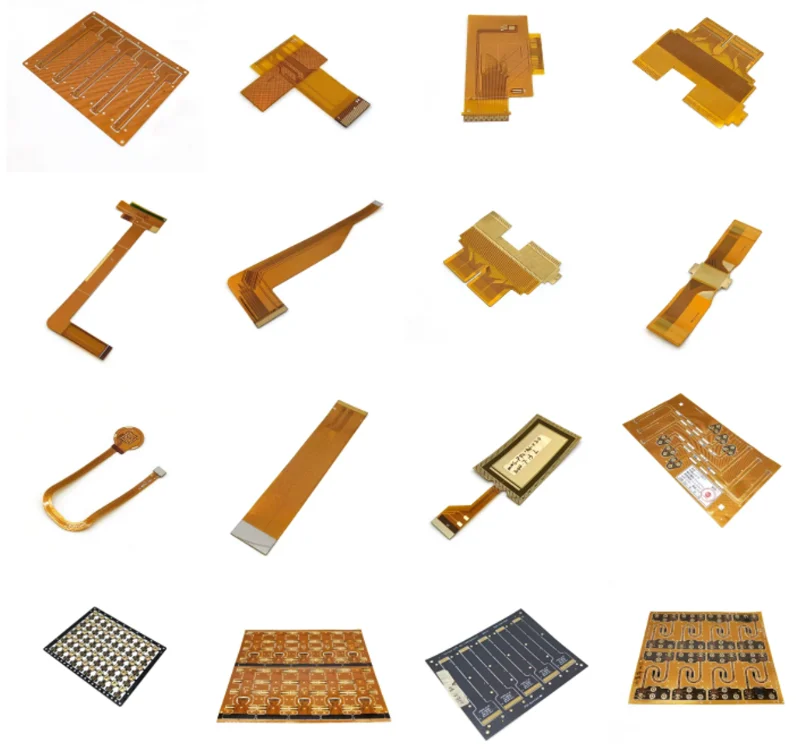

Exploring Flexible PCB Technology: Strength, Reliability, and Endless Possibilities

Modern electronics demand designs that are thinner, lighter, and more adaptable than ever before. From wearable health sensors to advanced automotive systems, innovation often begins at the circuit level. Flexible PCBs have emerged as a cornerstone of next-generation electronics, providing engineers with the unique ability to bend, fold, twist, and integrate circuitry into spaces traditional rigid PCBs cannot reach.

Benlida Circuit has become a leader in this transformation, manufacturing flexible circuit solutions engineered to endure continuous stress and extreme environments. With the ability to withstand over 100,000 flex cycles, operate from -40°C to 150°C, and fit into irregular 3D spaces, Benlida’s flexible printed circuits support innovation across industries from healthcare and consumer electronics to aerospace and automotive engineering.

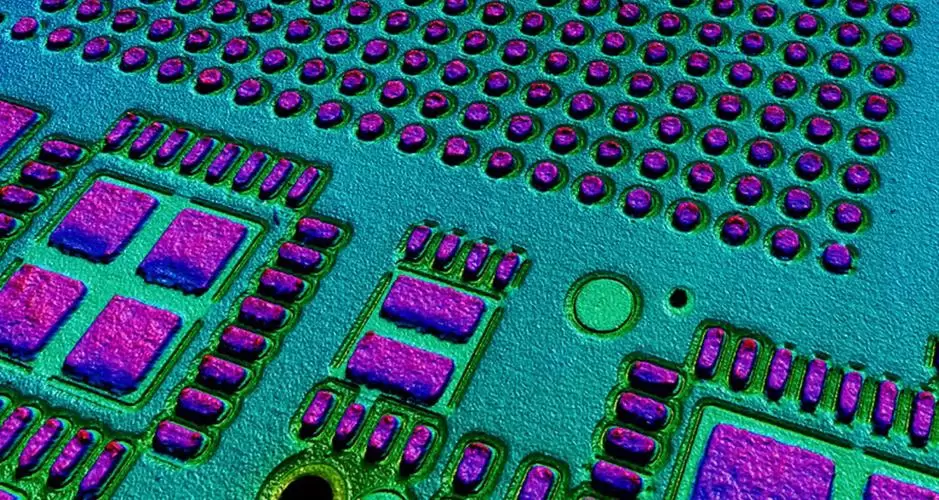

Understanding Flexible PCB Technology

A flexible printed circuit board (Flexible PCB or FPC) uses a polyimide, PET, or PTFE base material instead of rigid fiberglass. This provides mechanical flexibility without compromising electrical performance.

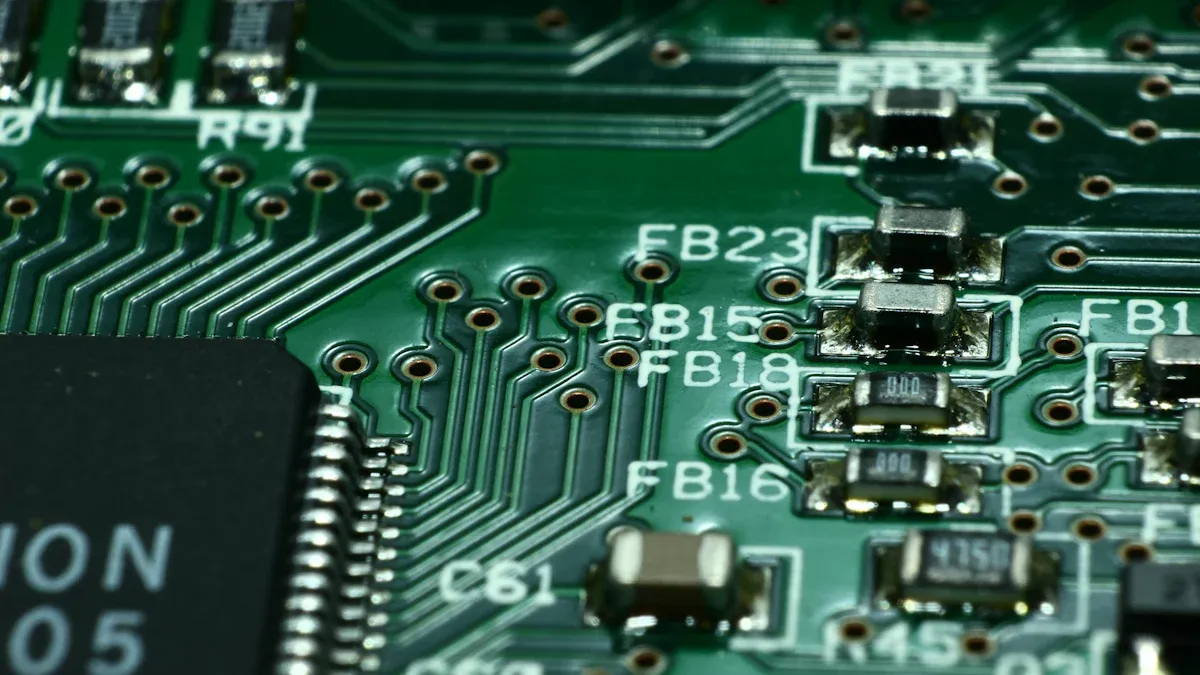

Key production capabilities include:

Layer options from 1 to 12 layers

Copper thickness 0.5oz – 1oz

Minimum trace/space 0.10mm / 0.10mm

Min. hole size 0.05mm – 0.1mm

Finished thickness as thin as 0.1mm

Surface finish options: ENIG, Immersion Silver, OSP

These specifications enable high-density circuits suitable for compact, precision-driven devices.

To explore complete product options and customization opportunities, visit the category page:

<a href="https://www.benpcb.com/pcb-category/flexible-pcb.html">Benlida Flexible PCB Solutions</a>

Built for Dynamic, Real-World Applications

Flexible PCBs excel where rigid boards simply cannot perform. They support designs in motion, environments under stress, and installations with irregular geometries.

1. Mechanical Flexibility and Durability

Benlida designs flexible PCBs that endure:

Repeated bending cycles

Vibration and shock

Dynamic motion in wearable devices and robotic assemblies

In folding phones and AR glasses, circuits must flex continuously without fracture. In medical implants, movement inside the body requires extremely reliable mechanical performance. Benlida’s flexible boards are engineered to function through demanding mechanical cycles while maintaining electrical stability.

2. 3D Spatial Design Freedom

A major advantage of flexible circuits is their ability to route through tight or unusual spaces. This supports:

Curved automotive dashboards

Miniature surgical tools

Drone and satellite avionics

Smart textiles and skin-mounted electronics

Instead of forcing the electronics to fit the board, engineers can now shape boards to fit the product.

3. Lightweight and Thin Construction

Thicknesses as low as 0.05–0.3mm give flexible boards a significant advantage in applications where size and mass matter. In aerospace and drone designs, reduced board weight translates to improved efficiency and payload capability. Smaller medical devices also benefit, allowing more compact implants and diagnostic tools.

Performance Under Extreme Conditions

Flexible PCBs are not only about freedom of movement—they deliver reliability in demanding environments.

Benlida solutions offer:

Operating range from -40°C to 150°C

Resistance to moisture, chemicals, and vibration

Reduced connectors and solder joints, lowering failure risk

In aviation electronics or pacemakers, reliability is essential. Eliminating wiring harnesses and rigid connectors reduces points of failure and ensures signal stability where it matters most.

High-Frequency and Signal-Critical Uses

In 5G systems, RF modules, and medical equipment, signal performance can determine system accuracy. Benlida’s flexible PCBs maintain:

Tight impedance control

Minimal EMI interference

Stable high-speed data transmission

HDI structures with micro traces (50µm) support advanced digital and RF architectures, delivering clarity and reliability even in mission-critical applications.

Industry Applications of Flexible PCBs

Flexible PCBs continue to shape emerging and mature industries alike.

Healthcare

Implantable medical devices

Bio-patches and diagnostic sensors

Wearable monitors

Consumer Electronics

Foldable smartphones and tablets

Smart wearables and glasses

Compact audio and portable devices

Automotive and EV

Curved dashboards and displays

Battery management systems

Sensor and safety modules

Aerospace and Defense

Lightweight avionics

Satellite power systems

Rugged communications hardware

Across all these sectors, flexible boards support miniaturization, mobility, and rugged reliability.

Manufacturing Precision and Material Selection

Quality flexible circuits require cleanroom processes, advanced copper bonding, and precise layer lamination. Benlida engineers utilize PI, PET, and PTFE substrates selected for thermal, mechanical, and electrical performance. Surface finishes like ENIG and silver immersion support corrosion resistance and solder reliability for long-term field use.

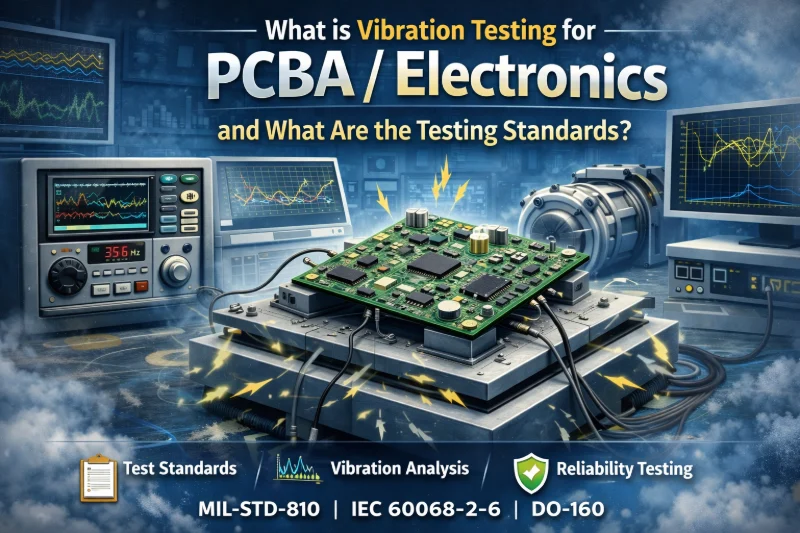

Rigorous testing includes:

Flex cycle fatigue benchmarks

Thermal shock and vibration qualification

Impedance and EMI verification

Microvia inspection and dimensional accuracy testing

These processes ensure every project meets demanding international reliability standards.

Why Engineers Choose Benlida Flexible PCBs

Benlida brings engineering support, manufacturing depth, and quality control to every order, supported by years of PCB expertise across flexible, rigid-flex, and high-density circuit solutions.

Core value points include:

Precision engineering and customization

Dedicated technical consultation

Controlled manufacturing and inspection processes

Ability to scale from prototypes to high-volume production

For innovators, the combination of materials expertise, precision manufacturing, and flexibility in design unlocks possibilities that rigid PCBs alone cannot achieve.

Final Thoughts

Flexible printed circuits are changing how engineers build electronics. They make possible the next generation of smaller, smarter, and more adaptable technology. From foldable consumer devices to life-sustaining medical instruments, flexible PCBs are more than a design choice—they are a foundation for modern engineering.

Benlida Circuit continues to advance flexible PCB manufacturing with systems tuned for reliability, electrical performance, and real-world durability. As applications grow more ambitious, materials science and PCB design will move in parallel, allowing products to shrink, strengthen, and perform where they never could before.

en

en

WhatsApp

WhatsApp