Beyond Bending Limits: Flexible Circuits That Withstand 100,000 Flex Cycles

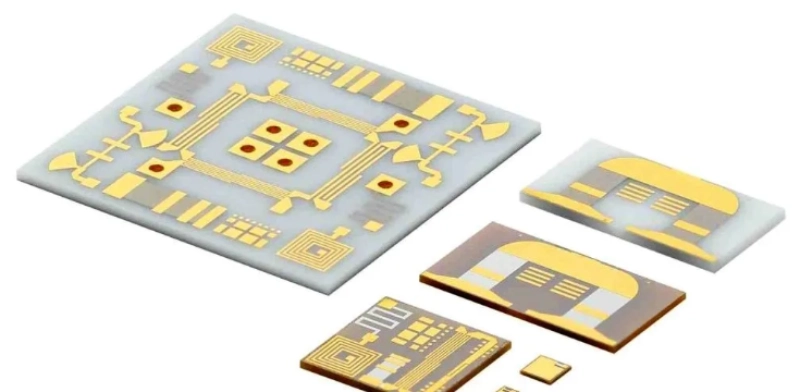

In today’s world of compact, mobile, and wearable electronics, design flexibility isn’t just a convenience—it’s a necessity. Devices are getting smaller, lighter, and more sophisticated, requiring internal components that can adapt to motion, vibration, and tight geometries. Traditional rigid printed circuit boards (PCBs) can’t meet these challenges. The solution lies in Flexible Printed Circuit Boards (Flexible PCBs or FPCs)—engineered to endure extreme mechanical stress while maintaining flawless electrical performance.

Benlida Circuit, a global manufacturer of high-reliability flexible PCBs, has perfected the science of durability. Its FPCs are designed to withstand over 100,000 flex cycles without failure, empowering engineers to create products that move, fold, and twist—without compromising performance. From wearable sensors to folding smartphones and curved automotive dashboards, Benlida’s technology ensures reliability in motion.

1. The Evolution of Flexibility in Electronics

Modern electronics have evolved beyond rigid geometries. From fitness trackers to aerospace sensors, engineers are constantly seeking ways to reduce weight, eliminate wiring harnesses, and increase reliability. This evolution has driven the demand for flexible circuits—thin, lightweight, and capable of dynamic movement.

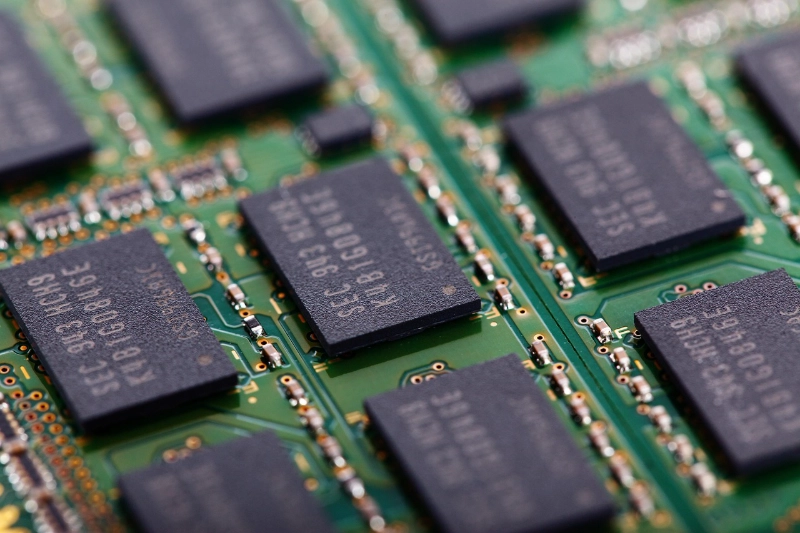

Flexible PCBs replace traditional fiberglass substrates with polyimide (PI), PET, or PTFE films, enabling circuits to bend, fold, and wrap around curved surfaces. Benlida’s circuits are specifically engineered to endure repetitive motion without delamination, fracture, or conductivity loss.

To explore available flexible PCB configurations and applications, visit:

Benlida Flexible PCB Solutions

2. Engineering That Defies Fatigue

What makes Benlida’s flexible PCBs exceptional is their ability to survive more than 100,000 bend cycles while maintaining signal integrity. This endurance is achieved through meticulous material selection and precise manufacturing techniques.

Key durability factors include:

High-grade substrates: Polyimide and PET layers designed for continuous motion.

Optimized copper adhesion: Prevents cracking during flexing.

Tight mechanical tolerances: Ensure even stress distribution across the circuit.

Advanced lamination techniques: Enhance peel strength and reduce micro-cracks.

This combination allows Benlida’s circuits to perform reliably in dynamic environments where other PCBs would fail.

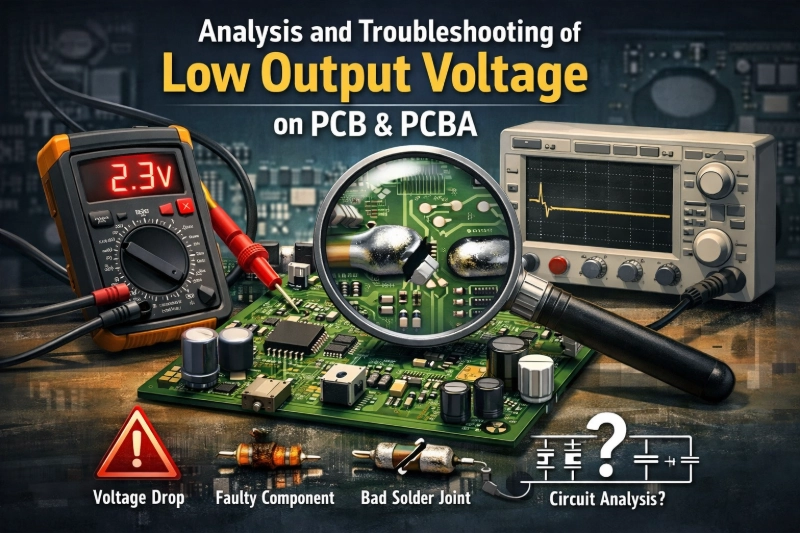

3. Mechanical Endurance Meets Electrical Precision

Durability alone isn’t enough—modern flexible circuits must also deliver high electrical performance. Benlida achieves this through high-density interconnect (HDI) design, ensuring low resistance, minimal electromagnetic interference (EMI), and excellent signal integrity.

Key electrical specifications include:

Trace/space: 0.10mm / 0.10mm

Copper thickness: 0.5oz–1oz

Min. hole size: 0.05mm–0.1mm

Surface finishes: ENIG, Immersion Silver, OSP

Layer options: 1–12 layers

These design parameters enable Benlida’s FPCs to power 5G communication modules, medical diagnostic devices, and compact industrial control systems that require stable high-speed data transmission.

4. Designed for Real-World Motion

The phrase “bend, fold, or roll” defines the spirit of flexible electronics. Devices today are no longer static; they move, adapt, and change shape with the user.

Benlida’s flexible circuits thrive in:

Wearable sensors and health monitors: Continuous bending during physical activity.

Folding smartphones and tablets: Dynamic hinge movements demanding extreme reliability.

Automotive electronics: Integration into curved dashboards and lighting systems.

Aerospace and drones: Lightweight and vibration-resistant circuitry.

The ability to withstand continuous flexing without degradation makes these circuits the foundation of innovation in every sector where movement is part of design.

5. Operating Under Extreme Conditions

Reliability extends beyond motion—Benlida’s flexible PCBs also perform flawlessly in harsh environmental conditions. They are tested to function in temperatures ranging from -40°C to 150°C and resist moisture, dust, and vibration.

This resilience makes them suitable for medical implants, automotive systems, and industrial automation—applications where stability under stress can mean the difference between success and failure.

Performance highlights:

Temperature tolerance for automotive and aerospace use.

Resistance to moisture and contaminants for long service life.

Shock and vibration stability for mobile and transport systems.

6. Lightweight, Space-Saving Design

One of the biggest advantages of flexible circuits is their ability to replace bulky wiring harnesses and reduce overall device size and weight.

Benlida’s flexible PCBs measure as thin as 0.05–0.3mm, reducing the need for multiple connectors and rigid interconnects. This not only saves space but also improves mechanical performance and simplifies assembly.

Practical benefits include:

Greater design freedom for compact or curved enclosures.

Lower assembly complexity and improved reliability.

Enhanced thermal dissipation in confined designs.

For portable and wearable devices, this reduction in bulk translates directly into better comfort, efficiency, and longevity.

7. Precision Manufacturing for Reliability

Benlida’s flexible PCBs are manufactured under strict process control to ensure precision and repeatability.

Manufacturing capabilities include:

Material options: PI, PET, PTFE

Finished thickness: 0.1mm–0.3mm

Color: Customizable per project requirements

Multi-layer lamination: Up to 12 layers for complex circuits

Each circuit undergoes mechanical fatigue testing, thermal cycling, and signal verification to confirm its performance under real-world conditions. The result is a product that exceeds expectations in both endurance and functionality.

8. Applications Across Industries

Benlida’s flexible circuits are trusted across a range of demanding applications:

Consumer Electronics

Folding smartphones

Smartwatches and wearables

Compact IoT devices

Automotive

Curved dashboards and lighting systems

EV battery management circuits

ADAS and infotainment units

Medical Technology

Implantable devices

Health monitoring patches

Portable diagnostic systems

Aerospace and Industrial

Lightweight avionics

Sensor integration

Robotics and control panels

In each of these industries, flexible PCBs are not just components—they’re enablers of innovation, allowing smaller, lighter, and more reliable electronic systems to become reality.

9. The Future of Flexible Endurance

As electronics continue to evolve, durability and adaptability will remain key design priorities. Flexible PCBs will be at the heart of this evolution, bridging the gap between performance and flexibility.

Benlida’s ongoing advancements in material science, process engineering, and multi-layer flexibility will continue to push the limits of what circuits can endure—setting new benchmarks for mechanical resilience and electrical precision.

In a world where technology bends to human needs, Benlida’s flexible PCBs ensure that performance bends—but never breaks.

en

en

WhatsApp

WhatsApp