Advanced Printed Circuit Materials: Innovations and Developments in PCB Substrates

You see new changes in printed circuit materials. These changes are making electronics better. Recent reports show big growth:

The global PCB market will be about $75 billion in 2024.

HDI PCBs are growing faster than other types.

Asia is growing the most, but North America is also doing well in special areas.

New flexible boards and advanced laminates help devices last longer. They also help devices work better, even when things move fast or get tough. Companies like Benlida use these new ideas to make strong solutions for your next project.

Key Takeaways

Advanced printed circuit materials help devices work better. They keep signals strong and lower heat problems.

Flexible and rigid-flex PCBs let designers create new shapes. These are used in wearables and small electronics. They make products last longer.

Eco-friendly PCB materials help cut down on waste. They also lower pollution. This is good for the planet and helps products last.

Automation in PCB manufacturing makes work faster and better. It helps make more products quickly and saves money.

Picking a trusted partner like Benlida gives you new materials. You also get the latest technology for your projects.

Innovations in Printed Circuit Materials

High-Frequency Substrates

High-frequency substrates are changing how electronics are made. These materials help devices send signals faster and clearer. Devices like 5G phones and radar systems work better with them. Advanced computers also use these materials for better performance. High-frequency substrates use special materials to keep signal loss low. This helps devices work well, even with lots of data. Benlida makes high-frequency PCB solutions with these advanced substrates. Their team can help your projects meet tough performance needs.

Flexible and Rigid-Flex Materials

Flexible and rigid-flex materials let you build electronics in new ways. You can bend, twist, or fold these boards and they still work. This is great for wearables, medical tools, and smart gadgets. Rigid-flex PCBs mix strong and bendable layers. This keeps your devices tough and reliable. They last in places with lots of shocks or shaking. These boards can bend many times, so wearables last longer.

Recent breakthroughs in flexible and rigid-flex PCB materials include:

High-precision processing and low-dielectric loss materials lower signal loss.

New polymer technology lets devices handle higher heat.

Bigger and more flexible PCBs help with larger uses.

More parts and embedded components make performance better.

Hybrid circuits and optical PCB technology give new design choices.

Printed electronics integration brings new solutions for many industries.

Benlida uses these new Printed Circuit Materials to make boards for your needs. You get products you can trust for simple or complex projects.

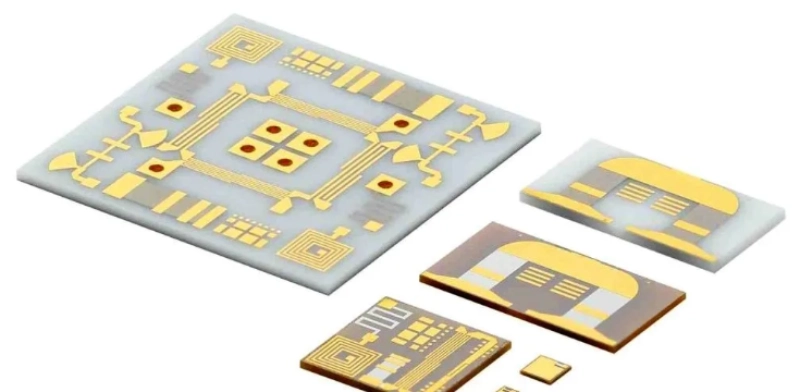

Nanocomposites and Advanced Polymers

Nanocomposites and advanced polymers change how people use Printed Circuit Materials. These substrates have tiny particles that make boards stronger and better. You get stronger boards, better heat control, and improved electrical features. This means PCBs can be smaller, lighter, and more reliable.

Here is a table showing some important advancements:

Advancement Type | Description |

|---|---|

Flexible Substrates | Polyimide-based materials let you bend PCBs for wearables and new designs. |

Rigid-Flex Substrates | Mix flexible and rigid layers to keep boards strong and adaptable. |

Nanocomposite Materials | Add nanoparticles to make PCBs stronger, cooler, and better for small designs. |

Benlida uses these advanced Printed Circuit Materials in their process. You get the newest technology for your projects. Their experience helps you make products that stand out.

Tip: Using advanced Printed Circuit Materials makes your device faster, tougher, and gives you more design choices. Benlida can help you find the best solution for your needs.

Impact on Device Performance

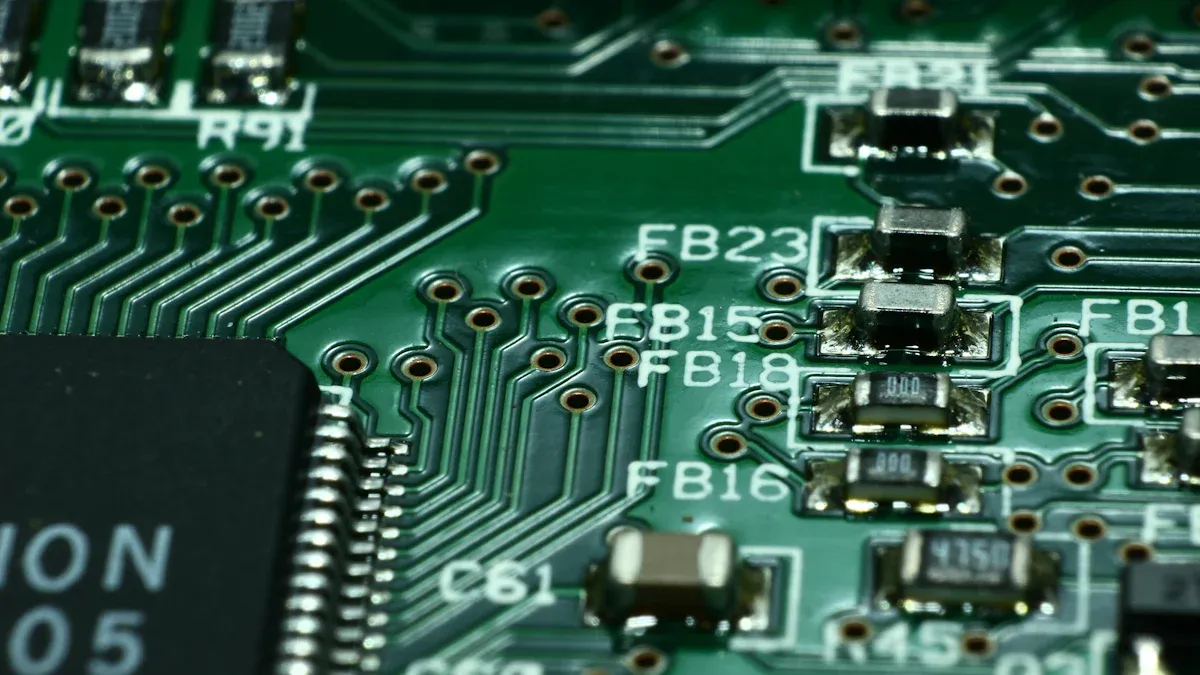

Signal Integrity

You want your devices to be fast and correct. Signal integrity is very important for this. Signals need a clear path in the circuit. Advanced Printed Circuit Materials help keep signals strong and clean. High-speed devices like computers and 5G phones work better because of this.

Some things affect signal integrity:

Impedance control stops signals from bouncing and making mistakes.

Signal reflections happen if the path is not smooth, causing problems.

Crosstalk is when signals mix and make noise.

Ground bounce and switching noise can change voltage and cause errors.

Timing jitter and skew make signals arrive at the wrong time.

You should also think about these properties:

Property | How It Affects Signal Integrity |

|---|---|

Dielectric Constant (Dk) | Lower Dk lets signals move faster in fast designs. |

Loss Tangent (Df) | Lower Df means less signal loss and less change. |

Thermal Stability | Stable materials keep things steady, even when it gets hot or cold. |

Moisture Absorption | Low moisture keeps the board working in many places. |

Mechanical Strength | Strong materials protect signals, especially in flexible PCBs. |

Studies show signal loss goes up at higher frequencies. Rough copper can cause up to 38% of signal loss. You can help signals by picking smooth copper and the right substrate.

Tip: If you want your device to send data fast and right, focus on signal integrity. Benlida uses advanced materials and careful design to help you reach your goals.

Thermal Management

Heat can hurt your electronics. Good thermal management keeps devices safe and working longer. You need materials that move heat away from important parts. Where you put parts on the board also helps control heat.

Here are some ways to manage heat:

Use materials with high thermal conductivity, like ceramics and metal cores.

Place parts and traces to spread heat across the board.

Add thermal vias to move heat to other layers.

Use more copper surface area to help cooling.

Pick resins with looser fiber weaves for high-voltage designs.

Evidence Description | Explanation |

|---|---|

Spread heat across the board and use thermal vias and heat sinks. | Layout and placement help manage heat. |

Use higher resin content with looser fiber weave. | Material choice boosts thermal performance. |

Thermal vias move heat to the other side of the PCB. | This method improves heat dissipation. |

More copper surface area increases cooling. | Design choices make a big difference. |

Ceramic materials can move heat 20 to 100 times better than FR4. Metal core PCBs also help in tough places. PTFE laminates with metal cores work well for very high-frequency uses.

Note: If your device gets hot, you need the right materials and smart design. Benlida can help you pick the best options for your project.

Miniaturization and Density

You want smaller devices that do more things. Miniaturization and higher circuit density make this possible. New PCB substrates let you fit more circuits in less space. You can use HDI and MLB to add more features to your device.

Here are some ways advanced substrates help:

HDI and MLB designs allow more connections in small spaces.

MLBs connect layers with special circuits, making miniaturization easier.

IC substrates increase routing density and connect many cores.

Fine-line designs with pitches as small as 20µm let you add more circuits.

Extreme miniaturization helps make faster, smarter, and smaller devices.

Size reduction can shrink waste PCBs to 5 mm or less. Most metals are freed when the size drops to 2–5 mm. Shredding can make pieces as small as 3 mm, and pulverizing can reach 1 mm.

Callout: You can build powerful, small devices with the right Printed Circuit Materials. Benlida supports your designs with advanced solutions for miniaturization and density.

Applications of Printed Circuit Materials

5G and IoT Devices

You see many new devices today. Phones, smart watches, and sensors connect online. These devices talk to each other. They need fast and steady circuits. Advanced Printed Circuit Materials help them send data quickly. They also use less power. This means your device works better and the battery lasts longer. Benlida gives you high-frequency PCBs and flexible boards. You can use these in your smart home, factory, or city. You can trust these boards to work well.

Automotive and Aerospace

You want your car or airplane to be safe. These places can be very tough. Good PCB materials help with this. These boards handle heat, shaking, and chemicals. You get strong and steady circuits that last a long time. Benlida follows strict rules for safety and quality.

Here is a table that shows how advanced PCB materials help:

Evidence | Description |

|---|---|

AS9100 Standards | Extra rules for aerospace quality, making sure boards are reliable. |

FAA and EASA | Safety groups that set rules for airplane electronics. |

Quality Control | Careful planning and checking keep boards safe and working. |

You also get these good features:

High-performance materials help boards last longer and work better.

Polyimide and PTFE substrates stand up to heat and chemicals.

FR-4 with high Tg can handle very hot places.

Benlida uses these materials and checks them carefully. You get boards that work in cars, planes, and rockets.

Industrial and Consumer Electronics

You use electronics at home, work, and in factories. Advanced PCB materials make these devices faster and smarter. You get more features in a smaller space. Benlida makes boards for many things, like computers and smart TVs.

Here is a table with the main benefits:

Benefit | Description |

|---|---|

Enhanced Performance | Faster and more efficient systems for your needs. |

Increased Flexibility | Smaller designs fit in tight spaces. |

Improved Integration | Boards support many functions in one device. |

Reduced Power Consumption | Devices use less energy and work longer. |

You also see new ideas to make electronics greener. Some studies show new board materials can help devices last longer. They can also be easier to recycle. Researchers are testing new boards made from plants and things that break down naturally. These are not in stores yet, but they may help the planet soon.

Tip: You can pick Benlida for boards you can trust. Their experience helps your products work better and last longer.

Trends in PCB Manufacturing

Automation and SMT Assembly

Automation is changing how people make PCBs. Machines now put small parts on boards very fast. They are also very accurate. Some machines can place over 100,000 parts every hour. They can be right within 0.01mm. Laser direct structuring lets you put parts on curved boards. This gives you more ways to design things. Vapor phase soldering spreads heat evenly. This helps keep your board safe from heat damage.

Automation gives you many good things:

Benefit | Description |

|---|---|

Enhanced Efficiency | Machines work quickly and make more boards. |

Consistent Quality | Automated systems make fewer mistakes and keep quality high. |

Cost Savings | Less waste and fewer errors save money over time. |

Flexibility | You can change machines for new products or markets. |

Advanced PCB materials help machines work better. They let you load and place fragile parts with care. Automated solder paste keeps waste low and accuracy high. Machines test each board to check quality. You can follow each PCB as it is made. This helps you find problems early.

Quality Standards and Testing

You want your boards to work every time. Makers use many tests to check quality. Electrical testing checks if your board works right. Aging tests show how long your board will last. Laser detection finds tiny problems. Flying probe testing checks for issues without special tools. Hot oil tests see if solder joints can take heat. TDR impedance testing keeps signals strong. Solderability tests check if joints will hold. Microsection analysis looks inside the board for hidden problems.

Testing Method | Purpose |

|---|---|

Electrical Testing | Checks if the PCB works as it should. |

Aging Testing | Shows if the board will last a long time. |

Laser Detection | Finds tiny problems on or inside the PCB. |

Flying Probe Testing | Finds many problems without needing special tools. |

Hot Oil Test | Checks if solder joints can take heat. |

TDR Impedance Testing | Makes sure signals stay strong by checking impedance. |

Solderability Testing | Checks if solder joints are strong and reliable. |

Microsection Analysis | Looks inside the board for hidden problems. |

Continuity Testing | Checks that all paths on the PCB are complete. |

Solder Float Testing | Checks if the board stays flat and strong during soldering. |

Peel Test | Checks if copper traces stick well to the board. |

Accelerated Life Testing | Tests if the board will last under tough conditions. |

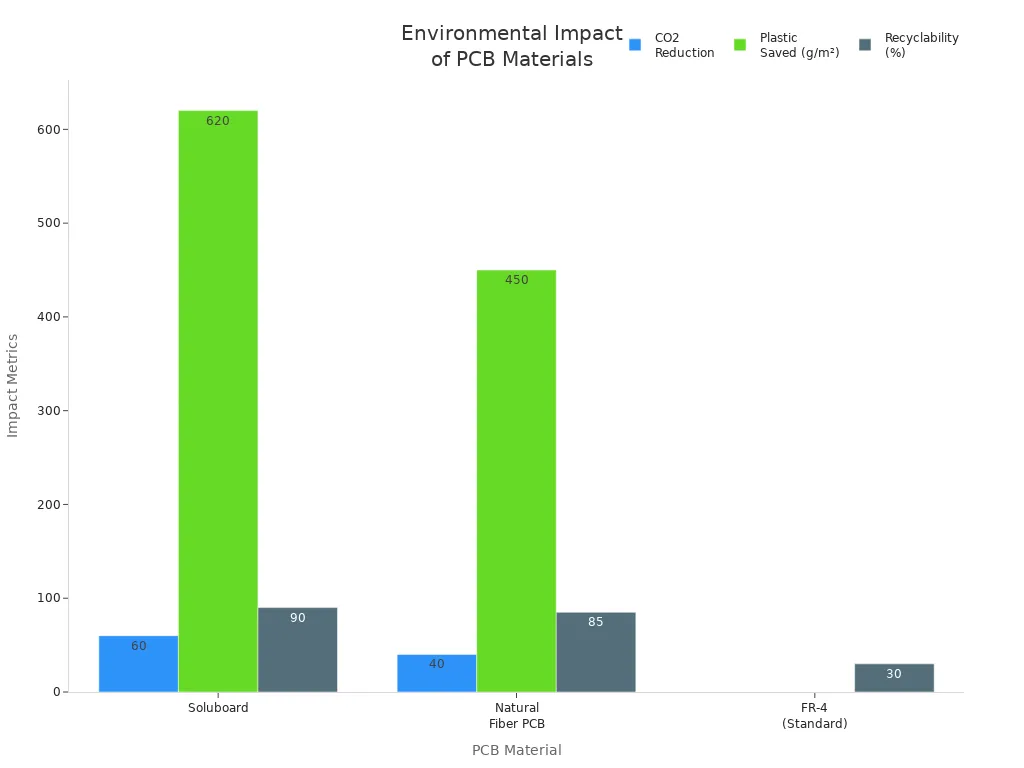

Sustainable Materials

You care about the Earth. New PCB materials help cut waste and pollution. Recyclad uses recycled stuff and works like halogen-free laminates. Soluboard is made from jute fiber and a polymer that breaks down, so it makes less e-waste. Papershell and CirEl use paper for boards, which helps use renewable things. Bamboo and wood-based PCBs use natural resources. Bio-based epoxy resins help make greener chemistry.

Using these materials lowers carbon and saves plastic. Soluboard cuts carbon by 60% and is 90% recyclable. Natural fiber PCBs save 450g of plastic for each square meter. Standard FR-4 boards recycle less than 30%.

Material | CO2 Reduction | Plastic Saved | Recyclability |

|---|---|---|---|

Soluboard | 60% | 620g/m² | 90% |

Natural Fiber PCB | 40% | 450g/m² | 85% |

FR-4 (Standard) | 0% | 0g/m² | <30% |

Tip: Picking green PCB materials helps the planet and makes better products for the future.

Future Directions

3D-Printed Electronics

You can make PCBs in new ways with 3D printing. This method builds circuits one layer at a time. Some new materials carry electricity almost as well as copper. Hybrid manufacturing mixes 3D printing with older methods. This makes boards stronger and gives you more choices. Some printers put tiny chips and wires in while printing. You can make smart devices faster and with fewer steps.

New conductive materials work almost like copper.

Hybrid manufacturing mixes 3D printing with old PCB methods.

You can add electronics while printing the board.

Tip: 3D-printed electronics let you make special shapes and features. You can design boards for things like wearables or sensors.

Eco-Friendly Substrates

You want to help the planet. Eco-friendly PCB substrates use materials that break down over time. These boards help cut down on waste. You may pay more for these boards. Biodegradable substrates cost two to three times more than regular FR-4, which costs about $0.50 for each square foot. These boards work a bit differently. Biodegradable materials have higher dielectric constants, usually between 4.0 and 5.0. High-frequency devices work best with lower values, around 2.5 to 3.5. You need to think about both how well the board works and how it helps the environment.

Biodegradable substrates cost more than regular FR-4.

Eco-friendly materials have higher dielectric constants.

You need to think about performance and the environment.

Note: Eco-friendly PCBs help you make greener products. You can show customers you care about the planet.

Integration with Emerging Technologies

Electronics are changing quickly. New PCB materials let you connect with smart systems, sensors, and wireless networks. You can use boards that work with artificial intelligence and machine learning. Flexible and high-frequency substrates help you build devices for 5G, IoT, and smart factories. You can fit more features in smaller spaces. Benlida gives you advanced materials and expert help. You get boards ready for new technology.

Technology | PCB Material Benefit |

|---|---|

5G & IoT | High-frequency, flexible PCBs |

AI & Machine Learning | Dense, reliable substrates |

Smart Factories | Durable, adaptable boards |

Callout: You can be a leader in electronics by picking advanced PCB materials. Benlida helps you stay ahead with new solutions.

You can see printed circuit materials changing quickly. These changes help your devices last longer and work better. Reports show some big trends:

HDI PCBs could be worth $40 billion by 2032.

AI and automation make PCB assembly smarter and faster.

Flexible and rigid-flex PCBs are used a lot in portable electronics.

People care more about the environment, so lead-free and energy-saving ways are important.

3D printing helps make new boards faster and makes less waste.

If you pick a trusted partner like Benlida, you get advanced solutions. Learn about new materials and trends to keep your projects ahead.

FAQ

What are advanced PCB substrates?

Advanced PCB substrates use special materials like polyimide, ceramics, and nanocomposites. These materials help your devices go faster and stay strong. They also help control heat better. Your devices can last longer and work well.

How do flexible PCBs help my project?

Flexible PCBs can bend and twist without breaking. You can put them in wearables, medical tools, and small gadgets. These boards save space in your designs. They let you make more creative products.

Why should I choose Benlida for PCB manufacturing?

Benlida gives you high-quality boards and quick service. Their team uses advanced materials and careful testing. You can trust your project will meet tough rules.

Are eco-friendly PCB materials reliable?

Eco-friendly PCB materials work well for many things. You help the planet when you pick them. These boards last a long time and support green technology.

What industries use advanced PCB materials?

You find advanced PCB materials in 5G devices, cars, airplanes, factories, and smart homes. These materials help electronics stay strong and work better.

en

en

WhatsApp

WhatsApp