Essential Materials Used in Modern Circuit Board Manufacturing

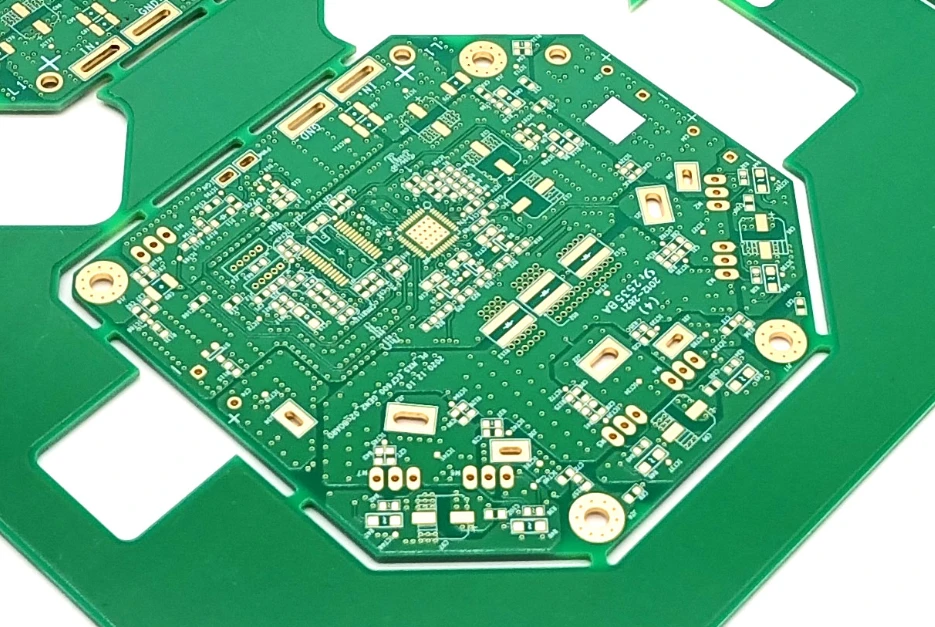

You will see many important materials in modern circuit board manufacturing. These include substrates like FR4, PTFE, and polyimide. Other materials are copper foil, laminates, prepreg, solder mask, silkscreen ink, adhesives, and solder alloys. The materials you pick affect how well the PCB handles heat. They also affect how strong it is and how it deals with electricity. Good materials help stop problems like tiny cracks and layers coming apart. These problems can make the board less reliable and cause it to fail more often. Benlida uses advanced ways to make circuit boards. This helps them meet industry standards and provide reliable products.

Trend | Description |

|---|---|

Advancements in High-Density and Flexible PCBs | New ideas in HDI and flexible boards help make electronics smaller. They also help them work better. |

Adoption of Automation and Digital Manufacturing | AI and robots make production faster. They also help control quality. |

Sustainability and Green Manufacturing Initiatives | Eco-friendly methods are used more now. This is because of rules and worries about the environment. |

Growth in Automotive and 5G Applications | More people want strong PCBs for electric cars and 5G devices. This pushes new ideas for heat control and signal quality. |

Benlida is a trusted partner. They have extensive knowledge and use top materials for every job in modern circuit board manufacturing.

Key Takeaways

Picking the best materials is very important for strong circuit boards.

Substrate materials such as FR4, PTFE, and polyimide help with heat and electricity.

Copper foil and laminates help make good electrical connections and keep boards strong.

Solder mask keeps PCBs safe from damage and stops short circuits.

Benlida gives expert help to choose materials that make your circuit boards work better and last longer.

Substrate Materials in Modern Circuit Board Manufacturing

Substrate materials are the base of every printed circuit board. These materials give your PCB strength and help it stay stable. They also help your board handle heat and electricity. Picking the right substrate helps your board last longer. It also helps your board work well in different places. Epoxy resin and glass fiber are used a lot. PTFE and polyimide are advanced materials. They have special features for high-performance electronics.

Benlida knows substrate selection is very important. You can choose from many high-quality substrates with Benlida. Their team helps you pick the best material for your project. This is true for simple boards and for complex ones.

FR4 and High-Performance Substrates

FR4 is the most common substrate in modern circuit board manufacturing. You find FR4 in many electronics, computers, and industrial devices. FR4 uses woven glass fiber and epoxy resin. It gives your board good strength and electrical insulation. FR4 resists moisture and heat. This makes it reliable for most uses.

High-performance substrates are better than FR4. You need these for boards that face very high temperatures or fast signals. Advanced epoxy blends and ceramics help your PCB work in tough conditions. Benlida gets these high-performance substrates for projects that need extra durability or special electrical properties.

Tip: If your PCB needs to work in tough places, ask Benlida about high-performance substrate choices.

PTFE and Polyimide Substrates

PTFE and polyimide substrates are used for high-frequency and flexible PCBs. PTFE is good when you need low signal loss and steady performance at high speeds. Polyimide works well for flexible circuits. It is used when the board needs to bend or twist.

Here is a table that shows how PTFE and polyimide compare. It lists dielectric constant and loss tangent. These numbers show how well each material handles electrical signals.

Material | Dielectric Constant (Dk) | Loss Tangent (Df) |

|---|---|---|

PTFE | 3.5 - 4.5 | 0.002 - 0.02 |

2.1 - 2.6 | 0.0001 - 0.002 | |

3.0 - 10.0 | 0.001 - 0.005 | |

Polyimide | 2.8 - 4.1 | 0.003 - 0.01 |

You also want to know how PTFE and polyimide compare for cost and performance. The table below helps you pick which material is best for aerospace and telecommunications.

Property | PTFE | Polyimide |

|---|---|---|

Dielectric Constant (Dk) | 2.5 to 10.2 | 2.8 to 4.1 |

Dissipation Factor (Df) | 0.0014 to 0.0038 at 10 GHz | 0.003 to 0.01 |

Cost | Much more expensive | Mid-range price |

Performance | Best for high-frequency | Good, flexible option |

Application Suitability | RF, microwave, high-speed | Flexible high-frequency |

Benlida helps you pick PTFE or polyimide substrates for your project. Their experience with modern circuit board manufacturing means you get advice that fits your budget and performance needs.

Metal Core and Flexible Substrates

Metal core substrates help your PCB handle heat better. You use these in devices that get hot, like LED lights and power supplies. Flexible substrates let your board bend and fit into small or moving spaces. These are important for wearable electronics and devices that need to flex.

You see metal core and flexible substrates in many industries:

LED backlight units and general lighting

Automotive motor control for electric and hybrid cars

Motor drives

Solid-state relays

Power supply devices, including voltage regulators and DC-DC converters

Solar panels and photovoltaic cells

Motion control systems

Benlida offers both metal core and flexible substrates for modern circuit board manufacturing. Their team helps you pick the right type for your project. This helps your PCB work well and last longer.

Copper Foil and Laminates

Copper foil and laminates are very important in circuit boards. Copper foil makes the paths that connect all the parts. Laminates and prepreg hold the board together and make it strong. Picking good materials helps your board work well and last longer.

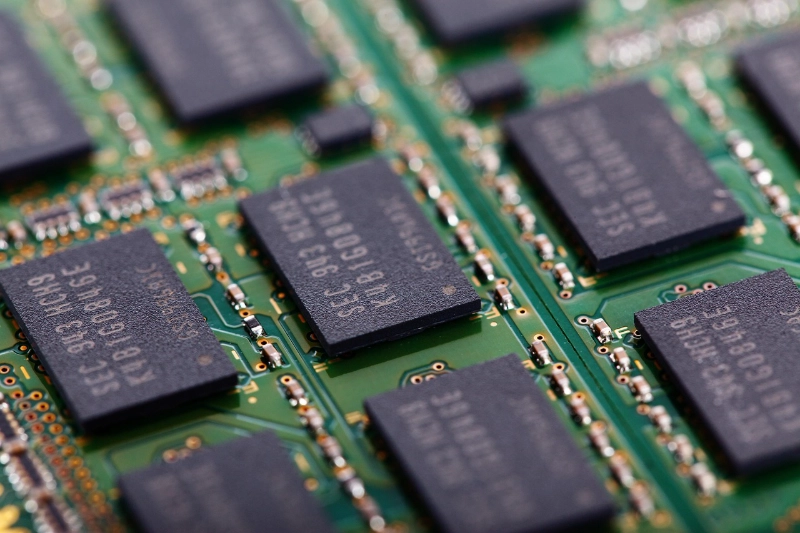

Copper Foil Types and Functions

Copper foil is a thin, shiny layer on the board. These layers make tracks for electricity to move. There are two main copper foil types: Electrolytic (ED) and Rolled Annealed (RA). Each type is good for different things.

Type of Copper | Purity Level | Thickness Range |

|---|---|---|

Electrolytic (ED) | High-purity | 1 oz/ft² (35 µm) to 3 oz/ft² (105 µm) or larger |

Rolled Annealed (RA) | Lead-free level | 1 oz/ft² (35 µm) to 3 oz/ft² (105 µm) or larger |

You pick the copper type based on what your board needs. Rolled Annealed copper bends easily and works for fast signals. Electrolytic copper is used for most regular boards.

Type of Copper Foil | Key Characteristics | Impact on Performance and Durability |

|---|---|---|

Rolled Annealed (RA) | Very flexible, smooth, handles heat well | Good for fast signals and flexible boards |

Electrodeposited (ED) | Easy to shape | Used in regular boards, not as good for fast signals |

Tip: Thicker copper foil lets your board carry more current. Thin copper can cause voltage drops or signal problems. Thick copper can make building harder and cost more.

When you pick copper foil, you should:

Think about how much current your board needs.

Check how pure and smooth the copper is.

Find a good balance between thickness and how easy it is to build.

Benlida helps you choose the best copper foil for your board. Their team checks every batch to make sure it is good.

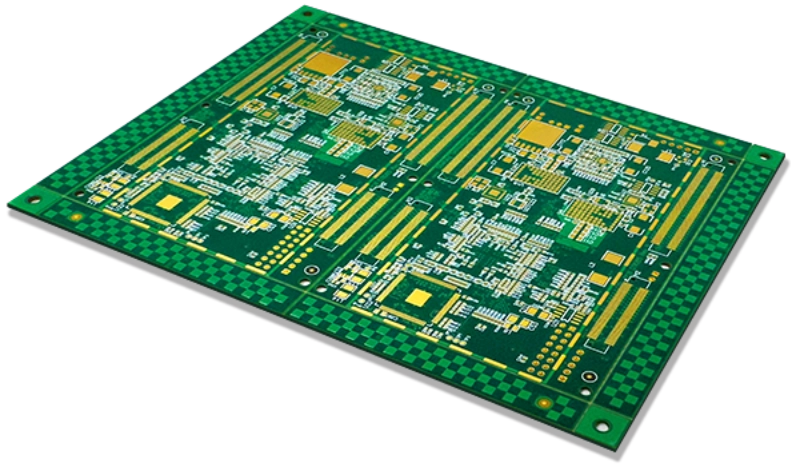

Laminate and Prepreg Materials

Laminates and prepreg keep the copper layers together. Laminates are hard sheets made from glass fiber and resin. Prepreg is sticky and melts to bond copper and laminate when heated.

Material Type | Tensile Strength (MPa) | Flexural Strength (MPa) | Young's Modulus (GPa) | Glass Transition Temp (°C) |

|---|---|---|---|---|

Core (Machine Direction) | 380-420 | 550 (Room Temp) | 22-24 | 170-180 |

Core (Cross Direction) | 340-380 | 480 (150°C) | N/A | N/A |

Prepreg (Pre-cure, Machine Direction) | 280-320 | 520 (Room Temp) | 20-22 | 165-175 |

Prepreg (Post-cure, Machine Direction) | 360-400 | 450 (150°C) | N/A | N/A |

Strong laminates keep your board from bending or breaking. Prepreg glues the layers and keeps the board solid. Good laminates and prepreg help your board handle heat and keep signals clear.

Electrical insulation stops signals from mixing and causing shorts.

Mechanical stability keeps your board strong and stops warping.

Environmental protection keeps water and dirt out so your board lasts.

Signal integrity means your board can handle fast signals without losing data.

Benlida uses only high-quality laminates and prepreg. Their team tests every material for strength and heat resistance.

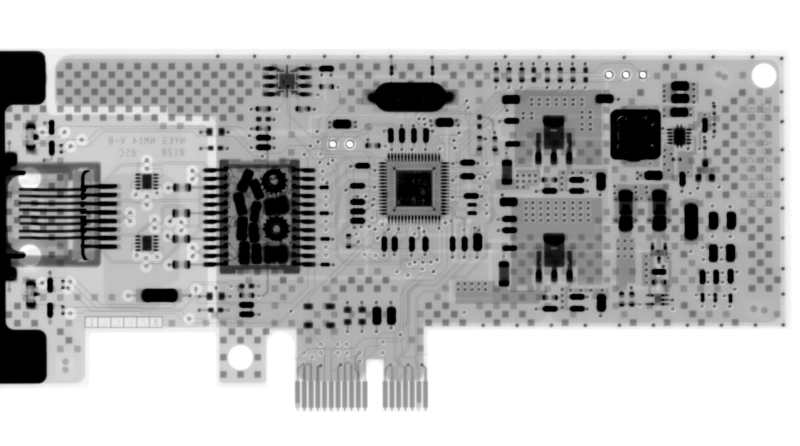

Impact on Conductivity and Reliability

Copper foil and laminates work together to make your board safe and strong. Copper foil lets electricity flow easily. Laminates give your board strength and insulation.

Copper foil is important because it helps electricity move well. Laminates keep your board strong and stop it from breaking. If you pick good copper and laminate, your board will last longer and work better.

Benlida checks every board with strict tests. They use insulation resistance tests to make sure the board does not leak electricity. They also use HiPot testing to check if the board can handle high voltage.

Test Type | Description |

|---|---|

Insulation Resistance Test | Measures how well the insulation works by applying voltage and checking the current flow. |

HiPot Testing | Uses high voltage to check insulation by measuring leakage current; if the insulation holds, it is good. |

Note: Benlida’s quality checks help you get a board that works well and lasts a long time. You can trust their team to use the best materials and the right tests for every project.

Copper foil and laminates help your board work better in modern circuit board manufacturing. Benlida gives you expert help and strong quality control for every board.

Protective Coatings and Markings

Solder Mask Applications

Solder mask is the colored layer on most circuit boards. It can be green, blue, or black. This layer keeps your PCB safe from dust and water. It also protects it from chemicals. Solder mask stops metal lines from touching each other. This helps prevent shorts. It also keeps solder bridges from forming when building the board. If you use a strong solder mask, your board works well in hard places.

Here is a table that lists the main features of solder mask materials:

Property | Description |

|---|---|

Insulation | Stops shorts between close metal lines or pads. |

Chemical Resistance | Fights off damage from solder flux, cleaners, and other chemicals. |

Adhesion | Sticks tightly to the board and copper so it does not peel. |

Dielectric Strength | High dielectric constant helps stop shorts and track movement. |

Colorfastness | Should not fade or change color from heat, wetness, or sunlight. |

A good solder mask keeps your board safe from things around it. It stops solder bridges and helps your PCB last longer. For important jobs, a strong solder mask makes sure your board works well.

Silkscreen Ink Uses

Silkscreen ink puts letters, numbers, and symbols on your PCB. These marks help you find parts and check where things go. You need clear marks to make building and fixing easy.

PCB Color | Recommended Silkscreen Color | Contrast Level |

|---|---|---|

Green | White or Yellow | Best Contrast |

Black | White | Maximum Contrast |

Blue | White | Good Contrast |

White | Black | Sharp Contrast |

Red | White or Black | Varies |

Silkscreen ink must last through heat, cleaning, and wet air. High heat can make the ink fade and hard to see. Pick colors that stand out so you can read the marks. It is more important to see the marks than to make the board look pretty.

Tip: Use silkscreen colors that are easy to see on your PCB for the best results.

Adhesives and Bonding Agents

Adhesives and bonding agents stick the layers of your PCB together. You use them to hold parts in place and keep the board strong. Good adhesives stop layers from peeling or bubbling up. They help your board stand up to heat and shaking. In Modern Circuit Board Manufacturing, strong bonding agents help your PCB last longer and work better.

Adhesives keep layers together and stop them from coming apart.

Bonding agents help your board handle stress and movement.

Good adhesives help make strong, high-quality boards.

Solder Alloys in Modern Circuit Board Manufacturing

Solder alloys join electronic parts to the circuit board. You need the right solder for strong and safe connections. There are two main solder types: lead-free and leaded. Each type works best for certain jobs.

Lead-Free and Leaded Solder

Lead-free solder is used in most new electronics. It has metals like tin, silver, and copper. Lead-free solder is safer for people and nature. It melts at a higher temperature than leaded solder. You must set your heat higher when using it.

Leaded solder has tin and lead. It melts at a lower temperature. Leaded solder makes smooth and shiny joints. Some old devices still use leaded solder. Many places now want lead-free solder because it is safer.

Solder Type | Main Metals | Melting Point (°C) | Safety Level | Typical Use Cases |

|---|---|---|---|---|

Lead-Free | Tin, Silver, Copper | 217-221 | High | Consumer electronics |

Leaded | Tin, Lead | 183 | Moderate | Legacy and repair boards |

Tip: Always check which solder type is best for your project and local rules.

Fluxes and Cleaning Agents

Flux helps solder stick to metal parts. It cleans the metal and stops rust from forming. There are three main flux types: rosin, no-clean, and water-soluble. Each type needs a different way to clean.

Flux Type | Chemical Composition | Cleaning Method | Cleaning Efficiency |

|---|---|---|---|

Rosin | Natural resin, solvents | Isopropyl Alcohol (IPA) | Cleans rosin off well |

No-Clean | Isopropyl alcohol, siloxanes, etc. | Solvent-based cleaners | Removes residue without problems |

Water-Soluble | Organic acids, for water cleaning | Deionized water | Cleans ionic residue well |

You use isopropyl alcohol to clean rosin and no-clean flux. Deionized water is best for water-soluble flux. No-clean cleaning agents remove residue without causing new problems.

Note: Cleaning off flux is important. If you leave flux, it can cause rust and damage. Cleaning helps solder joints last longer.

Evidence Description | Impact on Solder Joints |

|---|---|

Leftover flux can rust parts and hurt PCBs. | Makes solder joints weaker. |

Cleaning stops damage and keeps PCBs safe. | Helps boards work longer. |

Ionic residue from flux can cause rust. | Can make boards fail. |

Cleaning well stops these problems. | Makes boards last longer. |

New cleaning agents help boards work better. | Makes electronics last longer. |

Removing all residue is very important. | Stops problems in the future. |

You should clean off all flux residue. This keeps your board safe and working well for a long time. Good cleaning agents help stop rust and other problems.

Picking the right materials makes your circuit board strong.

Every material changes how your board deals with heat.

Materials also affect signals and how much stress the board can take.

Benlida helps you get good PCBs by choosing the best materials.

They use advanced ways to make circuit boards.

If you choose good materials for your circuit board, it works better and lasts longer. Smart choices help you get a product you can trust.

FAQ

What is the most common material used for PCB substrates?

You will find FR4 as the most popular substrate. FR4 uses glass fiber and epoxy resin. This material gives your board strength and helps it resist heat and moisture.

Why does copper foil matter in circuit boards?

Copper foil creates the paths for electricity. You need copper foil for strong connections. Thicker copper lets your board carry more current. Thin copper works for small signals.

Tip: Choose copper thickness based on your board’s power needs.

How does solder mask protect your PCB?

Solder mask covers the board’s surface. It stops dust, water, and chemicals from damaging the metal lines. Solder mask also prevents short circuits and keeps solder from spreading.

What is the difference between lead-free and leaded solder?

Solder Type | Melting Point | Safety | Use Case |

|---|---|---|---|

Lead-Free | Higher | Safer | New electronics |

Leaded | Lower | Less safe | Older devices |

You should use lead-free solder for most new projects.

en

en

WhatsApp

WhatsApp