JLCPCB vs Traditional PCB Manufacturers: Advantages, Limits, and Survival Strategies

In recent years, with the integration of the internet and capital, various industries are going through reform, PCB industry has also undergoing challenges. Nowadays, traditional PCB manufacturers are facing the pressure and challenges from JLCPCB, in PCB and PCBA industry. This article compares the advantages & limitations of JLCPCB and traditional PCB manufacturers systematically, hope it could provide profound insights and help readers to understand this industry.

Part One: JLCPCB vs. Traditional PCB Factories/SMT Workshops

Advantages of the JLCPCB(Compared to Traditional PCB Factories)

1. Standardization and Online Processing:

Advantages: Fully online ordering, real-time quoting, and progress tracking. Users do not need to repeatedly communicate about quotations and processes; it's as simple and transparent as online shopping.

Limitations of Traditional PCB&PCBA Manufacturers: Relying on personnel communication, slow procurement and quotation, opaque processes, and certain fees such as engineering & setup fees are unfriendly to small customers.

2. Exceptional Cost-Effectiveness and Fast Small-Batch Delivery:

Advantages: By centralizing massive orders, automating production, and standardizing processes, it achieves incredibly low prices and extremely fast delivery (e.g., 24-hour prototyping, 5-day small-batch production) for small-batch and prototype applications. This is its core competitive advantage.

Limitations of Traditional PCB&PCBA Manufacturers: Long engineering process & times, production line switchover costs are high, difficulties in scheduling small orders, and no price advantage.

3. End-to-End Integration of "EDA Design + PCB Manufacturing + Component Procurement + SMT Assembly":

Advantages: Creates a powerful closed-loop ecosystem, designers complete design in LCEDA, place orders by one click, and components can be matched from the LCSC online store for direct SMT assembly. This reduces the barrier and time required from design to physical product, significantly.

Limitations of Traditional PCB&PCBA Manufacturers: Typically only focuses on the manufacturing stage, requiring customers to handle design software, component procurement, and assembly coordination themselves, resulting in a broken or seperated supply chain.

4. Extremely User-Friendly for Beginners and Creaters:

Advantages: The website offers numerous tutorials, process instructions, and pricing tools, lowering the industry knowledge barrier. Supports various individual customer orders.

Limitations of Traditional PCB&PCBA Manufacturers: Typically serves experienced engineers or companies, lacking patience for individual customers.

5. Data-driven and intelligent:

Advantages: Utilizes historical order data, to optimize production schedule, board utilization rate, and common processes, reduce costs and increase efficiency.

Limitations of Traditional PCB&PCBA Manufacturers:

Inconsistent levels of digitalization, heavily reliant on experience.

Limitations of the JLCPCB mode:

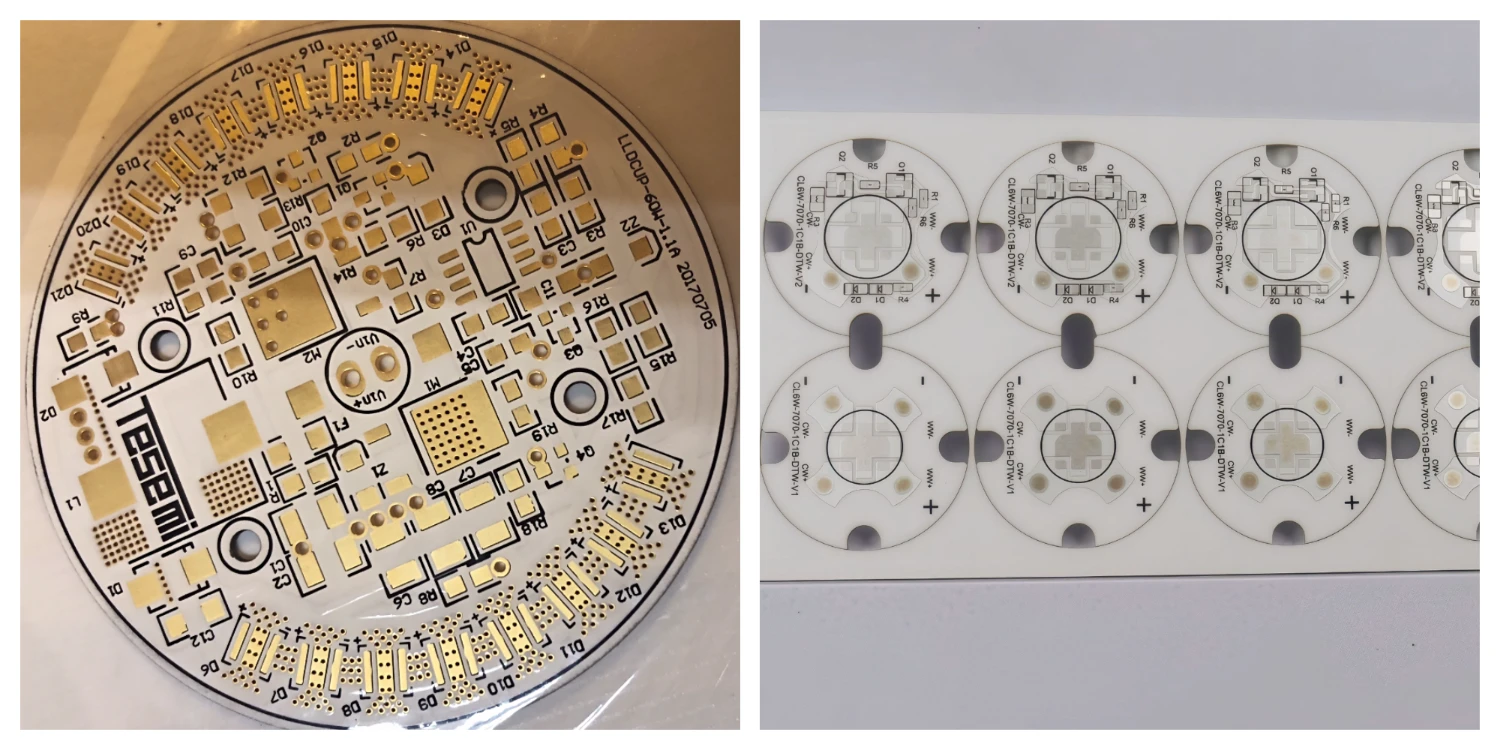

1. Limited process flexibility:

Limitations: Primarily provides conventional processes in pursuit of efficiency and standardization. For non-standard boards (such as high-frequency RF boards, metal substrates, heavy copper boards, rigid-flex boards), special processes (such as back drilling, deep hole drilling, through-hole plating), and extremely high precision (such as HDI blind & buried vias), it either does not support or offers no advantages for price and delivery times.

Traditional factory advantages: Accept non-standard orders, customizing production processes, highly flexible by according to customers' needs.

2. Potential Reversal of Cost-Effectiveness when go for Bulk Orders:

Limitations: When order volume reaches a certain scale (e.g., mass production), JLCPCB's pricing model may not be as competitive as traditional PCB manufacturers that focus on large volumes and offer additional discounts through long-term partnerships.

Advantages of Traditional Manufacturers: In mass production, they can engage in in-depth negotiations regarding price, payment methods, and dedicated services.

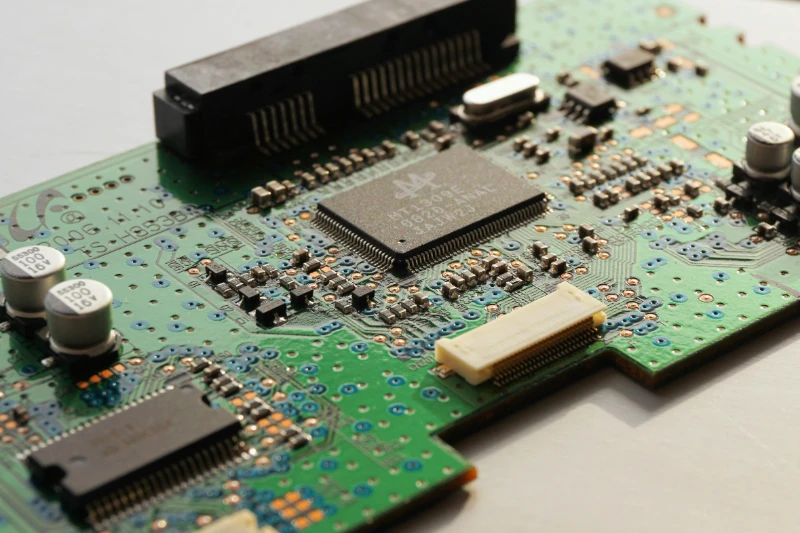

3. Perceive Differences in Quality and Reliability Control:

Limitations: While it's quality requirement is sufficient for consumer and industrial applications, but in high-reliability fields (such as automotive electronics, military, medical, and aerospace), customers trust traditional manufacturers with strict quality control systems, full certifications (such as IATF 16949 and ISO 13485), and deep involvement in the process.

Advantages of Traditional Manufacturers: They possess complete reliability testing laboratories (such as cross-section analysis, thermal shock, and CAF testing), traceability systems, and provide professional engineering support (more in-depth DFM analysis).

4. Simplified Service and Customer Relationships:

Limitations: JLCPCB is a "self-service" model. When encountering complex technical problems, requiring urgent coordination, or personalized needs, there is a lack of dedicated sales, managers or engineering teams for rapid response.

Traditional manufacturers' advantages: provide "high-touch" service, with sales and engineering teams closely following up and resolving various unexpected issues during the production process.

5. Component supply chain:

Limitations: While LCSC's online store offers a comprehensive range of products, it's support for very niche, discontinued, or components requiring specific channels is limited. SMT inventory also cannot compare to the procurement channels of traditional EMS factories, especially when encounter alternative components.

Traditional manufacturers/EMS advantages: They possess a mature supply chain system, capable of handling complex BOM lists for procurement and material preparation, flexible and professional engineers could recommend solutions.

Part Two: How can traditional PCB manufacturers survive from JLCPCB?

The survival strategy for traditional PCB manufacturers is "differentiated competition" and "value upgrading," avoiding price competition in the standardized small-batch production. Specific strategies such as follow:

1. Focus on high-end and special processes:

Become a "special process expert." 1. Vigorously develop high-tech products such as high-frequency and high-speed boards, HDI, rigid-flex boards, IC substrates, thick copper boards, and ceramic substrates.

Survival Space: These areas have high added value orders and are currently difficult for JLCPCB's model to cover on a large scale.

2. Deepen Industry Solutions and Bond with Clients:

Transform from a "manufacturer" to a "solution provider." Deepen understanding of specific standards and reliability requirements in one or more industries (e.g., automotive, medical, communication equipment).

Action: Obtain relevant industry certifications, establish joint laboratories, proactively participate in customer R&D, provide a full range of services from DFM to reliability testing, and form strategic partnerships with major clients.

3. Embrace Digitalization and Improve Standard Product Efficiency:

Learn from JLCPCB's "online" advantages. Establish your own online quotation and order management system, to improve the efficiency and transparency of processing small-batch standard orders.

Action: Offer more flexible "standard product + light customization" services than JLCPCB for existing clients or clients in specific regions.

4. Enhance Engineering Services and Value-Added Technology:

Sell "technology" and "experience," not just "PCBs." Provide in-depth technical consulting, signal integrity/power integrity analysis, thermal simulation support, and process improvement suggestions.

Living Space: Many complex product R&D teams require this support, which is precisely what online standardized platforms cannot provide.

5. Extend Downstream in the Industry Chain and Strengthen EMS (Electronic Manufacturing Services):

Not only PCBs, but also strengthening back-end services such as SMT placement, assembly testing, programming, and packaging, becoming a one-stop manufacturing partner for customers.

Action: Establish strong partnerships with component distributors, improve procurement and material management capabilities for complex BOMs, establish efficient and flexible production lines, and undertake small-to-medium batch orders for complete machine delivery.

6. Regionalized and Localized Services:

Leverage geographical advantages to provide "rapid response" and "face-to-face" services. For local industrial clusters (such as a specific industry in the Pearl River Delta or Yangtze River Delta), provide more agile and closer delivery and support than nationwide online platforms.

Summary:

● JLCPCB: Reformed the rules of the PCB industry in the small-batch, prototype, and standard product market. With "fast, economical, and easy" as its core, it captured the long-tail market that traditional PCB manufacturers were unwilling to pursue, and cultivated user habits among a new generation of engineers.

● Traditional PCB&PCBA manufacturers: Must abandon the entanglement in low-value-added standard products and transform towards "high-end, precise, specialized, and in-depth" products. Must build new competitive advantages based on process depth, technical experience, industry solutions, and personalized services.

The future landscape is likely to be one of "layering and integration":

● Top Class: High-end specialty processes and high-reliability fields, dominated by traditional large manufacturers.

● Mid Class: Large-batch standard products, competition between large traditional manufacturers with good cost control and some upgraded manufacturers.

● Bottom Class and Entry Level: Small-batch, prototype, and creater markets, dominated by platforms like JLCPCB, which become huge traffic entry points. Some traditional manufacturers may also capable to participate through self-built platforms or partnerships.

Simultaneously, the two may merge. For example, traditional large manufacturers may invest in or incubate their own online standard product brands, while JLCPCB, after accumulating sufficient technology and capital, will gradually emerge into the high-end process field.

Benlida has been focusing on PCB manufacturing and PCB assembly for 14 years. Nowadays we also under the competition and our traditional business has also been impacted by the JLCPCB mode, honestly some customers' small-batch needs have shifted to JLCPCB. Facing this pressure, Benlida actively seeks to provide value-added engineering services, while strictly controlling quality, emphasizing the initiative and enthusiasm of people in the production process, responding to industry challenges, and continuing to provide high-quality services to domestic and global customers!

en

en

.webp)

WhatsApp

WhatsApp