What is the mindset of PCBA components sourcing?

PCBA components sourcing (also known as BOM sourcing or component procurement sourcing) is a crucial work of electronics manufacturing, directly affect project quality, costs and delivery time. An excellent procurement team must be proficient in PCBA components sourcing strategies and techniques.

The following will share a comprehensive overview for four aspects: core concepts, practical techniques, common pitfalls, and tool recommendations.

I. Core Concepts (The Mindset)

PCBA components sourcing isn't just simply submitting the models from the BOM for procurement, it's a systematic process and the core concepts could be summarized as:

Accuracy: Ensuring "buying the right one" comes on top, it guarantees the project progress and results, if sourced the wrong components, it will definitely lead to a lot of losses of time and financial, lead to fatal mistakes.

Balance the Triangle: Quality, cost and lead time, they are 3 key factors which affect the project progress. Of course, good quality, low cost and fast delivery time are the ideal situation but it is pretty difficult to acheive and since the market isn't thoroughly transparent and the information flow isn't always reflect the best options from various suppliers, so the procurement team have to balance these 3 factors from various options.

Awareness of Supply Chain Risk: Pay attention to supply chain risks, including stockout, cease-production, single-supplier(only choice) and geopolitical risks. It requires awareness, assessment and management mindset for market fluctuation.

Lifecycle: Select components in the active production stage, avoiding discontinued (EOL/Obsolete) or unrecommended for new designs (NRND). Ensure the products could be produced with plenty supply of components in following years, avoid re-select, re-design and re-verifying process in following years.

For example:

● Consumer Products: Usually cost is primary concern and the lead time follows, and sometimes quality with industry standards is sufficient enough.

● Industrial/Automotive/Medical Products: Quality and reliability are absolutely the primary concerns, then the secondary is cost.

● R&D Prototypes: Lead time is the most primary concern, more important than cost especially when the team have to verify the design in urgent.

II. Practical Techniques & Steps

Step 1: BOM Preparation

Standard Format: Ensure the BOM is a neat tablet, including: designators, specification&description, part numbers/models, manufacturers, package, quantity.

Verify key parameters:

● Resistors/Capacitors/Inductors: Value, accuracy&tolerance, power rating, withstand voltage, package.

● ICs/Transistors: Part number/model, package, voltage, temperature rating (industrial grade, automotive grade, etc.).

● Connectors: Pins, spacing, height, soldering method (through-hole/surface mount).

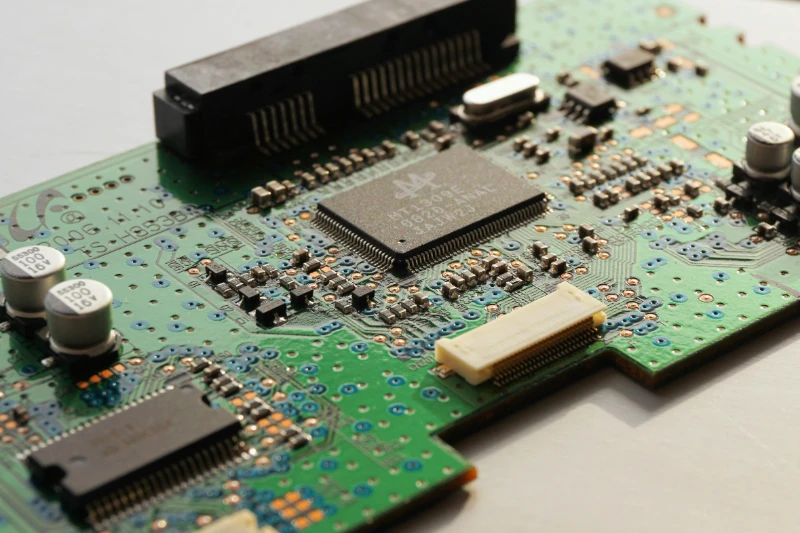

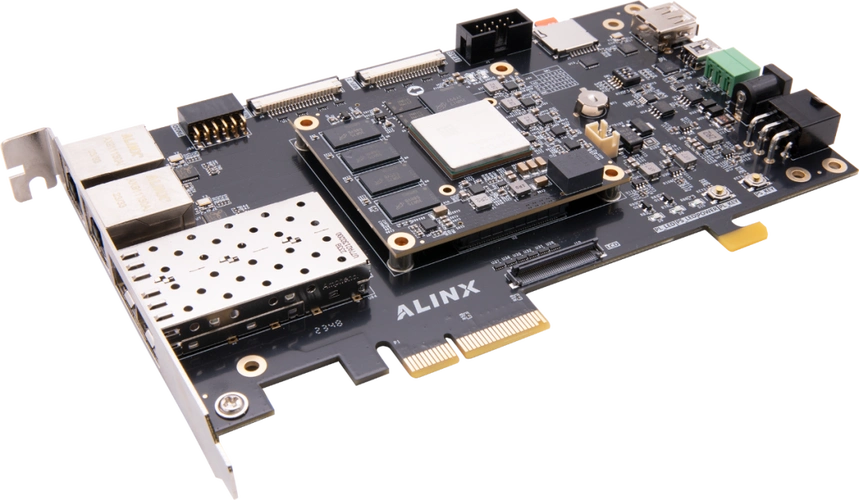

Identify key components: Identify core, high-value, long-lead-time MCU/chips in the BOM, such as CPU, MCU, Memory, and FPGA.

Step 2: Sourcing & Quotation

Multiple channels for quoting:

Manufacturer: Receive official quotes and the latest model information, but usually the manufacturer does not directly sell products to customers, especially when the order quantity is small.

Authorized Distributors: Preferred channel, option 1, normally they are authorized from manufacturer, could guarantee the products are genuine and in good quality, provides technical support, consulting service, and transparent pricing.

Independent Distributors/Trading Companies: option 2, when authorized distributors out of stock or need to find rare parts. Should be aware and inspect the quality of products, such as used, refurbished.

E-shop: such as Arrow, Avnet, Digi-Key, Mouser, Future, LCSC, they are suitable for small batches, prototypes, and common components. They are fast, but the models might be limited and the prices aren't competitive when the quantity goes higher.

Get a detailed quotation: Request a quotation from the suppliers, with the following information: part number/model, brand/manufacturer, quantity, unit price, delivery date, availability, minimum package quantity (MPQ), and production batch information. Delivery date and minimum package quantity are important!

Price comparison strategy: Don't just compare unit prices; calculate the total cost of ownership (TCO), including: total component price + shipping + customs duties + capital tied up. Sometimes, a single component's lead time can be as long as 52 weeks, resulting in project delay and costs will be far exceeding the price difference.

Step 3: Alternative Components Recommendation.

A purchasing engineer should be good at for how to find alternative components. This is a core skill in component sourcing.

Why need alternative components?

● Original model discontinued (EOL)

● Original model lead time too long or out of stock

● Original model price too high

● Upgrade design, reduce costs

How to find alternative components?

● Official Channel: Almost all manufacturers (such as TI, ADI, ST) have product cross-reference or parameter search tools.

● Distributors: Digi-Key, Mouser, and LCSC have very powerful parameter filtering functions, assisting you to search options by setting parameter and sort by core factors, such as price, stock, etc.

● Search Engines: Search for "XXX alternative" or "XXX replacement model".

Alternative component confirmation principles (very important!):

● Package compatibility: Preferred, can be directly replaced without PCB modification.

● Parameter compatibility: Electrical parameters (voltage, current, speed, accuracy, etc.) and package must be compatible with the original design.

● Software/driver compatibility: For MCUs, sensors, etc., it is necessary to confirm whether the underlying driver needs modification.

● Sample verification: Before replace the original on batch production, a full-function test must be performed by applying alternative components on a sample board and verifying they work as expected&required.

Step 4: Order Placement & Tracking

Summarized Procurement: Collect part numbers with few suppliers, to get better prices and services, and reduce management work.

Confirm Delivery Dates: According to the PCBA plan, estimate the arrival dates, so the production schedule won't be postponed. For components with long lead times, place orders to lock the stock, even the price is slightly higher.

Batch Strategy: For prototypes, purchase small batches from Digi-Key/Mouser/LCSC for fast delivery; for mass production, place orders from distributors.

Status Tracking: Placing an order is not the end of progress. Keep tracking and monitoring the order status, especially for components with long lead times, keep communicate with suppliers, and be updated for any supply changes.

III. Common Pitfalls and Risk Management

● Pitfall of Counterfeit/Refurbished components: Especially when purchasing from trading companies, we should always request original manufacturer labels, production date, factory reports, and the third-party testing should be a back-up option.

● Wrong Components: A difference of letter in the part number suffix (e.g., TLV70033DDCR vs TLV70033DDCT) might be completely 2 different components with very different functions. Be careful when inputting numbers and make sure the part numbers are correct.

● Pitfall of Delivery Time: Supplier-quoted delivery times may be "optimistic estimates." For critical, long-lead-time components, we have to consider multiple options.

● Minimum Order Quantity (MOQ): Some not so-common components have MOQ, such as 4000 pieces per tray or reel, but only need 100 pieces, it will waste a lot of costs, so sometimes we have to consider alternative components.

● Package: The packages in schematic and PCB libraries might be different from the actual package (e.g., SOT-23-5 vs SC-74A). Check the datasheet for confirmation or least compare the package before assembly.

IV. Tools & Resources Recommendations

BOM Management Tools:

Excel: Most commonly used, but with limited functionality.

Professional Software: Altium Concord Pro, Arena Solutions, OpenBOM, etc.

Platform Tools: JLCPCB/LCSC's BOM management tool assists one-click component matching and pricing.

Component Search Platforms:

Digi-Key, Mouser: The world's two largest catalog distributors, offering the most comprehensive information, ideal for searching and comparing prices.

LCSC/LCSC Mall: The top choice in China, offering transparent pricing and fast delivery.

Octopart: A component search engine that allows simultaneous queries of inventory and prices from multiple distributors.

Lifecycle Inquiry:

Original Manufacturer's Website: The most authoritative.

Distributor Website: Usually indicates EOL status.

Summary

PCBA component sourcing is a comprehensive, integrative technique, it requires knowledge, experience, market insight, supply chain management and awareness of risks. With experience for 14 years, Benlida has established an excellent procurement team and built strong&reliable supply chain relationships. Adhering to accuracy as a prerequisite and risk control as the core, Benlida balances cost, delivery time, and quality, with engineering support of alternative components, make reasonable&rational decision.

If you need PCBA component sourcing services or confront supply chain issues, please contact Benlida for consulting and service!

en

en

WhatsApp

WhatsApp