For PCB Assembly equipments: comparison of YAMAHA, Panasonic and JUKI

YAMAHA, Panasonic and JUKI are the world's leading pick-and-place machine manufacturer, each has it's own positioning and characteristics. The following is a detailed comparison of the them:

1. Overview

YAMAHA: "The Flexible All-Capable Performer." Famous for it's high cost-performance ratio, excellent flexibility, and wide applicability, it excels particularly in handling multi-variety, small-to-medium batch production.

Panasonic: "The King of High Speed and Precision." Famous for it's top-tier speed, precision and stability, it is the first choice for large enterprises, automotive electronics, and high-end consumer electronics, when go for mass production.

JUKI: "The Reliable Expert of Practical." Favored for it's reliability, ease of operation and maintenance, and excellent cost-performance ratio (especially in the general-purpose machine field), it is a solid choice for medium-sized enterprises and stable batch production.

2. Comparative Analysis

1) YAMAHA:

● Extremely High Flexibility: Excellent modular design, any SMT line could easily be configured with nozzles for different functions. It's "intelligent feeder" concept (arbitrary placement, automatic machine recognition) improves line changeover efficiency significantly, making it ideal for frequent line changes.

● High Cost-Effectiveness: Initial investments and subsequent maintenance costs are typically lower than Panasonic's for similar performance and configuration.

● Software-Friendly: Programming software (such as YRM) is relatively intuitive and easy to learn, with powerful offline programming and optimization functions.

● Comprehensive Product Line: Covers a wide range from entry-level to high-speed, ultra-high-speed, and irregularly shaped component placement machines.

Typical Application Scenarios:

● Small to medium batch, multi-variety production (e.g., industrial control, instrumentation, small-batch customized products).

● R&D centers, laboratories, educational institutions.

● As a supplement to production lines or a flexible unit.

Potential Considerations: In ultra-high-speed, ultra-large board (e.g., TV motherboard) production, peak speeds may be slightly lower than Panasonic's top-of-the-line models.

2) Panasonic:

● Top-tier speed and precision: The NPM and CM series employ innovative designs (such as dual-beam structure and synchronous placement) to achieve astonishing placement speeds while maintaining micron-level precision.

● Superior stability and reliability: Demonstrates extremely high uptime (mean time between failures) in 24/7 large-scale production, ensuring maximum capacity for companies pursuing maximum output.

● Production line integration capabilities: Provides complete solutions from printing, placement, reflow soldering to inspection, with highly advanced inter-equipment linkage and data management (such as Panasonic's "Factory Cloud").

● Ability to place complex components: Mature and stable placement processes for large, heavy, irregularly shaped components and fine-pitch components (e.g., 01005, 0.3mm pitch BGA).

Typical Application Scenarios:

● Large-scale, standardized production of a single product type (e.g., smartphones, computer motherboards, automotive controllers).

● Fields with extremely high reliability requirements (automotive electronics, aerospace, medical electronics).

● "Lights-out factories" pursuing fully automated and intelligent production.

Potential Considerations:

● Equipment price and Total Cost of Ownership (TCO) are usually the highest of the three.

● High technical skill requirements for operators and maintenance personnel.

3) JUKI:

● Excellent reliability and durability: Robust mechanical structure, simple design, low failure rate, and relatively low maintenance costs. Reputed in the industry for its "robustness and durability."

● Simple operation and maintenance: User-friendly human-machine interface, intuitive mechanical structure, short training cycle, and simple daily maintenance.

● King of cost-effectiveness for general-purpose machines: Its RX series and KE series general-purpose machines achieve a very good balance in placement accuracy, stability, and price, making them the main models for placing ICs, connectors, and irregularly shaped components.

● Fast ROI: For medium-volume, stable product structure production, it can achieve stable output with relatively low investment.

Typical Application Scenarios:

● Medium-volume, stable product production for medium-sized enterprises (e.g., home appliance control boards, power modules, LED lighting).

● Used in conjunction with high-speed machines as a "general-purpose machine/irregular component machine" on the production line.

● Customers sensitive to initial investment but requiring reliable equipment to ensure production.

Potential Considerations:

● In the process of high-speed placement for small components (e.g., 0201, 01005 in large quantities), it's speed is not as fast as Panasonic's high-speed machines.

● Brand influence and high-end market share are slightly inferior to Panasonic and Yamaha.

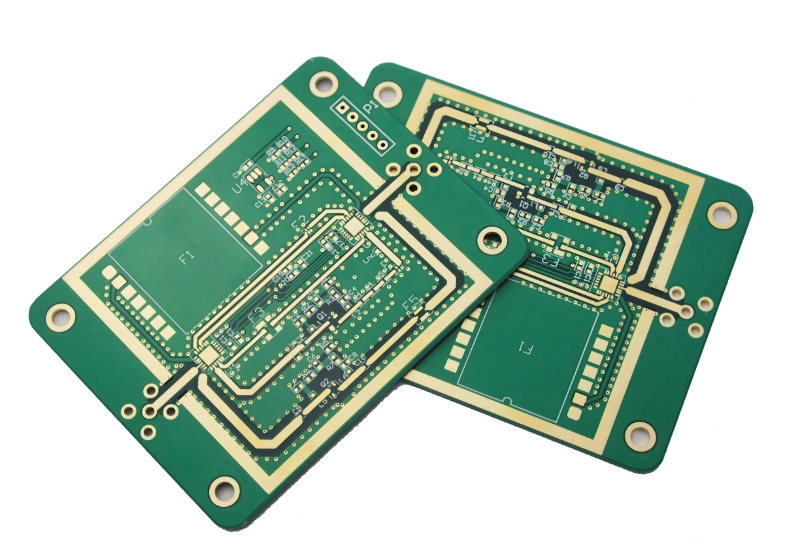

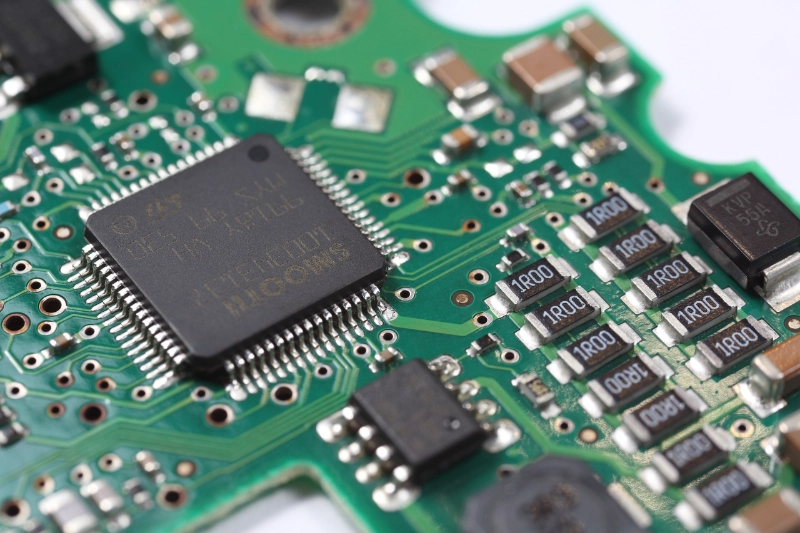

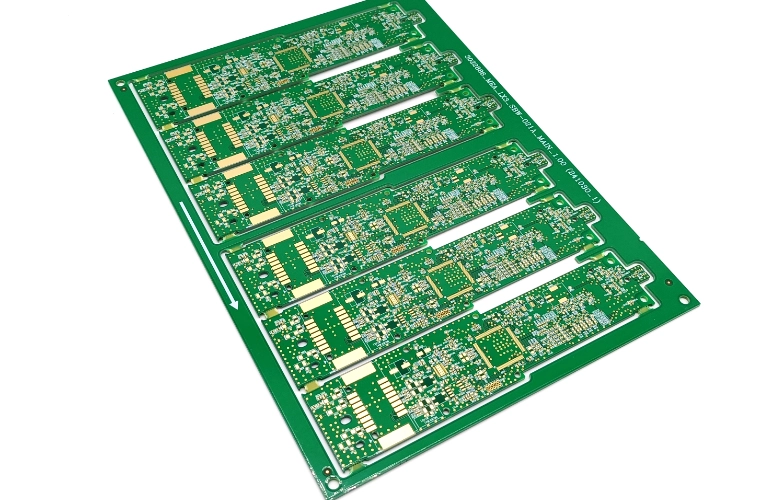

Benlida is a professional PCB manufacturer, provides PCB fabrication services for over 14 years, from domestic to global customers. It has also built an assembly division by Yamaha and Juki SMT machines. With advanced equipments and excellent engineering & quality team, from hardware to software, Benlida is committed to providing high-quality one-stop PCB&PCBA services to all customers!

en

en

WhatsApp

WhatsApp