Material Selection for PCB Manufacturing: Industry Best Practices and Recommendations

You make important choices when it comes to material selection for your printed circuit boards. The right materials help your PCB work well, last longer, and stay within your budget. Different material features change cost and reliability in special ways:

Material Property | Impact on Cost and Reliability |

|---|---|

Electrical Properties | These affect how signals move; low Dk and Df are needed for high-frequency uses to keep signals strong. |

Thermal Performance | Good thermal conductivity and low CTE stop overheating in high-power uses. |

Mechanical Strength | This shows if the PCB can handle stress; flexible PCBs need materials that bend easily. |

Environmental Resistance | Materials must fight off water, chemicals, and extreme temperatures for tough jobs. |

Long-term cost is most important for high reliability.

Paying more at first often means better performance and longer life, so you avoid fixing things later.

You can trust Benlida, a top maker of high-quality PCB and PCBA solutions, to provide you with products you can count on for your projects. Smart material selection now leads to good results later.

Key Takeaways

Pick materials that fit your PCB's needs. Think about speed, power, and where it will be used. This helps your PCB work well.

Use materials with low dielectric constant and dissipation factor for high-frequency circuits. These materials keep signals strong.

Choose high-Tg materials if your PCB will get hot. These materials stay strong and work well in tough places.

Work with manufacturers you trust to get good quality. Good partners help you find the best materials and stop problems in making PCBs.

Always check rules for the environment. Following rules like RoHS and REACH keeps your products safe and legal.

Why Material Selection Matters

Impact on Electrical Performance

You must think about how your PCB handles signals. This is very important for high-speed circuits. Dielectric constant and dissipation factor are key things to check. A low dielectric constant lets signals move faster. It also helps keep impedance steady. A low dissipation factor means less energy turns into heat. This keeps your signals strong.

The substrate and copper foil you pick can help stop signal loss.

Dielectric materials can lose energy when molecules shake in electric fields. This problem gets worse at higher frequencies.

Copper loss happens because of the skin effect. You can fix this by making traces wider.

If you want your PCB to work well at high frequencies, pick materials with low dielectric constant and low dissipation factor.

Reliability and Product Lifespan

The materials you choose affect how long your PCB lasts. They also help your board work in tough places. You want your board to keep working when it gets hot or wet. The table below shows why your choices matter:

Aspect | Explanation |

|---|---|

Material Selection | Picking the right materials helps your PCB last longer and stay strong. |

Common Substrate | FR-4 works for many uses, but you need special materials for high heat or frequency. |

High-Performance Materials | Polyimide or ceramic-filled laminates work better in harsh environments. |

Environmental Resistance | Materials with high glass transition temperatures (Tg) are best for extreme conditions. |

You should also think about resin systems and insulation. Good choices help your PCB handle temperature changes and moisture.

Cost and Manufacturing Efficiency

When you make lots of PCBs, your material choices can save time and money.

Substrates make your board strong and help you meet production goals. This is extra important for multilayer boards.

Copper foil is the main conductor. If you run out, you cannot finish your boards.

Solder mask and silkscreen inks protect your board. If you do not have enough, production slows down.

Prepreg and laminates stick layers together. You need them for complex boards.

Smart material choices help you avoid delays and keep costs low.

Key Properties for PCB Material Selection

Dielectric Constant (Dk) and Dissipation Factor (Df)

When you choose PCB materials, you need to look at the dielectric constant (Dk) and dissipation factor (Df). These numbers tell you how signals move through your board. If you work with high-frequency circuits, you want a Dk that matches your needs. A higher Dk can help shrink your circuit, but you must balance it with other features like thermal conductivity. Here are some common Dk values:

FR-4: 4.2 to 4.8

Ceramic: 3 to 10

PTFE: about 2.1

A low Df is important for strong signals. If the Df is high, more energy turns into heat, and your signals get weaker. You should pick materials with low Df for multilayer and high-frequency PCBs.

Thermal Conductivity and Heat Resistance

Thermal conductivity shows how well your PCB moves heat away from hot spots. If you design power electronics, you need materials that handle heat well. Check this table for common thermal conductivity values:

Material Type | Thermal Conductivity (W/m-K) |

|---|---|

Metal-core PCBs | 1 to 4 |

Ceramic fillers | 1 to 2 |

Graphite-based materials | 100 to 400 |

Rogers RT laminate | Up to 1.44 |

Copper moves heat very well, with a value of 386 W/m-K. Ceramic materials can move heat 20 to 100 times better than FR-4.

Glass Transition Temperature (Tg) and Decomposition Temperature (Td)

Glass transition temperature (Tg) tells you when your PCB starts to soften. In cars, you need high Tg because engines get hot and temperatures change quickly. High-Tg PCBs keep their shape and work well even when things heat up. You should look for materials with Tg above 160°C and Td around 335°C for tough jobs.

Coefficient of Thermal Expansion (CTE)

CTE measures how much your PCB grows or shrinks with heat. If you want your board to last, pick materials with controlled z-axis expansion. You can test for delamination and make sure the plating thickness is at least 1.2 mils. Shock and thermal tests help you check reliability.

Mechanical Strength and Flexibility

Mechanical strength and flexibility matter most for flexible PCBs. You need materials that bend, twist, or stretch without breaking. Look at the bend radius and tensile strength. The coverlay thickness and finish affect how well your board handles stress. If you pick the right material, your flexible circuits last longer and work better.

Tip: Always match your material selection to your application’s needs. This helps your PCB perform well and stay reliable.

Common PCB Materials and Their Uses

FR-4: Versatility and Limitations

FR-4 is in many electronics. It uses fiberglass cloth and epoxy resin. FR-4 is cheap and works well. You can use it in home gadgets, factories, and cars. The table below shows how FR-4 and high-speed laminates are different:

Feature | FR-4 | High-Speed Laminates |

|---|---|---|

Cost | Cheaper for low-frequency jobs | Costs more, but works better |

Frequency Handling | Good for slow signals | Best for fast signals |

Signal Integrity | Loses more signal above 1 GHz | Keeps signals strong |

Mechanical Strength | Strong and easy to make | Very strong for special boards |

Application Suitability | Used in control boards and telecom | Used in 5G, microwave, and satellites |

Performance Consistency | Changes with heat and frequency | Stays the same in many situations |

Note: FR-4 is good for most uses. But you need other materials for fast or hot jobs.

High-Tg Epoxy Laminates

Pick high-Tg epoxy laminates for boards that get hot or stressed. These materials keep their shape when hot. They are used in cars, factories, and power electronics. High-Tg laminates last longer than regular FR-4.

Polyimide and Flexible Materials

Polyimide is special because it handles heat and bends. It is used in planes, medical tools, and smart wearables. Polyimide films can take heat up to 400°C. They bend and twist without breaking. This is good for fitness bands and smart clothes. Polyimide circuits can take the place of many stiff boards. This saves space and money. You can also shape them for special needs.

Rogers and High-Frequency Substrates

Rogers materials are for high-frequency circuits. These boards have low loss, so signals stay strong in 5G, radar, and microwaves. Rogers boards keep their dielectric constant steady. This helps control impedance. They resist heat, water, and shaking. You can use them outside or in tough places.

Low signal loss for fast circuits.

Works well when temperatures change.

Strong and lasts in hard jobs.

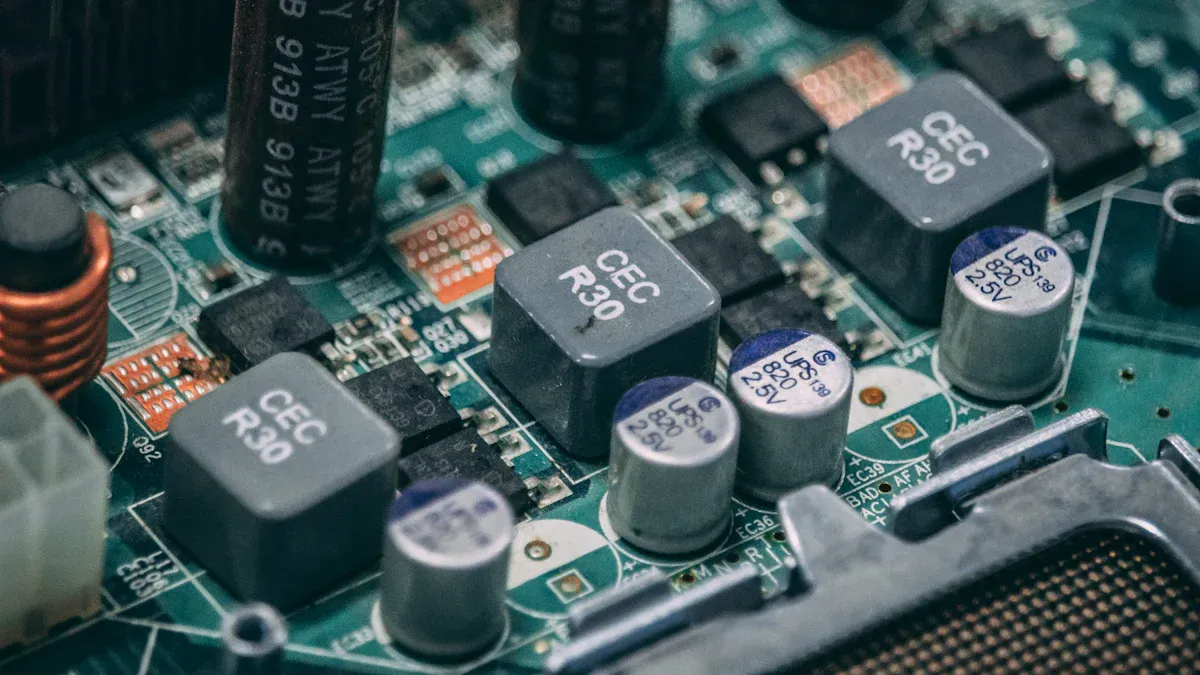

Metal Core and Ceramic PCBs

Use metal core PCBs to move heat away fast. These boards are good for LED lights and power supplies. Ceramic PCBs move heat well and insulate electricity. You find them in planes, medical tools, and strong electronics. Both types help your board last longer in hard jobs.

Tip: The material you pick changes how your PCB works, costs, and lasts. Pick the right one for your job to get the best results.

Application-Based Material Recommendations

Picking the best PCB material depends on your project’s needs. Each industry wants different things from its PCBs. Some need strong boards, others want low cost or long life. The table below shows which materials work best for each job:

Application Area | Recommended PCB Materials | Key Properties & Benefits |

|---|---|---|

Consumer Electronics | FR-4, Polyimide | Cost-effective, good insulation, flexible for wearables |

Automotive Electronics | High-Tg FR-4, Polyimide, Ceramic | High thermal stability, vibration resistance, durability |

RF & Microwave | PTFE, Ceramic-filled PTFE, Rogers | Low loss, stable dielectric, high-frequency performance |

Aerospace & Defense | Polyimide, Rogers, High-purity Copper | Extreme temperature range, low weight, high reliability |

Power Electronics & LED | Metal Core, Ceramic, Heavy Copper | Superior heat dissipation, long lifespan, compact design |

Industrial/Specialized | Rigid-Flex, Heavy Copper, Polyimide | Flexibility, high current, chemical and heat resistance |

Consumer Electronics

FR-4 is used in many home gadgets and toys. It is cheap and works well for most devices. Polyimide is good for smartwatches and fitness bands. It bends easily and can take more heat than FR-4.

Polyimide substrates are great for flexible circuit boards. They handle heat and tough conditions better than other materials.

FR-4 saves money and works for many uses.

Polyimide is better when things get hot.

If you use the wrong material, your device may not work right. It could break sooner or have signal problems. Picking the right material helps your device last longer.

Automotive Electronics

Car electronics need strong materials. They must handle heat, water, shaking, and dust. High-Tg FR-4 works for many car parts. Polyimide and ceramic PCBs are even stronger. They help your board survive near the engine.

Material Property | Description |

|---|---|

Extreme Temperatures | High heat can stress materials. Cold can make them break. |

Humidity and Moisture | Water can cause short circuits and rust. |

Vibration and Shock | Shaking can hurt parts and solder joints. |

Chemical Exposure | Chemicals can damage materials and coatings. |

FR-4 is fine for normal car jobs.

High-Tg FR-4 is better for hot places.

Polyimide is great for heat and shaking.

Ceramic PCBs are best for very hot and tough spots.

Benlida makes special PCBs for cars. They offer high-Tg and ceramic boards to meet strict rules.

RF and Microwave Applications

RF and microwave boards need special materials. These keep signals strong and clear. PTFE, ceramic-filled PTFE, and Rogers are top picks. They work well at high frequencies.

Ceramic-filled PTFE composites

Ultra-low loss laminates

Woven glass reinforced PTFE laminates

Hydrocarbon ceramic laminates

Benlida builds high-frequency PCBs with these materials. They help with wireless, radar, and 5G projects.

Aerospace and Defense

Aerospace and defense boards work in tough places. They must handle big temperature changes, shaking, and bumps. Polyimide and Rogers laminates are good for heat and strong signals. High-purity copper keeps signals safe.

Polyimide helps with heat.

Rogers laminates keep signals strong.

High-purity copper is used for conductors.

Boards must work from -150°C to +200°C.

Substrates should have Tg at least 20°C higher than the working temperature.

Boards should be light and small. Benlida helps with advanced designs for aerospace jobs.

Power Electronics and LED

Power electronics and LED lights get very hot. Metal core PCBs and ceramic PCBs help move heat away. This keeps parts cool and working longer.

Good thermal conductivity lowers part temperatures.

Cooler parts last up to 30% longer.

Better heat control means smaller designs.

LED headlights use metal core PCBs to stay bright.

Electric cars use metal core PCBs for cooling.

Solar inverters use metal core PCBs for high efficiency.

Benlida makes metal core and ceramic PCBs for power and lighting. Their boards help your products work well and last longer.

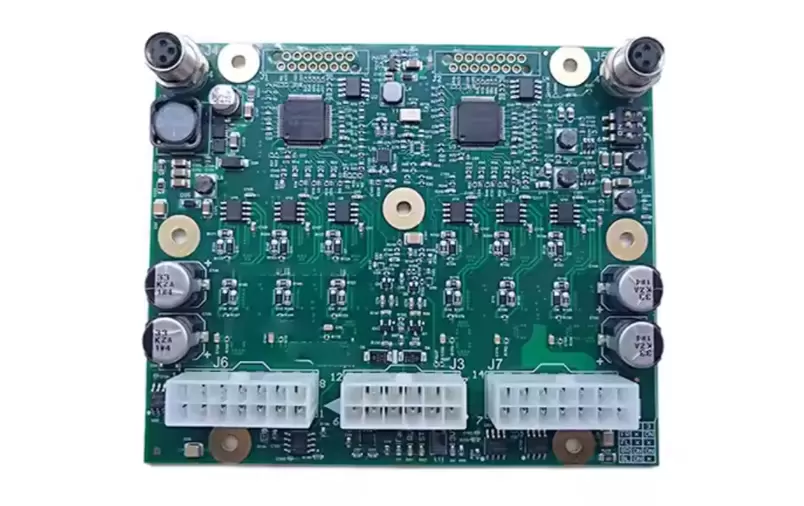

Industrial and Specialized Applications

Factories and robots need tough PCBs. Rigid-flex PCBs bend and last in moving machines. Heavy copper PCBs carry lots of power. Polyimide laminates resist heat and chemicals.

Rigid-Flex PCBs bend and last long.

Heavy Copper PCBs carry lots of current.

FR-4 epoxy glass cloth is good for many jobs.

Polyimide laminates resist heat and chemicals.

Metal-Core PCBs are best for high-power and LEDs.

High-frequency laminates are used for fast communications.

Benlida offers many types of PCBs. They make flexible, heavy copper, and high-frequency boards for all kinds of jobs.

Tip: Always pick PCB materials that fit your project’s needs. This helps your product work better and last longer.

Best Practices for Material Selection

Evaluating Design and Performance Needs

You should start with a clear plan for your PCB. Think about what your project needs. This helps you pick the right materials. Here are some steps to follow:

Write down what your PCB must do. List things like speed, power, and size.

Think about heat, signal strength, cost, and where it will be used. These things change how your board works.

Check out different materials. Compare how well they work and how much they cost.

Test your top choices. Use computer tests or real tests to see if they work.

Pick the material that fits your project best. Make sure it works for your design and your budget.

If you check these things early, you can avoid problems later. Good planning helps your PCB work better and last longer.

Considering Environmental and Regulatory Factors

You need to think about where your PCB will be used. Some places have rules about what materials you can use. These rules keep people and the planet safe. Here is a table with some important rules:

Regulation | Description |

|---|---|

RoHS | Limits six harmful substances in electronics. You must pick safe materials. |

REACH | Makes sure chemicals in PCBs are safe. You need to check and register them. |

WEEE | Promotes recycling of electronic waste. You should choose materials that are easy to recycle. |

You must follow these rules if you sell your products in other countries. Always check the laws before you pick your PCB materials.

Tip: Picking materials that follow safety and recycling rules helps you avoid trouble and keeps your products safe.

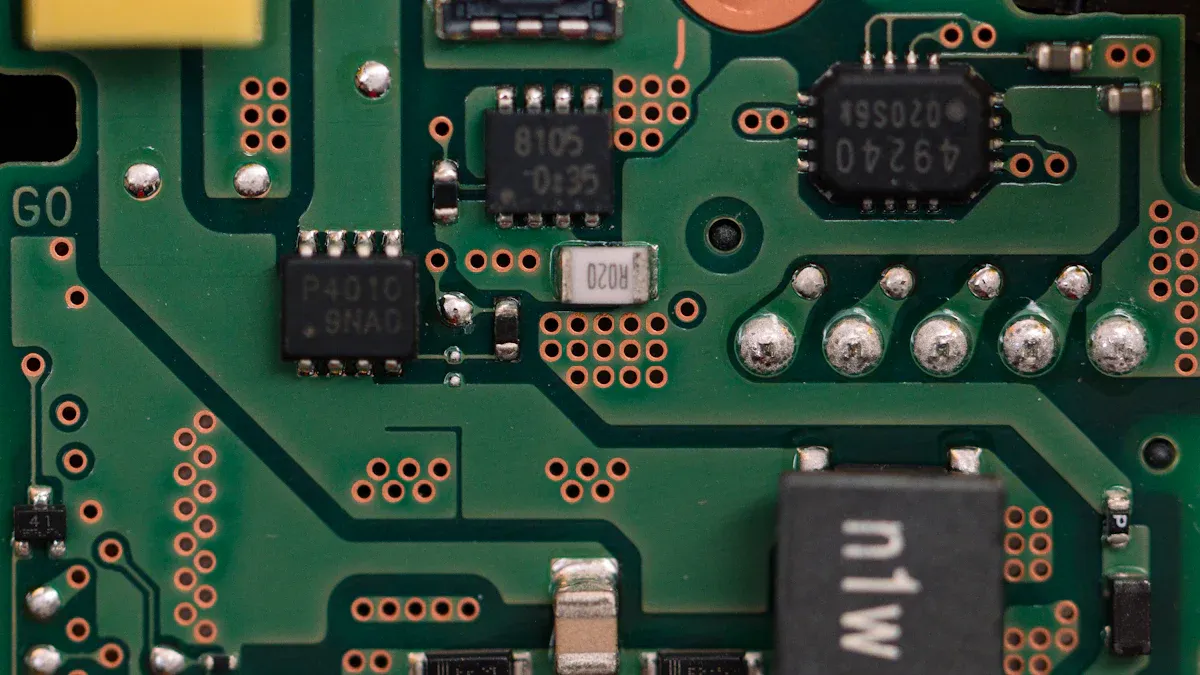

Working with Trusted Manufacturers

You should work with a manufacturer that knows how to make PCBs. A good partner helps you get the best materials and quality. Look for these things when you pick a manufacturer:

Skill and experience. Pick a company that has made many PCBs before.

Quality checks. Make sure they test every board and follow strict rules.

Good materials. Choose a manufacturer that gets materials from trusted suppliers.

Industry standards. Check if they follow rules like IPC-A-600 and IPC-A-610.

You can also look for extra help:

Design for Manufacturing (DFM) reviews. These help you find problems before you start making boards.

Final checks and tests. Good manufacturers use many tests to make sure your boards work well.

Benlida uses advanced tools and strict tests to make strong PCBs. Their team checks every step, from picking materials to the last test. You get boards that meet your needs and industry rules.

Note: Working with a trusted manufacturer saves you time and money. You get better boards and fewer problems.

Pitfalls and Considerations

Overlooking Key Material Properties

If you choose materials too quickly, you might miss something important. Every PCB material has special features that change how your board works. Things like dielectric constant, thermal conductivity, and mechanical strength all matter. If you do not check these, your board might not send signals well or last in hard places. Always look at the details for each material before picking one. This helps you stop problems like weak signals, too much heat, or boards breaking early.

Ignoring Manufacturability Constraints

How easy it is to make your board is just as important as how it works. Some materials seem good but are hard to use in the factory. You need to pick materials that match how your board will be made. The table below shows which materials work best for different jobs:

Material Type | Dielectric Constant | Suitability |

|---|---|---|

FR-4 | 4.5 | General use |

Rogers | 2.2 - 3.5 | High-frequency designs |

Teflon | 2.2 - 3.5 | High-frequency designs |

If you pick a material that is hard to make, you might have to wait longer or pay more. Talk to your manufacturer early to make sure your choices fit their machines.

Balancing Cost and Performance

You want your PCB to work well but not cost too much. Start by making your design in smaller parts. This can help you spend less on testing. Use normal board sizes so you do not waste material or pay extra. Try out your design with software to see if you can save space. Put parts in smart places to make your board smaller. Work with your manufacturer early to learn what makes things cost more.

To save money, you need to think about material prices, how you cut the boards, and how you make them. Try not to waste materials and keep testing costs low. But do not forget about how well your board needs to work. Good signals, heat control, and where you put parts are all important.

Ensuring Supplier Quality and Consistency

The quality of your supplier changes how good your PCB is. Good PCBs are easier to put together and work better. If your boards are more complex, you need the same good quality every time. Quality checks help your boards meet the rules and stop mistakes. If you pay for good quality, you will not have to fix or replace as many boards. Good suppliers help your products last longer and work well.

Tip: Always check your supplier’s quality records and how they test boards before you buy. This helps protect your money and makes your project more likely to succeed.

Picking the right PCB material changes how your product works and how long it lasts. Here are some easy steps you can follow:

Think about what your project needs.

Look at different materials you can use.

Plan your board layers to save money and work well.

Ask a trusted manufacturer for help if you need it.

You can get more help from the table below. If you want to talk to someone, you can contact Benlida’s team.

Resource Type | Link |

|---|---|

PCB Material Selection Guide | PCB Material Selection |

Material Selector Tool | Material Selector |

Supplier Quality Requirements | Supplier Quality Requirements |

Supplier Code of Conduct | Supplier Code of Conduct |

Quality Standards | Quality Standards |

FAQ

What is the most common PCB material?

FR-4 is the most used PCB material. It is strong and saves money. FR-4 gives good insulation. You see it in toys and computers.

How do you choose the right PCB material for high temperatures?

Pick materials with high glass transition temperature (Tg). Polyimide and high-Tg FR-4 are good for heat. These materials keep your board safe and strong.

Can Benlida help with custom PCB material selection?

Yes! You can ask Benlida’s team for help. They will help you pick the best material. You get expert advice and support for your project.

Why does dielectric constant (Dk) matter in PCB design?

Dielectric constant (Dk) changes how signals move in your board. A lower Dk keeps signals fast and clear. Match Dk to your circuit for the best results.

What testing does Benlida use to ensure PCB quality?

Benlida uses automated optical inspection, X-ray checks, and functional tests. These tests make sure your PCBs are reliable and meet industry rules.

en

en

WhatsApp

WhatsApp