How Benlida Flexible PCBs Enable Compact and Dynamic Electronic Designs

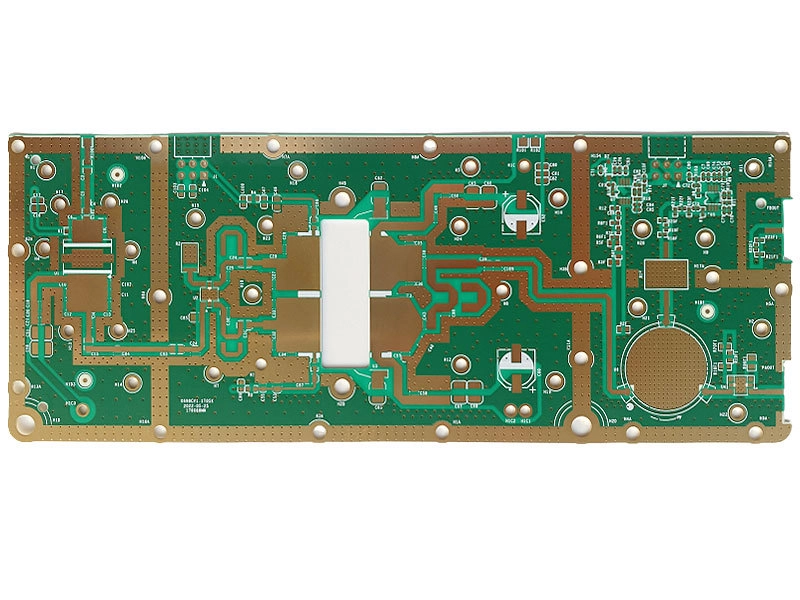

In the era of miniaturized and high-performance electronics, circuit design is no longer limited to flat, rigid boards. Engineers today need solutions that can bend, twist, and adapt to irregular spaces without sacrificing performance or reliability. Flexible Printed Circuit Boards (FPCs) meet this demand—offering freedom of design and exceptional mechanical endurance.

At the forefront of this innovation is Benlida Circuit, a leading manufacturer of flexible PCBs designed for dynamic applications such as wearable sensors, folding smartphones, curved automotive dashboards, and implantable medical devices. With the ability to endure over 100,000 flex cycles, Benlida’s flexible PCBs combine precision engineering with proven durability—enabling compact, high-reliability electronic systems across industries.

1. What Makes Flexible PCBs So Transformative

Unlike traditional rigid PCBs, flexible circuits are built on polyimide (PI), PET, or PTFE substrates—materials that allow the circuit to bend or fold repeatedly without failure. This flexibility provides several critical benefits for modern electronics design:

Lightweight construction: Reduces overall product mass and thickness.

Compact architecture: Routes circuits through limited or irregular spaces.

Enhanced durability: Absorbs mechanical stress and vibration better than rigid boards.

Improved reliability: Fewer solder joints and connectors mean fewer potential failure points.

This adaptability opens the door to truly three-dimensional product designs, where form and function can merge seamlessly.

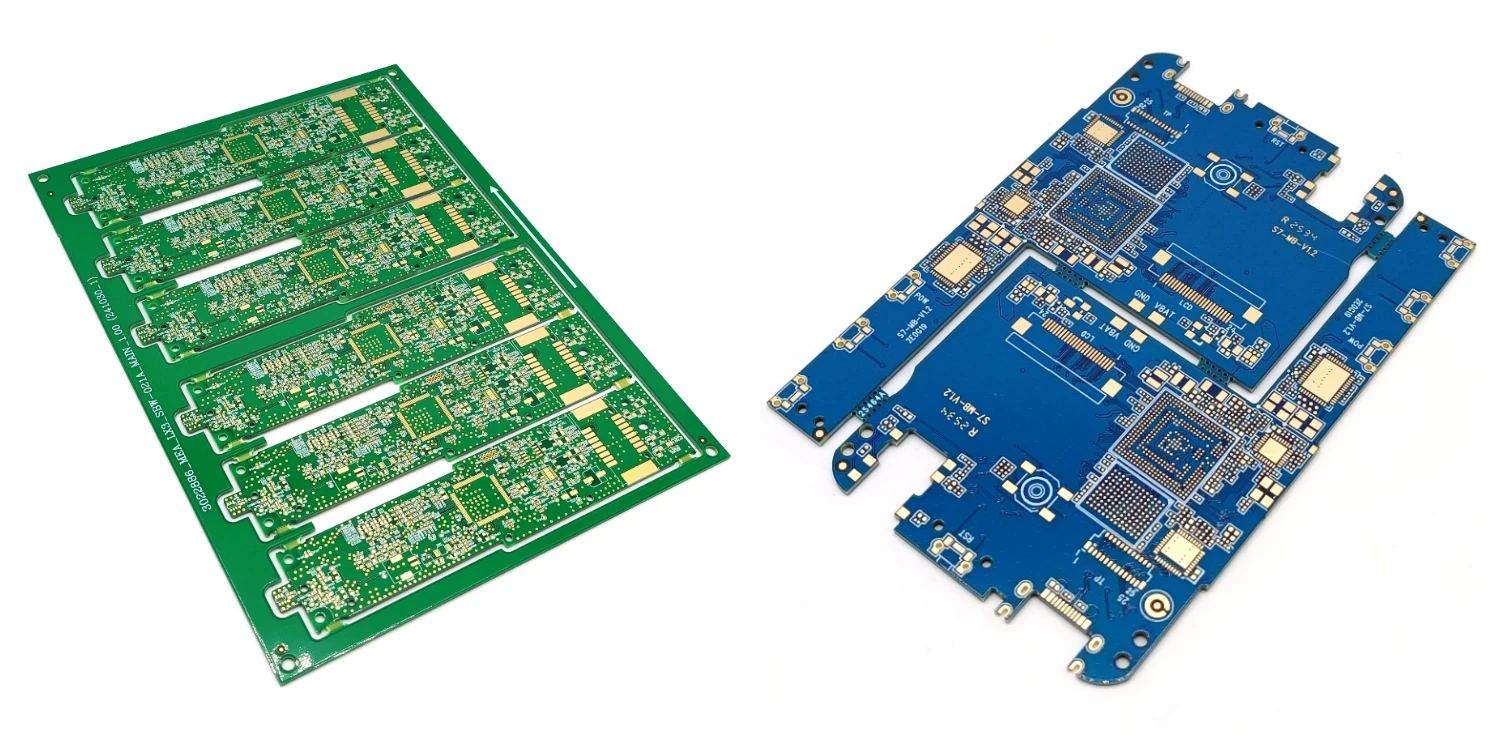

2. Compact Design, Infinite Possibilities

Flexible PCBs play a central role in developing space-efficient electronics. At thicknesses between 0.05–0.3mm, these boards are up to 70% thinner than conventional rigid PCBs.

Applications that rely on compact form factors include:

Wearable technology: Heart-rate monitors, smartwatches, and biosensors.

Portable electronics: Foldable phones, tablets, and compact cameras.

Automotive electronics: Curved dashboards, seat sensors, and interior lighting.

Aerospace and defense: Lightweight satellite and UAV components.

For these applications, weight and space savings are critical. Every gram saved in a drone or medical implant enhances performance and usability.

3. Reliability in Motion

The hallmark of Benlida’s flexible PCBs is mechanical endurance. Designed to withstand over 100,000 bending cycles, these circuits maintain electrical continuity and structural integrity even in devices that move constantly.

This resilience is especially valuable in applications that experience continuous motion—such as wearable fitness trackers or folding displays. Traditional rigid boards would fracture or delaminate under similar conditions.

Benlida achieves this through:

Optimized copper thickness (0.5oz–1oz) for mechanical strength.

Advanced adhesion and lamination techniques to prevent peeling.

Precision etching and patterning for consistent electrical paths.

The result is a flexible circuit that performs flawlessly under repetitive stress.

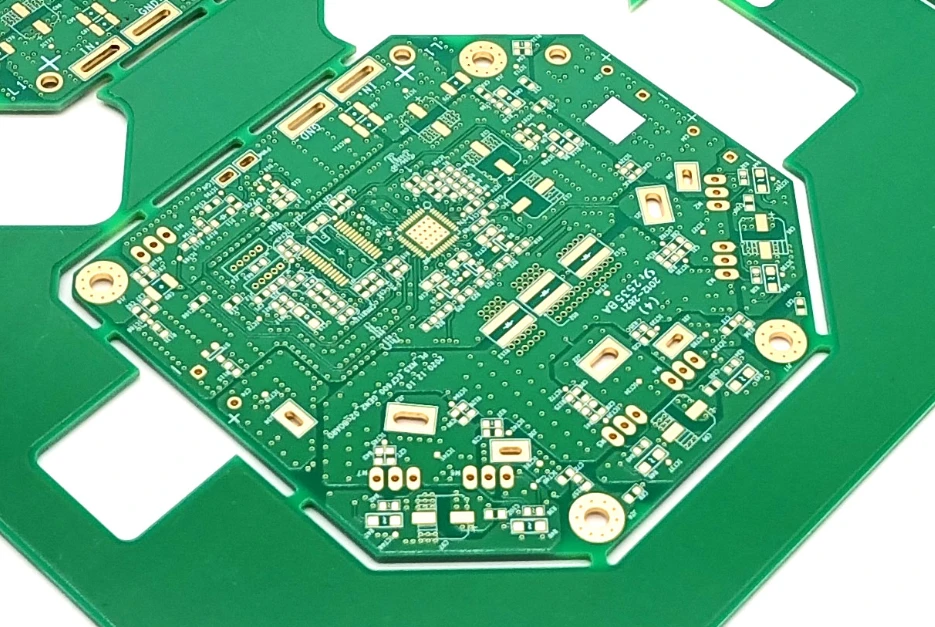

4. 3D Spatial Efficiency: The Engineer's Advantage

The ability to bend, fold, or roll allows flexible circuits to fit into designs that were once impossible. Engineers can route circuits around corners, through hinges, or within curved structures—eliminating bulky wiring harnesses and simplifying assembly.

In automotive dashboards, flexible PCBs support ergonomic curved displays and integrated control panels. In implantable medical devices, they conform to organic shapes without compromising reliability.

This 3D design flexibility not only improves functionality but also reduces assembly time, wiring complexity, and product thickness.

5. Withstanding Extreme Conditions

Benlida’s flexible PCBs are built for real-world durability. They operate flawlessly between -40°C and 150°C, resist moisture, dust, and vibration, and maintain performance in high-stress environments.

This makes them ideal for critical applications such as:

Aerospace communication systems

Automotive engine control modules

Medical diagnostic equipment

Outdoor industrial sensors

By removing traditional wiring harnesses and connectors, flexible PCBs minimize mechanical stress points, improving system reliability and longevity.

6. Superior Electrical Performance

Modern electronics rely on high-speed data transmission and signal integrity, both of which are strengths of Benlida’s flexible PCB designs.

Key electrical advantages include:

High-density interconnects (HDI): Up to 50μm trace/space for fine-line circuits.

Reduced EMI (electromagnetic interference): Ideal for RF and 5G applications.

Stable impedance control: Ensures precise signal timing for communication and control systems.

These attributes make Benlida’s flex PCBs ideal for high-frequency, low-loss, and high-reliability products—from medical imaging equipment to next-generation mobile devices.

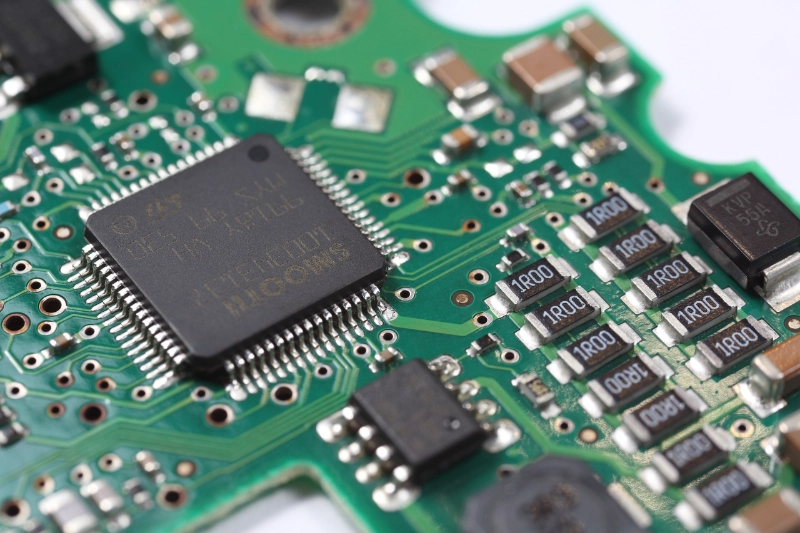

7. Benlida’s Manufacturing Expertise

Behind every flexible PCB is a complex, precision-driven manufacturing process. Benlida employs advanced fabrication techniques and strict quality control at every stage.

Manufacturing specifications include:

Layers: 1–12

Copper thickness: 0.5oz–1oz

Hole size: 0.05mm–0.1mm

Surface finishes: ENIG, Immersion Silver, OSP

Finished thickness: 0.1–0.3mm

These parameters allow engineers to select materials and configurations tailored to their product’s needs—whether optimizing for flexibility, current capacity, or thermal stability.

Each PCB undergoes comprehensive reliability testing, including flex durability, thermal shock, and signal verification.

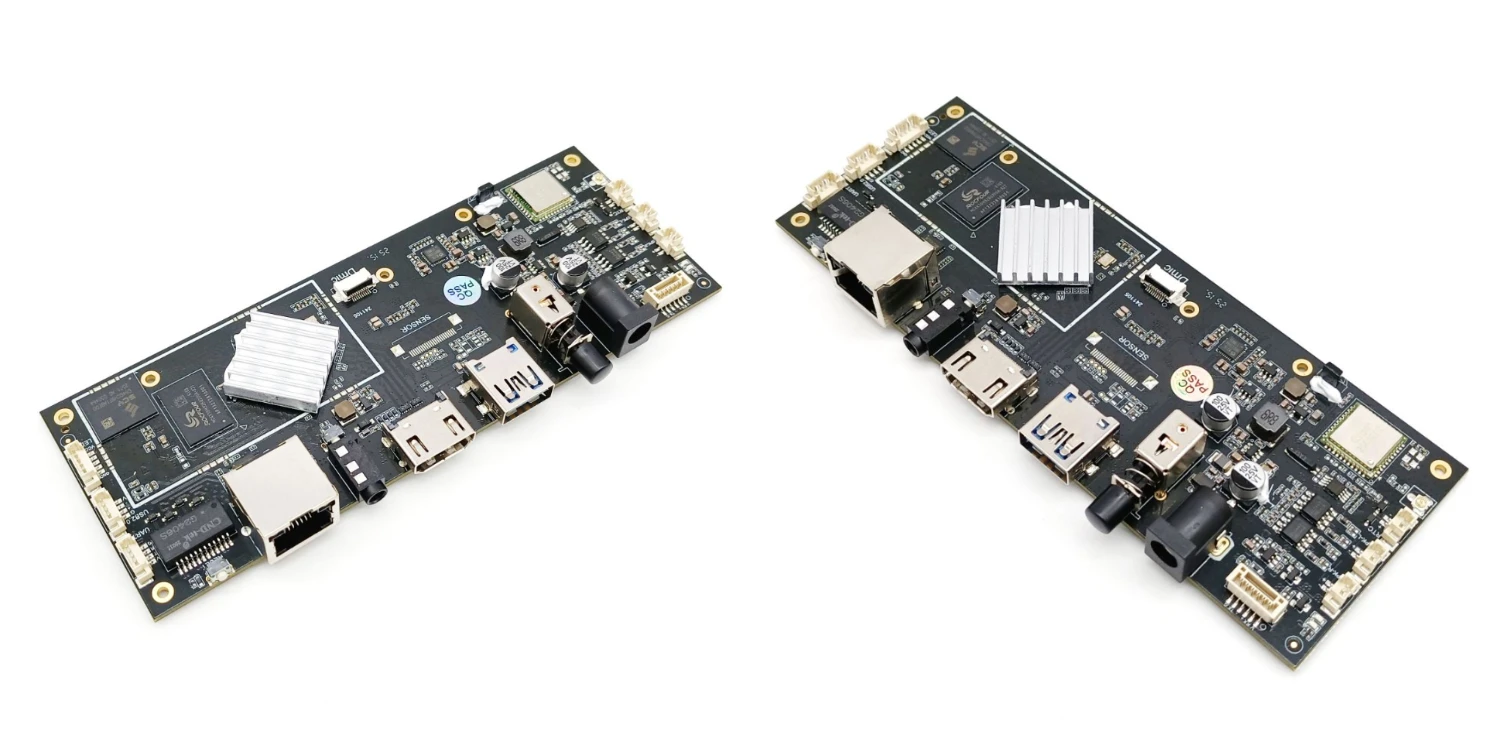

8. Enabling Smarter, Smaller, and Stronger Products

The evolution of electronics increasingly depends on materials and processes that support high performance within small footprints. Flexible PCBs embody this philosophy by offering a platform that reduces bulk, enhances reliability, and allows electronic designs to evolve beyond two dimensions.

Benlida’s continuous innovation in flexible PCB materials, copper etching, and signal optimization ensures that customers can integrate flexibility without compromise. Whether for a curved automotive console, a wearable ECG patch, or a foldable display, Benlida circuits bring structure and stability to complex design environments.

Conclusion

As technology trends move toward mobility, interconnectivity, and miniaturization, the demand for flexible circuit solutions continues to rise. Benlida Circuit’s advanced flexible PCBs provide the balance of durability, performance, and adaptability required to meet these evolving challenges.

By merging mechanical flexibility with electrical precision, Benlida helps manufacturers design smarter, lighter, and more resilient products that shape the future of modern electronics.

en

en

.webp)

WhatsApp

WhatsApp