A study on the application of polyimide QR code labels in SMT production

Abstract

The surface mount technology (SMT) process parameters of printed circuit board (PCB) assemblies and the fixation of components are key links in the full lifecycle management of electronic products, and QR code labels serve as an important carrier for achieving this function. To address the quality problems of existing matte silver QR code labels—such as deformation and curling—which occur because they cannot withstand the high temperature of reflow soldering during PCB assembly, this study investigates the application of polyimide (PI) labels in the SMT production process of PCB assemblies. Experimental results show that under reflow soldering conditions with a peak temperature of 260 °C, PI labels maintain a 100% integrity rate; after spray cleaning, the detachment rate of PI labels is below 3.7%, and the QR codes remain clear and readable. The study demonstrates that PI labels can stably function as information carriers throughout the entire SMT production process, providing reliable support for the full lifecycle management of electronic products.

Keywords: printed circuit board components; QR code label; polyimide; full lifecycle management; surface mount technology

0 Introduction

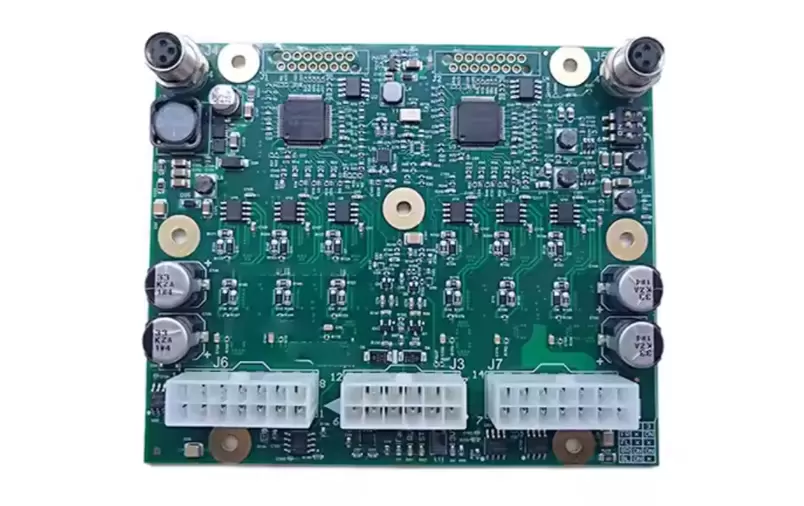

Surface mount technology (SMT) is a manufacturing process in which electronic components are directly mounted onto the surface of a printed circuit board (PCB). It has become the core process of modern electronic manufacturing, driving electronic products toward high performance, miniaturization, and high reliability. Throughout the full lifecycle of an electronic product—from raw material procurement, production and manufacturing, sales and distribution, to after-sales service—each link requires precise information recording and traceability. QR code technology is a commonly used approach for achieving this goal. QR code labels can store a large amount of information, including product model, batch number, production date, and more.

As information management and traceability requirements for PCB assembly during SMT production continue to grow, the accurate recording of production process parameters on PCB assemblies has become crucial. During PCB assembly, production line equipment scans the QR code on the PCB to lock in SMT process parameters, which are stored in the information system. This provides strong support for quality control, after-sales service, and recall management of electronic products. This paper conducts an in-depth study on the application of polyimide (PI) film-based QR code labels in the SMT production process, elaborating in detail on their material characteristics and practical application performance.

1 Overview of QR Code Technology

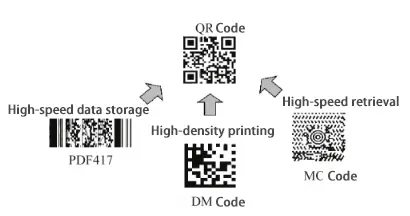

A QR code is a graphic composed of geometric shapes arranged according to certain rules on a specified plane to record symbol information. According to different encoding rules, QR codes can be categorized into stacked QR codes and matrix QR codes [1]–[3]. Stacked QR codes are formed by stacking multiple one-dimensional barcodes according to specific rules, with common examples including stacked PDF417 and Code49. Matrix QR codes use a binary matrix to represent character information by encoding code blocks of different coordinates and gray levels on a two-dimensional plane. Common matrix QR codes include QR code, DM code, and MC code. The QR code achieves the high-capacity data storage capability of the PDF417 code and the high-density printing characteristics of the DM code, while also having the high-speed reading capability of the MC code, as shown in Figure 1. Therefore, QR codes are commonly used for production traceability in the SMT manufacturing process of PCB assemblies.

Figure 1 QR code

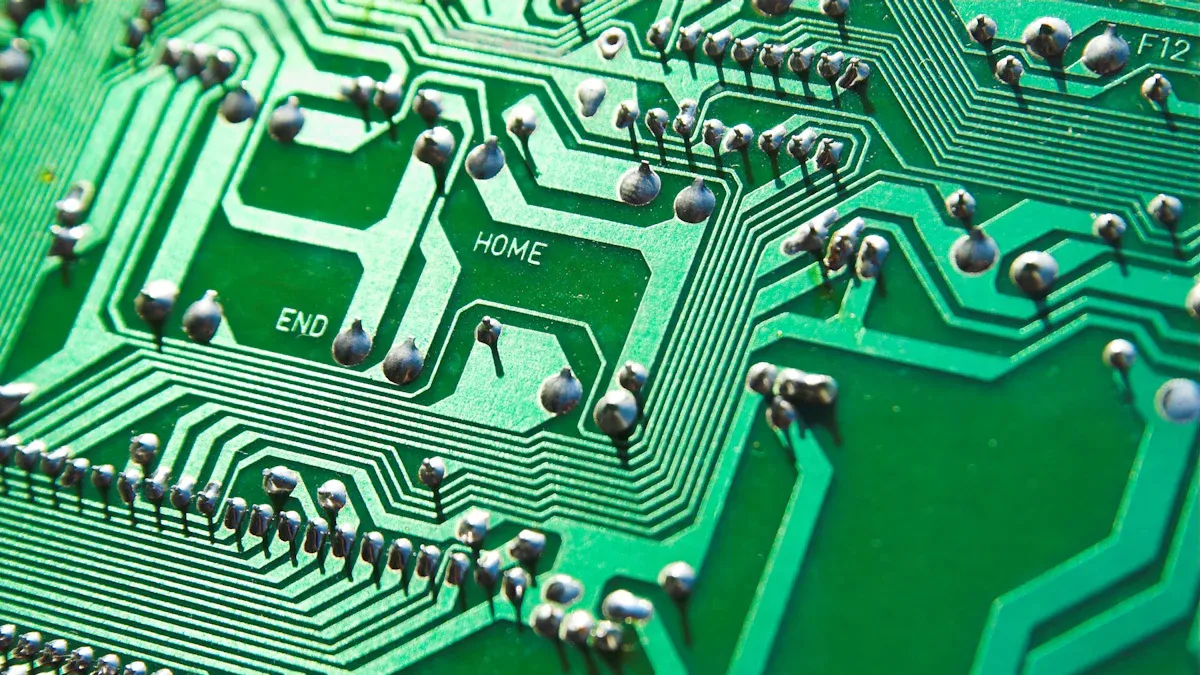

Currently, three QR code technologies are commonly used on PCBs: substrate screen printing, laser engraving, and thermal transfer [4]–[6]. Substrate screen printing directly prints QR code patterns onto the PCB surface using ink. Although the process is simple, it is suitable only for larger QR codes. Small QR codes often suffer from blurred edges, resulting in low data readability. Laser engraving uses a laser beam to etch micro-pits or color contrasts on the PCB surface to represent QR code information. It offers high precision and resolution, with the smallest QR code size reaching 2 mm × 2 mm. Compared to printing, laser engraving is slower and more costly. Thermal transfer technology transfers QR code patterns from ribbon media onto film labels through a thermal printing process before attaching them to the PCB surface. It offers high accuracy, high durability, high production efficiency, and strong reworkability, with the lowest overall cost. Therefore, thermal transfer technology is currently the most economical and flexible QR code labeling method widely adopted by manufacturers.

2 Analysis of QR Code Label Material Characteristics

2.1 Characteristics of Matte Silver Label Material

Matte silver labels made of polyester (polyethylene terephthalate, PET) or polyvinyl chloride (PVC) are still widely used by PCB assembly manufacturers due to their cost advantage. Their short-term temperature resistance can reach 150 °C. The bonding process of matte silver labels must be performed after PCB assembly and cleaning processes.

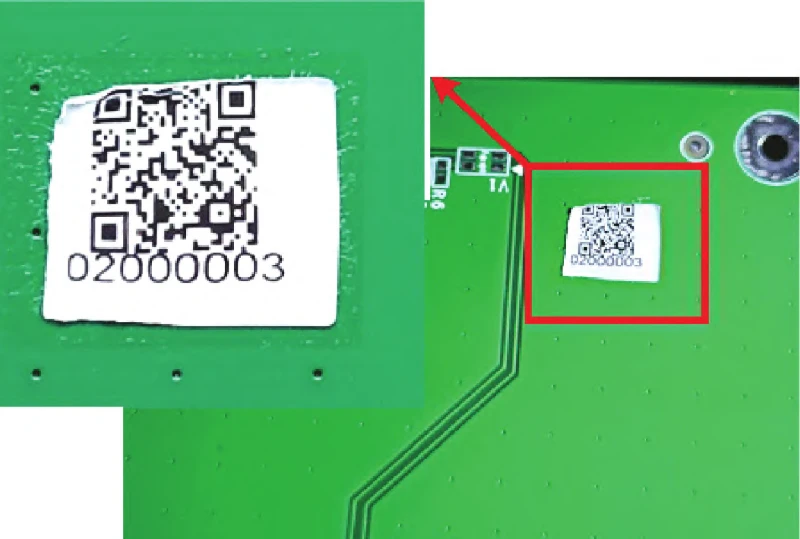

However, to bind SMT process parameters with PCB identification, the QR code labeling process needs to occur before SMT production. The material properties of matte silver labels make them unable to withstand the peak temperature of the reflow soldering process. Using a rework station to simulate SMT reflow soldering at 245 °C, the labels exhibited deformation, bubbling, and curling, as shown in Figure 2, resulting in blurred QR codes. These issues cause loss of SMT process parameter information and seriously affect the effectiveness and scientific nature of lifecycle management for electronic products.

Figure 2 High-temperature defects of matte silver labels

2.2 Characteristics of PI Label Material

Polyimide (PI), as a high-performance polymer material, exhibits excellent high-temperature resistance, good mechanical properties, outstanding chemical stability, and strong electrical insulation. Research on PI QR code labels from a certain manufacturer shows that they remain unaffected after a 5-minute heat resistance test at 300 °C, demonstrating stable performance in the high-temperature environment of SMT reflow soldering.

During reflow soldering, when the temperature reaches 240–260 °C, PI labels do not undergo melting, deformation, or decomposition as ordinary label materials do. Instead, they maintain complete physical form and functional integrity. The structure of PI labels is shown in Figure 3.

Figure 3 PI tag structure

3 PI Label SMT Production Process Experiments

The SMT production process is complex and highly precise, consisting mainly of solder paste printing, component placement, reflow soldering, inspection, water-based cleaning, and rework. Among these, the high-temperature environment during reflow soldering and rework, as well as the impact force during water-based cleaning, pose major challenges to both the high-temperature resistance and adhesive strength of PI labels.

3.1 Reflow Soldering Test

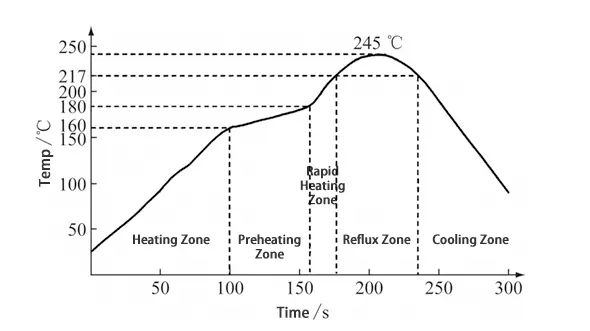

A typical lead-free soldering process curve is shown in Figure 4, where the reflow zone temperature ranges from 217 °C to 245 °C, with a dwell time of 60–150 seconds. For complex PCB assembly production, the peak temperature must reach 260 °C.

Figure 4 Lead-free soldering temperature profile

To verify the temperature resistance performance of the QR code labels, PI labels were attached to a 2 mm thick circuit board. The soldering temperature curve used the lead-free soldering profile, with a reflow peak temperature set to 260 °C, a soldering duration of 150 seconds, and 5 reflow cycles.

After reflow soldering, the label surface showed no peeling, wrinkling, discoloration, or other defects, and the QR code pattern on the label remained clear and readable, as shown in Figure 5.

Figure 5 QR code after reflow soldering

3.2 Automatic Cleaning Test

After soldering the PCB assembly, water-based automatic cleaning is required. The solvent temperature reaches a maximum of 50 °C, with a cleaning duration of 50 minutes. To verify whether the temperature-resistant labels that passed the reflow soldering test could withstand the automatic cleaning process, an automatic cleaning experiment was conducted:

A total of 60 QR code labels that had undergone lead-free reflow soldering were applied on 30 PCBs, divided into 3 batches for automatic cleaning experiments.

After automatic cleaning, only 2 labels detached, resulting in a detachment rate of 3.3%, and an overall pass rate of 96.7%. The remaining labels did not detach; some showed slight corner lifting. The QR code patterns on all remaining labels remained clear.

3.3 Rework Station High-Temperature Resistance Test

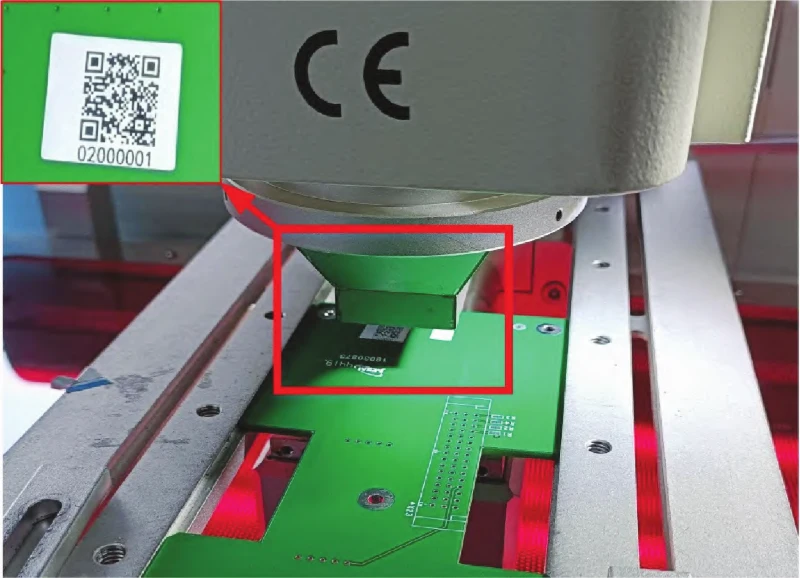

After water-based cleaning, the PCB was placed on a rework station to verify the effect of high temperature during component rework on PI labels, as shown in Figure 6.

Figure 6 High-temperature resistance test of PI labels during rework

The label was positioned within the heating chamber, with the maximum temperature set to 280 °C, applied for 120 seconds per cycle. After experiencing two cycles of high-temperature exposure, the label surface did not show peeling, wrinkling, or discoloration. The QR code pattern on the label remained clear and readable.

4 Conclusion

In order to solve the problem of QR code label high-temperature resistance during the SMT production process of PCBs, this paper conducted a series of application verification tests on PI QR code labels. Experimental results show that PI labels can withstand the high temperatures of reflow soldering and rework, as well as the impact of water-based automatic cleaning processes. They meet the SMT production requirements of PCB assembly, enabling consistency between SMT process parameters and PCB identification. This provides a feasible solution for the full lifecycle management of electronic products.

References

- [1]Qin Shoujun, Wang Zhengkun. Research on the Application of QR Code Technology on Printed Circuit Boards [J]. Printed Circuit Information, 2020, 28(4): 20-22.

- [2]Xiao Cong. Research on the Encoding and Decoding System of Hole Array Code in PCB Quality Traceability [D]. Guangzhou: Guangdong University of Technology, 2019.

- [3]Zheng Jingbiao. Development of an X-ray Embedded DataMatrix QR Code Imaging and Reading Device [D]. Shenzhen: Shenzhen University, 2023.

- [4]Liang Shihe, Zhuang Jiahao. Comparison and Analysis of Common QR Code Printing Methods [J]. China Auto-ID Technology, 2023(4): 73-78.

- [5]Ai Yuanqing. Extensive Application of Laser Marking in the PCB Industry [C] // Proceedings of the 2021 China High-End SMT Academic Conference. Chongqing, China: SMT/MPT Committee of Sichuan Institute of Electronics, 2021: 273-279.

- [6]Li Yang, Wu Yongjin, Wang Wenbao, et al. Research on Fabricating QR Codes on Flexible Printed Circuit Boards Based on Etching Technology [J]. Printed Circuit Information, 2025, 33(S1): 1-6.

en

en

WhatsApp

WhatsApp