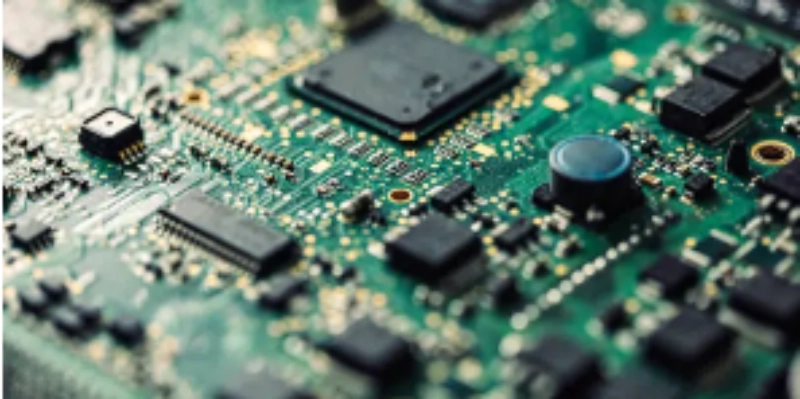

What are the potential risks and hazards of manual soldering on printed circuit boards/PCB?

Manual soldering on printed circuit boards/PCB is a fundamental operation for THT/DIP, repair and rework, but it has several potential risks. These risks not only threaten the safety and health of operators but also affect product quality and reliability directly.

This article summarizes the main risks systematically in the soldering process and how they may affect the work:

I. Safety Risks to Operators

1. Risks for High Temperature Burns and Fire

● Heat: The working temperature of the soldering iron tip is usually above 300°C to 400°C, it could cause severe burns even an instantaneous contact.

● Molten Solder: Liquid solder splatter is a common risk.

● Fire: Improper placement of the soldering iron (such as placing it on flammable materials), solder beads ignites objects nearby, or excessive heating time which cause plastic components to burn.

2. Inhalation of Toxic Fumes and Gases

This is the most common and neglected threat for long-term health. During soldering, the heated flux release fumes&gases which carry various harmful substances:

● Rosin (resin) fumes: Inhalation irritates the respiratory tract; long-term exposure may cause operators' fever (a flu-like metal fume fever) or asthma and chronic bronchitis.

● Organic acid activators: Such as adipic acid and glutaric acid, which are highly irritating to the eyes and respiratory tract.

● Aldehydes: High-temperature decomposition may produce carcinogens such as formaldehyde.

● Special risks of lead-free solders: Lead-free solders (such as SAC305) operate at higher temperatures, produce more finer and abundant fumes.

3. Risks of Metal Exposure

● Lead Exposure: Although lead-free soldering is the trend, exposure to lead-containing solders is still possible when repairing old equipment or in certain fields. Lead is a cumulative poison that can enter the body through the respiratory tract or hand-to-mouth, damages the nervous, hematopoietic, and reproductive systems.

● Other metal fumes: Tiny particles of metals such as tin, silver, and copper, when inhaled into the lungs, may cause metal fume fever.

4. Safety Risks of Electrical

● Electric Shock: Using a poor-quality or damaged soldering iron, or when there is water or metal shavings on the workbench, may result in electric shock.

● Short Circuit Accidents: Soldering while the circuit is on power or accidentally touching the power supply section of the board with the soldering iron tip, it may cause an electric arc, explosion, or equipment damage.

II. Potential Risks to Electronic Products (Circuit Boards and Components)

1. Thermal Damage

● PCB Delamination and Blistering: overheating may cause the glass transition temperature of the resin in the PCB substrate (especially FR-4) to exceed its limit, lead to delamination and blistering.

● Component Thermal Failure: Semiconductor components (such as chips, diodes, MLCC, etc) are sensitive to static electricity and overheating. Excessive temperature from soldering iron or prolonged soldering time may hurt the internal structure.

● Solderpad/Trace Peeling: Overheating or improper force may cause copper foil, solderpads and trace to peel off from the substrate.

2. Electrostatic Damages

● Sources: Static electricity generated by the human body, synthetic clothing, or plastic tools may be directly transferred to static-sensitive components through the soldering iron tip or the user's hands.

● Consequences: Causes potential damages or immediate failure. Devices such as MOSFETs, CMOS chips, and LEDs are highly sensible.

3. Soldering Quality Defects

● Cold Soldering/Insufficient Soldering: Insufficient temperature or soldering time results in poor mechanical strength and high resistance at the solder joint.

● Solder Short: Too many solder may connects adjacent pins accidentally, cause short circuit.

● Excessive Solder/Insufficient Solder: Affects the reliability and mechanical strength of electrical connections.

● Flux Residue: Corrosive residues, if not properly cleaned, may cause leakage, short circuits, or chemical corrosion over time.

III. Potential Environmental Hazards

Improper Waste Disposal: Lead-containing solder slag, discarded PCB boards, and chemical cleaning agents (such as board cleaning solutions) disposed of as ordinary waste which shall cause heavy-metal and organic pollution on soil and water sources.

Category of Hazards and Main Protective Methods

● Human Health

1. Mandatory Ventilation: Use exhaust tubes and general ventilation system to exhaust the fumes&gases.

2. Personal Protection: Wear anti-static wrist straps, protective masks or respirators and goggles.

3. Operation Habits: Wash hands after handling equipment; Do not eat or drink in the workshop.

● Product Safety

1. ESD Protection: Use anti-static workbenches, floor mats, and wrist straps; use grounded, temperature-controlled soldering irons.

2. Precise Temperature Control: Use adjustable temperature soldering stations and adjust appropriate temperatures (not the higher the better).

3. Standard Operation: standard and formal training to operators, train for correct soldering techniques and times (usually 2-4 seconds).

● Environmental and Comprehensive Management

1. Waste Classification: Establish dedicated containers to collect solder slag, waste boards, etc., and hand them over to qualified companies for disposal.

2. Equipment Maintenance: Regularly check the grounding of soldering iron and replace aged soldering iron tips.

3. Alternative Materials: use low-smoke, low-halogen, or halogen-free fluxes.

The hazards of printed circuit board/PCB soldering are multi-dimensional, the key of protection is proper management and the mindset. Establish a comprehensive assessment system (identifying fumes, high temperatures, static electricity, chemical, and electrical hazards) and strictly implement corresponding environmental controls (ventilation), administrative management (training, standards), and personal protective equipments, we can maximize personnel safety, improve product quality, and fulfill environmental responsibility. Integrating safety and quality awareness into every solder joint is the responsibility of electronics manufacturing and repair work.

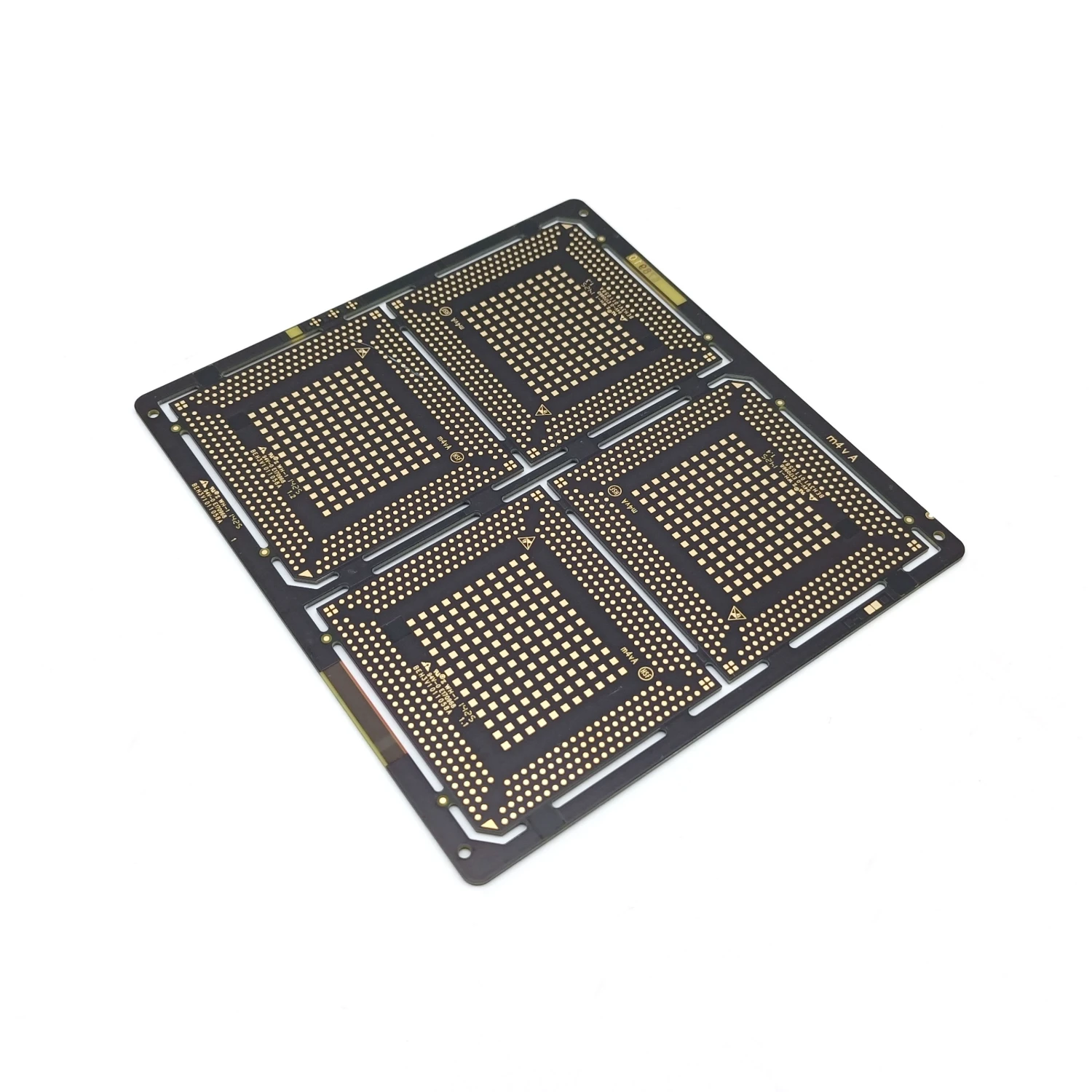

Benlida has been manufacturing PCB and PCB assembly for 14 years, while focuse on quality and provide excellent service to customers, we also care the physical and mental health of our employees, rigorously training them for skills and daily operation procedures. Every employee is a member of our family and the team.

Benlida cares it's members.

en

en

WhatsApp

WhatsApp