HDI Circuit Boards: Cost-Benefit Analysis for Different Applications and Industries

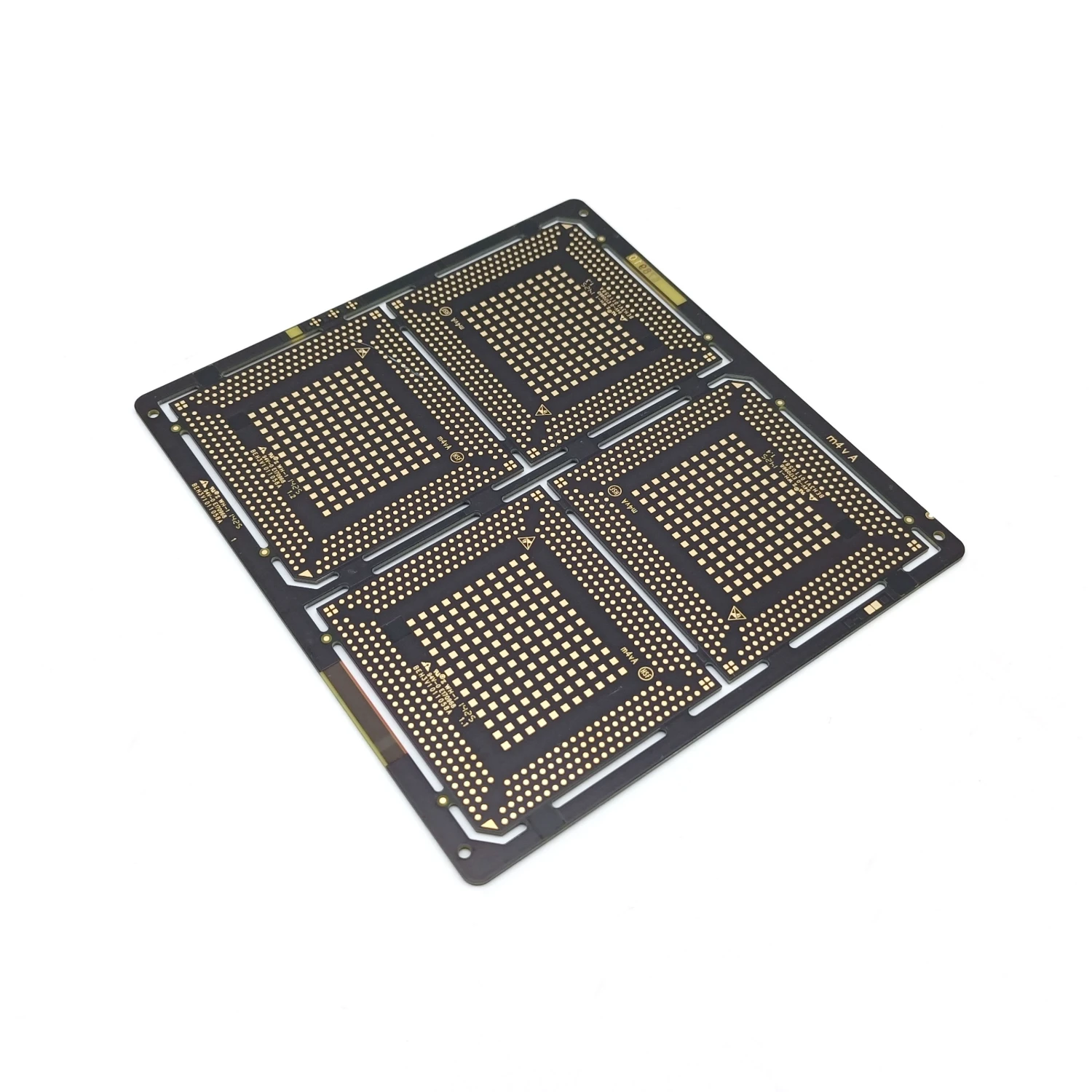

You might ask if HDI PCBs are useful in many industries. The answer is yes. Benlida Circuit’s HDI PCB helps make things smaller and more reliable. It also helps save money. You can fit more parts on your board. Your designs will have better signal quality. When you look at the Cost-Benefit Analysis, you see clear benefits. These benefits are best for projects that need high performance. You may think about material costs and design difficulty. You may also wonder about long-term gains. This part helps you make good choices for your projects.

Key Takeaways

HDI PCBs make devices smaller and more dependable. They fit more parts into less space. They give better signal quality. This makes them good for fast devices like smartphones and medical tools. HDI technology can shrink board size by up to 60%. This lets designers make things compact. HDI boards can save money over time. They lower material costs and need less fixing. Picking the best materials and designs helps save money. It also makes HDI PCBs work better. Making a prototype early can find problems. This saves time and money before making many boards. Working with a skilled HDI PCB maker gives good quality. It also helps you get your boards on time. Think about what your project needs and how many you will make. This helps you decide if HDI PCBs are the best choice.

HDI PCB Cost-Benefit Analysis

Comparing HDI vs. Standard PCBs

You might wonder how HDI PCBs stack up against standard boards. The cost-benefit analysis shows they work better and last longer. HDI boards use new technology for stronger signals and more parts on each board. These benefits help in places where space and speed are important.

Here is a table that shows the main differences:

Feature | HDI PCBs | Standard PCBs |

|---|---|---|

Signal Integrity | Superior, reduced electrical noise | Adequate, limited at high frequencies |

High-Speed Application Suitability | Better suited for high-speed applications | Less suitable for high-speed applications |

Impedance Control | Precise matching for high-speed signals | Greater discontinuity in impedance due to normal vias |

Miniaturization | Remarkable due to thin cores and build-up layers | Limited miniaturization capabilities |

HDI PCBs give you better signals and let you make smaller gadgets. These features make HDI boards smart for things like phones, medical tools, and AI machines.

Value of HDI Technology

HDI technology gives you special benefits. You can make devices smaller and add more parts to each board. This matters for smartphones, wearables, and medical sensors. You also get better performance because HDI boards use microvias and fine traces.

HDI PCBs can shrink board size by up to 60%. This helps you make tiny products for small spaces.

Smaller traces and vias let you pack in more parts. You fit more pieces in the same spot.

Microvias increase connection density by up to 50%. You get better paths and stronger links.

You can put passive parts inside the board. This saves room and lets you add more active parts.

Benlida Circuit’s HDI PCB uses these features to help you build cool new devices. You get boards with lots of connections that work in many places. The cost-benefit analysis shows you save space and get better results.

ROI Scenarios for HDI PCB

You might ask if HDI PCBs are a good deal for your project. The cost-benefit analysis helps you see if you get your money’s worth. HDI boards can cost more to make, but you save in other ways. You use fewer layers, so you spend less on materials. You also get more good boards and less waste.

Here are some examples:

Consumer Electronics: You design a smartwatch. HDI PCB lets you fit over 5,000 parts in a tiny space. You use fewer layers, so your cost drops. You get better performance and longer battery life.

Medical Devices: You build a sensor for inside the body. HDI technology helps you shrink the board by 60%. You get strong signals and steady operation. Your device lasts longer and works better.

AI Hardware: You make a fast processor board. HDI PCB gives you exact impedance control and quick signal paths. You use fewer layers, which saves money. Your product handles more data and stays cooler.

HDI PCBs give you big benefits in many areas. The cost-benefit analysis shows you get better density, stronger boards, and better performance. You also save money over time because your devices last longer and work better. Benlida Circuit’s hdi board helps you reach your goals with fewer layers and lower costs.

HDI PCB Cost Drivers

Materials and Substrates

Advanced Laminates

You need to choose the right materials for your hdi project. The substrate you pick changes the cost and quality of your board. FR-4 is a common choice because it is affordable and easy to find. You pay about $0.50 to $1.50 per square foot for FR-4. If you want better performance for high-speed signals, you may use PTFE. PTFE costs three to five times more than FR-4. You should look for materials with a Tg of at least 170°C. This helps your hdi pcb handle multiple lamination cycles without warping. When you work with Benlida Circuit, you get help choosing materials that balance cost and quality.

FR-4 is budget-friendly but may not support high-speed signals.

PTFE supports high-frequency signals but costs more.

High-Tg laminates improve thermal performance and reliability.

You should talk with your fabrication partner to find materials that fit your needs and budget.

Copper and Finishes

Copper thickness matters for both cost and quality. Thicker copper gives you better conductivity, but it adds weight and increases cost. You need to find the right balance. The finish you choose also affects quality. Some finishes protect the copper from oxidation and improve soldering. Others help with signal integrity in hdi designs. You should select finishes that match your performance goals and budget.

Layer Count and Lamination

Single vs. Multi-Layer

The number of layers in your hdi pcb design changes the cost. More layers mean higher expenses. You can save money by using hdi technology to fit more parts on fewer layers. Benlida Circuit’s boards often use eight layers to do the work of a sixteen-layer standard board. This reduces material costs by up to 25%. You get high quality and performance with fewer layers.

Manufacturing Time

Manufacturing time is another cost driver. HDI boards need more lamination cycles than standard boards. This takes more time but gives you better quality and reliability. Benlida Circuit uses high-yield processes to keep defect rates low. You get boards faster and with fewer problems.

PCB Type | Lamination Cycles | Plating Yield |

|---|---|---|

HDI PCB | 5+ | <0.1% defect rate |

Standard PCB | 1-2 | >98% (mature process) |

Via Types and Density

Microvias

Microvias are tiny holes that connect layers in hdi boards. They let you fit more connections in a small space. Microvias help you shrink your design and boost quality. Benlida Circuit uses laser drilling to make microvias as small as 50μm. This increases density and improves performance.

Blind/Buried Vias

You can use blind or buried vias to connect layers without going through the whole board. Skip vias cost less because they need fewer lamination steps. You may lower manufacturing costs by 15–30% with skip vias. Blind vias, especially when stacked, cost more and may reduce yield by 10–15%. You should choose via types based on your performance needs and budget. Benlida Circuit helps you pick the best option for quality and cost.

Manufacturing Techniques

Laser Drilling

Laser drilling makes tiny holes in hdi boards. This method lets you control where the drill hits copper. You get more good boards because it is very exact. Laser drilling helps you make microvias that link layers without hurting the board. You can use traces bigger than 3 mils, so you save money. You also need fewer layers in your hdi pcb, which lowers your cost.

Here is how these advanced methods help you:

The drill hits copper in the right spot, so you get more good boards.

Traces above 3 mils help you spend less.

Fewer layers mean your cost drops.

Laser drilling helps you build hdi boards that are dense and strong. You can fit more links in a small area. This lets you make smaller and faster gadgets.

Direct Imaging

Direct imaging uses light to make patterns on your hdi pcb. You do not need masks for this step. This way is more exact and lets you make thin traces. You get more automation, so you save time and money. Direct imaging also lets you add more links. You can make harder designs without spending a lot more.

You should know that laser drilling and direct imaging can cost more at first. You need special tools and clean rooms. Over time, you save money because you get more good boards and fewer mistakes. Benlida Circuit uses these ways to give you hdi boards with almost no defects.

Design Complexity

CAD and Prototyping

You use CAD software to plan your hdi pcb. Adding more layers makes your design harder. Hard designs take more time and skill. You may need extra test boards to check your ideas. This can make your first cost higher and slow down your project.

Here is a table that shows how your choices change cost:

Factor | How It Changes Cost |

|---|---|

Number of Layers | More layers make things cost more and take longer. |

Material Selection | Some materials cost more because they are special or hard to find. |

Type of Vias | Picking between mechanical and laser drilling changes cost. |

Production Yield | Harder designs can mean fewer good boards, so you need to make more. |

Prototyping Requirements | More test boards mean higher first costs and longer wait times. |

You should work with your maker to keep your hdi design easy. Fewer layers and smart microvias help you spend less. Benlida Circuit uses good CAD tools and high-yield ways to make sure your hdi pcb fits your needs without extra cost.

You can spend less by picking the best ways to make your board and keeping your design simple. This helps you get strong hdi boards for your project.

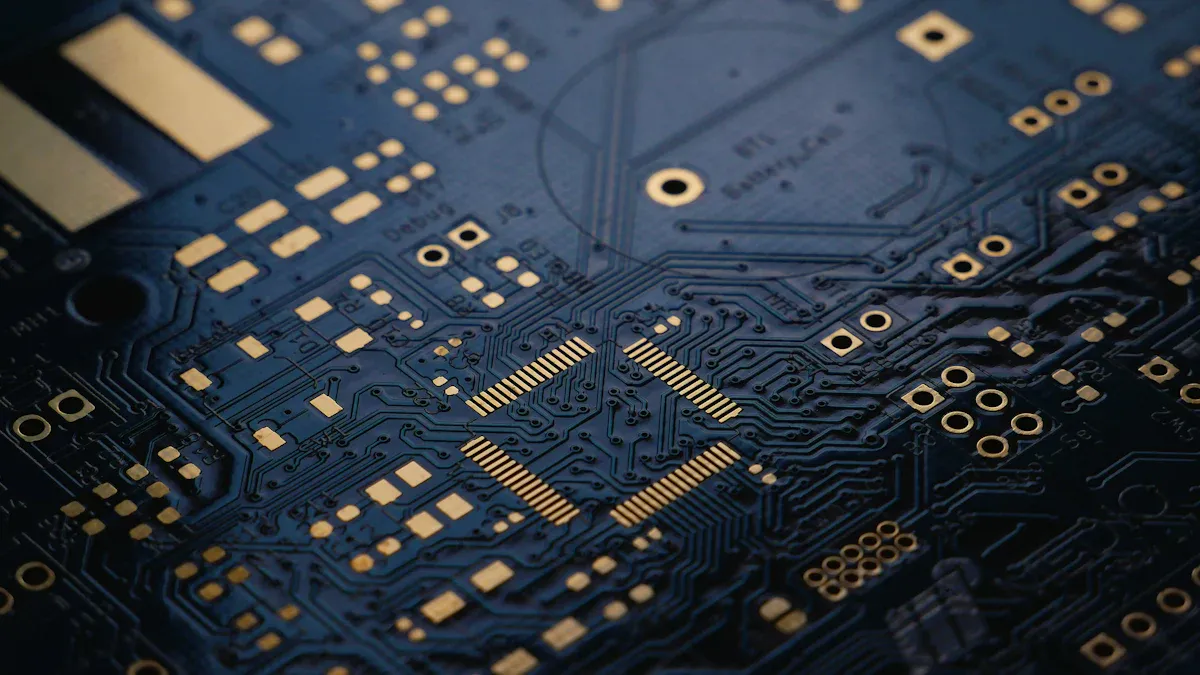

HDI Cost-Benefit: Performance Impact

Electrical Performance

Signal Integrity

You want your circuits to be fast and work well. HDI boards help you do this. They use special ways to build and fit more parts close together. This means you get fewer problems with signals and better control. You see less noise and smoother data flow. HDI technology uses microvias, not regular holes. This change helps keep signals strong and lowers losses.

Here is a table that shows how HDI boards help electrical performance:

Improvement Type | Description |

|---|---|

Signal Integrity | Fewer signal problems because of more parts and better building methods. |

Crossing Delays | Big drop in crossing delays, so things work faster. |

Signal Losses | Less signal loss because of microvias instead of regular holes. |

You can also use stacked, staggered, blind, and buried vias. These choices let you fit more parts in less space. You get better paths for signals and less waiting. This matters for fast devices like smartphones and AI hardware.

High-Speed Data

You need your devices to move data fast. HDI boards help with high-speed signals. They use thin traces and short paths. This design makes crossing delays smaller and keeps data moving quickly. You see better results in fast systems like 5G phones and new computers.

HDI boards let you use more layers and thinner traces. You can fit more circuits in a small spot. This helps you make devices that handle fast data easily. You get strong and steady performance.

Reliability and Durability

Thermal Cycles

You want your devices to last long. HDI boards use microvias to handle heat changes. These microvias let the board stretch and shrink without breaking. Your devices stay strong, even in hard places.

CAF Resistance

HDI boards also fight problems like CAF growth. This means your circuits are safe from shorts and breaking. You get longer life and better strength for your products.

Tip: HDI technology gives you tough boards that work well in busy places like cars, planes, and medical tools.

Miniaturization Benefits

Component Density

You can fit more parts on an HDI board. This is because you can pack circuits closer and use special vias. You use less space but get more features. Your devices get smarter and stronger.

Space Savings

HDI boards help you make smaller and lighter things. Here is a table that shows the good points:

Benefit | Quantifiable Impact |

|---|---|

Device Size Reduction | 30–50% smaller than regular PCBs |

Board Thickness Reduction | 50% less thickness |

Material Usage Reduction | 30–40% less material used |

You see these savings in thin phones, small wearables, and tiny medical tools. HDI boards let you make products that are easy to carry and use.

Power Efficiency

Short Signal Paths

You want your device to use less power. HDI PCB design helps with this. HDI lets you make short signal paths. Signals move fast on these paths. Less energy turns into heat. Your device stays cool and works longer.

Short paths also help signals stay clear. There is less noise and fewer losses. Your device works better in fast jobs. Finer traces and microvias make this happen. Your device reacts quickly and saves battery. This matters for phones, wearables, and medical sensors.

Tip: Short signal paths help your device work fast and save power.

Embedded Passives

You can make your device better with embedded passives. These are tiny parts inside the board. You do not need to put them on top. This saves space and makes building easier.

Using embedded passives lowers your design cost. You need fewer outside parts. Your board gets smaller and lighter. Signals do not travel far, so they stay strong. Your device keeps good performance and uses less power.

HDI technology lets you add more features in less space. You get more paths and better links. Your device uses less energy and works well. You see these good things in smartwatches and AI hardware.

Here is a table that shows how HDI PCB helps power efficiency:

Feature | How It Helps Power Efficiency |

|---|---|

Short Signal Paths | Less energy lost, faster response |

Embedded Passives | Fewer external parts, smaller board |

Finer Traces & Vias | Efficient signal transmission |

High Routing Density | Reduced power consumption |

HDI PCB gives you strong power efficiency. Your device runs longer, stays cool, and works great.

HDI PCB in Industry Applications

Consumer Electronics

Smartphones

You use your smartphone every day. You want it to be small and fast. HDI technology helps make this happen. Engineers can fit more parts in less space. Your phone can have a better camera and bigger battery. It can also have more memory without getting heavier. The smart design helps your phone run faster and last longer.

Here is a table that shows how HDI helps smartphones:

Benefit | Description |

|---|---|

Enhanced Space Efficiency | HDI substrates achieve higher interconnection densities, allowing for smaller devices with more features. |

Improved Electrical Performance | Reduced trace lengths and optimized layer stacking lead to faster signal transmission and better circuit performance. |

Long-term Cost-effectiveness | Smaller, efficient designs reduce material and assembly costs, leading to lower overall costs and fewer failures. |

Design Flexibility | Engineers can innovate with various layouts and materials, resulting in tailored solutions for specific applications. |

Tip: Benlida Circuit’s HDI PCBs help you get more features in your smartphone without making it bigger.

Wearables

Wearables like smartwatches need to be light and comfy. HDI technology lets you fit many tiny parts inside. Your smartwatch can track steps and measure your heart rate. It can also connect to your phone. The small size makes wearables easy to wear all day.

You get better battery life and more features. HDI boards make your device stronger and less likely to break. You can trust your wearable to work well every day.

Medical Devices

Implantable Sensors

Doctors use implantable sensors to check your health. These sensors must be very small and reliable. HDI PCBs make this possible. Engineers build sensors that fit inside your body. They send clear signals to doctors. The strong design means the sensor will last a long time.

Here is a table that shows how HDI helps medical devices:

Benefit | Description |

|---|---|

Miniaturization | HDI PCBs enable significant size reduction, often up to 60% compared to standard boards. |

Enhanced Reliability | The use of microvias and advanced materials reduces the risk of failure, essential for life-critical applications. |

Improved Signal Integrity | Shorter signal paths reduce signal loss and improve speeds, ensuring accurate data transmission. |

Increased Functionality | HDI technology allows for more layers (often 10 or more) in a smaller footprint, enabling advanced features like wireless connectivity. |

Cost Savings | Despite higher upfront costs, they reduce the need for multiple boards or larger enclosures, leading to long-term savings. |

Diagnostic Equipment

Hospitals use diagnostic equipment to help patients. These machines need to be accurate and fast. HDI PCBs make the circuits inside smaller and more reliable. The equipment gives results quickly and works for many years. You get better care because the machines work well every time.

Automotive Electronics

ADAS

Cars today use ADAS to help keep you safe. These systems process lots of data from cameras and sensors. HDI PCBs fit many circuits into a small space. You get fast communication between parts. Your car can react quickly to the road.

High performance in ADAS systems.

Good integration of sensors.

More features in infotainment systems.

Advantage | Description |

|---|---|

Circuit Density | HDI PCBs allow for high circuit density, reducing weight and footprint, which is critical in automotive design. |

Signal Integrity | They support reliable isolation between analog and digital signals, minimizing interference. |

Component Integration | Engineers can integrate various sensors, microcontrollers, and memory chips into a compact unit. |

Infotainment

You enjoy music, maps, and apps in your car. Infotainment systems use HDI PCBs for complex tasks. These boards help your car’s system run smoothly. They let your car connect to your phone or the internet. You get a better driving experience with fewer problems.

Note: HDI technology from Benlida Circuit gives you strong, reliable automotive electronics for safer and smarter cars.

Aerospace and Defense

Avionics

Airplanes and spacecraft need electronics that always work. Avionics systems help control flight, guide navigation, and send messages. HDI technology gives you tough boards for hard jobs. These boards can handle shaking, hot and cold, and even radiation.

Flight control systems use HDI PCBs for quick, correct data.

Radar and communication gear need strong signals.

Navigation and GPS systems want boards that block interference.

Surveillance and electronic warfare gear must work in tough places.

Satellites and space vehicles need boards that are light and small.

Missile and weapon guidance systems must be very reliable.

UAVs use HDI boards for smart control.

Aerospace has strict rules you must follow. Boards often meet military standards like MIL-PRF-31032. This makes sure your avionics work every time, even when it is important. Benlida Circuit’s HDI PCBs help you get high performance and trust.

Military Systems

Military systems need the best electronics. You want PCBs that can take shock, heat, and noise. HDI boards are strong and can do this job. You use them in vehicles, radios, and control gear. These boards help keep your stuff small and light, which is good for moving around.

You also get help against interference. This keeps your signals clear, even in loud places. Benlida Circuit’s HDI PCBs meet military rules, so your systems work when you need them.

Industrial and IoT

Automation

Factories and smart machines need strong boards that last. HDI PCBs help you build control systems that work well. You can use fewer boards because HDI fits more circuits in a small spot. This saves money and makes machines easy to fix.

Benefit | Description |

|---|---|

Cost Savings | HDI PCBs can lower costs by using fewer boards. |

Improved Functionality | They give you more circuits and better features for new devices. |

Reduced Power Consumption | HDI PCBs help use less power, which is good for IoT sensors. |

Enhanced Thermal Management | They handle heat better, so machines work longer. |

HDI boards can take heat and shaking in busy factories. You can trust them in places with lots of dust and movement. They last longer, so you do not need to change them often.

Sensor Networks

Sensor networks collect data all the time. These networks need small boards that use little power. HDI technology lets you put many sensors and circuits in tiny spaces. Your sensors use less power, so batteries last longer.

The main benefit of HDI printed circuit boards is they "do more with less"; HDI PCBs make the space between equipment and wires shorter, so you can add more circuits. This makes electronics work better and use less power.

HDI PCBs also block interference. This is important in factories and outside where machines and weather can cause trouble. You get good data and equipment that lasts. Benlida Circuit’s HDI PCBs help your industrial and IoT projects work well for a long time.

When to Choose HDI PCB

Application Needs

Think about what your project needs before picking a circuit board. Some projects need more from your design. If you want a device that is small, strong, and works well, you should look at hdi technology. The biggest benefits show up in products that need lots of circuits packed close together and miniaturization. Here is a table that shows which applications are best for hdi PCBs:

Application Type | Justification for HDI PCBs |

|---|---|

Smartphones | Require compact design and high circuit density. |

Wearables | Need miniaturization and high performance. |

Aerospace | Demand reliability and compactness in design. |

Medical Electronics | Require precision and high-density connections. |

If you work on smartphones or wearables, you want to fit many features in a tiny space. Aerospace and medical electronics need boards that are both steady and exact. Pick hdi PCBs when your project needs these things.

Production Scale

Think about how many boards you want to make. The number you make changes your costs and how well your project goes. If you only make a few test boards, costs can be higher because tricky designs may cause more waste. When you make lots of boards, yield is very important. For example, if you make 10,000 boards and only half work, your costs double. You need smart design choices to keep costs low and yields high. Here are some things to remember:

Tricky hdi PCB designs can cause more waste and higher costs, especially for test boards.

A 50% yield means you lose half your boards, which hurts your budget.

Good design helps you save money and get more working boards.

Work with your supplier to plan your design and how you build your boards. This helps you avoid mistakes and save money.

Regulatory Factors

You must follow rules when you design and build PCBs for important uses. These rules help keep your products safe and ready for sale. Check if your boards meet standards like IPC and RoHS. Here are some things to think about:

Following IPC standards makes sure your materials are safe and good.

RoHS rules limit bad materials in your boards.

Meeting these rules is needed to sell your product in many places.

Following environmental rules helps keep people and nature safe.

RoHS helps lower harm to the environment and matches world rules.

If you build things for cars, medicine, or planes, pay close attention to these rules. Always check the rules before you start your design. This helps you avoid trouble and makes sure your product is ready for customers.

Long-Term Costs

You want your project to last and work well for years. When you choose a circuit board, you should think about how much it will cost to keep it running. Many people look only at the price to make the board. You should also look at the cost to fix, replace, or maintain it over time.

HDI boards help you save money in the long run. These boards use strong materials and smart designs. You get fewer problems and less need for repairs. Your devices work longer without breaking. You spend less on fixing things and more time using your products.

Let’s look at how HDI PCBs compare to standard PCBs for long-term costs:

Dimension | HDI PCB | Standard PCB |

|---|---|---|

Maintenance Cost | Low (high reliability) | Higher (potential reliability issues) |

You see that HDI boards cost less to maintain. They use advanced technology that keeps them strong. You do not need to replace them as often. Your devices stay reliable, even in tough places like factories, cars, or medical equipment.

Here are some ways HDI boards help you save money over time:

You get fewer failures. Your devices work longer without stopping.

You spend less on repairs. HDI boards need less fixing.

You avoid downtime. Your machines and tools keep running.

You use less energy. HDI boards help your devices run cooler and more efficiently.

You reduce waste. Fewer broken boards mean less trash and lower costs.

Tip: If you want your products to last and cost less to maintain, HDI technology is a smart choice.

You should also think about the total cost of ownership. This means you add up the price to make, use, and fix your device over its life. HDI boards often cost more at first, but you save money later. You get better performance, fewer repairs, and longer life.

When you plan your project, look at the big picture. HDI boards help you build products that last, work well, and cost less over time. You make a smart investment that pays off year after year.

HDI Cost Optimization Strategies

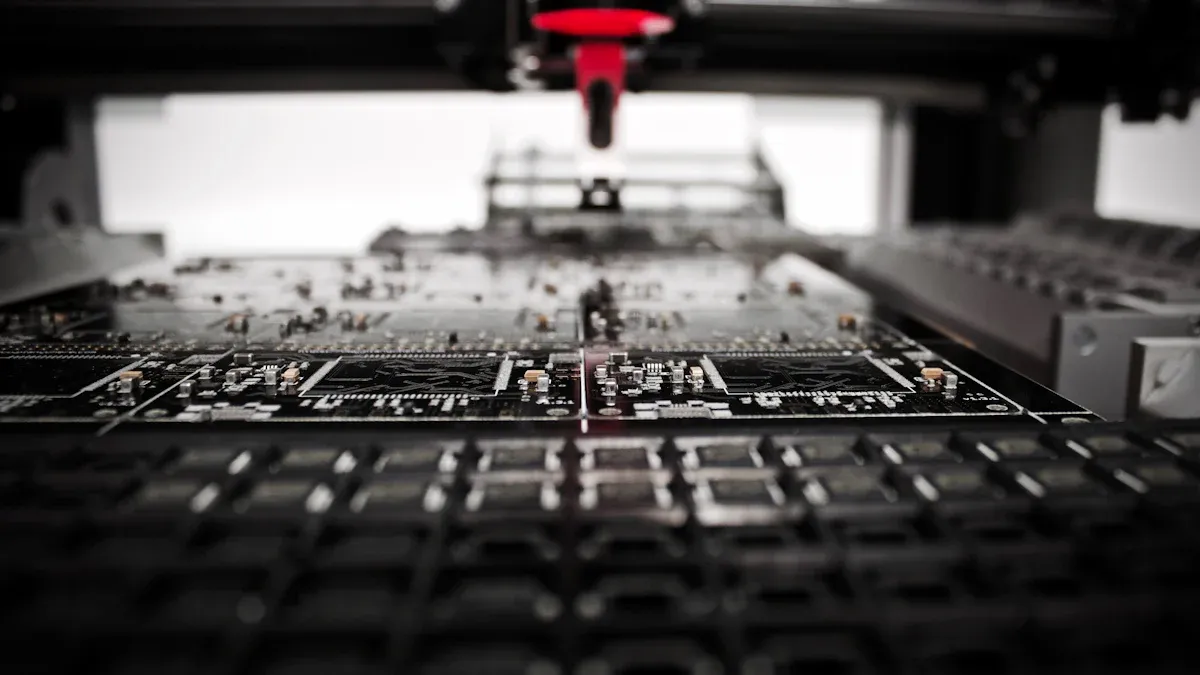

Design for Manufacturability

You want your project to be easy and cheap. Design for manufacturability helps you do this. When you plan your board, think about each step. Every choice can change the cost and quality. Manufacturability means making choices that help the factory work faster. You get fewer mistakes and save money. Use smart panel layouts and simple shapes. Clear rules help you avoid problems. These steps keep costs low.

Here is a table that shows how different manufacturability strategies help you save:

Strategy | Description | Cost Benefits |

|---|---|---|

Microvia Optimization | Use hybrid processes for microvias | Reduced hole processing costs by 40% |

Material Selection | Choose low-loss substrates and thin copper foils | 15% material cost reduction |

DFM Integration | Follow strict design rules for manufacturability | 30% less assembly time |

You can also use these tips for manufacturability:

Use thinner copper to save time and money.

Make panel layouts fit more boards.

Cut down drilling steps to make things faster.

If you follow manufacturability rules, you get more good boards. You spend less money. Benlida Circuit uses these ideas to help you get high yields and low costs.

Try these steps for manufacturability:

Make your design simple for manufacturability.

Plan panel layouts for easy assembly.

Use laser drilling for microvias.

Tip: Manufacturability helps you avoid delays and extra costs. You get boards that work well and arrive on time.

Material Selection

Picking the right materials is important for saving money. You should see how each material changes your board’s price and performance. Manufacturability means picking materials that are easy to use and last long. You want to balance cost and quality.

Start by looking at what your design needs. If your board needs high-speed signals, pick materials with low signal loss. Manufacturability gets better with good thermal and electrical properties. Check the glass transition temperature and thermal conductivity. These features help your board last longer and handle heat.

Here are steps for smart material selection:

Find out what your design needs for manufacturability.

Check how many layers you need for cost and manufacturability.

Think about long-term reliability for manufacturability.

Work with suppliers to get good prices.

You can also use these tips for manufacturability:

Pick dielectric materials that match your board’s needs.

Use materials with low dielectric constants for better signals.

Choose materials with high glass transition temperature for heat resistance.

Balance manufacturability and cost for the best results.

Benlida Circuit helps you pick materials that fit your goals and budget. You get boards that work well and cost less.

Via Optimization

Vias connect layers in your board. Optimizing vias helps you save money. You want to use the right type and number of vias. Microvias help you fit more connections in less space. Manufacturability gets better with hybrid processes for microvias. This step can cut hole processing costs by 40%.

You should also look at blind and buried vias. These vias connect layers without drilling through the whole board. Skip vias need fewer lamination steps. You spend less and get more good boards.

Try these tips for manufacturability and vias:

Use microvias for higher density.

Pick blind and buried vias for lower costs.

Use skip vias for fewer steps.

Benlida Circuit uses these strategies to help you get strong boards. You save money and get better performance.

Note: Manufacturability is the key to making your hdi project cost-effective and reliable.

Prototyping Best Practices

You want your HDI project to succeed from the start. Prototyping helps you test your ideas before you make many boards. Good prototyping saves you time and money. You can find problems early and fix them before full production.

Start with a clear design. Use simple shapes and clear rules for your layout. This makes your prototype easier to build and test. Benlida Circuit recommends using proven design tools. These tools help you spot errors before you send your files to the factory.

Here are some best practices for prototyping:

Plan your stack-up early: Decide how many layers you need. Fewer layers can save you money. Make sure your design fits your needs.

Use standard materials: Pick materials that are easy to find. This helps you get your prototype faster and keeps costs low.

Check your design rules: Follow the rules for trace width, spacing, and via size. This helps you avoid mistakes that can slow down your project.

Test with small batches: Make a few boards first. Test them for function and reliability. Fix any problems before you order more.

Work with your supplier: Share your design files and ask for feedback. Benlida Circuit can review your files and suggest changes to improve yield and lower costs.

Tip: Always review your prototype results. Look for signal issues, heat spots, or weak connections. Make changes as needed before moving to mass production.

You can use a table to track your prototyping steps:

Step | What to Check | Why It Matters |

|---|---|---|

Stack-up Planning | Layer count, material choice | Impacts cost and performance |

Design Rule Check | Trace/via sizes, spacing | Prevents build errors |

Batch Testing | Function, reliability | Finds problems early |

Supplier Review | Feedback, suggestions | Improves design and yield |

Prototyping with these steps helps you avoid costly mistakes. You get a working board that meets your needs. You also save money by fixing problems early. Benlida Circuit’s team can guide you through each step. You get expert advice and fast feedback.

Remember, a strong prototype leads to a strong final product. Take your time with each step. Test, review, and improve. This approach gives you the best results for your hdi project.

Working with HDI PCB Manufacturers

Choosing a Partner

You need to pick the best company for your HDI circuit boards. This choice can change how much your project costs. It also affects how fast and well your boards are made. You should find a partner who knows what you need and can do a good job.

First, check if the company has lots of experience. A company that has made HDI boards for a long time knows how to fix problems. They also make fewer mistakes. You can look for reviews from other customers. Good reviews mean you can trust the company.

Quality is very important for every project. Ask the company about their quality checks. See if they have certifications like ISO. These show they follow strict rules. Companies with new machines and tools can make boards with tiny details. Their boards are also more reliable.

Sometimes your project needs special shapes or features. A good partner can change their process to fit your design. You should also ask about how long it takes to get your boards. Fast and on-time delivery helps your project stay on schedule.

It is important to know how much everything costs. Ask for a list that shows all the prices. This helps you see what you are paying for. You do not want any surprise fees. Good partners answer your questions and give helpful advice.

Where the company is located can change shipping speed and cost. A company with good shipping can get your boards to you on time. You should also ask if they care about the environment. Responsible companies use safe materials and green methods.

Here is a table to help you compare what matters when picking an HDI PCB partner:

Criteria | Description |

|---|---|

Experience and Expertise | Pick a supplier who has made HDI PCBs for many years. |

Reputation and References | Look at reviews and what other customers say about them. |

Quality Control Standards | Ask about their quality checks and if they have certifications. |

Technology and Equipment | Check if they use new machines and good tools. |

Customization Options | See if they can make boards that fit your special needs. |

Lead Times and Delivery | Talk about how fast they can make and ship your boards. |

Pricing and Cost Transparency | Ask for clear prices and a list of all costs. |

Communication and Support | Choose a company that answers questions and gives good advice. |

Location and Logistics | Think about where they are and how fast they can ship. |

Environmental Responsibility | Ask if they use safe materials and care about the environment. |

Tip: Make a checklist with these points before you pick your HDI PCB company. This helps you find a partner who fits your project and goals.

Lead Times

You want your HDI PCB to arrive when you need it. Lead time is how long it takes from order to delivery. Fast lead times help you launch your product first. Slow lead times can make your project late and cost more money.

Many things can change how long you wait. Design complexity, material choices, and order size all matter. Simple boards with common materials ship faster. Harder designs or rare materials take longer to make. If you order a lot of boards, the factory needs more time.

You can do things to make lead times shorter. Make sure your design files are clear and correct. Check your details before sending them to the factory. This helps stop mistakes and saves time. Pick a supplier who has lots of experience and can make HDI boards well.

Here is a table that shows what affects lead times:

Factor | Impact on Lead Time |

|---|---|

Design Complexity | More layers or microvias add time |

Material Selection | Rare materials may cause delays |

Order Quantity | Large orders need more time |

Supplier Capacity | High-capacity suppliers deliver faster |

Quality Checks | Extra testing adds days |

You can ask your supplier how long they usually take. Some companies can make boards faster if you need them quickly. Benlida Circuit uses new machines and smart ways to keep lead times short. Their good systems help you get your boards sooner.

Tip: Add extra days to your plan for shipping and testing. This helps you avoid problems and keeps your project on time.

Talk to your supplier often. Ask for updates while your boards are being made. If you need to change something, tell them right away. Good talking helps stop delays and makes sure you get what you want.

You can also split your order into smaller groups. This lets you test some boards while the rest are still being made. You save time and can fix problems early.

Lead times are important for every HDI project. Fast delivery helps you finish on time and spend less. When you work with Benlida Circuit, you get quick service and fast boards.

HDI circuit boards help lots of industries save money and work better. Benlida Circuit makes boards that are smaller, stronger, and more reliable. You can make your product better by picking the right design and materials. Talk with your supplier to get the best results. If you make smart choices now, your devices will be better in the future.

FAQ

What makes HDI boards different from standard boards?

HDI boards are made with special methods. They let you put more parts on each board. You also get better signals. These boards help make small and strong devices.

How does HDI fabrication improve reliability?

HDI fabrication uses microvias and good laminates. This means you get fewer problems in your boards. The boards can handle heat and tough places without breaking.

Can you use HDI boards for medical devices?

Yes, you can use HDI boards in medical devices. These boards are small and send clear signals. HDI fabrication helps your boards meet strict medical rules.

Why do HDI boards cost more than regular boards?

HDI boards need special steps to make them. You pay for laser drilling and direct imaging. They use advanced materials. The higher cost is for better quality and performance.

How do you choose the right fabrication partner for HDI boards?

You should pick a partner with HDI experience. They must make boards with no mistakes. Ask about their tools and how they check quality. Good partners help you get strong boards.

What industries benefit most from HDI boards?

HDI boards are used in electronics, cars, planes, and medical tools. These boards help make small and fast devices. HDI fabrication fits many industries’ needs.

How does HDI fabrication affect lead times for boards?

HDI fabrication uses advanced steps. Sometimes, it takes longer to make tricky boards. If you plan well and send clear designs, you get your boards faster.

Can HDI boards help reduce long-term costs?

HDI boards last longer and break less. You spend less money fixing them. HDI fabrication gives you boards that save money over time.

Tip: Always check your board’s design before making it. This helps you stop mistakes and save money.

Question | Quick Answer |

|---|---|

HDI vs. standard boards | HDI boards fit more parts |

HDI fabrication reliability | Fewer problems, stronger boards |

HDI boards in medical devices | Yes, small and strong |

HDI boards cost | Special steps make them cost more |

Choosing fabrication partner | Pick one with skill and good checks |

Industries using HDI boards | Electronics, cars, medical, planes |

HDI fabrication lead times | Advanced steps may take longer |

HDI boards and long-term costs | Less fixing, longer use |

en

en

WhatsApp

WhatsApp