How Flexible PCBs Power the Next Generation of Wearable Devices

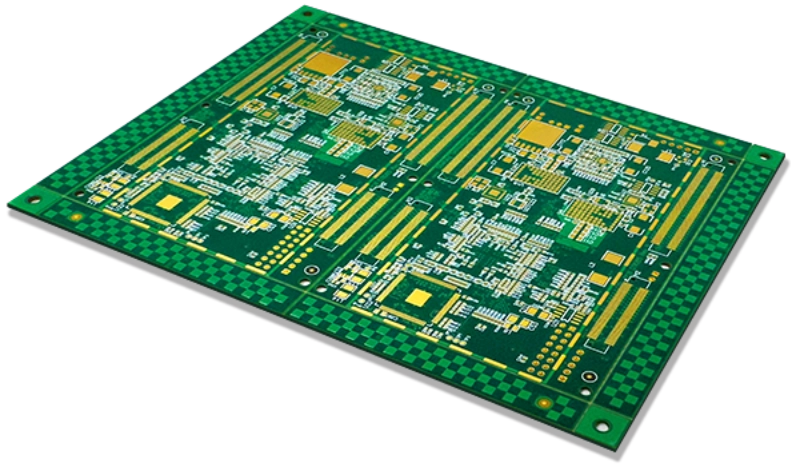

Wearable technology has rapidly evolved from simple fitness trackers to advanced medical monitors, smartwatches, AR glasses, and even flexible skin-mounted sensors. These devices are expected to be lightweight, compact, and durable—while also maintaining high-speed connectivity, accurate data collection, and long battery life. Achieving all this in such small, dynamic form factors demands a revolution in circuit design.

That revolution is driven by Flexible Printed Circuit Boards (Flexible PCBs or FPCs). Unlike traditional rigid boards, flexible PCBs can bend, twist, and conform to complex surfaces without compromising electrical performance. At the forefront of this technology is Benlida Circuit, a trusted manufacturer specializing in high-reliability flexible circuits that enable innovation in wearables and beyond.

1. The Rise of Flexible PCBs in Wearable Technology

Wearable devices combine performance electronics with ergonomics—they must integrate seamlessly with the human body or daily activity. This unique challenge requires electronics that are not only powerful but also flexible, thin, and lightweight.

Traditional rigid PCBs, while effective in stable environments, are too bulky and fragile for continuous movement or curved designs. Flexible PCBs solve this problem by allowing circuits to bend, fold, or roll along with the shape of the product—whether it’s a wristband, chest patch, or e-textile.

Benlida’s flexible PCBs are engineered to withstand over 100,000 flex cycles, making them ideal for applications where durability and reliability are crucial.

2. Design Freedom: Form Meets Function

The greatest advantage of flexible PCBs in wearable electronics is 3D spatial efficiency. Engineers can fit circuits into irregular or cramped spaces, reducing the need for connectors and improving comfort and usability.

Examples of flexible PCB integration include:

Smartwatches and fitness trackers: Where circuits follow curved housings.

Medical patches and biosensors: Designed to conform to skin or fabric.

AR/VR headsets: Which require compact layouts and high-speed signal integrity.

Smart textiles: Embedding flexible circuits directly into garments.

At just 0.05–0.3mm thick, Benlida’s flexible PCBs are up to 70% thinner than rigid boards—allowing designers to maximize internal space and minimize device weight.

3. Durability Through Dynamic Use

Wearable devices experience continuous motion—bending, stretching, and twisting during normal use. That’s where mechanical endurance becomes a defining factor.

Benlida’s flexible PCBs maintain structural integrity and electrical performance even under long-term mechanical stress. With materials such as polyimide (PI) and PET, combined with precise copper bonding techniques, these boards resist cracking, delamination, and fatigue.

Key durability features:

Over 100,000 flex cycles without failure.

Operating range from -40°C to 150°C.

Resistance to moisture, sweat, and vibration.

This makes Benlida’s FPCs ideal for wearables used in sports, healthcare, and outdoor environments, where reliability directly impacts performance.

4. Lightweight and Ultra-Compact Engineering

Weight reduction is crucial for comfort and portability. In wearable designs, every millimeter matters—space saved inside the housing can be used for larger batteries or sensors.

Benlida’s lightweight flexible circuits replace traditional wire harnesses and multiple connectors with a single integrated layer. This not only reduces weight but also simplifies assembly and improves long-term reliability.

For example, in smart medical devices, flexible PCBs help achieve thinner, more comfortable designs that can be worn for extended periods without irritation.

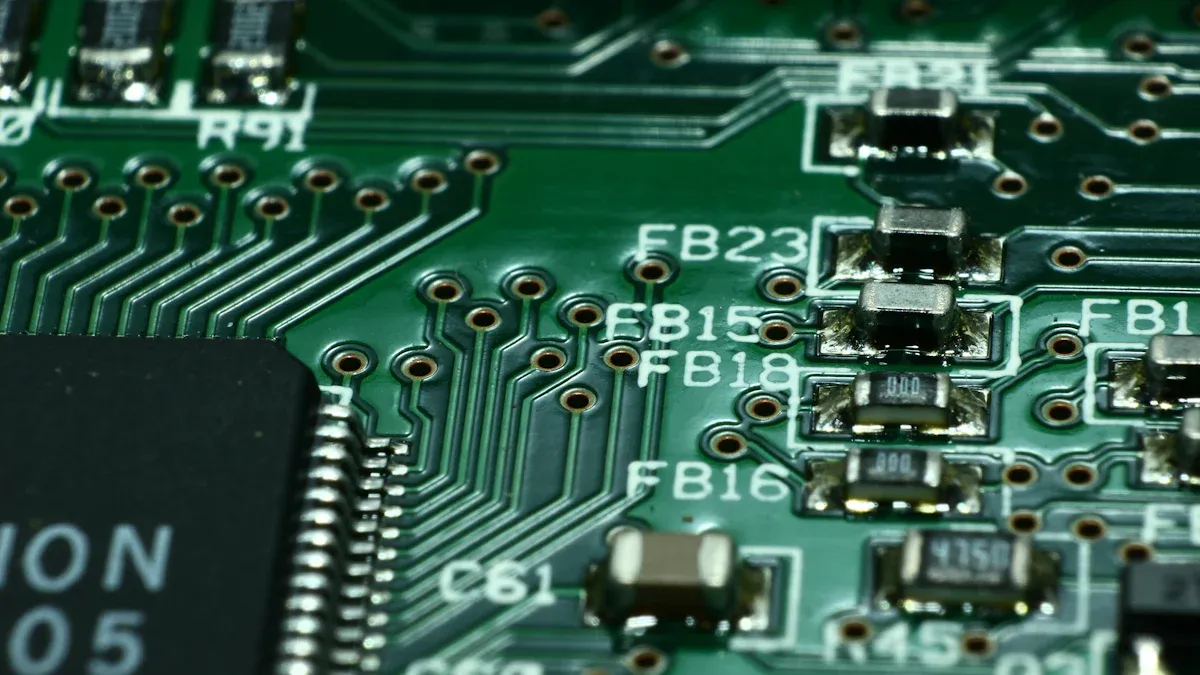

5. High-Speed Signal Integrity for Real-Time Data

Modern wearables demand fast and accurate data transmission—from biometric readings to Bluetooth and Wi-Fi signals. Poor circuit design can lead to signal loss or interference, which can distort readings or drain battery power.

Benlida addresses these challenges with high-density interconnect (HDI) flexible PCBs, featuring:

50μm trace and space for precision routing.

Low electromagnetic interference (EMI) for clear data transmission.

Stable impedance control for high-frequency applications.

Surface finishes like ENIG, Immersion Silver, and OSP for enhanced conductivity.

These characteristics ensure stable performance in 5G-connected wearables, medical monitoring systems, and IoT-enabled devices.

6. Reliable Performance in Harsh Conditions

Wearable devices operate in environments that vary widely—from gym workouts to outdoor adventures and even medical sterilization. Flexible PCBs must endure temperature fluctuations, humidity, and constant body contact.

Benlida’s flexible PCBs are designed to resist corrosion and maintain conductivity under environmental stress. The use of PTFE and polyimide materials enhances resistance to moisture and chemical exposure while preserving flexibility.

This durability ensures that products like heart rate monitors, health patches, and fitness bands maintain functionality through sweat, water exposure, and long-term use.

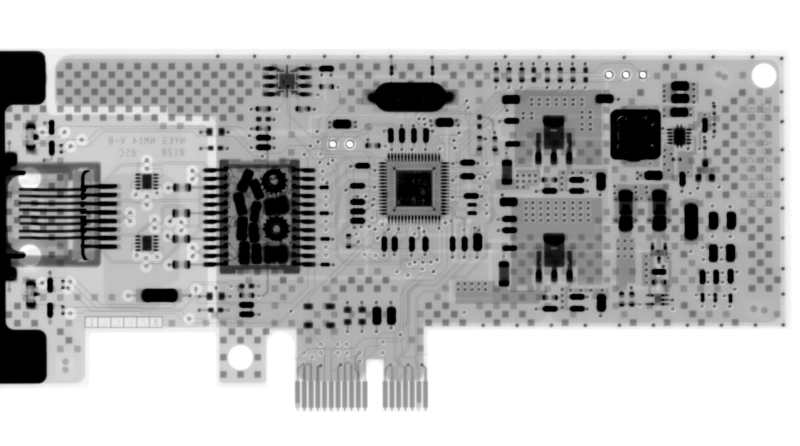

7. Precision Manufacturing and Scalability

Benlida’s manufacturing process combines automation, fine etching, and multi-layer lamination to produce consistent, high-quality circuits at scale.

Manufacturing highlights include:

Layers: 1–12

Copper thickness: 0.5oz–1oz

Hole size: 0.05mm–0.1mm

Trace/space: 0.10mm / 0.10mm

Finished thickness: 0.1mm–0.3mm

Each flexible PCB undergoes rigorous quality control—from mechanical flex testing to impedance verification—to ensure compatibility with high-precision wearable devices.

Whether for a startup prototyping a health tracker or a major brand producing millions of units, Benlida provides reliable, scalable support from concept to mass production.

8. The Future: Smarter, Smaller, and More Flexible

The next wave of wearable innovation will push electronics even further—toward skin-like sensors, flexible displays, and bio-integrated electronics.

Flexible PCBs will remain the backbone of this evolution by:

Supporting stretchable and transparent materials.

Integrating sensors directly into flexible substrates.

Enabling ultra-thin designs for medical and consumer applications.

Offering hybrid rigid-flex solutions for complex form factors.

Benlida continues to advance flexible circuit manufacturing to meet these future demands, ensuring that innovation in wearable technology remains both functional and comfortable.

Conclusion

From smartwatches to health monitors, flexible PCBs power the functionality and form of modern wearable devices. Their ability to bend, conform, and endure dynamic environments makes them indispensable to the next generation of connected technology.

With proven performance under motion, heat, and high-frequency operation, Benlida's flexible PCBs provide the foundation for wearable electronics that are not only compact and powerful but also reliable in everyday use.

As the wearable market continues to expand, flexibility—both mechanical and electrical—will be the key to unlocking smarter, more adaptive designs.

en

en

WhatsApp

WhatsApp