The Material Composition of PCBs: Core Substrates and Their Impact on Performance

You need PCB core substrates to make circuit boards strong and sturdy, and the material composition plays a crucial role in this. The materials decide how your board deals with electricity, heat, and pressure. When you pick a substrate, you are essentially choosing how well your board keeps signals clear, handles heat, and maintains strength over time. For example, the dielectric constant, which is part of the material composition, affects how fast signals move, while the dissipation factor indicates how much signal energy is converted into heat. Additionally, core thickness influences how signals bounce and travel. Benlida offers a variety of substrate choices tailored to your specific needs.

Key Takeaways

Picking the right PCB substrate is very important for how it works. It helps signals stay clear. It also helps control heat and makes the board last longer.

FR-4 is used a lot because it is not expensive and works well with electricity. But for fast electronics, you should use materials with lower dielectric constants.

Polyimide substrates can bend and handle high heat. This makes them great for things that need to bend or get very hot.

Metal core substrates, like aluminum and copper, are very good at moving heat away. This makes them perfect for LED lights and power electronics.

Talking to experts, like the people at Benlida, can help you pick the best substrate for your project.

Material Composition of PCB Core Substrates

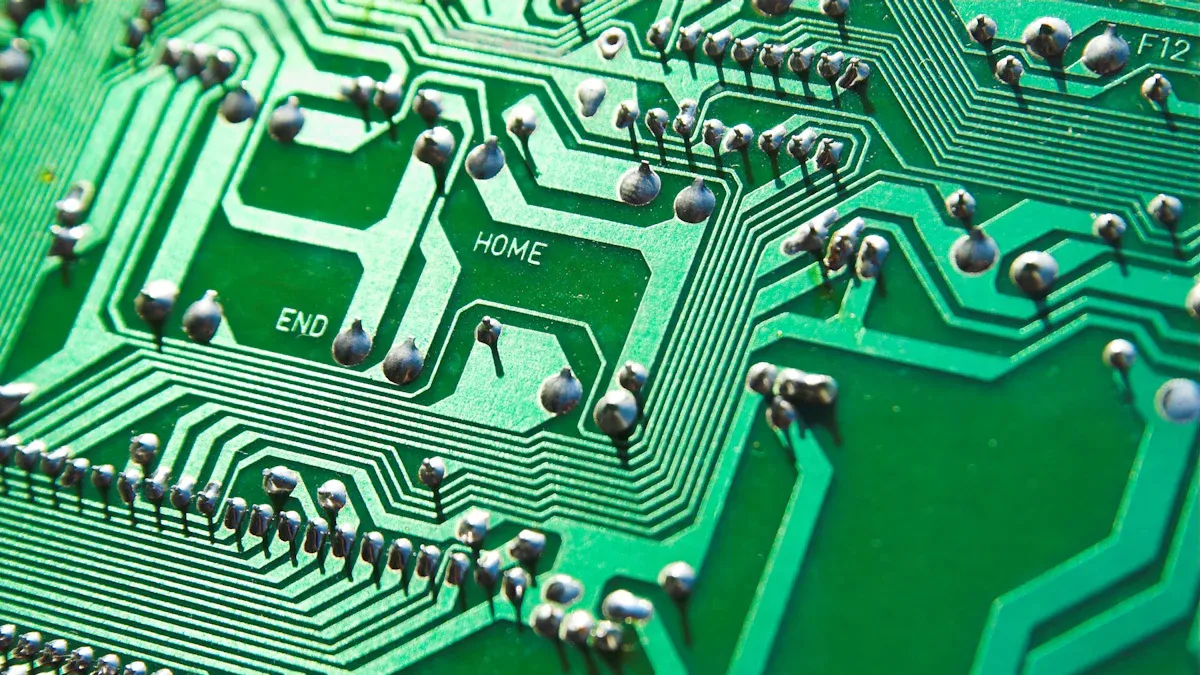

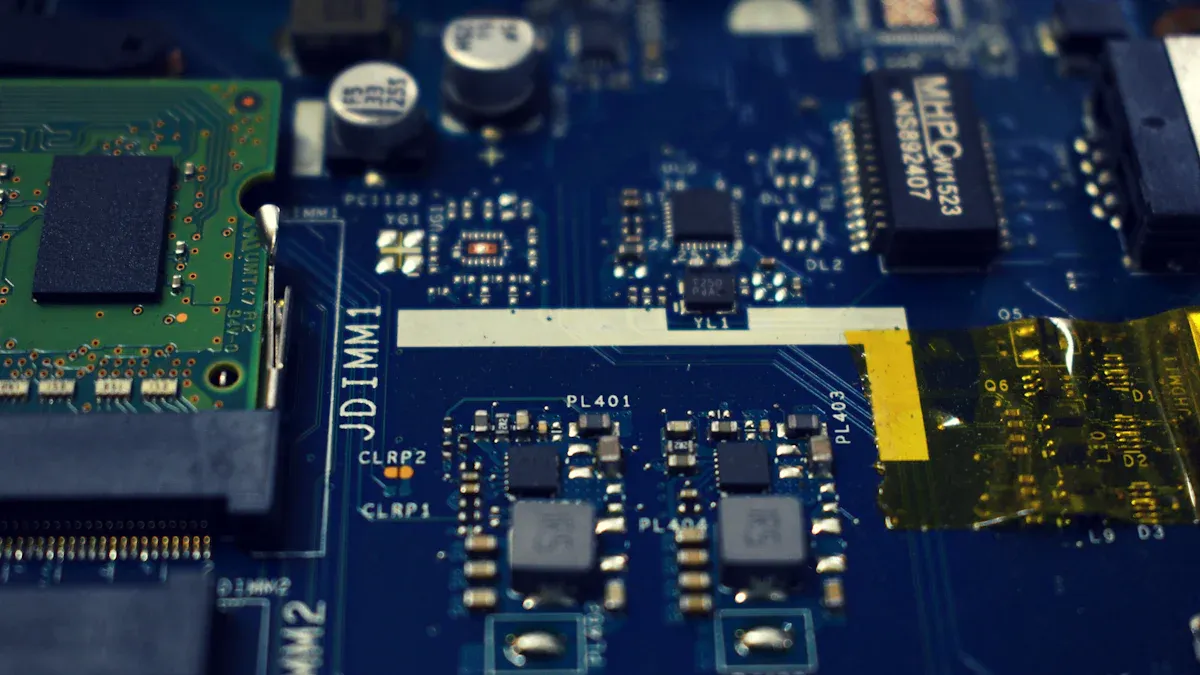

FR-4 and Epoxy Resin

FR-4 is a common material for PCB boards. It has woven fiberglass and epoxy resin mixed together. This mix makes the board strong and helps it work well with electricity. FR-4 does not catch fire easily and can handle many temperatures. Look at the table below to see its features:

Component | Description |

|---|---|

Composition | Epoxy resin plus woven fiberglass |

Flame Retardant | Yes (UL 94 V-0) |

Thermal Performance | High |

Glass Transition Temp (Tg) | 130°C to 180°C |

Dielectric Properties | Great for high-frequency uses |

FR-4 is not expensive and gives good strength. It works in many temperature ranges. Benlida makes boards with FR-4 for many uses.

Polyimide and Flexible Substrates

Sometimes you need a board that bends or twists. Polyimide substrates let your board bend and fit in small spaces. Polyimide can handle high heat and is very flexible. Your board will not break when it bends a lot. Flexible PCBs are thinner and lighter than stiff ones. Benlida makes flexible and rigid-flex PCBs for devices that move.

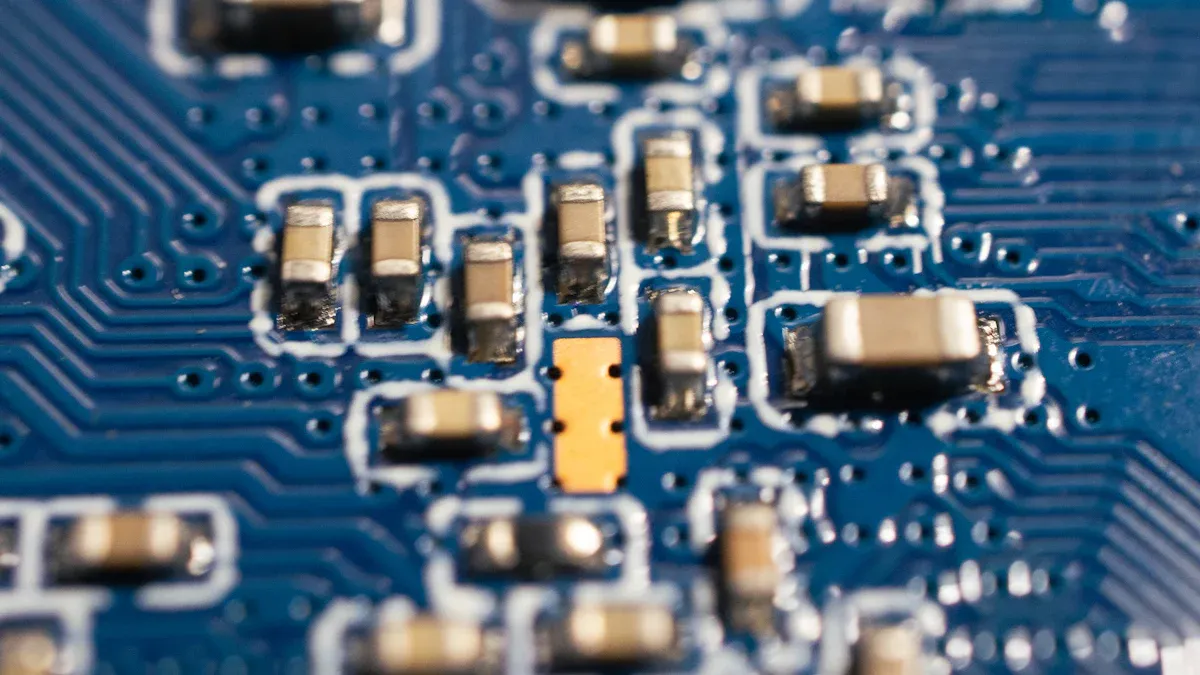

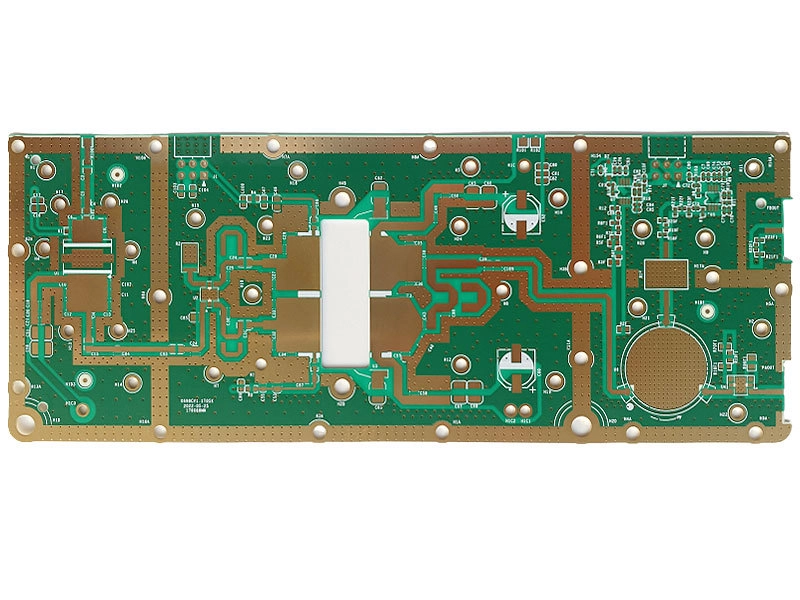

Metal Core Materials

You may want your PCB to handle heat better. Metal core substrates use metals like aluminum, copper, or steel alloys. These metals move heat away from parts fast. Here are some choices:

Aluminum: About 237 W/m·K, moves heat well, low cost

Copper: About 398 W/m·K, best heat transfer, costs more

Steel: Harder, does not move heat as well

Metal core PCBs are good for LED lights and power electronics. Benlida makes metal core boards for tough jobs.

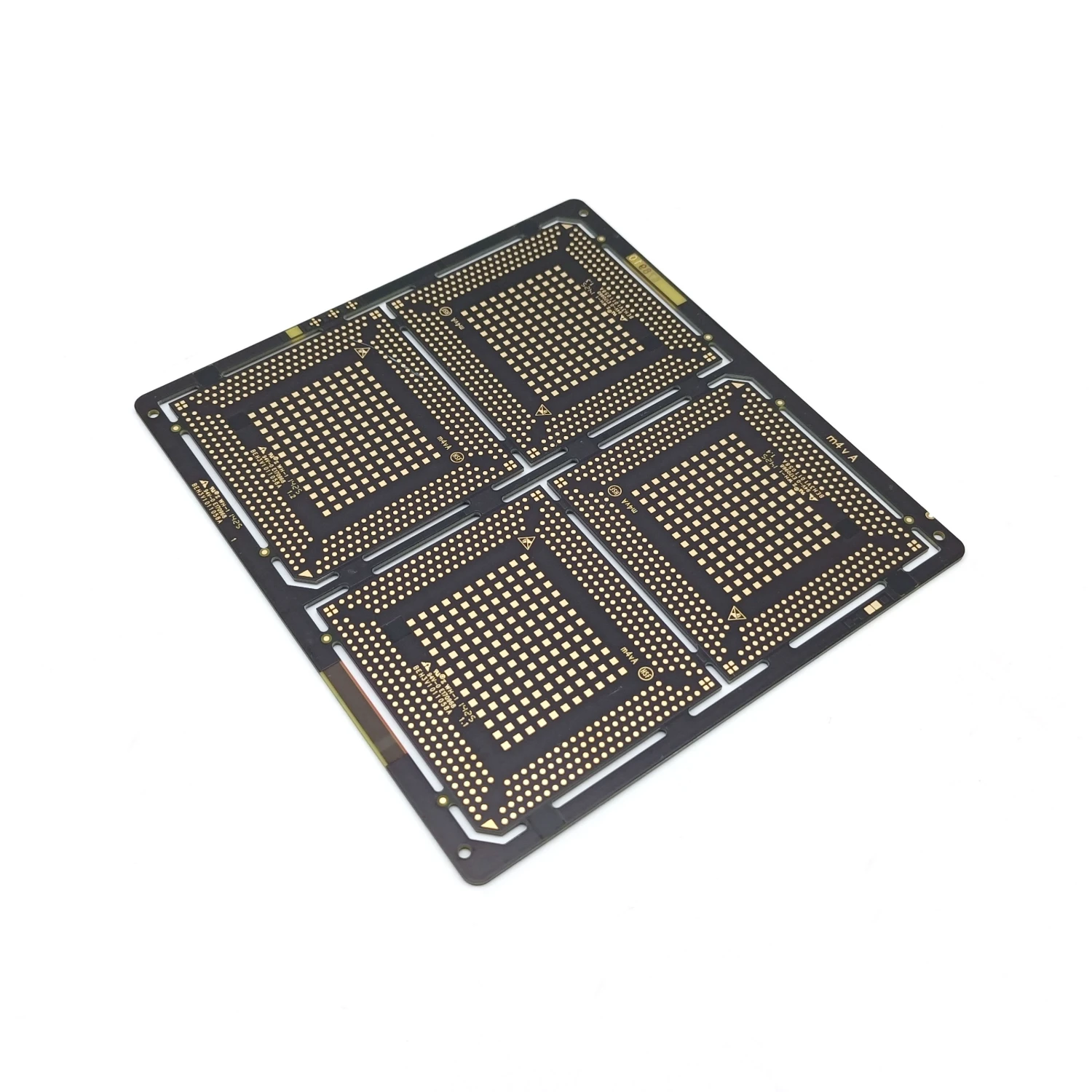

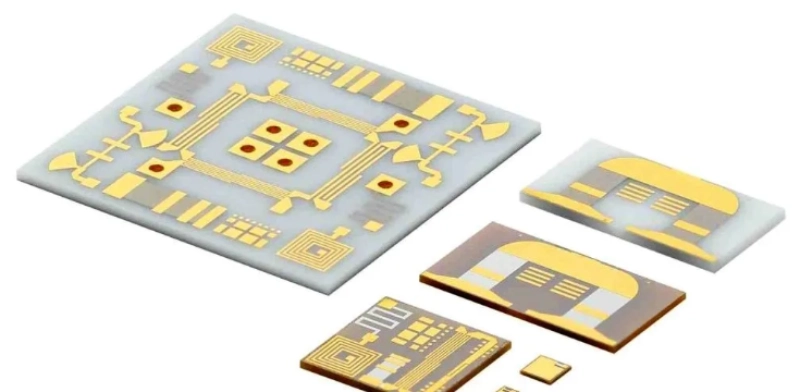

Ceramic and High-Performance Substrates

Some PCBs need to work in tough places. Ceramic substrates have high thermal conductivity and strong mechanical strength. They also resist chemicals very well. These materials keep their shape even in harsh conditions. Ceramic boards stop electrical interference. You can use ceramic PCBs in cars, planes, and factories. Benlida offers advanced materials for special needs.

Tip: Standards like IPC-4101 help you pick the right material. They list important things like dielectric constant and thermal conductivity.

Substrate Properties and Performance Impact

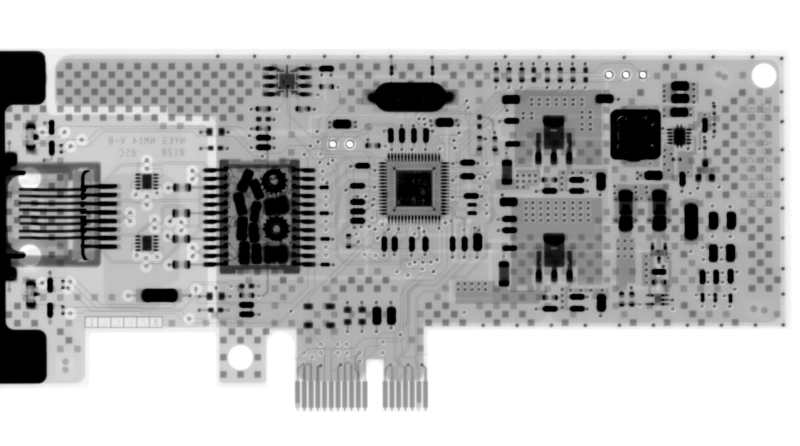

Electrical Characteristics

You should think about how your PCB sends signals. The material composition of your board changes how fast and clear signals move. If you pick a substrate with a low dielectric constant, signals travel faster and lose less energy. This is important for high-speed circuits in computers or phones.

The speed of signals in a PCB depends on the dielectric constant. Lower numbers mean signals move faster.

Lower dielectric constants also help signals stay strong and reduce delay.

If you use a material with a high loss tangent, signals can get weak, especially at high frequencies. This can cause mistakes in digital systems.

For example, FR-4 works for many uses, but for very fast signals, you may need a special material with a lower dielectric constant. Benlida has boards with different material composition choices to fit your needs.

Tip: For high-speed digital circuits, always check the dielectric constant and loss tangent of your substrate. This helps keep your signals clear and reliable.

Thermal Management

Heat can hurt your PCB if you do not control it. The material composition of your board decides how well it moves heat away from hot parts. Some materials, like aluminum and ceramic, have high thermal conductivity. They help your board stay cool, even when it works hard.

Aluminum core PCBs move heat fast. You often see them in LED lights and power electronics.

Ceramic substrates also handle heat well and work in hot places, like power supplies or car parts.

Polyimide can take very high heat, up to 260°C, so it is good for aerospace or medical devices.

PCB Substrate | Max Operating Temperature |

|---|---|

FR-4 | ~150–170°C |

Polyimide | Up to 260°C |

Ceramic | ~150–200°C (depends on construction) |

If you use the right material, your PCB will last longer and work better. Benlida can help you pick a substrate that fits your thermal needs.

Mechanical Strength and Durability

Your PCB must stay strong during use and assembly. The material composition affects how much bending or stress your board can take. FR-4 has good flexural strength, about 340 MPa, which makes it tough for most uses. Polyimide is flexible and does not crack when you bend it, so it works well in devices that move or fold.

Ceramic substrates have a low coefficient of thermal expansion. This means they do not change shape much with heat, so they protect solder joints and parts.

If the substrate and components expand at different rates, stress can build up. This can cause cracks or broken solder joints.

Note: Always match the mechanical properties of your substrate to your application. For example, use flexible materials for wearable devices and strong, stable materials for industrial machines.

Cost Considerations

You need to balance performance and price when you choose a substrate. The cost depends on the material composition, thickness, and how complex your board is.

Substrate Type | Cost per Square Meter (USD) |

|---|---|

FR-4 | $1.08 - $5.38 |

Polyimide | $53.82 - $215.28 |

Ceramic | $215.28 - $1,076.40 |

FR-4 is cost-effective and works for most general uses.

Polyimide costs more but gives you flexibility and high heat resistance.

Ceramic is the most expensive but offers top performance in harsh conditions.

Other things, like how many boards you order and how fast you need them, also change the cost. If you order more boards, the price for each one usually goes down. Benlida helps you find the best balance between cost and performance for your project.

Remember: The right material composition can save you money in the long run by making your PCB more reliable and reducing failures.

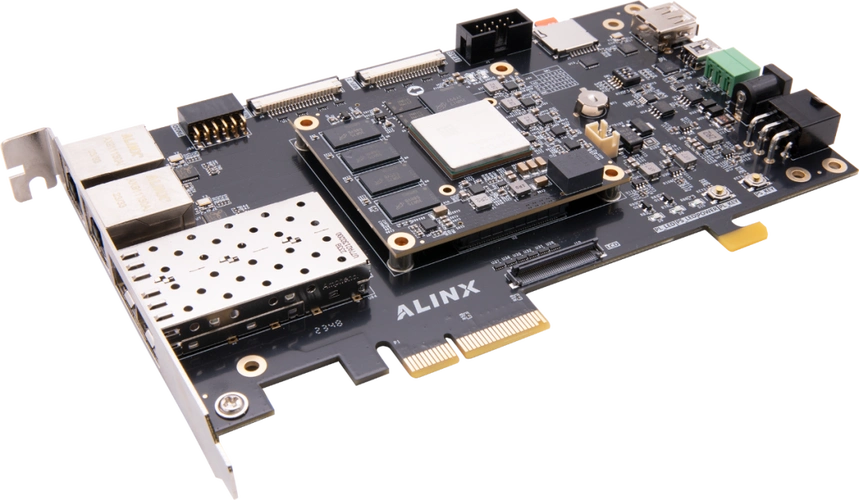

Choosing the Right Substrate Material

Application Requirements

You must pick a PCB substrate that fits your project. First, think about how you will use your board. Some boards need to work at high speeds or with lots of power. These need special materials. You should check:

Operating frequency

Power dissipation

Thermal management

Boards that run fast or get hot need good thermal conductivity and low dielectric loss. Ceramics and advanced organic materials are good for this. FR-4 is used a lot, but it has some limits. If your circuit gets too hot or uses too much power, FR-4 can stop working well. It may lose its ability to insulate. The environment matters too. High heat can make FR-4 bend or crack. Humidity can make it soak up water. This can hurt the board and mess up signals.

Performance vs. Cost

You have to think about both performance and price. FR-4 is cheap and works for most jobs, but it does not handle heat as well as other materials. Polyimide costs more, but it can take very high heat and bends without breaking. Ceramic substrates are best for moving heat away and last a long time in tough places, but they cost a lot and can break easily. Polyimide can take heat up to 260°C, so it is good for hard jobs, but it may be too expensive for some. Ceramic boards are great for LED lights and power electronics, but their high price and easy breaking make them hard to use in flexible boards.

PCB Type | Manufacturing Cost Range (per sq. inch) | Material Considerations |

|---|---|---|

Rigid PCBs | $0.10 to $5.00 | FR-4, cost-effective, high-volume manufacturing |

Flexible PCBs | $0.50 to $15.00 | Polyimide, extra steps needed |

Rigid-flex PCBs | $1.00 to $25.00 | Mix of rigid and flexible, complex process |

Decision Checklist

A checklist can help you pick the right substrate:

Temperature resilience

Moisture resistance

Thermal conductivity

Mechanical strength

Dielectric properties

Each material, like polyimide, PTFE, LCP, FR-4, and ceramics, has its own strengths. For cars or planes, you need boards that can take heat, moisture, and shaking. You also want signals to stay clear. Talking to the manufacturer gives you expert help. Benlida’s team can help you look at the choices and find what works best for you.

Tip: If you work with experts like Benlida, your PCB will meet all your needs and fit your budget.

Picking the right substrate material helps your PCB work well and last longer. The correct choice keeps your board safe from common problems:

Failure Mode | Description |

|---|---|

Inappropriate substrate material | Some circuits need special materials to work right. |

High-frequency signal issues | Regular substrates may not handle fast signals well. |

Thermal resistance, mechanical strength, and environmental resistance are important for long use.

Choosing good materials stops delamination, signal loss, and cracking.

You should talk to PCB experts. They help you pick the best materials and know what can be made. This advice helps you design better boards and avoid trouble. For important projects, always ask trusted partners like Benlida for help.

FAQ

What is the most common PCB substrate material?

Most PCBs use FR-4. It has fiberglass and epoxy resin. This mix makes the board strong. It also helps the board work well with electricity.

How do I choose the right substrate for my project?

Think about what your project needs. Check if it needs to handle heat. See if it needs to bend or send signals fast. If you are not sure, ask Benlida’s experts for help.

Can flexible PCBs handle high temperatures?

Flexible PCBs made with polyimide can take high heat. You can use them in things that bend or fold. They work well in hard places.

Why does thermal conductivity matter in PCB substrates?

Thermal conductivity helps the board move heat away. This keeps your electronics safe. It also helps them last longer.

Does substrate choice affect PCB cost?

Yes, the material you pick changes the price. FR-4 is cheaper. Polyimide and ceramic cost more but work better. You should think about your budget and what your project needs.

en

en

WhatsApp

WhatsApp