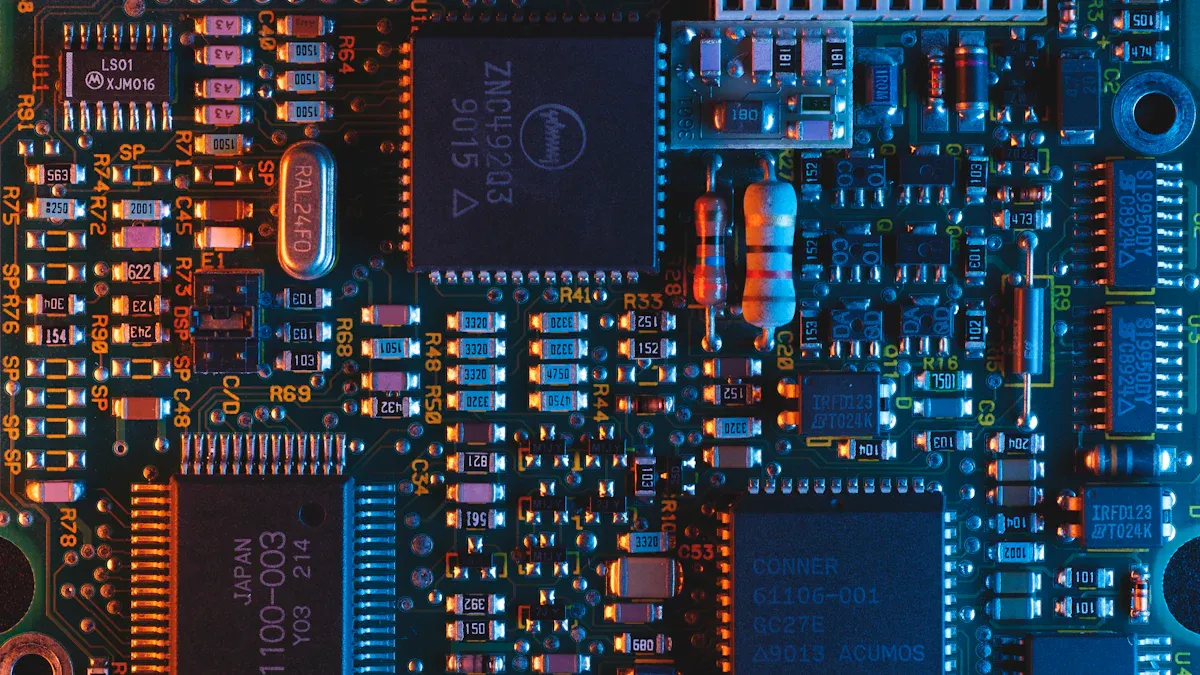

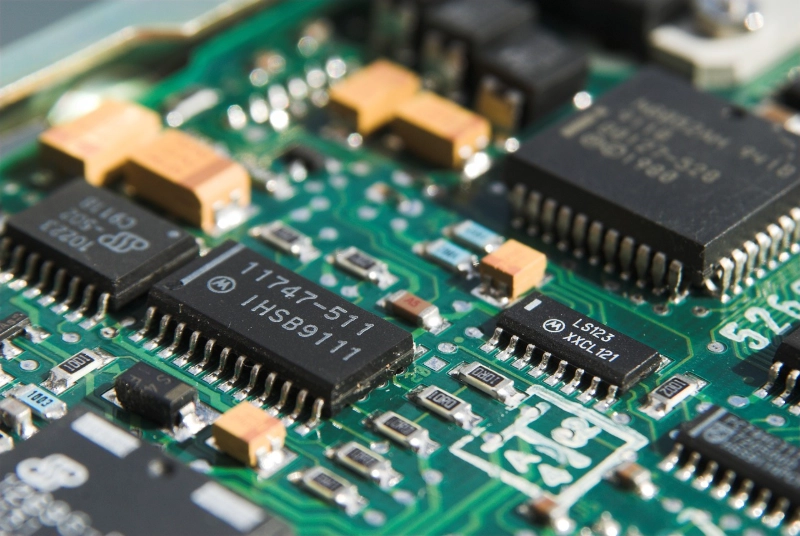

Exploring the Various Kinds of PCBs: From Consumer Electronics to Aerospace Applications

You use electronics every day. You use computers and medical devices. These devices need printed circuit boards, called PCBs, to work. Many industries use various kinds of PCBs. Some common examples are:

Medical devices and implants

Automotive onboard computers

Military equipment

Office machines

Benlida provides quality and skill for various kinds of PCBs. Choosing the right PCB helps your product work well and last longer.

Key Takeaways

Knowing about different types of PCBs, such as single-sided, double-sided, and multi-layer, helps you pick the best one for your project. Picking the right PCB can make your product work better and last longer, especially in tough places like cars and airplanes. Benlida has many kinds of PCBs made for special uses, so you get good quality and trust for things like electronics, medical tools, and machines.

Various Kinds of PCBs

You can find many kinds of PCBs in electronics. Each kind has special features for different jobs. Here are the main types you might use or see.

Single-Sided PCBs

Single-sided PCBs have copper on one side only. These boards are used in simple electronics. They are easy to make and cost less.

Key Features:

The base material, like FR-4, gives strength and insulation.

A thin copper layer makes the electrical paths.

A solder mask keeps the copper safe from damage.

Silkscreen labels help you put parts in the right place.

Making these boards includes cleaning, copper patterning, drilling, adding solder mask, and testing.

Common Applications:

Calculators and remote controls

LED lights

Power supplies and battery chargers

Simple car parts like dashboard indicators

Benlida uses advanced machines to make sure each single-sided PCB is high quality and reliable.

Double-Sided PCBs

Double-sided PCBs have copper on both sides. You can put parts and make connections on both sides. This helps with more complex circuits.

Key Features:

More room for parts and connections

Better signal flow and less noise

Easier to make complex circuits

Typical Uses:

Air conditioning units

LED lights

Industrial controls and power supplies

Car dashboards and airbags

Printers and phone systems

You can trust Benlida to make double-sided PCBs that work well in many devices.

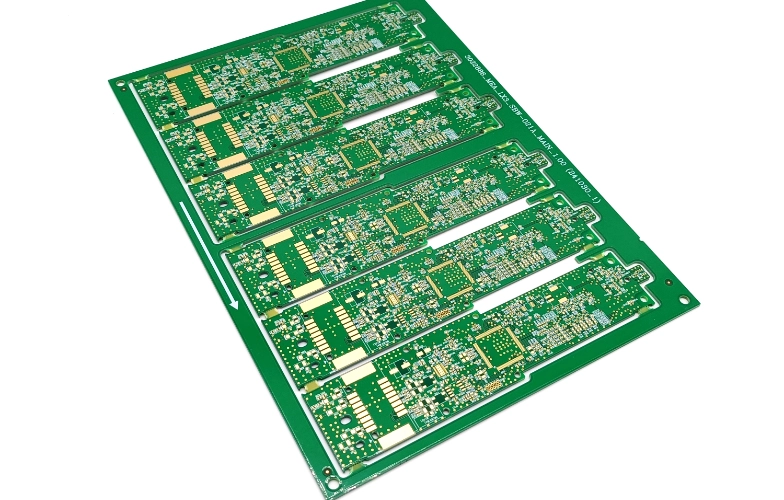

Multi-Layer PCBs

Multi-layer PCBs have three or more copper layers. Insulating material is between each layer. This lets you fit many circuits in a small space.

Advantage | Description |

|---|---|

Superior Signal Integrity | Inside layers shield signals and lower interference. |

High Circuit Density | You can fit complex circuits in small devices. |

Enhanced Reliability | The strong, laminated structure stands up to stress and heat. |

Reduced EMI Emissions | Inside planes help control electromagnetic interference. |

Most boards have 1 to 16 layers. Some advanced boards have over 30 layers. Benlida can make multi-layer PCBs with up to 36 layers for high-tech products.

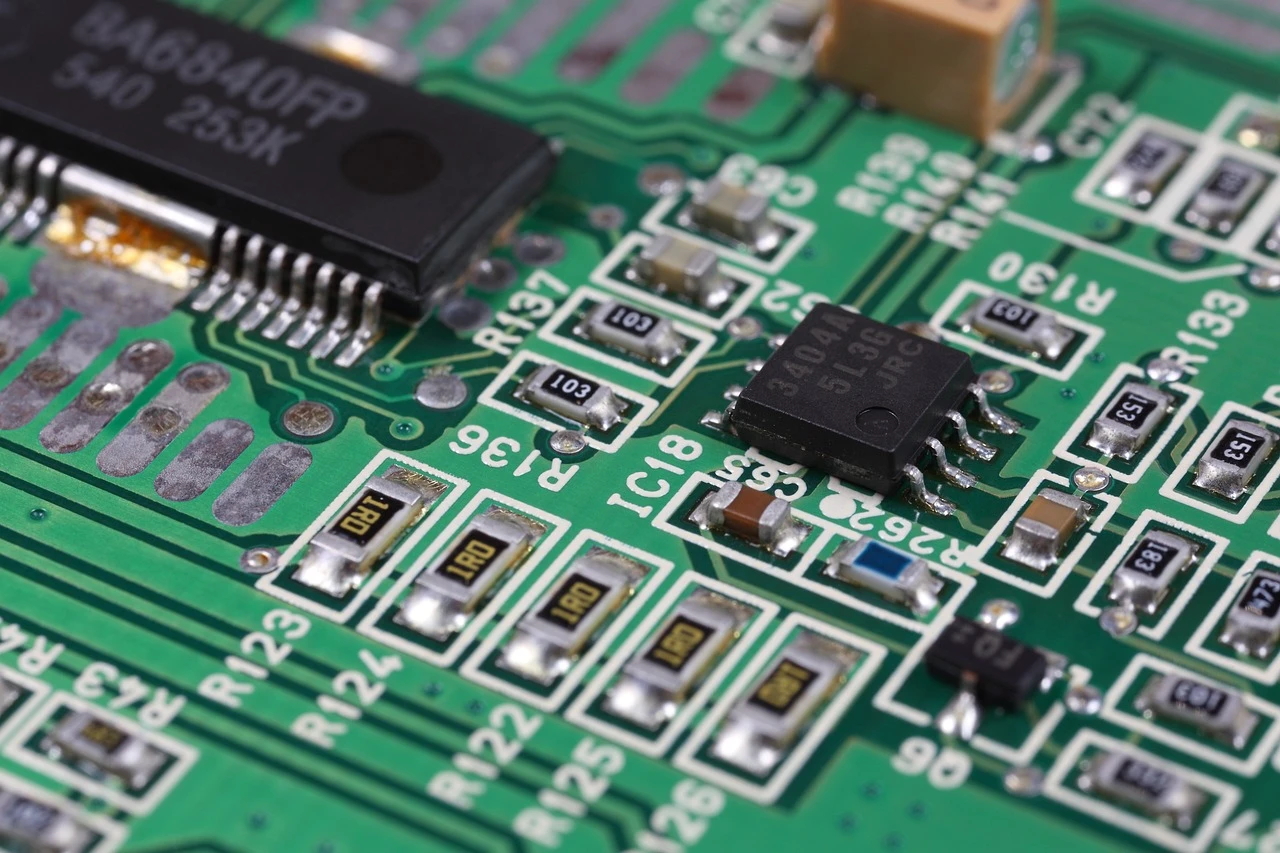

Rigid PCBs

Rigid PCBs use a solid, stiff base. These boards are strong and reliable. You will find them in many devices.

Key Features:

Good for making lots at once

Easy to test and fix

Low electronic noise

Absorbs vibrations for better stability

Supports high-density designs

Technique | Description |

|---|---|

Surface Mount Technology (SMT) | High part density and strong solder joints |

Reflow Soldering | Reliable connections between parts and board |

Automated Optical Inspection | Finds defects early |

Cleanroom Environment | Keeps boards clean for good quality |

Process Monitoring | Keeps quality high during production |

You will see rigid PCBs in computers, GPS systems, and medical devices. Benlida tests every rigid PCB to make sure it works well.

Flexible PCBs

Flexible PCBs, or FPCs, can bend and twist. They are great for devices that need to fit in small or curved spaces.

Unique Property | Description |

|---|---|

Ability to bend and conform | Fits into 3D shapes, good for wearables |

Lightweight construction | Makes devices easier to wear |

Resistance to vibration and stress | Works well in moving or shaking places |

Integration of multiple circuit sections | Needs fewer bulky connectors |

You will find flexible PCBs in smartwatches, fitness trackers, and medical sensors. Benlida uses special materials and careful steps to make sure these boards last.

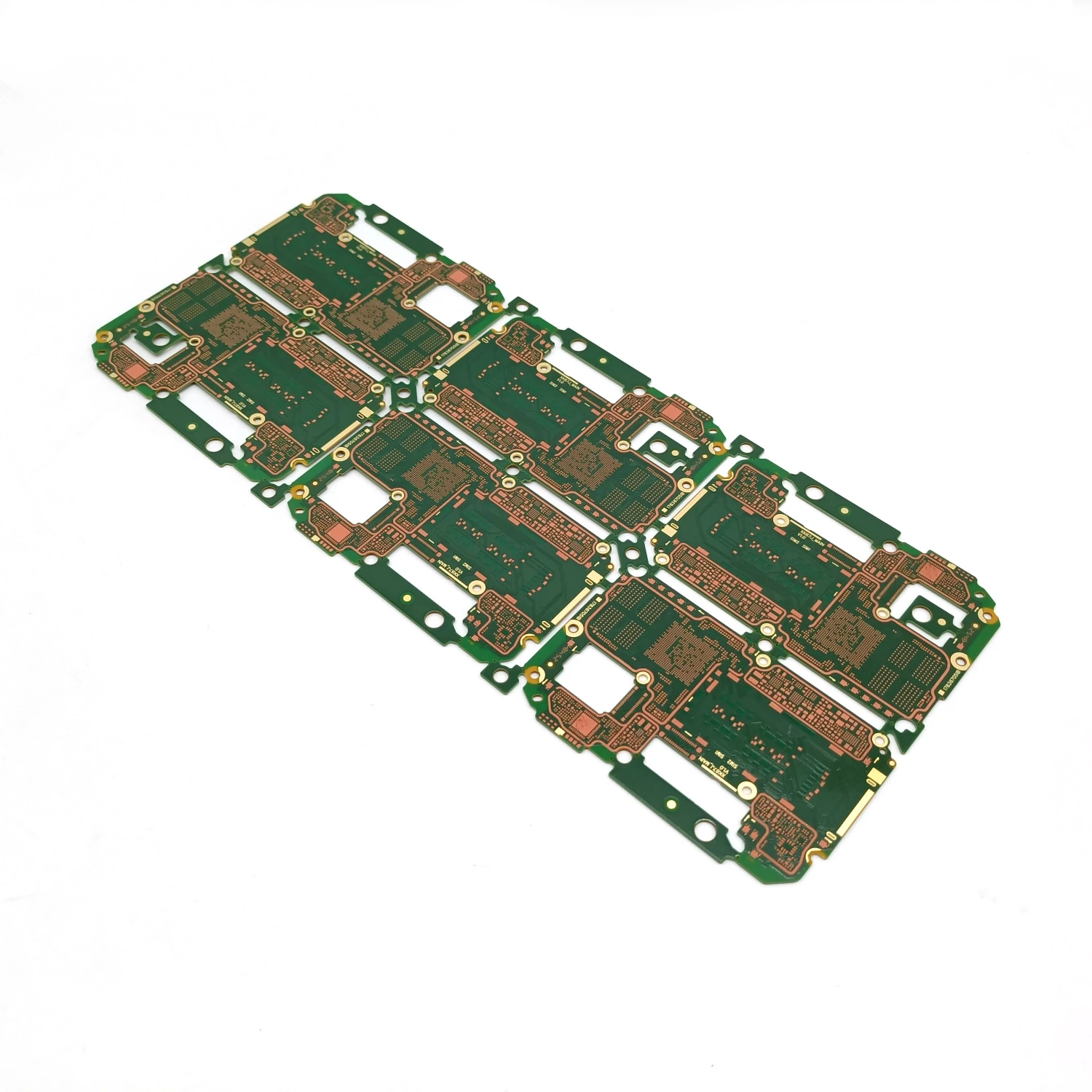

Rigid-Flex PCBs

Rigid-flex PCBs mix rigid and flexible parts in one board. This saves space and weight, which is important for advanced technology.

Benefit | Description |

|---|---|

Weight Reduction | Fewer connectors and wires mean lighter devices |

Improved Reliability | Fewer parts to break, better in tough conditions |

Space Saving | Fits in small or odd-shaped spaces |

Withstands Stress | Handles vibration, shock, and temperature changes |

You will see rigid-flex PCBs in aerospace, satellites, and high-end medical equipment. Benlida tests these boards with bending, heat, and humidity to make sure they work in hard conditions.

Metal Core PCBs

Metal core PCBs use a metal base, usually aluminum or copper. This helps move heat away from the board. It is important for devices that get hot, like LED lights.

Aluminum is common because it is light, resists rust, and costs less.

Copper moves heat better but is heavier and costs more.

These boards keep LEDs and power devices cool. This helps them last longer. Benlida’s metal core PCBs use good metals for the best heat control.

High-Frequency PCBs

High-frequency PCBs use special materials like PTFE (Teflon) or ceramic-filled laminates. These materials keep signals clear and fast, even at high speeds.

Low dielectric loss and controlled properties for stable signals

Can handle high temperatures and support lead-free assembly

You will find high-frequency PCBs in communication devices, radar, and advanced medical equipment. Benlida knows how to use these materials so your high-speed products work well.

Aluminum-Backed PCBs

Aluminum-backed PCBs have a layer of aluminum. This helps move heat away from the board. It keeps electronic parts cool and working well.

Lower temperatures for transistors and diodes

5-8% better efficiency in power electronics

Longer use times and better safety

You will see these boards in power supplies, LED lights, and RF technology. Benlida’s aluminum-backed PCBs help your devices run cooler and last longer.

When you choose Benlida, you get all these kinds of PCBs. They are made with advanced technology and strict quality checks. This makes your products reliable, safe, and ready for the future.

PCB Applications

Consumer Electronics

You use devices like phones, laptops, and cameras every day. These products need different PCBs to work well and stay small. The table shows how each main PCB type helps these devices:

PCB Type | Advantages |

|---|---|

Single-sided PCBs | Easy to design, cheap, good for simple circuits. |

HDI PCBs | Help make small, complex devices. |

Multi-layer PCBs | Fit more circuits in less space, work better. |

These boards are in computers, tablets, game consoles, and home appliances. Benlida makes strong PCBs for these devices. This helps your electronics work without problems.

Automotive

PCBs are used in cars for safety, control, and fun systems. Makers pick different PCBs for each system’s needs. Rigid-flex PCBs fit small spaces. Multi-layer boards handle hard controls. Car PCBs must work in heat, shaking, and bumps. Benlida builds boards for airbags, sensors, and dashboards. They focus on making them safe and reliable.

Industrial Equipment

Factories and machines need PCBs that handle lots of power and heat. Aluminum-backed PCBs help move heat away from parts. Rigid and flexible PCBs are also used in robots and tools. Benlida uses smart machines and careful checks. This makes sure every board is good for the job.

Medical Devices

Medical machines like scanners and monitors need safe and accurate PCBs. Multi-layer and rigid-flex PCBs are used in these devices. They must follow strict rules for safety and quality. Benlida follows these rules and uses special materials. This helps your medical devices work well.

Aerospace and Defense

PCBs are found in satellites, planes, and military gear. These boards must handle very hot and tough places. Light, multi-layer, and rigid-flex PCBs are used a lot. Benlida makes boards that meet hard standards. This helps your technology work in the sky and beyond.

When you pick the right PCB, your products get better. Benlida helps you with expert advice and makes strong PCBs for every job.

Talk to Benlida’s team to choose the best PCB for you. You will get good quality, great performance, and feel sure about your electronics.

FAQ

What is the difference between single-sided and double-sided PCBs?

Single-sided PCBs have copper on one side. Double-sided PCBs have copper on both sides. You can use double-sided PCBs for more complex circuits.

How do you choose the right PCB for your project?

You should think about your device’s size, heat, and how many parts you need. Benlida’s team can help you pick the best type.

Can Benlida make custom PCBs for special needs?

Yes! You can ask Benlida for custom shapes, sizes, or features. Their engineers will work with you to meet your project’s needs.

en

en

WhatsApp

WhatsApp