What are the key considerations for FPGA when going through PCBA design?

FPGA is a complex systems engineering that requires comprehensive consideration for multiple aspects, includes performance, cost, power consumption, development efficiency, and supply chain. Choosing wrong might lead to project delays, cost overruns, or even a complete overhaul. In this article, we are going to dive into the key considerations:

First: Top-Level Driver – Defining the Core Scenarios and Objectives

This is the starting point for all decisions.

1. What is the application area?

● Communications and Networks: Emphasis on high-speed transceivers (25G+), hard-core Ethernet IP, and high-bandwidth memory interfaces.

● Industrial Control and Automotive: Emphasis on reliability, industrial temperature ratings, functional safety certification, and long lead times.

● Consumer Electronics: Emphasis on cost, power consumption, and integration.

● Test and Measurement: Emphasis on high-performance ADC/DAC interfaces, logic resources, and high-speed I/O.

● Artificial Intelligence Acceleration: Emphasis on high-density DSPs/multipliers, large-capacity on-chip memory, and dedicated AI engines.

2. What stage is the project at now?

● Prototyping/Academic Research: Prioritize models with rich development board ecosystems and toolchain-friendly designs, such as the Xilinx Zynq-7000 or Intel Cyclone V SoC series.

● Mass Production Products: Cost, power consumption, and long-term supply guarantees that must be rigorously evaluated. Mature or cost-effective series are preferred.

Second: Core Hardware Resources – Meeting Basic Project Requirements

This is the foundation to ensure that the design can be implemented and run smoothly.

1. Logic Resources: Estimate the number of LUTs and registers required. Synthesis tools typically provide estimates after the initial design completed. Leave a 30%-50% margin for later debugging and feature additions.

2. Storage Resources:

● Block RAM: Used for large data buffers, FIFOs, and lookup tables. Depth and width need to be estimated.

● Distributed RAM/UltraRAM: Used for small-scale, distributed storage needs.

3. DSP/Arithmetic Units: Used for signal processing and algorithm acceleration (such as FIR filters, FFT, matrix operations). Estimate the number of multipliers and multiply-accumulate units required. 4. Clock Resources:

- Global Clock Network: Is the quantity sufficient to drive critical signals such as global reset and enable?

- Clock Management Unit: Do the quantity and performance (jitter, frequency synthesis range) of PLLs/DLLs meet the requirements of a multi-clock domain design?

Third: Key Functions and Performance – Determining Project Success or Failure

This layer determines the upper limit and feasibility of the design.

1. I/O Characteristics and High-Speed Interfaces:

● Quantity: How many transceiver channels are needed? Maximum Line Rate: Does it support the target protocol rate (e.g., PCIe Gen3 8Gbps, Gen4 16Gbps)?

● Protocol Hard Core: Does it integrate hard core IPs such as PCIe, SATA, and 100G Ethernet? Hard cores can save significant logic resources and improve performance.

● I/O Bank Quantity and Voltage: Does it support the various voltage standards required by the design?

● High-Speed Transceiver: This is of paramount importance in selection.

2. External Memory Interface:

● Is it necessary to connect to high-speed memory such as DDR4, LPDDR4, or DDR5? It's necessary to confirm the maximum data rate and maximum bit width of the memory controller hard core (MC) supported by the FPGA.

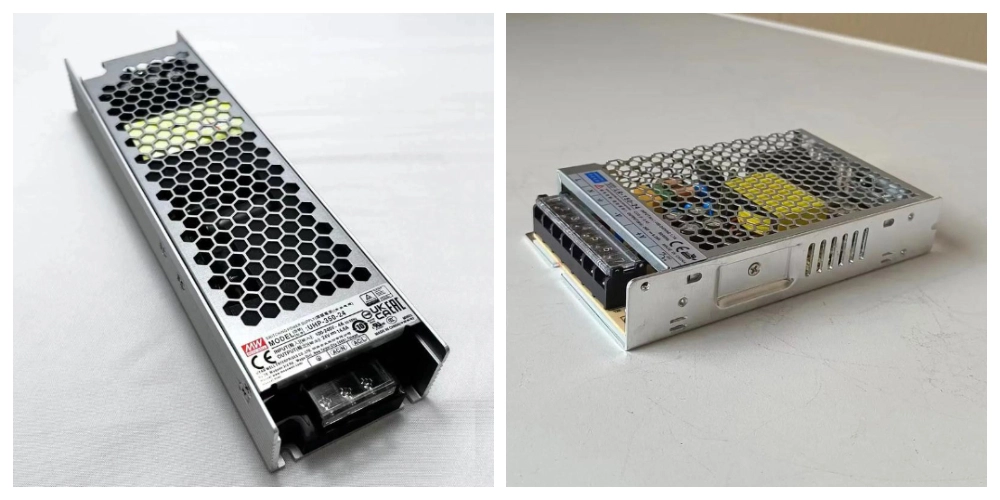

3. Power Consumption and Heat Dissipation:

● Static Power Consumption: Primarily determined by the manufacturing process.

● Dynamic Power Consumption: Directly related to resource utilization, toggle rate, and clock frequency. Use the manufacturer's power estimation tools for early assessment.

● Thermal Design: Power consumption determines package selection and heat dissipation solutions (whether heatsinks/fans are needed).

4. Performance Goals:

What is the target clock frequency for the design? Can the routing resources and architecture of the selected devices support timing convergence? More advanced processes and high-performance series typically achieve higher frequencies more easily.

Fourth: Development Support and Long-Term viability – Ensuring Smooth Project Implementation and Maintenance

1. Development Toolchain:

● Synthesis and Implementation Tools: Ease of use, compilation speed, and licensing fees for Vivado (Xilinx/AMD) or Quartus (Intel/Altera).

● Debugging Tools: How well do logic analyzers like ChipScope/SignalTap work?

● High-Level Language Support: Is HLS (High-Level Synthesis) or OpenCL required?

2. IP Cores and Ecosystem:

● Official IP Libraries: Do they provide mature IP cores with the required functions (e.g., video codecs, network protocol stacks)? What are the costs?

● Third-Party and Open-Source Ecosystem: Are there abundant reference designs on platforms like GitHub?

3. Supply Chain and Business Factors:

● Delivery Cycle and Lifecycle: For industrial, automotive, and medical products, devices with long-term supply commitments must be selected.

● Unit Cost: Aim for the best cost-performance ratio while meeting requirements.

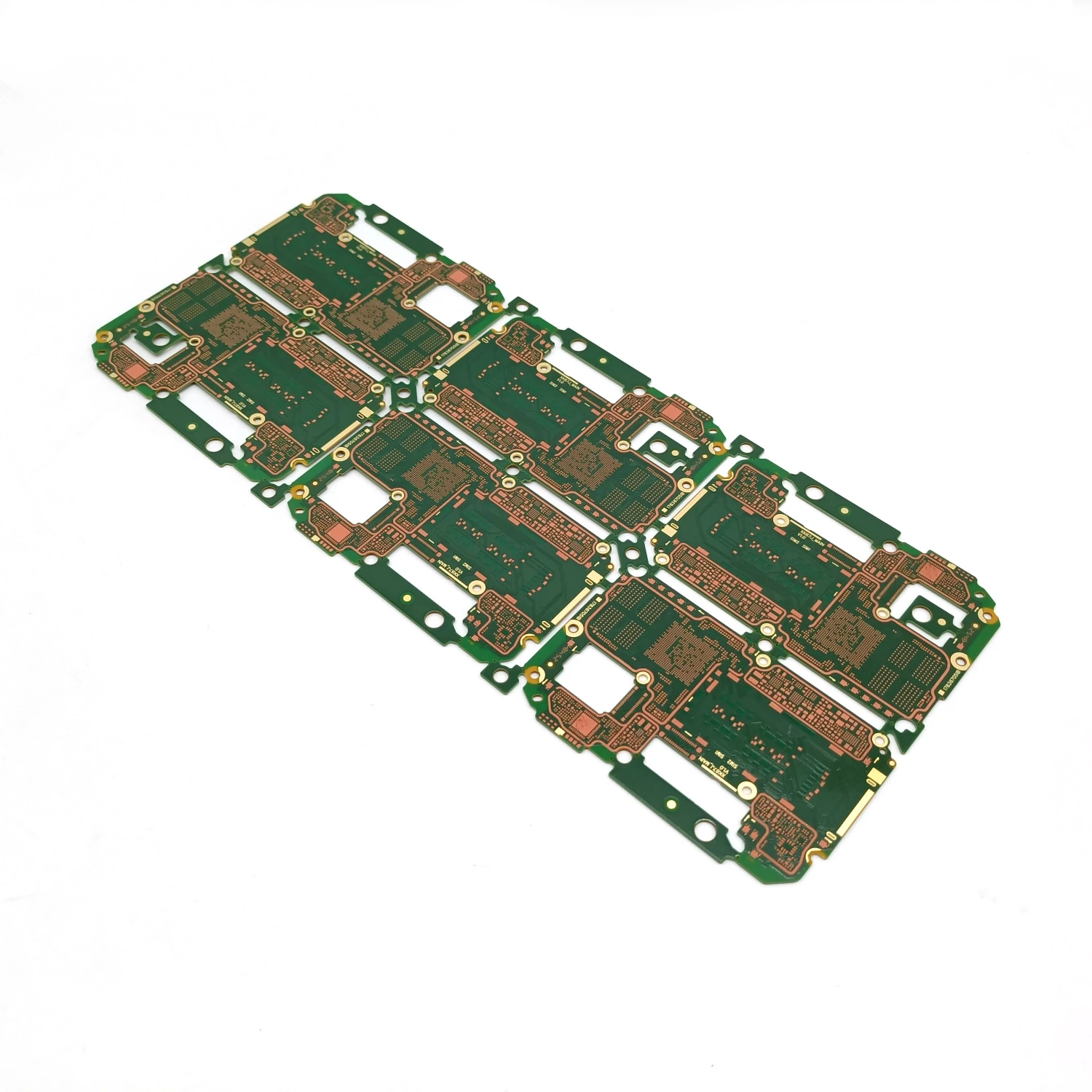

● Packaging and PCB Design: Package size and pin pitch (e.g., 0.8mm vs. 0.5mm BGA) directly affect the number of PCB layers, cost, and manufacturing difficulty.

Practical Process Recommendations for Selection

1. Requirements List: Based on the system design, list all hard specifications (e.g., number of transceivers, DDR interfaces, power consumption limits, temperature ratings) and flexibility specifications (e.g., logic resource margins).

2. Initial Vendor Screening: Visit the websites of major vendors such as Xilinx/AMD, Intel/Altera, Lattice, and Microchip, and use their selection tools (e.g., Xilinx's "Product Table," Intel's "Device Selector") for quick filtering.

3. Creating a Shortlist for Comparison: Select 2-3 potential models and compare their datasheets, DC/AC features, and IP availability in detail.

4. Power Consumption and Cost Assessment: Use the vendor's Power Estimator tool to estimate power consumption. Contact distributors or use online pricing tools to estimate costs.

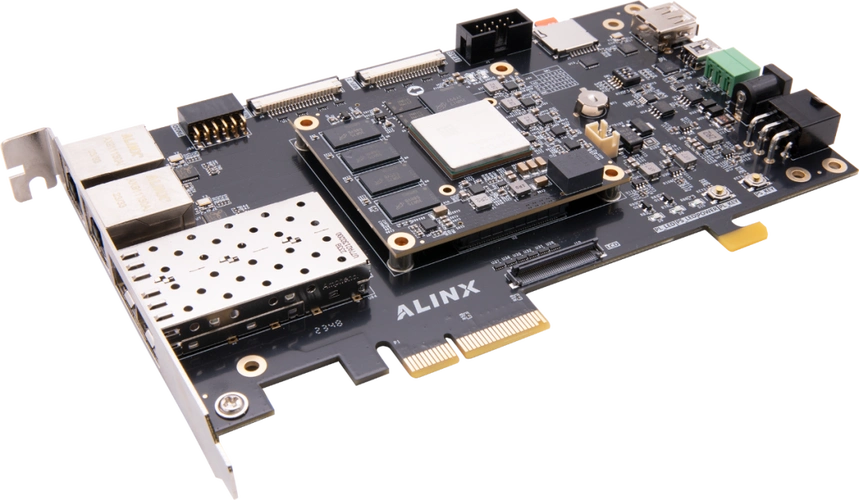

5. Development Board Verification: For critical designs or new platforms, it is strongly recommended to purchase or borrow corresponding development boards for early prototyping verification, especially for verifying high-speed interfaces and performance.

6. Final Decision: Strive for the best balance between performance, power consumption, cost, development cycle, and supply chain risks.

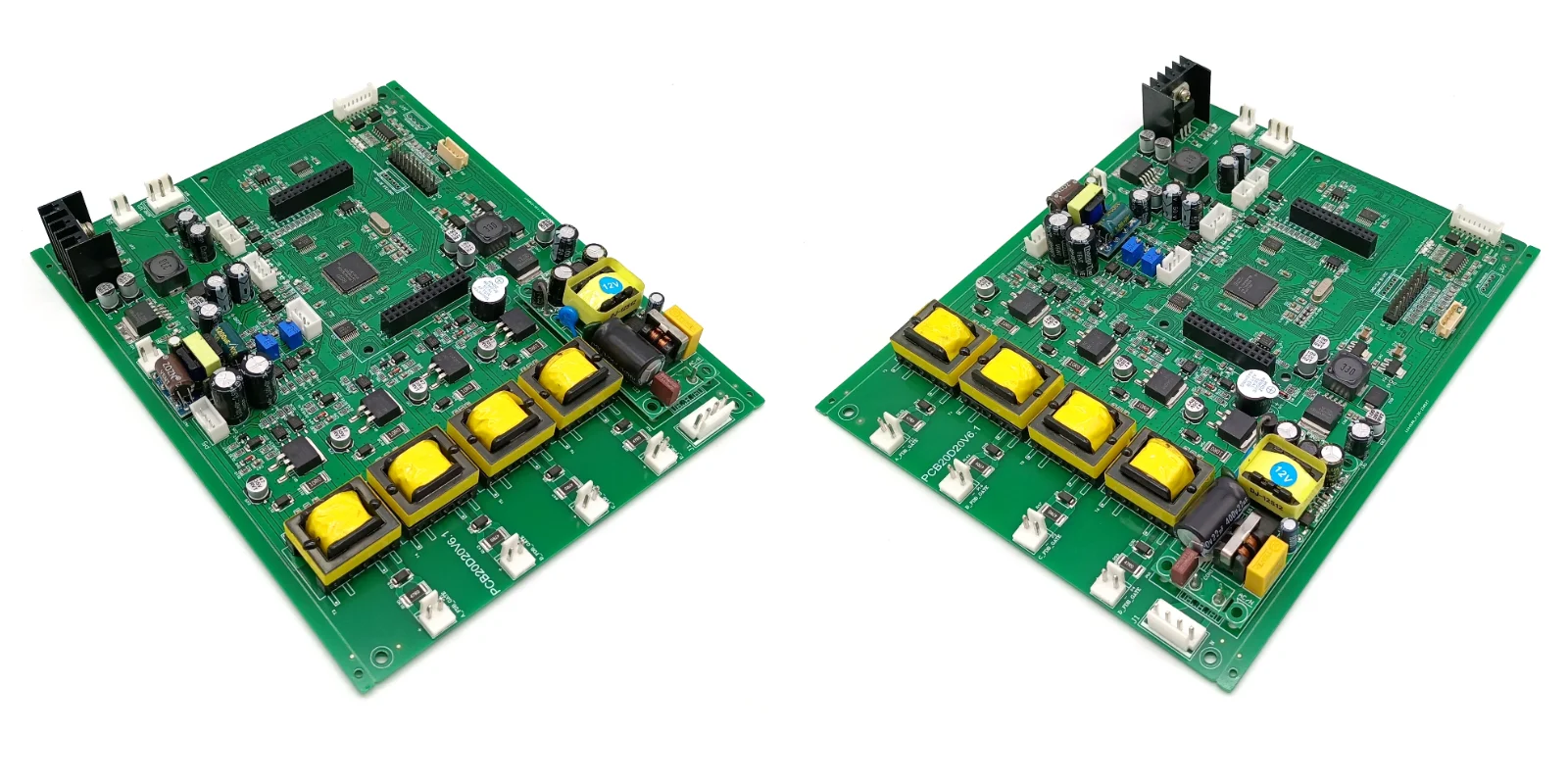

Benlida has been manufacturing PCB and provide PCBA assembly service for 14 years. While continuously upgrading PCB manufacturing processes, it has also established a stable and mature engineering team & supply chain. If you are designing FPGA project and planning to prototype, please contact Benlida! Benlida manufactures high-quality PCBs and can support your projects with cost-effective supply chain!

en

en

WhatsApp

WhatsApp