Advantages and Process of One-Stop PCBAManufacturing

The One-Stop PCBA Manufacturing Advantages and Process

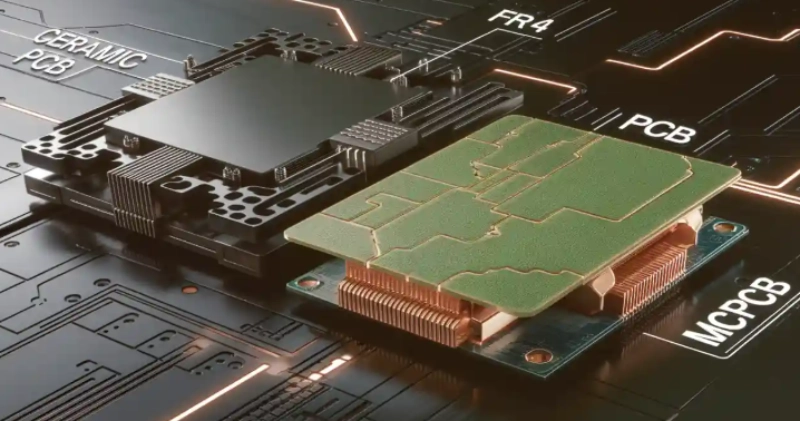

In the electronics manufacturing industry, one-stop PCBA (Printed Circuit Board Assembly) services integrate PCB fabrication, component sourcing, assembly, testing, and post-processing into a streamlined workflow. This all-in-one solution has become a preferred choice for businesses seeking efficiency, reliability, and cost-effectiveness. Below is a detailed breakdown of its core advantages and key processes.

Core Advantages of One-Stop PCBA Manufacturing

Simplified Project Management

By consolidating all stages under a single service provider, clients eliminate the need to coordinate with multiple vendors (e.g., PCB manufacturers, component suppliers, assembly factories). This reduces communication gaps, minimizes errors, and shortens overall lead times.

Cost Optimization

One-stop services leverage economies of scale: bulk purchasing of components, integrated production lines, and reduced logistics costs (e.g., fewer shipments between facilities) translate to lower expenses for clients. Additionally, centralized quality control prevents costly rework caused by mismatched components or subpar PCB fabrication.

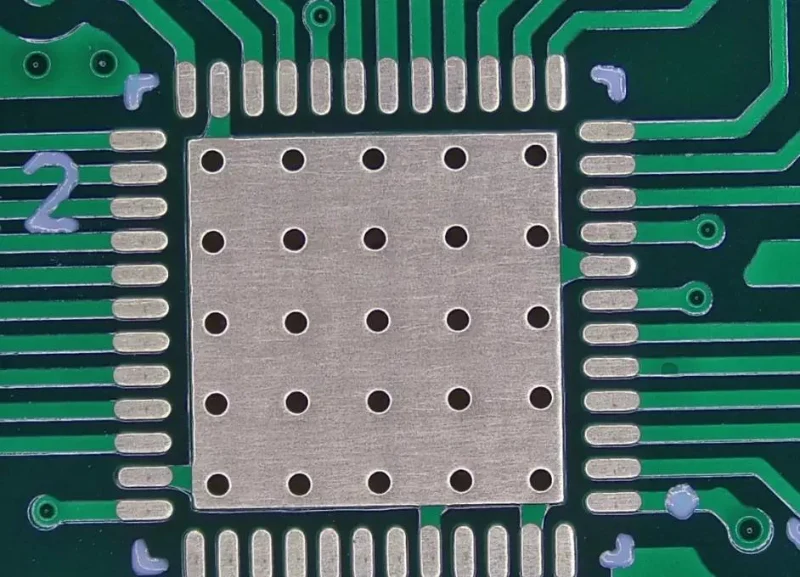

Enhanced Quality Control

A unified manufacturing process allows for stricter quality checks at every stage—from PCB design reviews and component authenticity verification to assembly precision and functional testing. This end-to-end oversight ensures compliance with industry standards (e.g., IPC, ISO) and reduces the risk of defective products reaching the market.

Flexibility and Scalability

Whether handling small-batch prototypes or large-scale mass production, one-stop providers adapt to varying project requirements. They can quickly adjust production schedules, accommodate design modifications, and scale output to meet tight deadlines, making them ideal for both R&D projects and high-volume manufacturing.

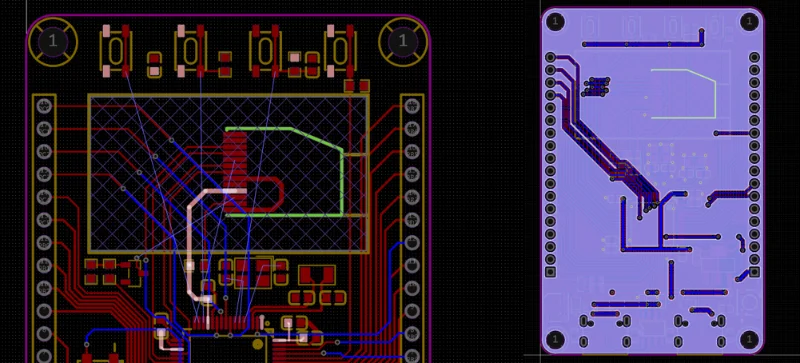

Technical Expertise and Support

Reputable one-stop PCBA manufacturers employ cross-functional teams (design engineers, component specialists, assembly technicians) who offer guidance from prototyping to production. This includes DFM (Design for Manufacturability) analysis, component substitution recommendations, and troubleshooting, ensuring smoother project execution.

en

en

WhatsApp

WhatsApp