Applications and Advantages of 3D SPI in PCB Assembly&PCBA Manufacturing Process

3D SPI (3D Solder Paste Inspection) is a key process control step in modern SMT (Surface Mount Technology) production. It inspects printing quality of of solder paste on PCB, by precise three-dimensional, after printing and before component placement(SMT). This article narrates the specific applications and core advantages of 3D SPI:

I. Applications

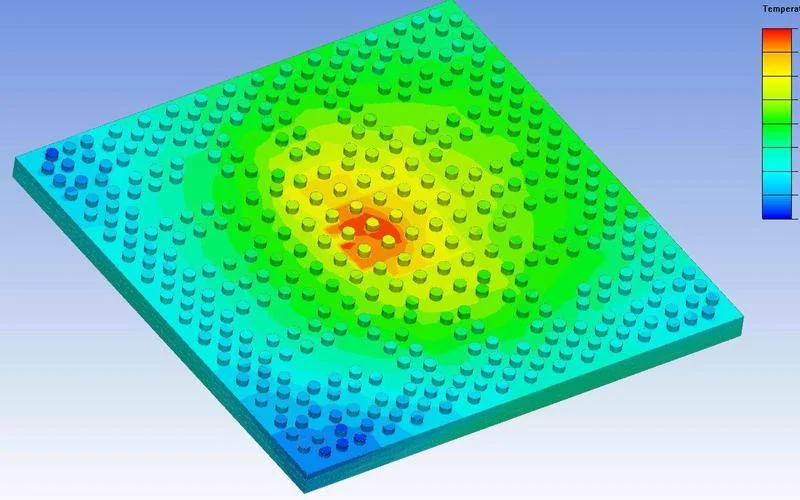

1. Measure the Volume of Solder Paste: measure the cubic volume of solder paste on each pad precisely, to ensure the amount of solder meets soldering reliability requirements and avoids cold solder joints or bridging/short.

2. Analysis for Height and Thickness of Solder Paste: Generates a height map through 3D scanning, to detect the flatness, uniformity, and presence of collapses or depressions in the solder paste.

3. Detection of Printing Offset: Identifies whether the solder paste printing is aligned with the pads, detects positional deviations in the X/Y directions, and prevents component placement errors.

4. Evaluation for Shape&Area of Solder Paste: Analyzes the diffusion, edge shape, and coverage area of the solder paste to ensure the solder paste shape meets process standards.

5. Automatic Identification for Defects: Automatically detects printing defects, such as insufficient solder, missing print, solder spikes, bridging/short, and contamination, automatically trigger alarms or adjustment commands timely.

II. Advantages

1. Preventative Quality Control: Intercepts printing defects before component placement(SMT), prevent the defects proceed into subsequent stage: reflow soldering, prevent yield rate and reduce rework costs&material waste significantly.

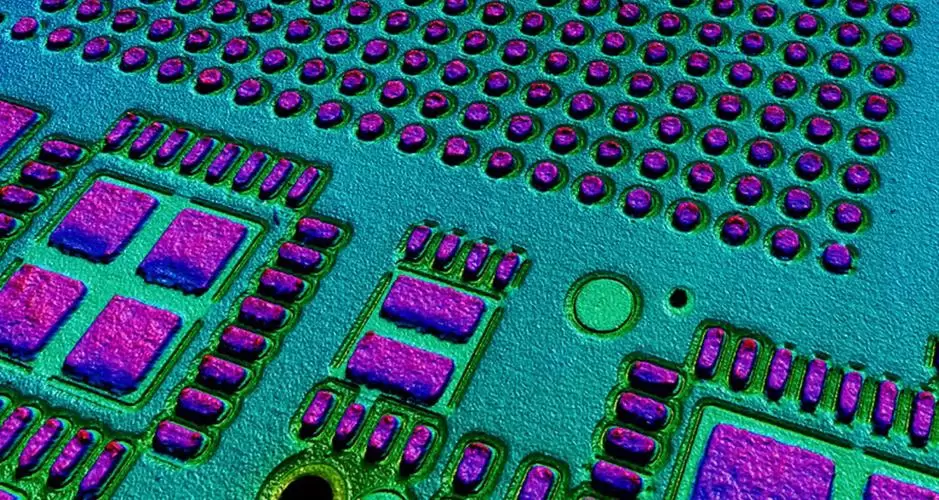

2. High Precision and Repeatability: Utilizes structured light technology to achieve micron-level precision (typically ±1μm), ensure high repeatability and reduce error from personnels.

3. Process Optimization and Data-Driven: Analyzes the volume and height of solder paste, so as the trends by Statistical Process Control (SPC), provides basis for stencil design and squeegee parameter adjustments, optimizing the printing process continuously.

4. Improve First-Pass Yield and Capacity: Prevent defects could reduce failure rates of SMT and reflow soldering, improve first-pass yield of the overall production line, while reducing the re-inspection load on AOI (Automated Optical Inspection).

5. Dedicated to High-Density Assembly

Inspect the solder paste, especially for fine-pitch components, such as 01005, CSP, and BGA, that 2D inspection cannot assess: not just coverage, but also volume and height.

6. Real-Time Monitoring and Feedback Control

Some systems can be connected&integrated with printers, to achieve closed-loop control, automatically adjusting squeegee pressure, speed, or cleaning cycle to improve process consistency.

III. Technological Development Trends

1. AI Intelligent Analysis: Combining machine learning algorithms to achieve defect classification and analysis of root cause, predict potential process risks.

2. Cross-Platform Integration: Seamlessly integrates with MES (Manufacturing Execution System) and SPC platforms, to achieve full-scale traceability of process quality.

3. High-Speed Inspection Capability: Applicable for the pace of flexible production lines, inspection speeds could reach tens of thousands of points per hour, meet the needs of large-scale production.

Summary:

3D SPI, through three-dimensional quantitative analysis for printing quality of solder paste, shifts the quality control node from "outcome inspection" to "process prevention," improve the reliability, efficiency, and process controllability of SMT production significantly, and it has become an indispensable process assurance in high-precision electronic manufacturing.

For 14 years, Benlida is committed to produce high-quality PCBs and PCBA assembly services. We have purchased advanced 3D SPI inspection equipment for solder paste printing. If you need PCB and PCBA assembly services, please feel free to contact Benlida!

en

en

WhatsApp

WhatsApp