Automotive PCB Design Requirements for Harsh Vehicle Environments

You face many problems when you work with Automotive PCB Design. Cars can make PCBs deal with heat, shaking, and wetness. New reports show even more problems, like:

Environmental Challenge | Description |

|---|---|

Sustainable Practices | The need for eco-friendly manufacturing processes is becoming a big reason for market growth. |

Supply Chain Vulnerabilities | Recent problems have shown weak spots in getting needed materials. |

Material Shortages | Not enough semiconductor parts makes it hard for makers to keep up with demand. |

You can see that people want better solutions as the market gets bigger:

The automotive PCB market may grow from $10.05 billion in 2024 to $10.57 billion in 2025, with a CAGR of 5.2%.

By 2029, the market could reach $14.34 billion, with a CAGR of 7.9%.

Benlida’s skills help you handle these needs with trust.

Key Takeaways

Automotive PCBs need to handle very hot and cold temperatures. They also need to resist water and shaking. This helps them work well in cars. - Picking the right materials, like FR-4 or aluminum, is very important. These materials help PCBs last longer and work better in tough places. - Using thicker copper layers lets more current flow. It also helps control heat. This makes PCBs stronger and more reliable. - Special coatings, like acrylic or epoxy, protect PCBs from water and chemicals. These coatings help PCBs last longer. - Testing and checking PCBs is very important. It helps find problems early. It also makes sure PCBs are safe for cars.

Harsh Vehicle Environment Factors

Temperature Extremes

Automotive PCBs need to work in many temperatures. Cars can get very cold or very hot. The table below shows the usual temperature ranges for automotive PCBs:

Temperature Range | Description |

|---|---|

-40°C to +85°C | Most automotive PCBs work in this temperature range. |

-40°C to +105°C | Some PCBs work in even hotter places. |

-40°C to +125°C | The toughest PCBs work in the hottest spots. |

Designing for these temperatures helps stop problems. It keeps electronics working in any weather.

Moisture and Humidity

Moisture is a big issue for automotive PCBs. High humidity can cause many problems:

Water can get inside and break layers apart.

Humidity can make soldering harder and cause shorts.

Too much water in the air can rust solder pads and cause failures.

Boards need protection from water and damp air. This helps them stay reliable.

Vibration and Shock

Cars drive on bumpy roads and shake a lot. PCBs must survive these bumps and shakes. There are standards to test for these problems:

Standard | Frequency Range | Acceleration Levels | Notes |

|---|---|---|---|

ISO 16750-3 | 10 Hz - 2,000 Hz | Changes by location | Tests for different places in the car. |

MIL-STD-810G | 5 Hz - 2,000 Hz | Changes by use | Checks for random shaking on rough roads. |

GMW3172 | N/A | Up to 20g | Tests for shaking at certain speeds. |

IEC 60068-2 | 5 Hz - 500 Hz | Up to 50g | Tests many things for electronics. |

Following these standards helps boards last longer.

Dust and Chemicals

Dust and chemicals can hurt PCBs in many ways:

Leftover flux can cause shorts.

Bad chemicals can rust parts and make them work worse.

Dust can hold water and other bad stuff.

Fingerprints can leave oil and mess up connections.

Salt, sand, and heat can also cause damage.

Boards need to be kept clean and safe to avoid these problems.

Electrical Stress

Automotive PCBs get electrical stress from different things. The table below shows some common causes:

Source of Electrical Stress | Description |

|---|---|

Changes in Altitude | Higher places have thinner air, which can cause sparks. |

Mechanical Stresses | Bumps and shakes can hurt parts and connections. |

Boards must be made to handle these stresses. This keeps electronics safe and working well.

Automotive PCB Design Requirements

Material Selection

You must pick the right materials for Automotive PCB Design. The materials need to handle heat, wetness, and shaking. FR-4 is used a lot because it stands up to heat and water. For harder jobs, aluminum or ceramic work better. These materials help boards last longer in tough places.

Benlida uses top-quality materials from trusted companies. This makes sure your PCBs follow strict car rules. Picking the right material helps boards survive tough spots and keeps car electronics safe.

Copper Thickness

Copper thickness matters a lot in Automotive PCB Design. The copper layer moves current and helps get rid of heat. Thicker copper lets the board handle more current and heat. This makes the board stronger and more dependable.

Thicker copper lets more current flow without big drops.

Better heat control stops overheating.

Strong boards bend less and handle stress better.

Here is a table that shows how copper thickness changes current capacity:

Copper Thickness | Current Capacity (A/mm) |

|---|---|

1 oz (≈ 35µm) | 1–1.5 |

2 oz (≈ 70µm) | up to 2.5 |

3 oz (≈ 105µm) | higher for industrial |

Benlida gives you choices for copper thickness. This helps you match your design to what you need. It makes sure your Automotive PCB Design is safe and strong.

Protective Coatings

Protective coatings keep your PCB safe from water, dust, and chemicals. You can pick from different types:

Acrylic Coatings: Easy to use and take off. Good for stopping moisture.

Silicone Coatings: Bendable and steady in heat. Great for places with lots of temperature changes.

Epoxy Coatings: Very tough against chemicals and water. Best for hard conditions.

Urethane Coatings: Good at fighting chemicals and bending. Works well for medium stress.

Benlida puts on these coatings with care. This keeps your boards safe and helps them last longer in tough car places.

Mechanical Reinforcement

Automotive PCB Design needs to stand up to shaking and bumps. You can add a metal layer, like aluminum or steel, to make the board stronger. This metal layer acts like a backbone. It spreads out stress and stops the board from cracking or bending.

Tests show that metal layers can lower cracking and solder joint problems by up to 30%. Benlida uses these tricks to keep your PCBs strong, even on rough roads.

EMI/RFI Shielding

Electromagnetic interference (EMI) and radio-frequency interference (RFI) can mess up your car’s electronics. You need to block or soak up these signals to keep things working right. Good shielding starts early in the design.

Put metal cages or Faraday cages around sensitive parts.

Think about the signal frequency when you design shields.

Plan for shielding early to avoid expensive fixes later.

Benlida’s team uses smart shielding methods. This helps your Automotive PCB Design meet strict EMI rules and keeps electronics safe from interference.

Note: Rules like ISO 26262 and AEC-Q100 set safety and reliability for car electronics. Benlida follows these rules and uses tests like Temperature Humidity Bias (THB) and EMI checks to make sure your boards are ready for the road.

By following these steps and working with Benlida, you can make Automotive PCB Design that lasts in the toughest car places.

Design Strategies for Reliability

Component Placement

You should put parts on your board carefully. Good placement helps your board work well. It also helps your board last longer. If you keep parts apart, you stop signal problems. This is important for Automotive PCB Design. It keeps signals strong and clear. Careful placement helps your board handle heat. It also helps with vibration, which happens a lot in cars.

Redundancy Features

Redundancy means you add backup parts or paths. If one part stops working, another can help. This keeps your system working if something fails. Safety systems like airbags use redundancy. Brakes also use it. Planning for backups makes your board safer. It also makes your board more reliable.

Testing and Validation

Testing and validation check your board before it goes in a car. There are many ways to test your board:

Testing Method | Description |

|---|---|

In-Circuit Testing (ICT) | Checks each part to make sure it works right. |

Functional Testing | Makes sure the whole board works as it should in real situations. |

Environmental Stress Testing | Tests the board in hot, cold, wet, or shaky places. |

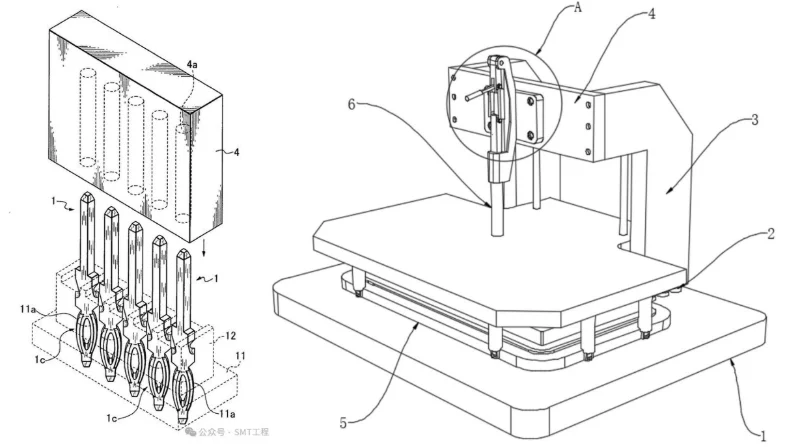

Automated Optical Inspection (AOI) | Uses cameras to find problems during making. |

Hardware-in-the-Loop (HIL) Testing | Tests how the board acts in a fake car setup. |

Benlida uses AOI, ICT, and flying probe testing. These tests find problems early. This helps you get boards that meet high standards.

Compliance Standards

You must follow strict rules for car electronics. Standards like ISO 26262 keep your board safe and reliable. Benlida checks boards to meet these rules. The team uses advanced tests. They follow a quality-first plan. This means you get boards that pass tough checks. Your boards will work well in real cars.

Tip: Using strong materials, protective coatings, and smart design helps your board last longer in tough places.

Strategy | Description |

|---|---|

Material Selection | Pick materials that handle heat and shaking. |

Protective Coatings | Use coatings to block water and dirt. |

Design Techniques | Plan your board to stop signal problems and make it stronger. |

If you use these strategies, your Automotive PCB Design will last in tough vehicle places.

Automotive PCB Applications

Engine Control Units

Engine control units are very important in cars. They control fuel, spark, and emissions. ECUs need PCBs that work fast and do not break. The boards must handle heat and electrical noise. Using strong materials helps ECUs last a long time. Careful design keeps engines safe and working well.

Safety Systems

Safety systems keep people safe in cars. Airbags and brakes use special PCBs. These boards must work fast and never stop working. Tough coatings and thick copper make boards stronger. Testing finds problems before cars use the boards. Following rules makes safety systems work in every situation.

Infotainment Modules

Infotainment modules give music, maps, and phone help. These systems make driving fun and safe. Designers have some problems with these boards:

Cost and design must be balanced. New features can make boards harder and cost more.

Boards must last a long time. Infotainment PCBs need to work for 10 to 15 years with heat and shaking.

Boards must follow rules. Not following rules can cause recalls and safety issues.

Planning helps meet these needs. Good materials and smart design make infotainment work well for years.

Powertrain Electronics

Powertrain electronics help cars move. These boards control the transmission, motors, and batteries. PCBs must handle strong currents and shaking. Thick copper and strong layers help boards last longer. Careful design keeps powertrain working in hard driving.

When you design Automotive PCBs, you need to think about some important things. You must make sure the board can handle hot and cold temperatures. It should also survive strong shaking. The board needs protection from electrical noise. It must block interference. You should use tough materials. Smart layouts help the board work better. Good manufacturing is important. Testing helps you find problems early. These steps keep your boards safe. They help you follow the rules. If you pick Benlida, you get quick help. You also get strong support. Benlida gives good results for car projects.

FAQ

What makes automotive PCBs different from regular PCBs?

Automotive PCBs face heat, shaking, and wetness. They use stronger materials and better coatings. These boards must pass tough tests to be safe in cars.

Why is copper thickness important in automotive PCBs?

Thicker copper lets boards move more current. It helps control heat better. This makes boards last longer and stay safe in cars.

How do you protect PCBs from moisture and chemicals?

You can use special coatings like acrylic or silicone. These coatings stop water and chemicals. They help boards stay safe and work well in tough places.

What tests do automotive PCBs go through?

Automated Optical Inspection (AOI)

In-Circuit Testing (ICT)

Environmental stress tests

These tests help find problems early. They make sure boards meet car rules.

en

en

WhatsApp

WhatsApp