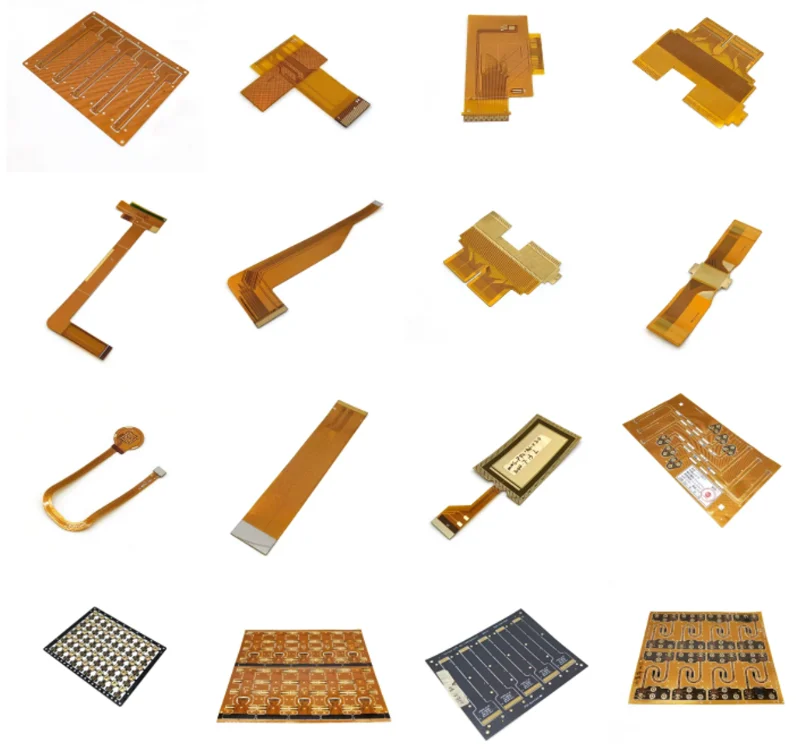

Features, Advantages and Applications of FPC(Flexible Printed Circuit)

FPC (Flexible Printed Circuit)is a type of printed circuit board made from a flexible substrate (such as polyimide or polyester film), characterized by it's flexibility, foldability, and three-dimensional assembly capabilities. The following is a detailed description of main features, advantages, and applications:

I. Features of FPC

1. Flexibility and Bending: The thin and flexible substrate can adapt to complex spatial layouts, enabling dynamic bending or static folding.

2. Thin and Light Design: Typically only 0.1-0.3mm thick, far thinner than rigid PCBs, making it suitable for space and weight sensitive devices.

3. High-Density Integration: Supports fine line widths/spacing (down to 0.05mm), enabling high-density wiring and reducing connector usage.

4. High Temperature Resistance and Stability: The polyimide substrate is resistant to high temperatures (-200°C to +300°C) and chemical corrosion, making it suitable for harsh environments.

5. Three-Dimensional Assembly Capability: Allows for three-dimensional wiring, optimizing internal device space and increasing design freedom.

II. Advantages of FPC

1. Space and Weight Savings

Replaces traditional wiring harnesses and connectors, reducing size and weight (e.g., mobile phones, drones).

2. High Reliability

Reduces solder joints and connection interfaces, lowering the risk of poor contact and improving system stability.

3. Dynamic Durability

Can withstand millions of repeated bending cycles (e.g., folding phone hinges, robotic arm joints).

4. Design Flexibility

Supports custom shapes, adapts to non-planar structures, and simplifies product assembly processes.

5. Signal Integrity

Suitable for high-frequency signal transmission (e.g., 5G antennas, high-speed cameras), reducing impedance mismatch.

III. Application Areas of FPC

1. Consumer Electronics

● Folding Phones: Hinge connection (e.g., Samsung Galaxy Fold, Huawei Mate X).

● Wearable Devices: Bending circuitry for smartwatches/bands.

● Laptops: Screen-to-motherboard connection (e.g., MacBook display cable).

2. Automotive Electronics

● In-vehicle Displays: Connection to curved screens on the center console.

● Sensors and Lighting: Flexible LED light strips, Battery Management System (BMS) wiring.

3. Medical Devices

● Implantable Devices: Flexible circuitry for pacemakers and nerve monitoring sensors.

● Portable Devices: Endoscopes, wearable health monitors.

4. Industrial and Aerospace

● Robotics: Wiring for robotic arm joints.

● Satellites and Aircraft: Lightweight circuit boards for confined spaces.

5. Communications and Military

● 5G Antennas: Millimeter-wave high-frequency signal transmission.

● Military Equipment: Vibration-resistant and extreme-environment-resistant circuit systems.

IV. Technological Challenges and Development Trends

1. Challenges: High cost (complex materials and processes), low mechanical strength, and high maintenance difficulty.

2. Trends:

● Rigid-Flex PCBs: Integrating rigid and flexible areas to improve structural stability.

● Stretchable Circuits: Adapting to more extreme deformation requirements (e.g., electronic skin).

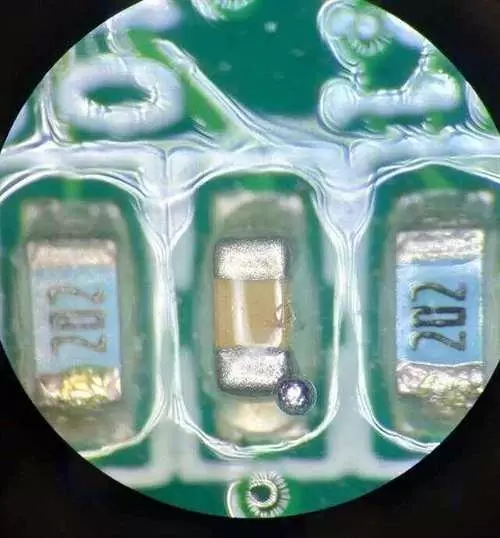

● Embedded Components: Resistors and capacitors are embedded within the FPC, further reducing its size.

Summary:

With it's lightweight, thin, flexible, and highly integrated characteristics, FPC has become a key component for the miniaturization and high performance of modern electronic devices. With the increasing needs of foldable devices, the Internet of Things, and new energy vehicles, FPC technology will continue to evolve towards higher reliability, lower cost, and more complex three-dimensional integration.

Benlida is a professional PCB, PCBA and electronics device manufacturer for 14 years, with advanced equipment and rich experience, committed to providing excellent service to global customers! In addition to it's traditional PCB and PCBA career, it has expanded into FPC production and FPC assembly service. If you need FPC and assembly services, please feel free to contact Benlida!

About the auther:

Sonic Yang

As a major of Electronics and Mechanical Automation, Sonic has been engaged in PCB design, R&D, manufacturing of eletronics for around 22 years, as engineering director and coordinates with supply chain(components&CNC parts), providing professional supports and consults for global customers.

en

en

WhatsApp

WhatsApp