Printed Circuit Board Materials: Properties, Applications, and Selection Criteria

You should pick the best Printed Circuit Board materials for good performance and lasting use. Different materials affect how your board deals with electricity, heat, and pressure. FR4 gives solid conductivity and stays steady. Polyimide is best for high-frequency and hot places. Aluminum boards work well with heat and tough conditions. Benlida gives expert help and advanced making so you can choose materials that fit your project.

Key Takeaways

Pick the right PCB material for your project’s needs. This helps your board work well and last longer.

Learn about how materials handle heat. Choose a material with a glass transition temperature (Tg) that is higher than your board’s temperature.

Think about electrical features like dielectric constant (Dk) and dissipation factor (Df) for fast circuits. Materials with low Df help stop signal loss.

Make sure your PCB follows industry rules and certifications. This keeps your board safe and reliable.

Talk to experts like Benlida when picking materials. Their advice helps you avoid errors and get good results.

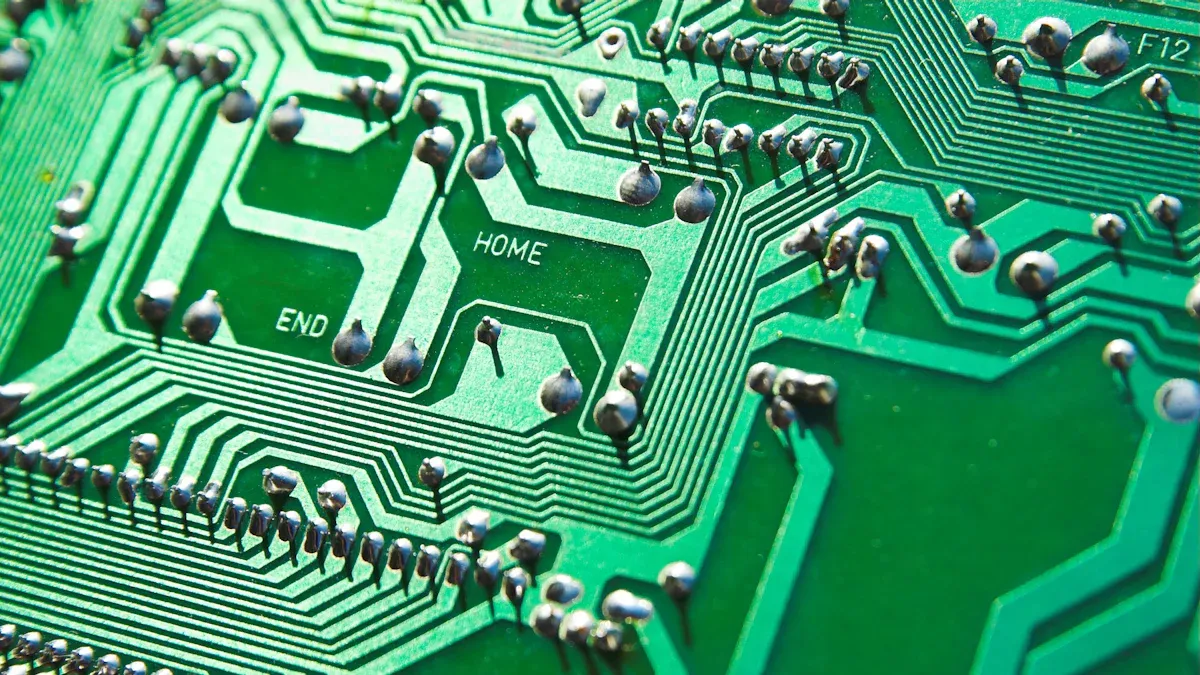

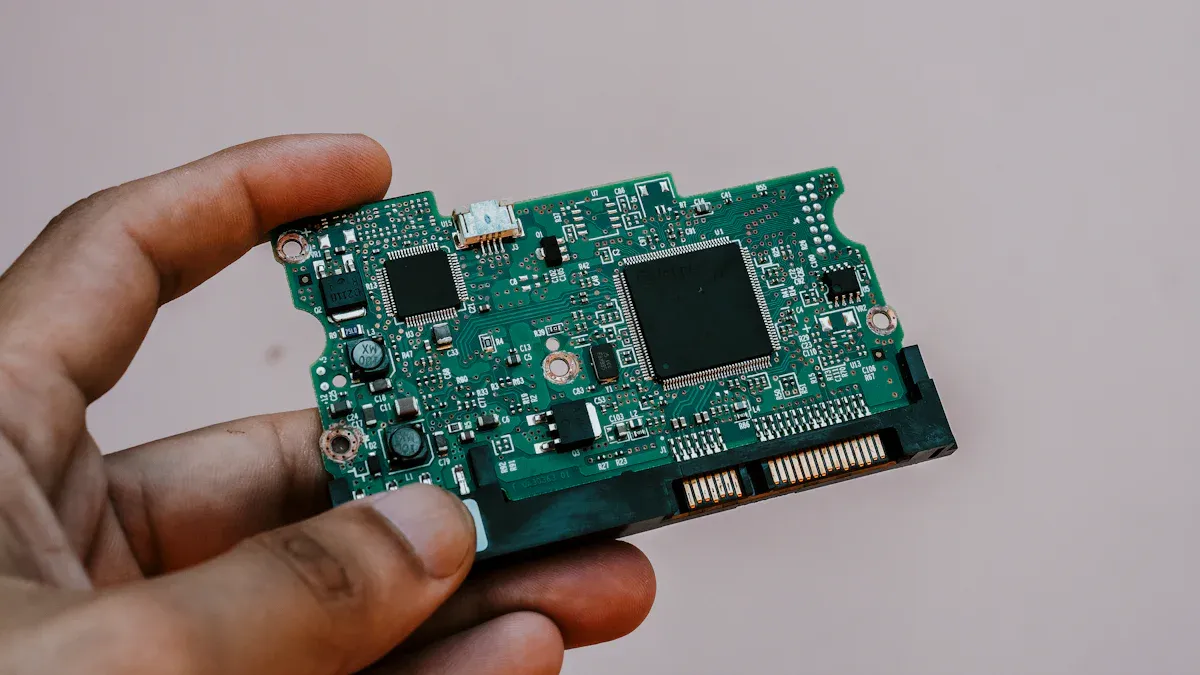

Printed Circuit Board Material Types

When you pick a Printed Circuit Board, you should know the main material types. Each type has its own features. These features help your design work better in different places.

FR-4 Laminates

FR-4 is used the most for making Printed Circuit Boards. You find it in lots of electronics because it costs less and works well. FR-4 can handle heat between 0.1 W/mK and 0.5 W/mK. This means it deals with heat okay for most jobs. Many boards use FR-4, like Isola 370HR and Isola FR408HR. FR-4 is the top choice in the world with about 43.14% of the market.

Polyimide Substrates

Polyimide substrates are good for places with high heat. You use them when heat is a big problem. Polyimide can take up to 300°C. Standard FR-4 only goes up to 110°C. High Tg FR-4 can go above 170°C, but polyimide is still better for very hot spots. Polyimide has about 6.88% of the market. You see polyimide a lot in aerospace and car electronics.

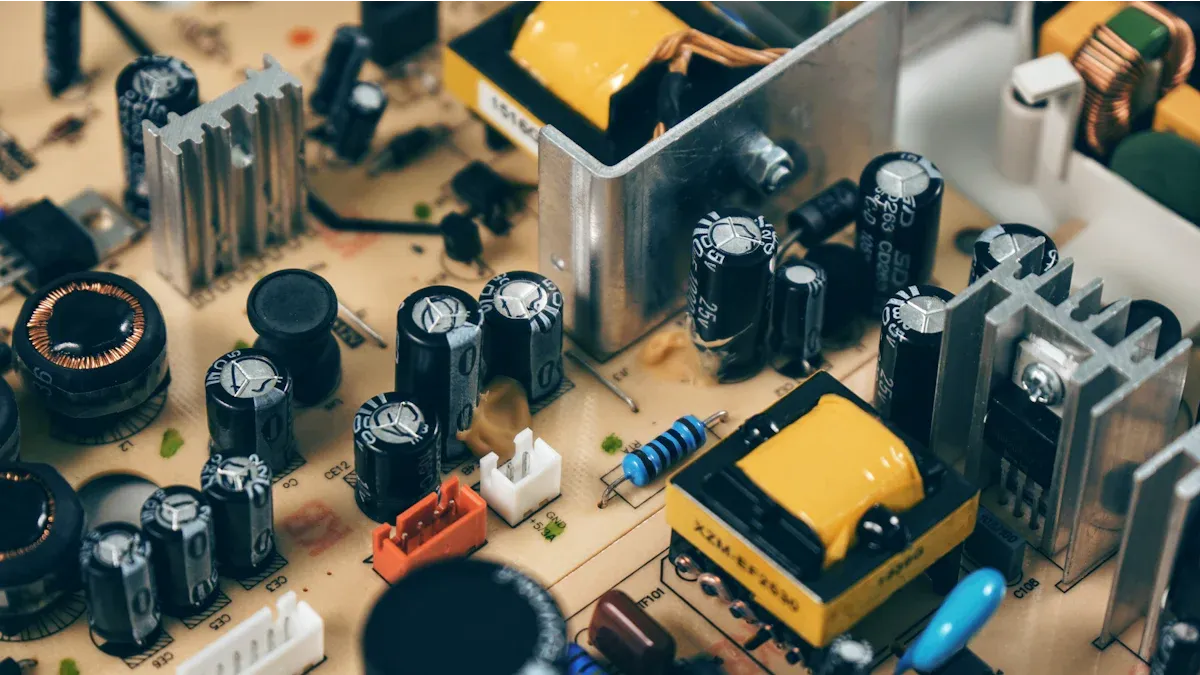

Metal Core Boards

Metal Core boards have a metal base, like aluminum or copper. This helps move heat away from important parts. You should use Metal Core boards for high-power jobs. They stop heat from building up and keep parts safe. Metal Core PCBs work as heat sinks. They are better than FR-4 boards for handling heat.

Metal Core PCBs:

Are great at moving heat

Use aluminum or copper bases

Flexible and Rigid-Flex Materials

Flexible and rigid-flex materials let you bend and shape your Printed Circuit Board. You need to follow some rules to keep the board safe:

Keep plated through holes at least 20 mil from bends

Use smooth bends, not sharp corners

Add tear guards for more strength

Make sure the bend is at least 10 times the layer’s thickness

These materials are good for things that fold or twist, like wearable electronics.

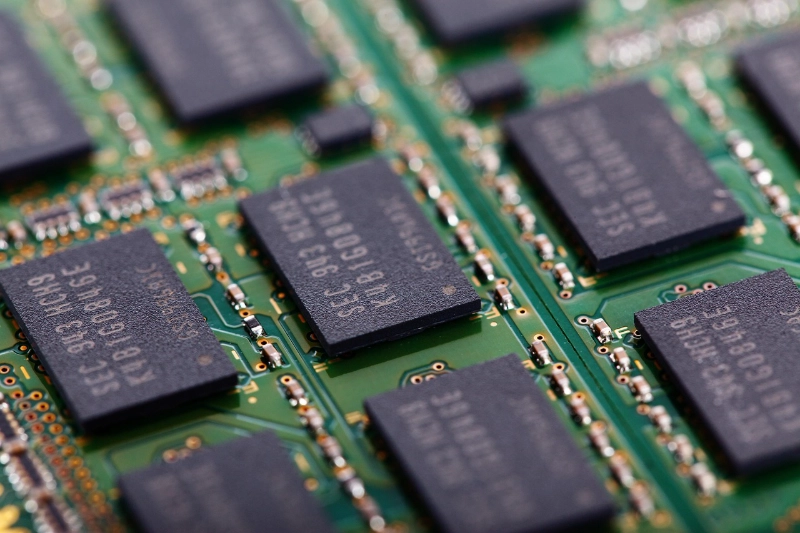

High-Frequency Materials

High-frequency materials, like Panasonic Megtron Series and Isola FR408HR, help with fast signals and advanced systems. You use these when your design needs to handle high-speed digital circuits. They have low dielectric loss and stay steady at high frequencies.

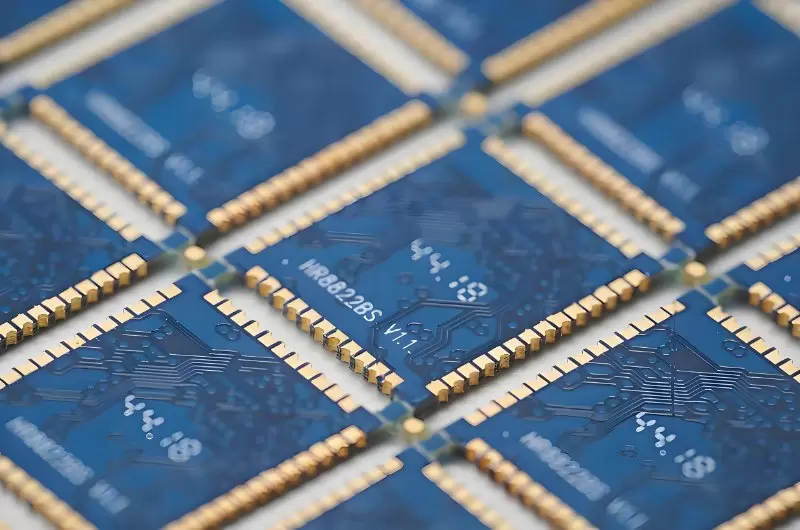

Ceramic PCBs

Ceramic PCBs use materials like Aluminum Nitride, Silicon Carbide, and Beryllium Oxide. These boards move heat very well, from 20 to 230 W/m·K. They also have great breakdown voltage (≥20KV/mm). You should use ceramic PCBs for high-power and high-frequency jobs. They work well in tough places and protect circuits from heat and electrical stress.

Feature | Ceramic Core PCB | Traditional PCB (FR-4) |

|---|---|---|

Thermal Conductivity | High (20-230 W/m·K) | Low (0.3 W/m·K) |

Breakdown Voltage | ≥20KV/mm | Needs extra insulation |

Tip: Pick your material based on what your project needs. This helps your board work better and last longer.

PCB Material Properties

Knowing about Printed Circuit Board materials helps you pick the right one. Each property changes how your board works. Here are the main things you should know.

Thermal Performance

Thermal performance means how well your board deals with heat. If it gets too hot, it might stop working or break. You need to know the glass transition temperature, called Tg. Tg is when the board goes from hard to soft. If your board gets hotter than Tg, it can bend or get weak.

Here is a table with Tg ranges for common PCB materials:

Material Type | Tg Range (°C) |

|---|---|

Standard FR-4 | 130 to 150 |

High Tg FR-4 | Above 180 |

Polyimide | 250 to 350 |

Rogers Laminates | 280 and Above |

Tip: Pick a material with Tg higher than your board’s working temperature. This helps your Printed Circuit Board last longer.

Thermal cycling reliability is important too. When your board heats up and cools down, it expands and shrinks. This can hurt solder joints and make tiny cracks. Boards with good thermal cycling reliability keep working after many temperature changes.

Electrical Characteristics

Electrical properties decide how signals move in your Printed Circuit Board. You should look at dielectric constant (Dk) and dissipation factor (Df). Dk shows how fast signals go. Df tells you how much energy turns into heat.

Here is a table comparing Dk and Df for different materials:

Material | Frequency | Dk | Df |

|---|---|---|---|

FR-4 | 1 GHz | 4.5 | 0.02 |

Rogers RO4350B | 10 GHz | 3.48 | 0.0037 |

Low Df means less signal loss. This is important for fast circuits. If you use quick signals, pick a material with low Df and steady Dk.

Mechanical Strength

Mechanical strength helps your board stay strong and not break. You want your Printed Circuit Board to resist bending and cracking. Flexural strength shows how much force your board can take before it bends or snaps. Makers test this by holding the board at both ends and pressing in the middle.

Young’s modulus, or modulus of elasticity, shows how stiff the board is. A higher modulus means it is harder to bend. IPC-4101 sets the lowest flexural strength for different PCB materials. Strong boards last longer and handle stress better.

Chemical Resistance

Chemical resistance keeps your board safe from water, chemicals, or pollution. If your board faces wet air or spills, you need materials that fight rust. Copper parts can react with water and air, causing rust or other problems. Humidity can also hurt exposed conductors.

Note: Good design, careful storage, and proper handling help stop damage from water and chemicals.

Environmental Reliability

Environmental reliability means your board can survive tough places like heat, cold, and wet air. Temperature changes can cause damage and make solder joints weak. Humidity can cause rust and other problems. These things can make your board fail faster.

Testing for environmental reliability checks how your board works with temperature and humidity changes. Combined temperature-humidity-bias tests help find weak spots. Industry standards, like IPC-6012, set rules for testing and quality.

Here is a table showing some key parts of these standards:

Aspect | Description |

|---|---|

Performance Class Definitions | Goes from general use to high-reliability jobs. |

Testing Methodologies | Tests for electrical, mechanical, and environmental checks. |

Acceptance Criteria | Standards for FR4 PCB and special substrate materials. |

Quality Conformance Requirements | Includes sampling and paperwork for quality checks. |

Mechanical Testing | Checks long-term reliability with heat, shaking, and stress. |

Environmental Testing | Tests PCB performance with different air and chemical conditions. |

Electrical Testing | Checks conductor resistance, insulation resistance, and impedance control. |

Callout: Always make sure your board meets industry standards for reliability. This helps your Printed Circuit Board work well in its environment.

PCB Material Applications

Consumer Electronics

Printed Circuit Board materials are in many things you use. Phones, tablets, and smart gadgets all need strong boards. FR-4 is picked most because it is cheap and can do many jobs. Aluminum helps cool down things like LED lights. PTFE is used for fast signals, like antennas in 5G phones.

Material | Application | Reason for Use |

|---|---|---|

FR-4 | General-purpose devices | Affordable and versatile |

Aluminum | Heat-intensive designs | Excellent thermal management |

PTFE | High-frequency circuits | Superior performance for fast signals |

Benlida makes boards for these needs, like multi-layer and LED PCBs.

Automotive Systems

Cars need boards that can take heat and shaking. High-Tg FR-4 and polyimide stay strong in hot places. Ceramic PCBs are good for high-power and hot jobs. These materials also keep electricity safe, which is important in cars.

Material Type | Property | Importance for Automotive PCBs |

|---|---|---|

High-Tg FR-4 | Thermal Stability | Handles heat and vibration |

Polyimide | Thermal Stability | Works in tough environments |

Ceramic | Thermal Conductivity | Great for high-power and heat |

Vibration Resistance | Protects electronics in cars | |

Electrical Insulation | Keeps systems safe |

Benlida makes rigid-flex and ceramic boards for cars.

Aerospace and Defense

Aerospace and defense need boards that never fail. Materials must have high Tg, be strong, and handle big temperature changes. Polyimide and PTFE laminates are top picks. High-temperature laminates like FR408 and Pyralux AP also work well.

High glass transition temperature (Tg)

Strong and tough

Handles big temperature changes

Benlida makes advanced boards for these hard jobs.

Industrial and Power

Industrial and power systems need boards for big currents and heat. Thick copper foil lets the board carry more current. FR-4 is cheap, but polyimide and metal bases help with heat. Dielectric materials must be strong and steady.

Material Type | Key Properties | Application Use Case |

|---|---|---|

Copper Foil | Thick for high current | Power PCBs |

FR-4 | Economical | Medium/low power systems |

Polyimide | Heat resistance | High-temperature jobs |

Metal Substrates | Heat dissipation | LED power systems |

Benlida makes LED and power boards for these uses.

High-Frequency Circuits

High-frequency circuits need special materials. PTFE and advanced laminates keep signals fast and clear. These materials lose less signal and stay steady. Benlida’s boards help with telecom and radar systems.

High-Temperature Uses

Boards for hot jobs need Tg above 170°C. FR-4 TG170, ISOLA IS410, and ARLON 85N are good picks. These materials work in factories, cars, and LED systems. Benlida’s high-Tg and ceramic boards work well in hot places.

Tip: Pick the right PCB material for your job. This helps your board last longer and work better.

Printed Circuit Board Material Selection

Choosing the right material for your Printed Circuit Board helps you get the best results for your project. You need to look at several factors before you decide. Each factor affects how your board works, how much it costs, and how long it lasts.

Performance Requirements

You should start by thinking about what your board needs to do. If you work with high-speed signals or radio frequencies, you must check the dielectric constant (Dk) and dissipation factor (Df). These numbers show how well your board moves signals and how much energy it loses as heat. For boards that get hot, thermal conductivity (TC) matters. TC tells you how fast heat moves away from parts. If your board is large or faces temperature changes, you need to look at the coefficient of thermal expansion (CTE). CTE shows how much the material grows or shrinks when it gets hot or cold.

Dielectric Constant (Dk): Affects signal speed and trace thickness.

Dissipation Factor (Df): Shows energy loss, important for fast and RF circuits.

Thermal Conductivity (TC): Helps with cooling in high-power jobs.

Coefficient of Thermal Expansion (CTE): Keeps large boards safe from cracks.

Tip: Always match the material’s properties to your project’s needs. This helps your board work better and last longer.

Cost and Availability

You need to think about your budget and how easy it is to get the materials. The price changes based on board size, number of layers, and the type of material you pick. If you choose special finishes or thicker copper, the cost goes up. The way the board is made also matters. For example, die punching usually costs less than routing. Labor costs in different regions can change the final price.

Enter your board’s size and layers to see the base price.

Pick your material and finish. These choices change the cost.

Change the order amount. Bigger orders often cost less per board.

Select your lead time. If you can wait longer, you may pay less.

Material cost depends on design, copper thickness, and finish.

Manufacturing process affects price.

Labor costs vary by region.

Note: You can save money by planning your order size and delivery time.

Standards and Certifications

You must make sure your board meets safety and quality rules. If you build boards for medical devices, you need to follow strict standards. These standards protect users and make sure the board works safely.

Standard/Certification | Key Requirements |

|---|---|

Dielectric strength, creepage and clearance, EMI control | |

FDA Regulations | Design controls, material safety, labeling and traceability |

UL Certification | Flammability, thermal management, aligns with IEC 60601 for medical PCBs |

Callout: Always check the standards for your industry. This keeps your boards safe and ready for use.

Manufacturability

You should pick materials that work well with your manufacturer’s process. Some materials need special tools or steps. If you choose a rare material, your manufacturer may not have it in stock. This can slow down your project. You need to talk with your manufacturer to make sure your material fits their process.

Check if the material is easy to cut, drill, and plate.

Make sure the material is available and matches your design.

Ask your manufacturer about their experience with your chosen material.

Tip: Working with an experienced manufacturer like Benlida helps you avoid problems and get high-quality boards.

Environmental Compliance

You need to think about the environment when you pick your material. Some rules require you to use safe materials and avoid harmful chemicals. You should check if your material meets RoHS and REACH standards. These rules protect people and the planet.

RoHS: Limits hazardous substances.

REACH: Controls chemicals in products.

IPC standards: Set rules for quality and safety.

Alert: Always choose materials that meet environmental rules. This helps you build safe and responsible products.

Selection Process

You can follow a simple process to pick the best material for your board. This helps you make smart choices and avoid mistakes.

Look at the material’s thermal and mechanical properties. These matter most for boards that need to last a long time.

Check how the material handles heat and stress. This is important for boards in planes or cars.

Pick the right plating for your board. For RF boards, use low-loss plating like OSP or immersion silver.

Work with your manufacturer. Make sure they have your material and can build your board the right way.

Tip: You can talk to Benlida’s experts for help with material selection. They offer advice and quality checks to make sure your board meets your needs.

By following these steps, you can choose the best material for your Printed Circuit Board. This helps you get reliable, safe, and cost-effective boards for any project.

Picking the right PCB material helps your electronics work well and last long. You need to make sure the material fits what your project needs. It is also important to follow the rules for your industry. If you want help, Benlida can give you advice and make quality boards.

Think about what your project needs.

Look at different materials.

Ask experts if you need help.

Tip: Benlida’s team can help you choose the best PCB material for your project.

FAQ

What is the most common PCB material?

You usually see FR-4 as the main PCB material. It gives good electrical insulation and works well for many electronics. You can use it for phones, computers, and home devices.

How do you choose the right PCB material?

You should check your project’s needs. Look at heat, signal speed, and strength. You can ask experts at Benlida for advice. They help you match materials to your design.

Can you use flexible PCBs in wearable devices?

Yes, you can use flexible PCBs for wearables. These boards bend and twist without breaking. You get better comfort and durability in smart watches and fitness bands.

What standards should your PCB meet?

You should make sure your PCB meets IPC, RoHS, and UL standards. These rules help you keep your boards safe and reliable. You can ask your manufacturer for certifications.

en

en

WhatsApp

WhatsApp