How to Select the Right HDI PCB Manufacturer

Selecting the right HDI PCB manufacturer is crucial for advanced electronics. When you select the right HDI PCB manufacturer, you ensure technical expertise, reliability, and top-quality HDI PCB fabrication. Effective processes from the right HDI PCB manufacturer help prevent issues in electronic products. A transparent, step-by-step HDI PCB fabrication process from your chosen manufacturer provides greater control and confidence. If you select the right HDI PCB manufacturer who understands failure mechanisms, your PCB will meet stringent standards. Superior design from the right HDI PCB manufacturer results in fewer issues and safer, more reliable electronics.

Key Takeaways

Pick a manufacturer who knows a lot about HDI PCBs. This helps make sure you get good quality.

Look for certifications like ISO 9001 and IPC. These show the manufacturer follows quality rules.

Ask for samples to check how good their work is. You can also see what technology they use.

Make sure the manufacturer can make enough PCBs for your project. They should be able to grow with your needs.

Good customer support and clear communication are important. This makes your project go smoothly.

Think about all the costs, not just the first price. This helps you avoid extra costs later.

Ask if the manufacturer delivers on time. This shows if you can trust them.

Use a checklist to compare different suppliers. This helps you pick the best one for your project.

Key Factors to Select the Right HDI PCB Manufacturer

Picking the right hdi pcb manufacturer is important for your project. You need to think about a few key things. The best partner gives you accurate and reliable hdi pcb solutions. They also have strong manufacturing skills. Here is what you should check.

Technical Expertise in HDI

Advanced Capabilities

You should look at the manufacturer’s technical skills. Top manufacturers have features for tough jobs. These are some important technical abilities to look for:

Higher line density means more circuits fit in less space.

Smaller size helps you make tiny devices like wearables.

Better signal integrity makes your pcb work well at fast speeds.

More design flexibility lets you add cool and complex features.

Good thermal management helps your device stay cool and last longer.

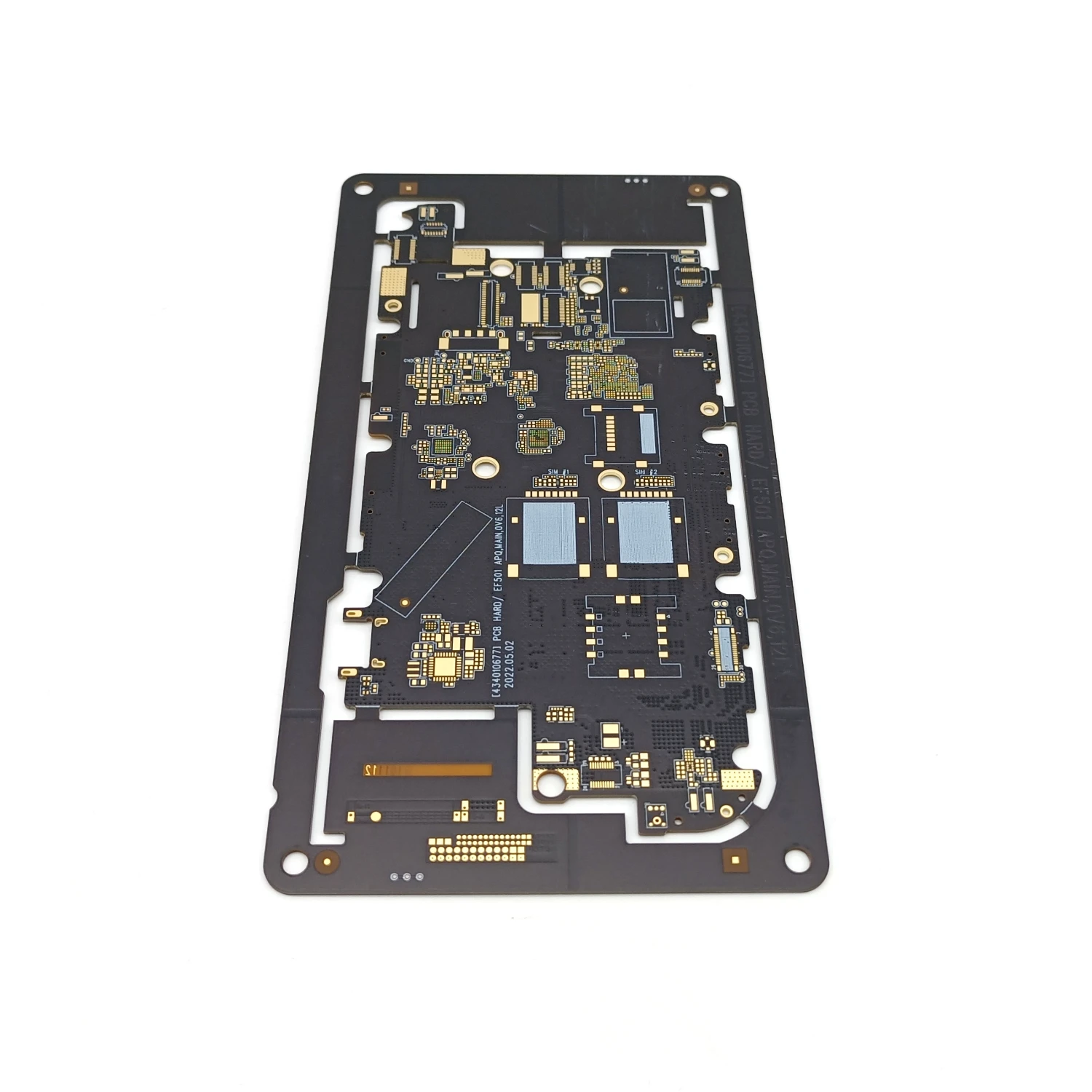

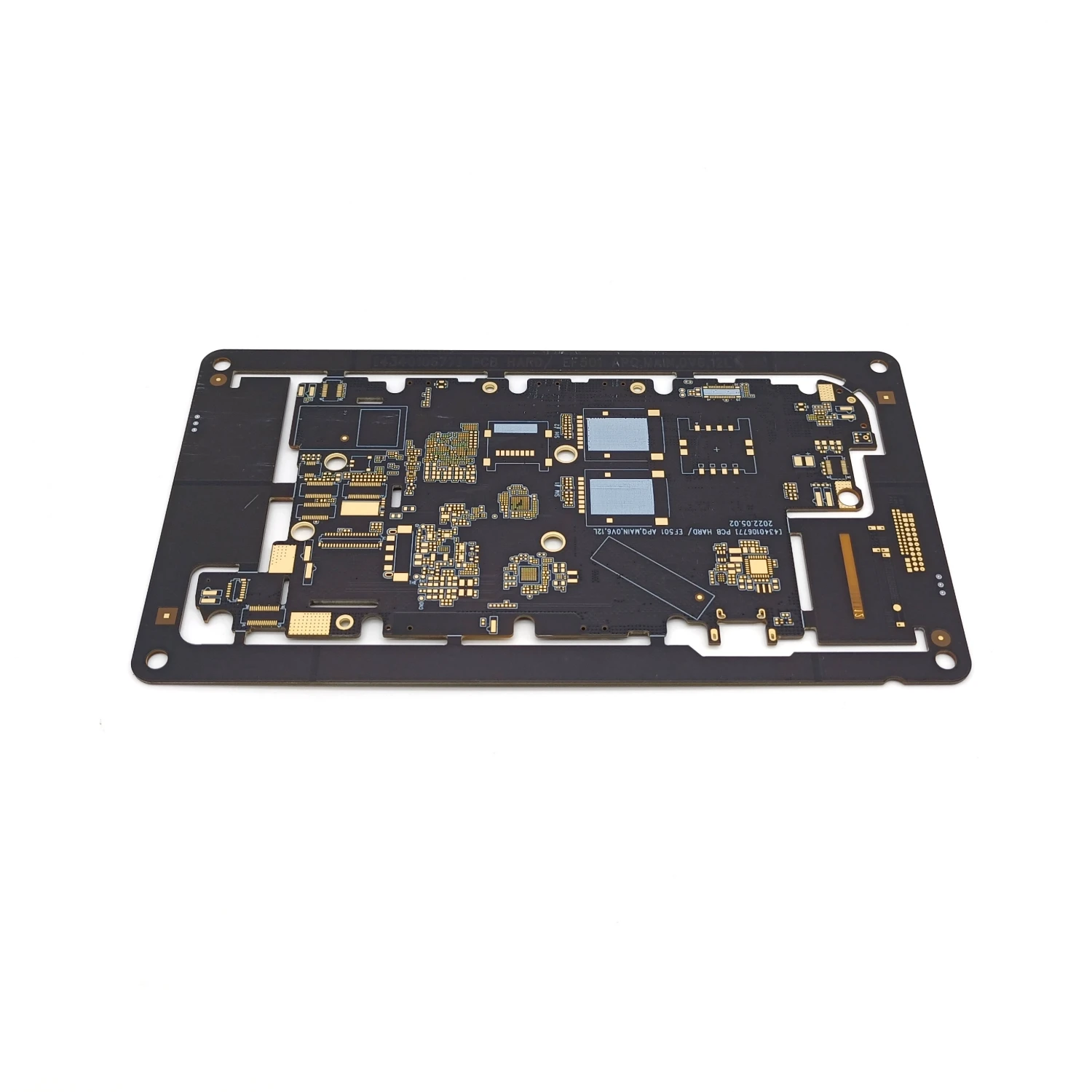

Benlida Circuit uses special hdi pcb fabrication steps. This helps them make boards with tiny traces and lots of parts. Their boards work well for new electronics.

Microvia and Fine Line Technology

Microvias and fine lines are very important for hdi technology. You should ask if your manufacturer knows how to use these. The best manufacturers use laser drilling and other smart methods. They also test every pcb to make sure it is good.

Manufacturers use sequential lamination to make strong vias.

They use different copper processes to build solid connections.

Via-in-pad puts vias under pads to save space.

Stacked and staggered microvias link many layers for hard designs.

Microvias can be as small as 0.004 inches and match pads as small as 0.008 inches.

Advanced hdi pcbs have many layers of copper-filled stacked microvias for better routing and signals.

Benlida Circuit’s hdi pcb process uses these smart steps. This makes their products work well and last longer.

Quality Standards and Certifications

IPC and ISO Compliance

Always check if your hdi pcb manufacturer follows world quality rules. Certifications show they care about doing things right. They use good steps in every hdi pcb process.

Certification | Description |

|---|---|

ISO 9001 | Makes sure the company has good processes and happy customers. |

ISO 13485 | For medical devices, checks if products are safe for people. |

IPC Class 3 | Needed for very reliable products, has strict quality rules. |

ITAR | Needed for defense or space projects, follows US export laws. |

UL Compliance | Checks if products are safe from fire and electricity. |

IPC standards help you get strong and good pcbs. They make sure every product is made the right way. If a manufacturer uses both IPC and ISO, you get even better quality. This helps you trust them and sell your products worldwide.

ISO 9001 checks quality for design, making, and putting together pcbs. ISO 13485 is for medical devices and checks safety and tracking.

Reliability Testing

A good hdi pcb manufacturer tests every pcb before sending it out. They check if the pcb works well and lasts long. Tests include heating and cooling, checking impedance, and making sure microvias are strong. These tests help your hdi pcb work well in real life.

Experience and Track Record

Industry Applications

Experience is important when picking a manufacturer. The best hdi pcb makers have about 20 years of work. This means they know how to fix problems and do hard jobs.

HDI technology is used in many fields. Here are some examples:

Industry | Applications |

|---|---|

Telecommunications | Fast memory, cool processors, and strong signals |

Medical Devices | Small designs for implants and tests, safe for life-support |

Automotive | Small pcbs for smart car electronics |

Industrial Control Systems | Machines, sensors, power systems, and tough environments |

AI and IoT | Smart designs for data and AI |

You can find hdi pcbs in phones, wearables, medical tools, cars, and planes. Benlida Circuit’s boards are used in smartwatches and AI machines.

Customer References

Always ask for customer feedback. A good manufacturer will show you happy clients. This helps you see how they work and solve problems. Look for reviews about quality, fast delivery, and help during the hdi pcb process.

Tip: Ask for sample boards or stories about past jobs. This helps you see if the manufacturer makes good and strong products.

If you focus on these things, you can pick an hdi pcb manufacturer who gives you quality, reliability, and smart technology.

Evaluating HDI PCB Manufacturer Reliability

When you pick an hdi pcb manufacturer, you should check if they are reliable. Reliability means you get your high-density interconnect pcb when you need it. It also means the quality is good and there are no big problems. You want a manufacturer who can handle your needs, even if your project gets bigger or changes.

Production Capacity

Scalability

You should see if the manufacturer can make more boards when needed. Some projects start small but can get bigger fast. A good hdi pcb manufacturer can make a few boards for testing. Later, they can make thousands for full production. This flexibility helps you avoid waiting too long.

Here is a table that shows important things to check for production capacity:

Metric | Description |

|---|---|

Technology & Innovation | Uses smart tools like laser-drilled microvias and AI inspection for accuracy. |

Production Capacity | Can make small or large amounts, with big factories and machines. |

Quality & Certifications | Follows strict rules like ISO 9001 and IPC-A-600 Class 3. |

Customer Service & Support | Gives good help, including DFM advice and quick answers. |

Cost & Value | Has clear prices, discounts for big orders, and no hidden fees. |

Equipment and Facilities

You want a manufacturer with new machines. Look for laser drills, automatic inspection, and clean rooms. These tools help the hdi pcb fabrication process stay correct and quick. Good equipment means fewer mistakes and better checks.

Supply Chain Stability

Material Sourcing

The materials in your pcb matter for how well it works. Good copper, low dielectric constant, and high thermal conductivity help your hdi pcb work better. Here is how different material properties affect your pcb:

Material Property | Impact on HDI PCB Quality |

|---|---|

High-quality copper | Fewer problems, better electrical work. |

Low dielectric constant | Less signal change, faster signals. |

Low dissipation factor | Less energy lost, keeps signals strong. |

Higher thermal conductivity | Stops hot spots, keeps signals steady. |

Risk Management

A strong hdi pcb manufacturer uses smart ways to keep the supply chain safe. Here are some things they do:

Work with many suppliers to avoid running out.

Keep extra parts for emergencies.

Design boards that can use different parts.

Use software to guess what is needed and manage stock.

Talk often with suppliers for help during shortages.

Balance fast delivery with keeping extra stock.

Watch world news to change buying plans.

Use technology to track orders and stock right away.

These steps help your high-density interconnect pcb project stay on track, even if things change.

Delivery Performance

Lead Times

You need to know how fast the manufacturer can send your pcb. Lead times depend on how hard your hdi design is. Quick turn services can send test boards in 72-120 hours. For big orders, you usually wait 5-7 days. Standard hdi pcb manufacturers may take 2-4 weeks for test boards and 4-8 weeks for big orders.

Manufacturer Type | Prototype Lead Time | Production Lead Time | Rush Service Availability |

|---|---|---|---|

Standard HDI PCB | 2-4 weeks | 4-8 weeks | Yes |

Quick Turn HDI PCB | 72-120 hours | 5-7 days | Yes |

On-Time History

Getting your boards on time is very important. The best manufacturers deliver on time more than 99% of the time. This means you get your boards when you need them. It helps you finish your project on schedule.

Tip: Always ask your hdi pcb manufacturer about how often they deliver on time and how they did in the past.

If you check these things, your hdi pcb fabrication process will go well. You get good quality, fast delivery, and strong help for your high-density interconnect projects.

Customer Support and Communication in HDI PCB Manufacturing

Picking an hdi pcb manufacturer with good customer support helps you avoid trouble. Good communication makes your project go smoother and faster. You need a manufacturer who listens and answers quickly.

Responsiveness

A manufacturer should answer your questions fast. Quick replies show they care about your project. You want updates about your pcb and clear answers to your questions.

Support Channels

You can contact your hdi pcb manufacturer in different ways. Some use email, phone, or online chat. Others have a customer portal for tracking orders and asking questions. Many ways to reach them make it easier for you to get help.

Availability

You need help at every step of your project. The best manufacturers give support during design, fabrication, and delivery. Their teams are ready to answer questions, even after normal hours.

Here is a table that shows what to look for in support:

Aspect of Support | Description |

|---|---|

Responsiveness to technical questions | Quick replies to questions about technical problems. |

Project updates | Regular news about how your project is going. |

Engineering support for DFM reviews | Help with Design for Manufacturability (DFM) checks. |

Material selection | Advice on picking the right materials for your project. |

Design feedback | Ideas to make your design better. |

Smooth communication | Clear talk to fix problems quickly. |

Engineering and DFM Support

You need engineering help for your hdi pcb project. Design for Manufacturability (DFM) helps you avoid mistakes and save money. The right manufacturer gives advice and checks your design before making your pcb.

Design Assistance

DFM support guides your pcb from idea to finished product. Early checks help you find problems before making your pcb. You get feedback on fine traces, microvias, and material choices. This makes your high-density interconnect pcb stronger and more reliable.

Here is a table that explains how engineering support helps:

Aspect | Description |

|---|---|

Fine Traces | HDI PCBs have fine traces that need careful making to avoid problems. |

Microvias | Using microvias means you must follow DFM rules to stop mistakes. |

Design Checks | DFM checks make sure designs fit the rules, so you have fewer errors. |

DFM is a process that helps products from start to finish.

Early checks of pcb designs lower risks and cut down on fixing mistakes.

Working together helps get faster approvals and better results.

Problem Resolution

If you have a problem, you want quick help. The best hdi pcb manufacturer works with you to fix issues. They give advice and change your design or process if needed. This keeps your project moving and protects quality.

After-Sales Service

After your pcb arrives, you still need help. Good service means you get help with any problems after delivery. The right manufacturer stands by their product and helps you solve issues.

Warranty

A strong warranty means the manufacturer trusts their process. You get protection if your pcb has problems or does not meet standards. This gives you peace of mind and helps you avoid extra costs.

Ongoing Support

Ongoing help matters for long-term success. You get help with future orders, design changes, and technical questions. The manufacturer gives full reports and batch tracking. You can see how your pcb was made and tested.

Here is a table that shows valued after-sales services:

After-Sales Service | Description |

|---|---|

Engineering Support | Dedicated engineer helps you, quick answers for design or process problems |

Traceability | Full reports and tracking with details about making and testing your pcb |

When you pick an hdi pcb manufacturer with strong support, you get better quality, faster delivery, and fewer problems. Good communication and service help you do well in every part of your hdi project.

Pricing and Value from Your HDI PCB Manufacturer

When you pick an hdi pcb manufacturer, you want prices that are easy to understand. You should know what you are paying for and how it helps your project. Good prices help you plan your money and stop surprises.

Transparent Cost Structure

Quotation Details

A trustworthy manufacturer gives you a clear quote. You can see the cost for materials, making the pcb, and testing. This lets you know where your money goes. You can look at quotes from different hdi pcb manufacturers and pick the one that works best for you.

Avoiding Hidden Fees

You should always ask about extra costs. Some companies charge more for fast shipping or special help. A good hdi pcb manufacturer tells you all the costs before you order. This helps you avoid surprises and keeps your project moving.

Tip: Always check the quote and ask if you do not understand something. Clear prices help you trust your manufacturer.

Price vs. Quality

Total Cost of Ownership

You might think the cheapest price is best, but quality is more important over time. Cheap pcbs can break and slow down your project. You may spend more fixing problems than you saved at first. Think about the total cost, like repairs, late deliveries, and lost time.

Long-Term Value

Good hdi pcb fabrication uses better materials and smart steps. For example, using microvias and via-in-pad technology costs more, but your pcb will be stronger and last longer. The right material, like high-frequency laminates, helps your signals and stops problems.

Here is a table that shows how price and quality change with different choices:

Factor | Description |

|---|---|

Material Selection | Better materials, like high-frequency laminates, cost more but improve quality and reliability. |

Fabrication Complexity | Advanced steps, such as microvias, increase cost but boost product quality. |

Cost Estimation Tools | Online tools help you see how design choices affect both cost and quality. |

You get more value when you pick a manufacturer who cares about quality. Your pcb will last longer and work better in hard places.

Payment Flexibility

Terms and Schedules

A good hdi pcb manufacturer lets you pay in different ways. You can pay some money before they start and the rest after you get your pcb. Some manufacturers let you choose a payment plan that fits your project. This helps you manage your money and feel less worried.

Note: Flexible payment plans show your manufacturer wants to help your business for a long time.

When you focus on clear prices, strong quality, and easy payments, you get the best value from your hdi pcb manufacturer. You build a team that helps your project from start to finish.

Turnaround Time and Flexibility in HDI PCB Production

When you pick an HDI PCB manufacturer, think about how fast they can send your boards. Also, check if they can handle changes to your order. Fast delivery and being flexible help you finish your project on time. They also help you keep your costs low.

Standard Lead Times

Prototyping vs. Mass Production

Lead times are different for each order. Making a prototype is faster than making many boards. You can get a prototype in just a few days. This lets you test your design quickly. Mass production takes more time because there are more steps. There are also more checks. Ask your manufacturer how long each type of order takes. This helps you plan and avoid waiting too long.

Prototyping: You get your board fast, in 3-7 days.

Mass Production: It takes longer, about 2-4 weeks.

Tip: Always ask about lead time before you start making your HDI PCB. This helps you know what to expect.

Expedited Services

Rush Orders

Sometimes you need your HDI PCB even faster. Many manufacturers have special rush services for urgent jobs. Rush orders can get your board in as little as 48 hours. These services cost more, but they help you meet tight deadlines. They also help you fix problems quickly.

Here is a table that shows how rush services change your project timeline:

Aspect | Impact on Project Timeline |

|---|---|

Rapid Prototyping | Lets you change your design faster and make quick fixes. |

Expedited Production | Gets your boards made in as little as 48 hours. |

Integrated Services | Makes talking to the team easier and stops delays. |

Agile Design Iterations | Helps you test ideas fast and move your project forward. |

High-Volume Delivery | Lets you get lots of boards quickly when you need them. |

Using rush services helps you go from design to finished board faster. This speed can help you beat your competition.

Adaptability

Handling Design Changes

Projects can change after you start. You might need to update your design. A flexible manufacturer can handle changes without big delays or extra cost. They use special steps to manage updates and keep your project moving.

Manufacturers use different ways to handle design changes:

Process Description | Details |

|---|---|

Feedback Loops | Learning from old projects helps make new ones better. |

Post-Production Reviews | Teams talk about what worked and what did not. This helps next time. |

Kickoff Meetings | Early meetings help find problems before making the board. |

Workarounds | Quick fixes, like laminate changes, can help but may not last long. |

Note: Talking often with your manufacturer makes it easier to handle changes and keep costs down.

If your manufacturer is flexible, your HDI PCB process goes smoother. You can try new ideas, fix problems fast, and finish your project on time.

Best Practices of Selecting the Right HDI PCB Supplier

Requesting and Reviewing Samples

When you want to find the best HDI PCB supplier, always ask for samples first. Samples show you the real quality of the boards. You can compare different suppliers by looking at their sample boards side by side. This step helps you see who uses the best technology and who pays attention to details.

Evaluating Sample Quality

You should use clear criteria to check each sample. Here are some important things to look for:

Check the technology and innovation. Look for features like laser-drilled microvias and fine lines.

Make sure the supplier can handle your order size. They should have enough machines and workers.

Ask about quality certifications. Look for ISO 9001 and IPC compliance.

You can also use this table to help you judge the samples:

Criteria | Description |

|---|---|

Decomposition Temperature (Td) | Should be much higher than the temperature your pcb will face. |

Coefficient of Thermal Expansion (CTE) | Should match other parts to stop cracks when the board heats up. Ideal CTE along the z-axis is 70 ppm or less. |

Thermal Conductivity (k) | High thermal conductivity helps the board stay cool. |

RoHS Compliance | Shows the board is safe for people and the environment. |

Benlida Circuit provides HDI PCB samples that meet strict standards. Their boards use advanced materials and pass tough tests.

Site Visits and Virtual Tours

You can learn a lot by visiting the supplier’s factory or taking a virtual tour. This step lets you see how they make the boards and what machines they use.

What to Observe

During your visit or tour, pay attention to these things:

Look at the equipment. Modern machines like laser drills show the supplier uses new technology.

Watch the workflow. See if the workers follow clear steps and keep the place clean.

Ask about quality checks. Good suppliers have many checks during and after making each pcb.

You can also ask for a 360-degree video tour. This gives you a close look at the process, even if you cannot visit in person.

Checking References and Reviews

Before you choose a supplier, check what other customers say. Good reviews and strong references show the supplier is trustworthy.

Reliable Feedback Sources

You can find reviews on the supplier’s website or on industry forums. Look for comments about quality, delivery, and support. Some companies, like Benlida Circuit, share stories from happy customers. These stories help you see how the supplier solves problems and supports clients.

Tip: Always ask for at least two customer references before making your final choice.

By following these best practices of selecting the right hdi pcb supplier, you make a smart choice for your project. You get better boards, fewer problems, and a smoother process.

Using Evaluation Checklists

Essential Criteria

If you want to compare HDI PCB suppliers, use a checklist. A checklist helps you stay organized and focused. You can look at each supplier the same way. This makes it easier to see who fits your needs. It also helps you make a better decision.

Here are the main things to put on your checklist:

Check how the supplier makes PCBs. Visit their factory or ask for a video tour. Make sure they can build your design and handle your order.

Watch how they check for mistakes. See what tests and tools they use. Ask about their steps to find defects.

Meet the team in person. Talking face-to-face helps you trust them. You can ask questions and get clear answers.

Look at their history and past clients. A good supplier has lots of experience. Make sure they have worked in your field before.

Know what your project needs. Write down your needs before meeting suppliers. This helps you ask better questions.

Get ready to ask technical questions. Ask about microvias, fine lines, and materials. See if they can make hard designs.

Check for important certificates. Look for ISO 9001, IPC, and other rules. These show the supplier follows strict standards.

Tip: Bring your checklist to every meeting. Mark off each item as you talk. This helps you stay on track and compare suppliers later.

You can also use a table to score each supplier:

Criteria | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

Manufacturing Capabilities | ✔️ | ✔️ | ❌ |

Quality Control | ✔️ | ❌ | ✔️ |

Certifications | ✔️ | ✔️ | ✔️ |

Industry Reputation | ✔️ | ❌ | ✔️ |

Technical Support | ✔️ | ✔️ | ❌ |

A checklist helps you see what each supplier does well. You can pick the best one for your PCB project. Using a checklist lowers your risk and helps you get better results.

Making the Final Choice: Select the Right HDI PCB Manufacturer

Weighing Pros and Cons

When you get to the last step, you need to look at the good and bad points before you pick the right hdi pcb manufacturer. You want to make sure your choice is right for your project and your business. Here are some things to think about:

Space efficiency means you can put more parts in a small space. This helps you make lighter and smaller things.

Better signal integrity means your board works well at fast speeds. Shorter paths lower noise and help the board work better, especially for signals over 1 GHz.

Flexibility in design gives you more choices. HDI technology lets you try new layouts and ideas.

Higher cost is something to think about. Special materials and careful work make HDI PCBs cost more than regular boards.

Design complexity can be hard. HDI layouts need special skills for stackup, via placement, and keeping things cool.

Manufacturing limits are important. Not every company can make good HDI boards. You need a partner with the right tools and know-how.

Prioritizing Needs

You should write down what your project needs before you pick the right hdi pcb manufacturer. Decide what is most important. Do you need the smallest board? Is fast signal speed the main thing? Are you trying to save money? Write your must-haves and nice-to-haves. This helps you compare companies and pick the one that fits your goals.

Tip: Make a simple table to rank your needs. Give each need a score from 1 to 5. This helps you see which things matter most.

Need | Importance (1-5) |

|---|---|

Space Efficiency | 5 |

Signal Integrity | 4 |

Cost | 3 |

Design Flexibility | 4 |

Reliability | 5 |

Negotiating Terms

After you pick the right hdi pcb manufacturer, you need to talk about the contract. Good talks help you avoid problems later. You want clear rules that keep your project safe.

Key Contract Points

Check these important things in your contract:

Delivery schedule: Make sure the timing works for you.

Quality standards: List the needed certificates and tests.

Payment terms: Decide when and how you will pay.

Warranty: Ask for help if the board has problems.

Support: Include help for design changes or questions.

Note: Always read the contract carefully. Ask questions if you do not understand something.

Trial Orders

You can start with a small order before you buy a lot. This lets you test how the manufacturer works and how good the boards are.

Monitoring Initial Results

Watch the first batch closely. Check if the boards are good enough. Look for problems with delivery, talking to the company, or quality. Write down what goes well and what needs to get better. If you are happy with the results, you can keep working with them.

Tip: Use a checklist to review the trial order. This helps you make a smart choice when you pick the right hdi pcb manufacturer.

You have learned how to pick the right HDI PCB manufacturer for your project. Look for good technical skills, strong reliability, and clear value. Follow these steps:

Make sure they have technical expertise and the right certifications.

Look at sample quality and read what customers say.

Compare prices and see what support they offer.

Want to get started? Contact Benlida Circuit for expert help or ask for a sample. You can start choosing with confidence.

FAQ

What is an HDI PCB?

HDI PCB means High-Density Interconnect Printed Circuit Board. It is used in electronics with lots of parts packed close together. This helps devices run faster and stay strong.

Why should you choose an HDI PCB for your project?

You can fit more parts in a small space. Your device gets smaller and lighter. HDI PCBs also make signals move faster and use less power.

How do you know if a manufacturer is qualified for HDI PCBs?

Look for ISO 9001 and IPC certificates. Ask to see sample boards. Read what customers say about them. Good manufacturers have strong skills and give reliable results.

What industries use HDI PCBs?

HDI PCBs are found in smartphones, wearables, medical tools, car electronics, and AI hardware. These boards help products stay small and work well.

How do you request a sample from Benlida Circuit?

Go to Benlida Circuit’s website or send an email. Ask for an HDI PCB sample. Their team will help you with each step.

What materials do HDI PCBs use?

HDI PCBs use special materials like Rogers 4003C and Megtron 7. These help the board work at high speeds and keep signals clear.

How fast can you get HDI PCBs delivered?

You can get test boards in 3-7 days. Making lots of boards takes 2-4 weeks. Rush orders are possible if you need them quickly.

What support does Benlida Circuit offer after you buy HDI PCBs?

Benlida Circuit gives you engineering help, warranty, and ongoing support. You get answers to questions and help with new orders.

en

en

.webp)

WhatsApp

WhatsApp