PCB Flying Probe Testing vs. PCBA Flying Probe Testing

The core difference between PCB flying probe testing and PCBA flying probe testing lies in the test object and test purpose, but they share similar testing principles and technical foundations. The following is a detailed comparative analysis:

I. Similarities

1. Same Testing Principle

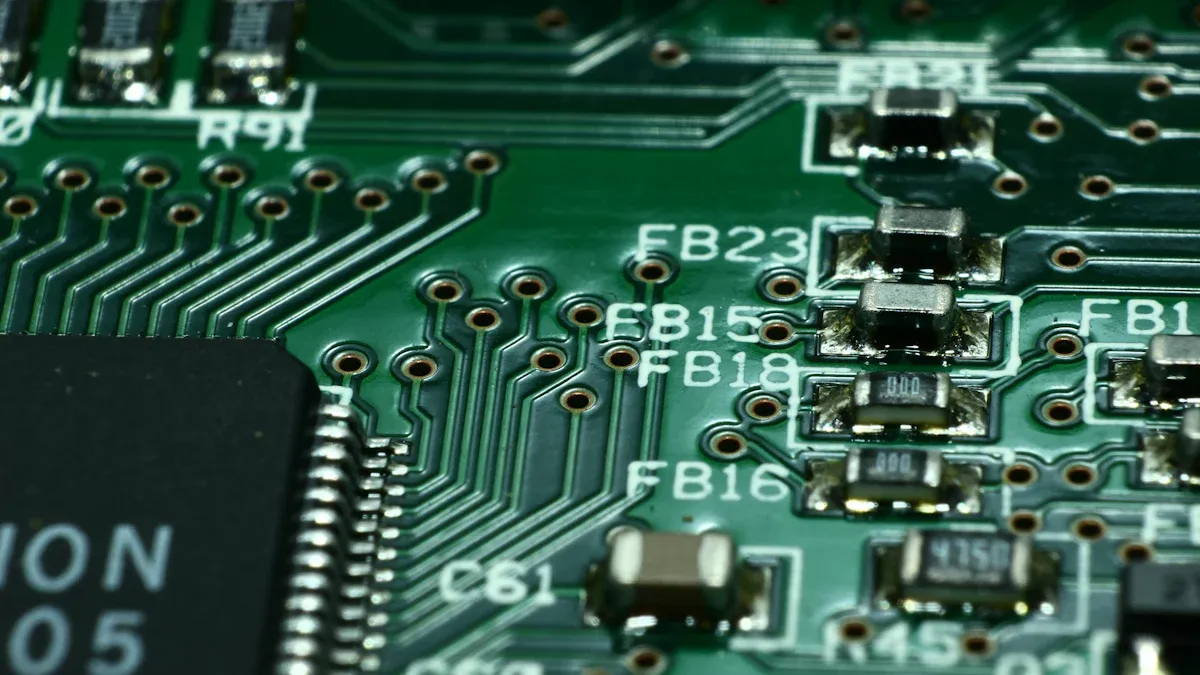

Both use precision-moving probes (flying probes) instead of traditional test fixtures to perform electrical performance testing, such as open circuits, short circuits, and impedance, by contacting the test points.

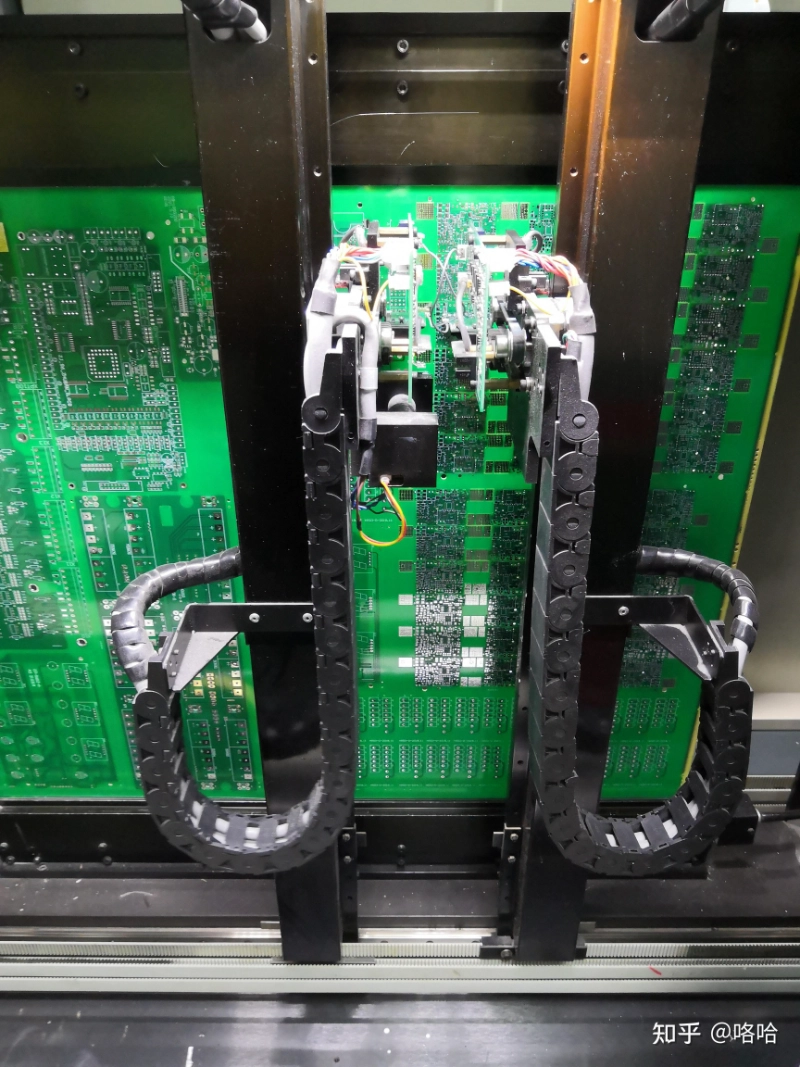

2. Similar Technical Equipment

Both use high-precision multi-axis motion systems, programmable probes, and high-speed measurement units, relying on the same underlying control and measurement technologies.

3. High Flexibility

Needs no special test fixtures, suitable for small-batch, multi-variety, and rapid changeover production models, especially suitable for R&D verification and prototype testing.

4. Test Coverage Capability

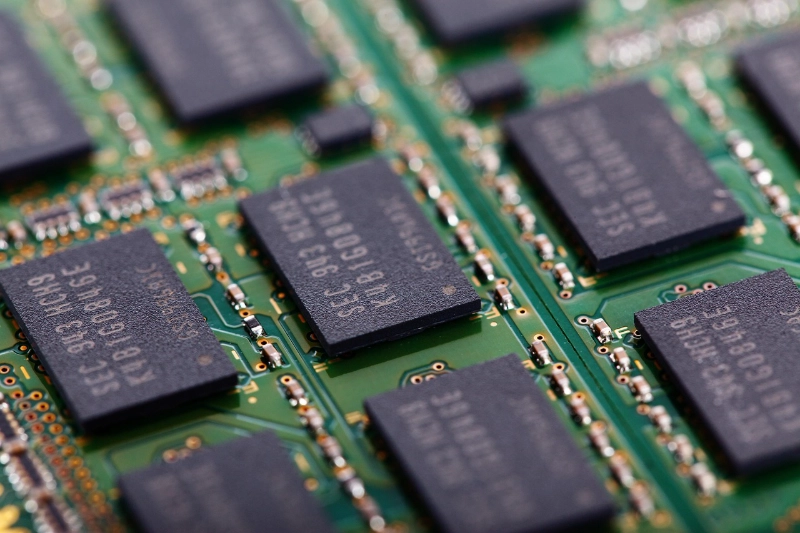

Both capable to achieve high-density, fine-pitch test point access (such as micro pads, BGA bottoms, etc.), with high adaptability to complex designs.

II. Differences

| Comparison | PCB Flying Probe Testing | PCBA Flying Probe Testing |

| Test Objects | PCB (printed circuit board without components) | PCBA&PCB assembly(Component-mounted) |

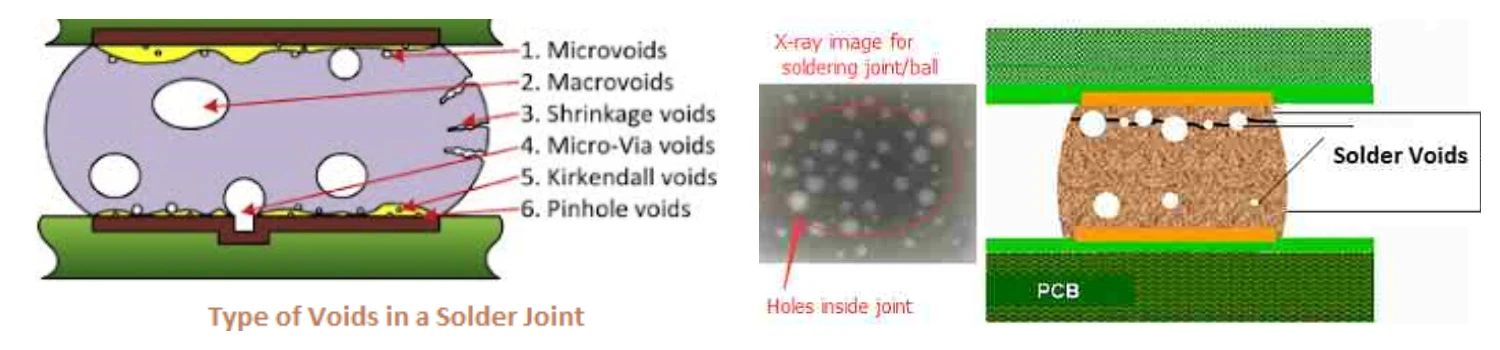

| Test Purpose | Detect manufacturing defects: open/short circuits, abnormal impedance, hole metallization problems, etc | Detect assembly defects: poor soldering, missing/incorrectly placed components, component malfunctions, etc. |

| Test Content | 1. Electrical continuity 2. Insulation resistance 3. Impedance control (e.g., high-frequency boards) | 1. Electrical connection of solder joint 2. Component parameters (resistance, capacitance values) 3. Simple functional tests (e.g., diode polarity) 4. Programming and flashing (optional) |

| Test Complexity | Relatively low, mainly focuse on network integrity of traces | Higher, requiring consideration of component characteristics, signal interaction, and power load |

| Test Speed | Faster (fewer test points, simpler logic) | Slower (requires multiple measurements, component verification, may require power-on testing) |

| Probe Requirements | Ordinary probes with low pressure | May require special probes (e.g., pointed, spring-loaded probes) to avoid damaging components or solder joints |

| Programming Differences | Network testing programs, generated from Gerber/CAD data | require integration with BOM, reference retrieval diagrams, and component parameters, making programming more complex |

| Typical Application Scenarios | Intermediate or final inspection during PCB manufacturing & electrical verification | after PCBA assembly, especially in small-batch, high-mix production |

III. Summary

1. Fundamental Difference: PCB flying probe testing inspects PCB's manufacturing quality, while PCBA flying probe testing inspects the assembly process and component placement&quality.

2. Technological Extension: PCBA flying probe testing could be taken as upgraded version of PCB testing, but testing more complex electrical status (such as power supply, signal isolation, and component protection), and may integrate basic functional testing (such as determining component functionality by measuring circuit nodes).

3. Trend Convergence: With the development of high-density assembly technology, both types of equipments are on trend for integration (such as flying probe platforms supporting composite testing), but testing strategies and programs still need to be specifically designed.

In actual production, PCB flying probe testing is typically performed on bare PCBs first, to ensure substrate qualification before SMT&THT assembly, finally, PCBA flying probe testing verifies quality of assembled PCBA.

Benlida is a professional PCB manufacturer and continuously invest to purchase advanced flying probe equipment, keeping on pace with the new technologies and upgrade itself, so it could be applicable to provide high-quality PCBs and excellent services to global customers! If you need PCB/printed circuit boards, please feel free to contact Benlida!

en

en

WhatsApp

WhatsApp