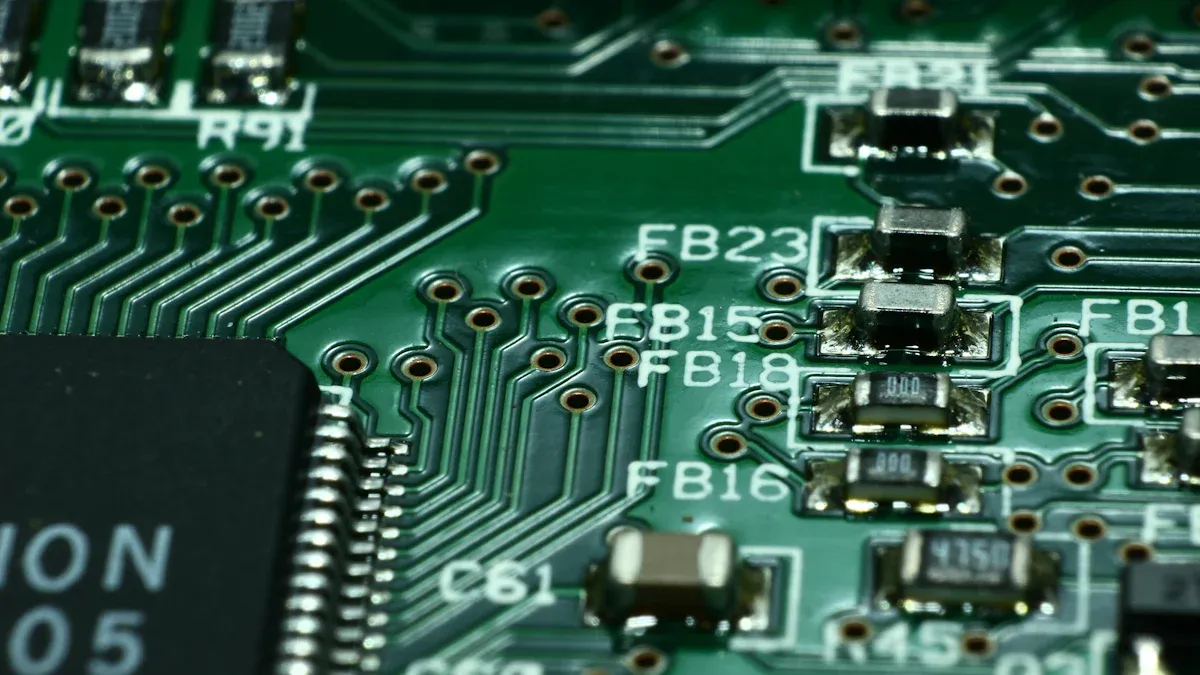

PCB Inner Layer Imaging & Etching Process

Inner-layer imaging and etching are PCB manufacturing processes that rarely gets attention outside a factory—until something goes wrong. Yet it’s the stage that decides whether your copper geometry is clean, impedance is controlled, and multilayer lamination has a stable foundation.

This guide breaks down how inner-layer imaging and etching actually work, what parameters matter most, what defects might occur during production, and how experienced manufacturers (like Benlida,) keep results consistent across batches.

1. Introduction to PCB Etching

The role of etching in PCB manufacturing

Etching is the step where a copper-clad substrate is transformed into functional circuitry. Start with a continuous copper foil, through imaging and chemical removal, copper is selectively remained, only where the circuit needs to be.

Why etching accuracy defines circuit performance

In modern electronics, “a trace is a trace” is not true. A trace is also a transmission line, a heat path, and sometimes a reliability risk. If etching shifts the line width or spacing—even slightly—the circuit board could end up with:

unexpected impedance drift

higher loss at high frequencies

tighter crosstalk margins

assembly yield issues due to pad deformation

Etching, signal integrity, and reliability

Etching affects signal integrity in two key ways:

Geometry control: width/spacing control impacts characteristic impedance, coupling, and timing.

Edge quality and copper profile: rough edges, undercutting, and inconsistent conductor shape can raise loss and reduce margins, especially when combined with copper roughness effects at higher frequencies.

Evolution of PCB etching techniques

Etching began with relatively simple chemical baths. Today, high-volume lines use controlled spray etching, closed-loop monitoring, and advanced imaging methods such as LDI (Laser Direct Imaging) to keep fine features stable for HDI and high-speed designs.

2. What Is PCB Etching?

Definition

PCB etching is a manufacturing process that removes unwanted copper from a laminate, to form the intended circuit pattern.

Why copper is selectively removed

A PCB starts as copper flat, fully covered by copper and the circuit requires copper only in specific paths. Etching removes copper to create:

electrical isolation between nets

defined conductor widths for current and impedance targets

clearances that prevent arcing, leakage, or shorts

The role of photo-resist

Photo-resist acts as a temporary protective mask. It defines where copper should remain and where should be removed. After exposure and development, the copper pattern is protected by resist and all unprotected copper is etched away.

3. What Is PCB Inner Layer Etching?

Definition and scope

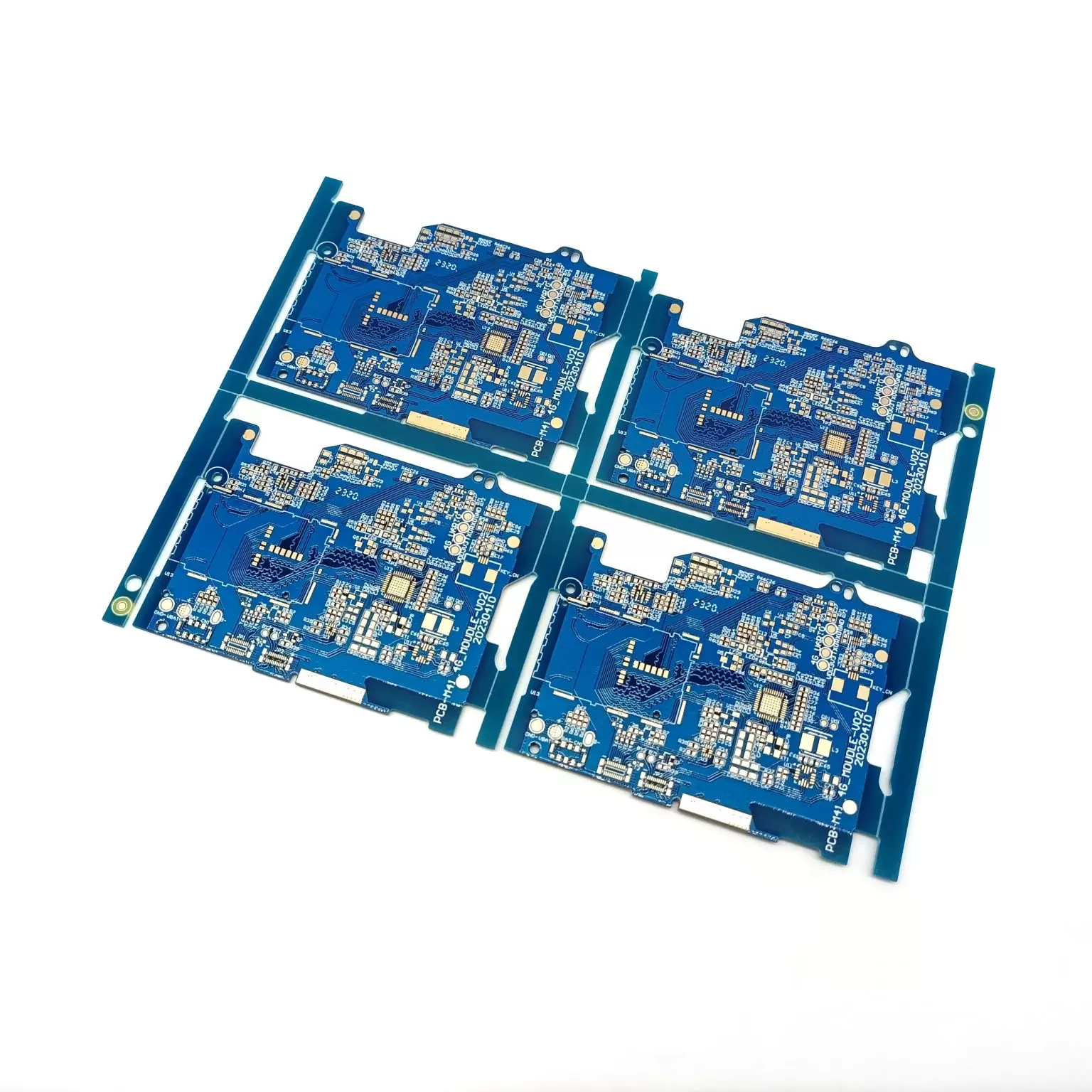

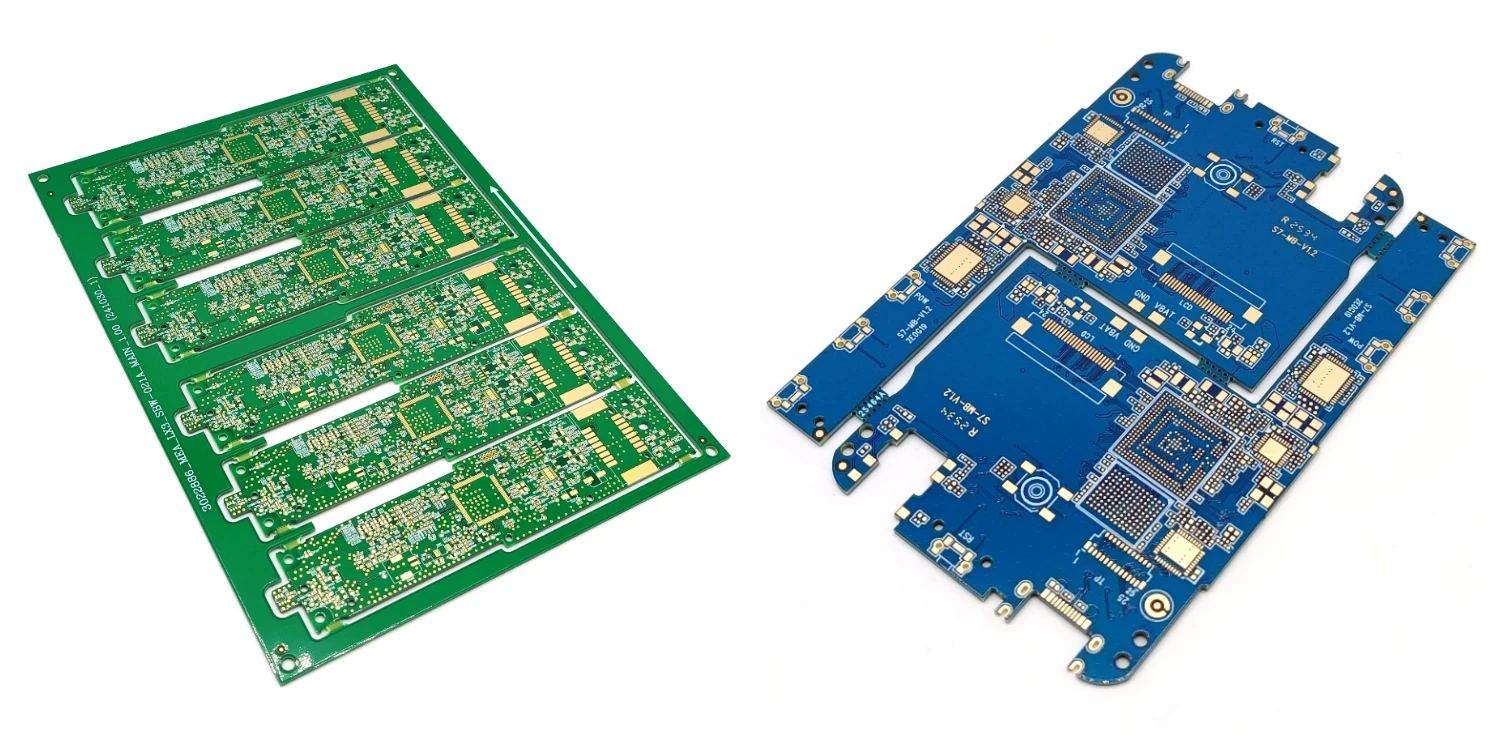

Inner layer etching refers to imaging and etching performed on layers that will later be buried(laminated) inside a multilayer PCB during lamination.

Inner vs outer layer etching (How they differ)

Inner layers are etched on flat laminates before lamination. After etching, they are typically treated (e.g., oxide or alternative bonding treatment) and then laminated.

Outer layers are formed after drilling and plating steps. Outer-layer processes often include pattern plating and must account for plated copper thickness and via structures.

In practice, inner layers are about foundational accuracy and registration stability for lamination; outer layers are about final connectivity, surface finish, solder mask alignment, and cosmetic/functional readiness.

Importance in multilayer PCB manufacturing

If inner layers are off—line width, spacing, or layer-to-layer registration—those defects become embedded. Rework is difficult or impossible. That’s why inner layer quality is a major yield driver.

Typical trace widths and tolerances

Realistic values depend on copper thickness, equipment capability, and design requirements. The key is that inner layers need consistent, repeatable geometry so the manufacturer needs to be capable to achieve:

minimum conductor width rules

spacing requirements

impedance targets after lamination

Impact on high-frequency and high-speed designs

For high-speed signals (DDR, PCIe, USB, HDMI) and RF structures, small geometry deviations are more important. Inner layers also contain reference planes or striplines where the dielectric environment is well controlled—making them critical for stable impedance.

4. Why Precision Matters in PCB Inner Layer Etching

Alignment and lamination consequences

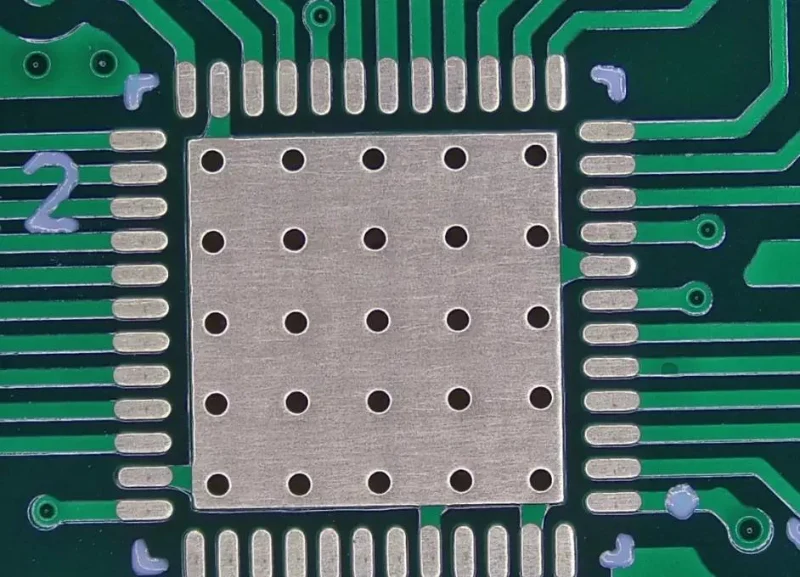

●Inner-layer mis-alignment will cause:

●annular ring reduction (pads don’t “center” around vias)

●breakout risk during drilling

●weak via-to-pad connections

●higher scrap rate during AOI or electrical test

Over-etching vs under-etching

●Over-etching can narrow traces and cause undercutting, changing impedance and current capacity.

●Under-etching can leave copper residues or bridges, creating shorts and leakage paths.

Impedance control and signal integrity

Controlled impedance is not only a “stack-up problem.” It's also an etching problem. If the intended trace width becomes narrower due to over-etch, impedance rises. If spacing changes, coupling changes. You may still “pass” basic continuity tests but fail signal integrity in real use.

Cost and yield implications

Inner-layer defects are expensive because they cause:

●scrap increases

●rework isn’t capable after lamination

●schedules slip

●troubleshooting gets harder because the defect is hidden under outerlayers

5. Overview of the PCB Etching Principle

The chemical reaction (copper + etchant)

Etchants react with copper and dissolve it into solution. The process is controlled so that copper is removed uniformly where exposed, preserved where is protected by mask.

Masking → etching → stripping

The core concept is simple:

Masking: photoresist protects copper where needs to keep

Etching: etchant removes exposed copper(where not needed)

Stripping: photoresist removed after etch

Wet etching vs dry etching (overview)

Wet etching (spray/chemical) is the mainstream approach for standard PCB production.

Dry (plasma) etching can offer high precision for certain specialized applications but is a little expensive and less common in general PCB fabrication.

6. PCB Imaging Process (Pre-Etching Stage)

6.1 Copper-Clad Laminate Preparation

Inner layer processing begins with copper-clad laminate selection:

FR-4 for general electronics

high-Tg systems for higher thermal robustness

high-frequency laminates where dielectric loss and stability matter

Surface cleaning and contamination control

Before resist application, copper surfaces must be clean and consistent. Oils, residues, oxidation, fingerprints, they reduce adhesion and might lead to pattern defects later.

6.2 Photo-resist Application

Dry film photo-resist

Dry film is widely used for inner layers due to consistency and handling stability. Uniform lamination matters—air bubbles or wrinkles might lead to defects.

Liquid photo-resist

Liquid resist is used in some processes, especially where different coating behaviors are required. Control of coating thickness and curing is critical.

Uniformity and thickness considerations

Resist thickness impacts:

resolution capability (fine lines need controlled thickness)

etch resistance and protection

risk of pinholes or incomplete coverage

6.3 UV Exposure and Pattern Transfer

Positive vs negative imaging

Depending on the resist and workflow, exposed areas either harden (negative) or become removable (positive). The goal is the same: create a resist pattern that matches the intended copper.

Film alignment and registration

Registration is fundamental in multilayer boards. Even if each layer is perfect individually, misalignment across layers creates downstream risks (drill breakout, annular ring reduction, impedance coupling changes).

Yellow-room requirements

Imaging areas often use controlled lighting and environment to avoid accidental exposure and to maintain stable process conditions.

6.4 Development Process

After exposure, development removes the intended portions of resist.

Alkaline developer solutions

Developers are commonly alkaline and must be controlled for concentration, temperature, and spray pressure.

Formation of protected copper patterns

When development is correct, the copper that should remain is fully protected by resist with clean edges—ready for etching.

7. PCB Etching Process (Copper Removal)

7.1 Chemical Etching Step

Etching removes exposed copper. Modern lines usually use conveyorized spray etching systems because they offer:

consistent exposure

controllable etch rate

high throughput

Why conveyor speed matters

Speed affects dwell time. Too fast may cause under-etch; too slow increases over-etch and undercut risk.

7.2 Common Etching Chemicals (and practical trade-offs)

Below are typical etchant families and what they’re known for in production:

Ferric chloride (FeCl₃)

A classic etchant, often used in smaller-scale contexts. It can be effective but requires good control and waste handling.

Cupric chloride (CuCl₂)

Can be regenerated and controlled in production environments. Often favored where process stability and reuse matter.

Ammoniacal etchants

Common in PCB production due to controllability and suitability for fine-line etching, but requires careful chemistry monitoring.

Sodium persulfate

Sometimes used in specific contexts; tends to be more common outside high-volume industrial lines.

Hydrogen peroxide + hydrochloric acid

Can etch copper efficiently but requires careful control due to reactivity, stability, and safety considerations.

Speed vs precision vs environmental impact

In industrial PCB fabrication, the best etchant is the one your factory can control most consistently:

stable etch rate

predictable undercut behavior

manageable regeneration and waste treatment

minimal drift across shifts and batches

8. Photo-resist Stripping After Etching

Why stripping is necessary

After etching, the resist has completed its job. It must be removed to expose the remaining copper.

Stripping solutions and control (e.g., NaOH)

Alkaline stripping is common. Control matters because:

insufficient stripping leaves residue that interferes with subsequent treatments

aggressive stripping can attack copper edges or create cleanliness problems if rinsing is incomplete

Risks of incomplete stripping

Incomplete stripping might cause:

poor lamination bonding (contamination)

later oxidation or adhesion issues

false AOI report due to residue patterns

Cleaning and rinsing requirements

Rinsing isn’t a “minor step.” It’s a reliability step. Chemical residues can create long-term leakage or corrosion risks, especially in humid or high-voltage environments.

9. Key Process Parameters That Affecting Etching Accuracy

9.1 Chemical concentration

Etch chemistry drifts over time. Monitor concentration continuously or at regular intervals, use controlled replenishment or regeneration.

9.2 Temperature control

Temperature affects reaction rate. Higher temperature increases etch rate but can reduce control margins. Stable temperature contributes to stable line width.

9.3 Etching time

Time is tied to conveyor speed and etch strength. Many factories use test coupons to validate results and reduce guesswork.

9.4 Agitation and distribution

Spray etching improves uniformity compared to static immersion because fresh etchant reaches the copper consistently and reaction byproducts are removed efficiently.

9.5 Photo-resist quality and alignment

Even perfect etch chemistry cannot fix:

resist adhesion failures

exposure errors

registration errors

pinholes or wrinkles

Etching accuracy is upstream-dependent.

10. Common Etching Defects and Root Causes

Over-etching and undercutting

Narrow traces

reduced spacing control

impedance drift

Under-etching and residual copper

copper “islands”

bridges between traces

shorts and leakage paths

Pinholes

Often linked to resist defects or contamination. Pinholes can expose copper unintentionally, leading to etched “nicks” or opens.

Bridging between traces

Usually caused by under-etch, poor development, or resist scumming.

Line width variation

Can be driven by:

uneven spray distribution

chemistry drift

inconsistent resist thickness

inconsistent copper thickness

11. Solutions and Troubleshooting Methods

Etch factor control

Etch factor relates to vertical vs lateral etch behavior. Strong process control aims to reduce undercut while achieving full copper removal.

Endpoint detection

Manufacturer may use process validation methods (coupons, measurement checks, AOI feedback loops) to ensure etching reaches the required endpoint without overshooting.

Chemistry monitoring and regeneration

Stable processes treat etchant as a controlled variable, not a “use until it’s weak” consumable. Regeneration and replenishment keep results consistent.

Photo-resist process optimization

Many “etch problems” are actually resist problems:

incorrect exposure energy

development drift

poor lamination conditions

cleanliness issues

Corrective adjustments

Practical adjustments often involve small, controlled changes:

tweak conveyor speed

adjust spray pressure distribution

correct temperature drift

Re-calibrate exposure/development windows

12. Quality Control and Inspection Methods

Visual and microscopic inspection

Useful for checking edge definition, pinholes, bridging, and obvious geometry issues.

Cross-section analysis

Cross-sections help validate layer structures and identify hidden issues.

Automated Optical Inspection (AOI)

AOI compares the manufactured image as expected patterns, to detect:

opens/shorts

nicks

over-etch artifacts

spacing violations

Electrical continuity verification

Electrical test spot out connectivity issues, but it does not guarantee geometry compliance. That’s why AOI + electrical verification together are stronger.

Comparison with Gerber for compliance

A disciplined process validates that produced layers match design intention, not just “pass continuity.”

13. IPC Standards and Design Constraints

IPC-6012 and etching allowances

IPC guidance provides accepted ranges and recommendations for manufacturing quality and conductor definitions.

Minimum conductor width rules

Minimum trace widths should be set based on:

copper thickness

required current capacity

etching capability (including undercut margin)

yield expectations

Solder pads for SMT

Pads must maintain defined shapes and clean copper surfaces, be reliable for soldering later.

Etching compensation in PCB design

Designers often apply “etch compensation” so the final conductor after etch matches the target width. This is especially relevant for fine-line and impedance-sensitive designs.

14. Track Width and Spacing Guidelines

Copper thickness strongly influences the minimum practical trace/space.

Relationship between copper thickness and minimum trace width

As copper gets thicker, it becomes harder to etch fine lines cleanly without undercut. That’s why thick copper power boards typically use wider features.

Typical constraints by copper thickness (conceptual)

1OZ copper: supports finer geometry and dense routing more easily

2OZ copper: requires more margin; fine-line routing becomes harder

3–4OZ copper: usually focuses on power handling; fine features are limited

Why manufacturer consultation matters

The same nominal “min trace/space” in a datasheet doesn’t guarantee equal yield across designs. Stack-up, copper distribution, and pattern density influence real results. Consult manufacturer and confirm the capacities would definitely reduces redesign loops.

15. Materials and Equipment Used in PCB Etching

Inner-layer imaging and etching looks simple on paper—“coat, expose, develop, etch, strip”—but in a factory it’s a controlled system made up of chemistry, equipment, and measurement. When any one of these drifts, line width and spacing will drift with it.

15.1 Chemicals (What each chemical actually does)

Etchants (Copper removers)

Etchants are the workhorses that dissolve exposed copper. A stable etching line doesn’t just “use etchant”—it manages etchant activity so the etch rate remains predictable across different copper thicknesses and pattern densities. In production, the focus is on:

consistent etch rate (not just “fast”)

low undercut tendency for better edge definition

controllable regeneration/replenishment to avoid performance drift

Developers (Pattern revealers)

Developers remove the intended portions of photo-resist after exposure. If the developer is too aggressive, it can erode resist edges; too weak, it can leave residue (“scum”) that later causes incomplete etching or bridging. Tight developer control is often the difference between “looks fine” and “fine-line stable.”

Strippers (Resist removers)

After etching, strippers remove remaining photo-resist without attacking copper or leaving residue. Incomplete stripping becomes a hidden risk: contamination can interfere with later bonding treatments and degrade reliability of lamination.

Neutralizers and cleaning agents (Reliability protectors)

These are easy to underestimate: their job is to stop chemical reactions, remove residues, and keep the copper surface consistent for the next step. Poor rinsing/neutralization doesn’t always fail immediately—but it increases the chance of long-term corrosion, leakage, or adhesion issues.

15.2 Equipment (Where consistency is “built in”)

Etching tanks and spray systems

Modern PCB factories rely heavily on conveyorized spray etchers because they provide controlled dwell time and uniform copper removal. Key design elements that influence results:

nozzle coverage uniformity

stable conveyor speed and tension

filtration and byproduct handling to maintain chemical performance

UV exposure units (or LDI systems)

Exposure equipment defines the pattern that etching must follow. Stable exposure energy and accurate registration reduce line width variation and alignment errors—especially important for multilayer builds.

Agitation and circulation systems

Etching performance depends on how uniformly fresh chemistry reaches the copper and how quickly reaction byproducts are removed. Proper circulation reduces localized over-etch/under-etch and helps maintain consistent results across a panel.

Safety and ventilation equipment

This is part of process control, not just compliance. Good ventilation and fume handling stabilize the working environment and support repeatable chemistry behavior, while also protecting operators and equipment.

16. Environmental and Safety Considerations

Etching involves reactive chemicals and dissolved metals, so safety is inseparable from quality. A factory that manages etching safely tends to manage it consistently—because both require discipline.

Personal protective equipment (PPE)

PPE protects operators from splash, fumes, and skin exposure. More importantly, it supports steady operations by reducing incidents and unplanned downtime.

Chemical storage and labeling

Correct segregation and clear labeling reduce contamination risk (mixing incompatible chemicals can damage product quality and create dangerous reactions). Stable storage also preserves chemical activity and reduces drift.

Safe mixing and handling procedures

Etching chemistry is sensitive: improper mixing can shift concentration, introduce impurities, or create unstable reactions—leading directly to line width variation and defect spikes.

Waste neutralization and disposal

Etchants accumulate to dissolve copper and reaction byproducts. Controlled neutralization and compliant disposal prevent environmental hazards and keep the process stable by avoiding “end-of-life” chemistry being pushed too far.

Copper recovery and recycling

Copper recovery isn’t just sustainability—it can improve process consistency by keeping etchant systems within a controlled operating window and reducing waste output.

Sustainable etching practices

Best-in-class lines aim for lower consumption and less drift through regeneration systems, closed-loop monitoring, and disciplined maintenance routines—improving both yield and environmental footprint.

17. Advanced Etching Technologies

As trace widths getting finer and stack-ups get more complex, “traditional” methods still work—but only when supported by better control, better imaging, and smarter feedback loops.

17.1 Etching for Multilayer and HDI PCBs

HDI and fine-pitch inner layers bring two major challenges: feature density and process sensitivity.

Microvias and fine-pitch traces demand tighter imaging accuracy and cleaner resist edges.

Differential etching strategies are often required because dense copper areas and sparse copper areas etch differently. Without compensation and monitoring, you’ll see uneven trace widths across the same panel.

17.2 Plasma and Dry Etching (Where it fits—and where it doesn’t)

Process principle: Dry etching uses reactive plasma environments rather than liquid chemistry to remove material.

Precision advantages: Reduced undercut in certain applications and highly controllable removal behavior.

Limitations: Higher cost, more specialized setups, and not always practical for mainstream PCB volumes. It’s typically reserved for niche requirements where the performance benefit is significant.

17.3 Laser Direct Imaging (LDI)

LDI exposes resist without traditional films, which reduces multiple sources of error:

film stretch and handling distortion

alignment drift due to film variability

slower iteration cycles when changes are needed

For high-density and tight-tolerance designs, LDI often improves registration consistency and reduces imaging-related defects—giving etching a cleaner pattern to follow.

17.4 Automation and Smart Process Control

Modern etching lines increasingly run like manufacturing systems, not “chemical lines.”

Real-time monitoring (concentration, temperature, conveyor speed, spray pressure)

Closed-loop replenishment to keep chemistry stable across shifts

AI-assisted parameter optimization (emerging) using AOI/test feedback to reduce defect recurrence

Yield improvement through trend detection—catching drift before it becomes scrap

The practical benefit is simple: fewer surprises, more predictable geometry, and better repeatability when scaling up.

18. Best Practices for Consistent Etching Results

Consistent etching is rarely achieved through one “secret setting.” It’s achieved through repeatable routines and clear design alignment.

Batch-to-batch consistency

A good line produces the same trace geometry today and next month. That requires process windows that are defined, monitored, and enforced.

Chemical maintenance routines

Stable results come from proactive chemistry management:

scheduled sampling and correction

regeneration/replenishment rules

filtration and contamination control

Waiting until defects appear is always more expensive than maintaining stability.

Process documentation

Documentation prevents “tribal knowledge drift.” When exposure energy, developer settings, etch speed, and temperature windows are documented, production is less sensitive to operator changes or shift-to-shift variation.

Preventive equipment maintenance

Nozzles wear, conveyors drift, filters clog, exposure lamps age. Preventive maintenance avoids slow degradation that shows up as line width variation or localized defects.

Design-for-etching considerations

Design decisions influence etch yield:

align copper thickness to routing density

avoid pushing minimum trace/space without functional need

plan etch compensation for controlled impedance traces

consult the manufacturer early for realistic limits and better first-pass success

19. Conclusion

Inner-layer imaging and etching is not just a middle step—it’s a core capability that sets the baseline for multilayer accuracy, impedance control, and long-term reliability. When etching is controlled, everything downstream becomes easier: lamination aligns better, drilling cleanly, electrical test passes more consistently, and field performance is more predictable.

The best results come from two factors that working together:

Process control + inspection (stable chemistry, stable imaging, reliable AOI/testing feedback)

The right manufacturing partner who can understand and perform design intention correctly into production

If you’re looking for suppliers or planning a new production for PCB that demands stable&professional performance, as an experienced PCB manufacturer Benlida is a good candidate PCB Fabrication Service, you can explore capabilities and check PCB categories.

Related PCB manufacturing processes

What is the PCB Lamination Process?

How do drilling (mechanical/laser) processes work in PCB manufacturing?

en

en

WhatsApp

WhatsApp