Applications of Ultraviolet (UV) Disinfection Lamps and PCBA Manufacturing Process

This article will detail the application of UV disinfection lamps and the manufacturing process of their core component—PCBA (Printed Circuit Board Assembly)—help you to understand them from application markets and core manufacturing mindsets.

Part One: Main Application of UV Disinfection Lamps

UV disinfection lamps primarily utilize the UVC band (200-280nm, especially 254nm) to destroy the DNA/RNA of microorganisms, so they will unable to replicate and thus achieving disinfection. Their applications have expanded from traditional fields to new scenarios.

1. Medical and Health (Core and traditional)

● Air Disinfection: Used for circulating air or static irradiation disinfection in operating rooms, wards, laboratories, halls, etc.

● Surface Disinfection: Irradiation on surfaces of medical devices, platform, equipments, etc.

● Water Disinfection: Used for hospital wastewater treatment and some medical pure water systems.

2. Water Treatment

● Municipal Water Supply: As a supplement or alternative to chlorine disinfection, leaving no chemical residue.

● Wastewater Treatment: Final disinfection of effluent.

● Household and Commercial Water Purification: Installed in water purifiers or drinking fountains, to eliminate bacteria and viruses.

● Aquaculture/Swimming Pools: Control the pathogens in water.

3. Air Purification and HVAC Systems

● Integrated into building central air conditioning, household air purifiers, and fresh air systems to disinfect airflow continuously.

4. Food, Drinks, and Pharmaceutical Industries

● Production Line Disinfection: Disinfects packaging surfaces, cans, workbenches, and production water.

● Space Disinfection: Ensures that microbiological indicators in workshops and cleanrooms meet standards.

5. Household and Personal Consumer Sector (Rapid Growth)

● Integration with Smart Household Appliance: Washing machines, dishwashers, robot vacuums, humidifiers, baby sterilizers, etc.

● Portable Disinfection Device: Disinfection boxes (for masks, mobile phones, keys), disinfection wands, disinfection cabinets.

● Surface Disinfection Lamps: Used for timed disinfection of items in rooms and vehicles.

6. Public and Commercial

● Regular disinfection and air purification in schools, hotels, restaurants, gyms, and public transportation (such as subways, buses, and airplanes).

Part Two: Manufacturing Process of PCBA for UV Disinfection Lamps

The core function of a UV disinfection lamp relies on it's internal PCBA, which is responsible for power management, UV lamp/LED driving, intelligent control, and safety protection. It's manufacturing process is typical and representative for electronics manufacturing.

Core Process:

1. Preliminary Preparation

● PCB: Manufacturing bare PCB boards (printed circuit boards) based on the designed files/Gerber files.

● Component Procurement and IQC/Inspection: Procure MCUs (microcontrollers/chips), MOSFETs, capacitors, inductors, UV sensors and other sensors(such as for humanbeing movement), etc., and conducting IQC/incoming material inspection.

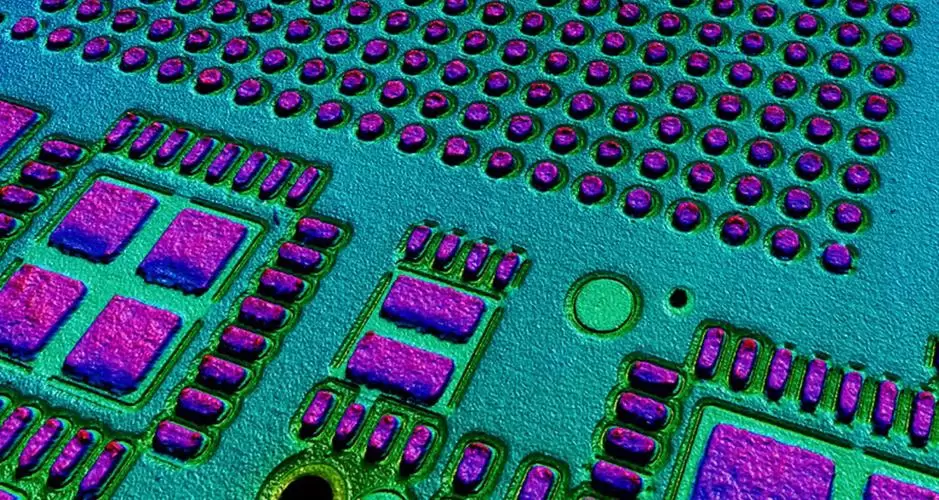

2. SMT (Surface Mount Technology)

● Printing Solder Paste: Printing solder paste precisely on the PCBs by stencil.

● Component Placement: Placing resistors, capacitors, ICs, and other small surface mount components onto the solder paste using a high-speed placement/SMT machine.

● Reflow Soldering: The PCB passed through reflow oven where solder paste melts and cools down, firmly soldering components onto the PCB.

3. THT Component Assembly and Soldering

● For larger electrolytic capacitors, connectors, and other through-hole components, component THT/DIP assembly.

● Wave Soldering: The board with THT/DIP components pass through wave soldering oven, to solder all component pins.

4. Inspection and Repair

● AOI/Automative Optical Inspection: Inspect the quality of solder joint, any components missing or misaligned, etc.

● In-Circuit Testing/Functional Testing: Use a bed of test leads/bed of nails or connect a simple power load to initially verify the basic electrical functions of the PCBA.

● Repair: Rework on the defective PCBAs which detected and sceened out by inspection.

5. Firmware Flashing/Programming and Functional Testing (Critical Step)

● Firmware Flashing/Programming: The firmware program controlling the UV lamp/LED, logic judgments (such as human body&light detection to turn off the light), timing, display, and other functions which flashes into the MCU.

● Full-Function Aging Test: Connect the PCBA to UV lamps/LED modules, sensors, etc., and conduct long-term aging tests in a simulated working environment, to verify it's stability, temperature rise, disinfection effect, and safety logic (such as "light on when no one is present" logic).

6. Cleaning, Conformal Coating, and Final Inspection

● Cleaning (if required): Remove residual flux, comtaminants, etc after soldering.

● Conformal Coating: UV Lamps which will be working in humid environments, they require conformal coating for protection.

● Final Inspection and Packaging: Perform a final inspection of the PCBA's appearance and performance. After passing the inspection, package and store them, waiting for final assembly with other parts, as complete UV lamps.

Relationship between Application Areas and PCBA Processes

Different application scenarios determine the design complexity and process focus of the PCBA:

● Home Portable Products: PCBAs require high integration, miniaturization, and low cost, and must integrate reliable human body sensing and delayed shutdown safety circuits. Manufacturing processes focus more on cost control and batch consistency.

● Industrial/Medical Grade Products: PCBA designs focus more on high reliability, long lifespan, stable power output, and accurate timing. The manufacturing process requires stricter standards, potentially employing industrial-grade components and undergoing more rigorous aging tests.

● Products integrated into home appliances: The PCBA needs to communicate with the main control system (e.g., via a Wi-Fi module) to achieve intelligent linkage. The manufacturing process must consider the compatibility testing of the communication module.

● Water treatment/air purification: The PCBA needs to have lamp life monitoring and intensity attenuation compensation functions, and may integrate water quality/flow sensor interfaces.

In summary, the application of ultraviolet/UV disinfection lamps are constantly expanding and deepening, which places diverse, highly reliable, and highly safe requirements on it's "intelligent core"—the PCBA. Correspondingly, it's PCBA manufacturing process must based on standard electronic manufacturing processes, be closely integrated with specific application scenarios. Through precise design, rigorous component selection, reliable manufacturing processes, and targeted functional and safety testing, the effectiveness and safety of the final disinfection lamp product can be ensured.

Benlida specializes in the production of PCBs and PCBAs for 14 years, we keep invest modern advanced equipments and enroll professional personnels, focus on quality control and provide customer-oriented service, committed to providing excellent PCB and PCBA manufacturing services to global customers! We currently provide PCB and PCB assembly services for multiple UV disinfection equipment, if you need related services, please feel free to contact Benlida!

en

en

WhatsApp

WhatsApp